Content Menu

● Introduction

● What is AOI SMT Line Technology?

● Key Benefits of AOI SMT Line Technology

>> Accuracy

>> Speed

>> Cost-effectiveness

>> Reduced Human Error

>> Enhanced Data Collection and Analysis

● Applications in Electronics Manufacturing

● The Role of AI in Enhancing AOI Capabilities

● Challenges and Future Trends

● The Importance of 3D AOI Systems

● Conclusion

● FAQ

>> 1. What does AOI stand for in SMT?

>> 2. How does AOI improve quality control?

>> 3. What are the main components of an AOI system?

>> 4. Can AOI be integrated with other inspection systems?

>> 5. What industries benefit most from AOI SMT Line Technology?

● Citations:

Introduction

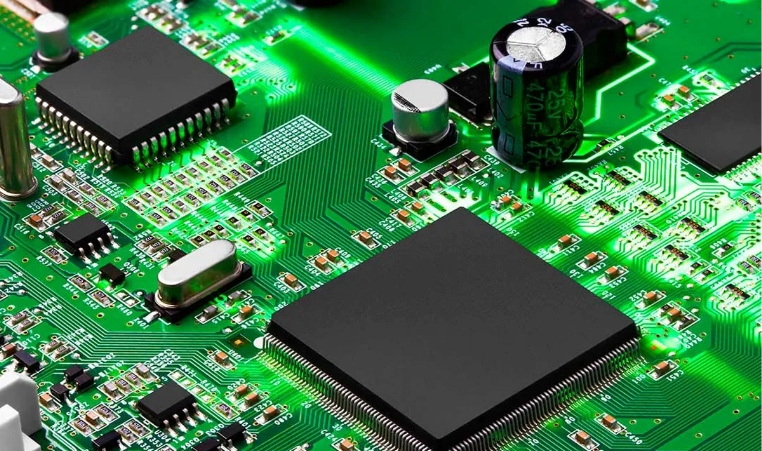

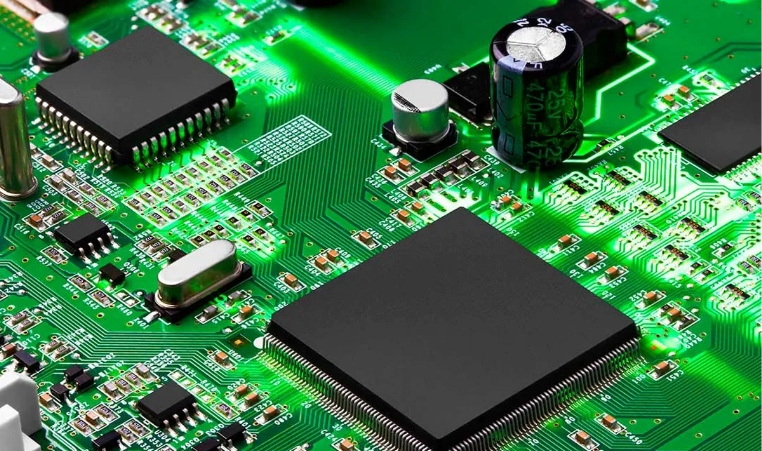

In the fast-paced world of electronics manufacturing, ensuring quality control is paramount. Automated Optical Inspection (AOI) SMT Line Technology has emerged as a game-changer, offering unparalleled precision and efficiency. This article explores how AOI SMT Line Technology enhances quality control, its benefits, applications, and future trends.

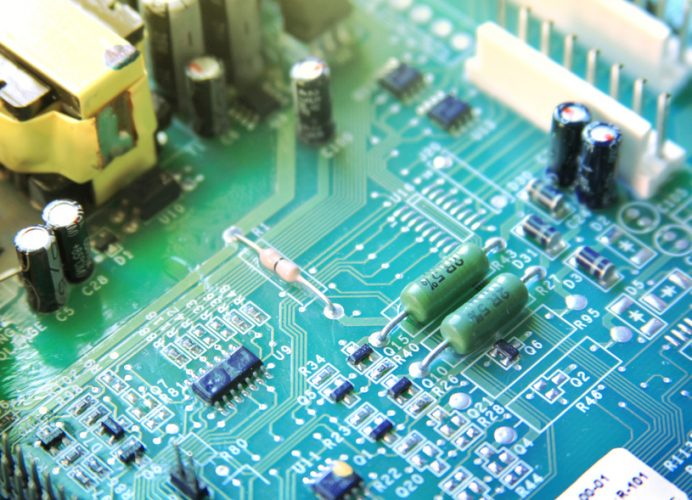

What is AOI SMT Line Technology?

