Content Menu

● Introduction to SMT PCB Cutting Machines

>> Key Features of SMT PCB Cutting Machines

● Enhancing PCB Design Flexibility

>> Design Considerations for SMT PCBs

>> Impact on Manufacturing Efficiency

● SMT PCB Assembly Process

>> Role of SMT PCB Cutting Machines in Assembly

● Flexible PCBs and SMT Assembly

>> SMT PCB Cutting Machines for Flexible PCBs

● Advanced Technologies in SMT PCB Cutting Machines

>> Laser Cutting Technology

>> CNC Systems

● Environmental Considerations

● Future Developments

● Conclusion

● FAQs

>> 1. What are the primary benefits of using SMT PCB cutting machines?

>> 2. How do SMT PCB cutting machines support flexible PCB assembly?

>> 3. What design considerations are crucial for SMT PCBs intended for cutting machines?

>> 4. Can SMT PCB cutting machines be used for different types of PCB materials?

>> 5. How does automation in SMT PCB cutting machines impact manufacturing efficiency?

The advent of Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by enabling the production of smaller, more complex electronic circuits. A crucial aspect of this technology is the use of SMT PCB cutting machines, which play a pivotal role in enhancing PCB design flexibility. This article explores how these machines contribute to the evolution of PCB design and manufacturing processes.

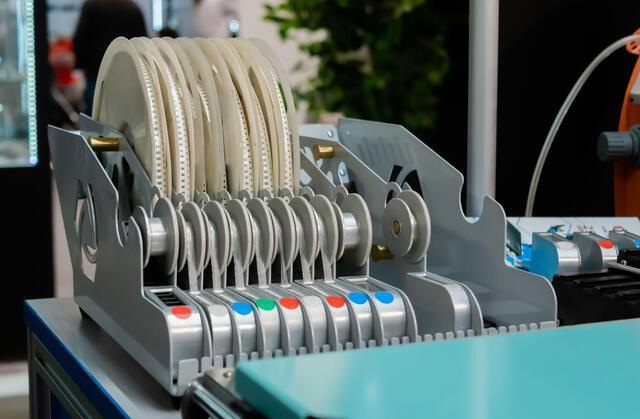

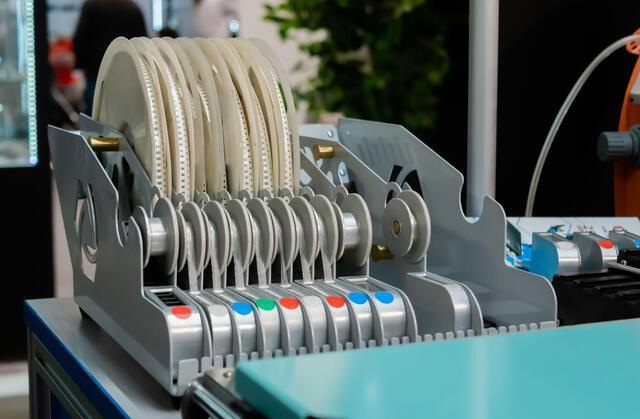

Introduction to SMT PCB Cutting Machines

SMT PCB cutting machines are specialized tools designed to efficiently cut printed circuit boards (PCBs) into individual units after the assembly process. These machines are essential for ensuring that PCBs are accurately sized and shaped according to design specifications, which is critical for maintaining the integrity and functionality of electronic devices.

Key Features of SMT PCB Cutting Machines

1. Precision and Speed: SMT PCB cutting machines are engineered to operate with high precision and speed, ensuring that PCBs are cut accurately and efficiently. This capability is vital for meeting the demands of high-volume