AOI SMT Line Technology refers to the use of automated optical systems to inspect printed circuit boards (PCBs) during the Surface Mount Technology (SMT) process. It involves high-resolution cameras, advanced lighting systems, and sophisticated algorithms to detect defects in component placement, soldering, and overall assembly. By comparing the actual PCB to a digital model, AOI systems ensure that every product meets stringent quality standards.

Key Benefits of AOI SMT Line Technology

Accuracy

One of the primary advantages of AOI SMT Line Technology is its accuracy. Advanced algorithms and high-speed imaging enable the detection of even the smallest defects, such as misalignments or soldering issues. This precision reduces the risk of faulty products reaching the market.

Speed

Speed is another critical benefit. AOI systems can inspect PCBs in real-time, allowing manufacturers to identify and rectify issues promptly. This capability minimizes downtime and enhances overall productivity.

Cost-effectiveness

Cost-effectiveness is also a significant advantage. By detecting defects early in the production process, AOI systems reduce repair costs and material wastage. This efficiency translates to higher profit margins for manufacturers.

Reduced Human Error

Automated Optical Inspection significantly reduces human error associated with manual inspections. Human inspectors may miss subtle defects due to fatigue or oversight; however, AOI systems consistently deliver high-quality inspections without bias or fatigue.

Enhanced Data Collection and Analysis

AOI systems provide valuable data on inspection processes, allowing manufacturers to analyze trends and identify areas for improvement. This data-driven approach enables continuous process optimization and enhances overall production quality.

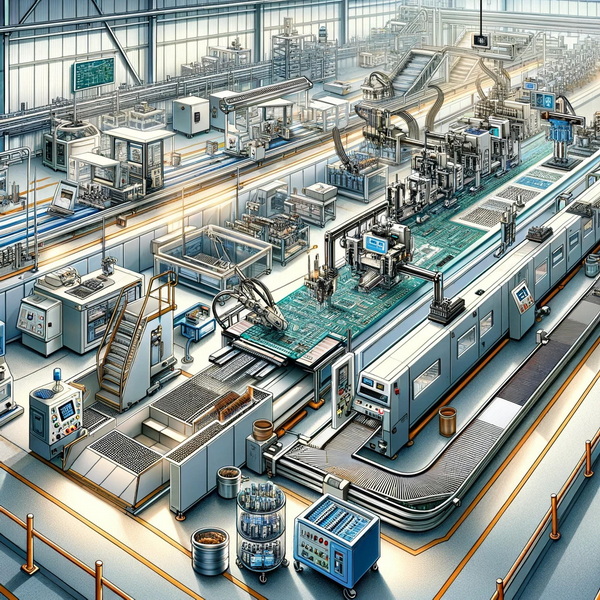

Applications in Electronics Manufacturing

AOI SMT Line Technology is versatile and can be applied at various stages of the SMT process. For instance:

- After Solder Paste Printing: Placing AOI systems after solder paste printing helps identify defects early, reducing repair costs.

- Before and After Reflow Soldering: Using AOI before and after reflow soldering ensures that components are correctly placed and soldered, maintaining high-quality standards.

- Final Assembly Inspection: At the end of the production line, AOI can verify that all components are correctly installed and functioning as intended.

In addition to quality control, AOI systems provide valuable data for process optimization. By analyzing defect trends, manufacturers can make informed decisions to improve production processes and achieve greater efficiency.

The Role of AI in Enhancing AOI Capabilities

The integration of Artificial Intelligence (AI) into AOI technology has revolutionized its effectiveness. Modern AI algorithms enhance defect detection capabilities by learning from past inspections and adapting to new defect types over time. Some key advantages include:

- Improved Detection Rates: AI-powered AOI systems have shown significant improvements in defect detection rates compared to traditional methods. Reports indicate reductions in false positives by up to 90%, leading to increased production efficiency.

- Faster Programming: AI simplifies the setup process for AOI systems. Traditional programming methods often require extensive time; however, AI-driven solutions enable one-click programming for quick deployment.

- Real-Time Feedback: AI allows for real-time monitoring of production lines, enabling immediate adjustments based on inspection results. This feedback loop helps maintain high-quality standards throughout the manufacturing process.

Challenges and Future Trends

Despite its advantages, AOI SMT Line Technology faces challenges such as high initial costs and the need for skilled operators. However, advancements in artificial intelligence (AI) and machine learning are addressing these issues. Future AOI systems are expected to be more user-friendly, cost-effective, and capable of handling complex inspections with minimal human intervention.

Integration with other inspection technologies, such as Automated X-ray Inspection (AXI) and Solder Paste Inspection (SPI), is another promising trend. This combination will provide comprehensive quality control solutions, further enhancing the reliability of electronics manufacturing.

Moreover, as industries continue to innovate, there will be an increasing demand for advanced inspection technologies capable of handling complex electronic components found in emerging sectors like automotive electronics, medical devices, and IoT applications.

The Importance of 3D AOI Systems

3D Automated Optical Inspection (AOI) systems represent a significant advancement over traditional 2D systems. These advanced systems utilize structured light technology and multi-angle imaging to provide comprehensive inspections that can detect complex defects often missed by 2D methods. The benefits include:

- Enhanced Defect Detection: 3D AOI can identify issues such as insufficient solder or misaligned components more effectively than 2D counterparts.

- Reduced False Alarms: The precision offered by 3D imaging reduces false alarms during inspections, leading to improved operational efficiency.

- Adaptability: As electronic components become smaller and more intricate due to miniaturization trends, 3D AOI systems can adapt to inspect these complex assemblies effectively.

Conclusion

AOI SMT Line Technology is revolutionizing quality control in electronics manufacturing. Its accuracy, speed, cost-effectiveness, and ability to reduce human error make it an indispensable tool for ensuring product reliability and customer satisfaction. As technology continues to evolve with AI integration and advancements in imaging techniques like 3D inspection, AOI systems will play an even more significant role in shaping the future of the electronics industry.

FAQ

1. What does AOI stand for in SMT?

AOI stands for Automated Optical Inspection, a technology used for inspecting PCBs.

2. How does AOI improve quality control?

By detecting defects early and providing precise inspection data.

3. What are the main components of an AOI system?

High-resolution cameras, lighting systems, and advanced software algorithms.

4. Can AOI be integrated with other inspection systems?

Yes, AOI can work alongside AXI and SPI for comprehensive inspection.

5. What industries benefit most from AOI SMT Line Technology?

Primarily electronics manufacturing, including consumer electronics and automotive sectors.

Citations:

[1] https://www.smtfactory.com/what-makes-smt-aoi-ai-inspection-technology-superior.html

[2] https://vicoimaging.com/aoi-lens-in-ensuring-flawless-smt-and-smd-production/

[3] https://www.marketresearchintellect.com/blog/aoi-technology-in-focus-transforming-electronics-manufacturing-standards/

[4] https://www.wevolver.com/article/automated-optical-inspection

[5] https://www.ipc.org/system/files/technical_resource/E10&S04_02.pdf

[6] https://delvi.tech/adolfo-juri-elettronica-selects-aton/

[7] https://www.fs-pcba.com/smt-aoi-inspection/

[8] https://electronicsera.in/the-crucial-role-of-ai-powered-inspection-in-the-advancement-of-electronics-manufacturing/

[9] https://www.zjyingxing.com/info/what-are-the-advantages-of-aoi-97189149.html

[10] https://www.grandviewresearch.com/industry-analysis/automated-optical-inspection-systems-market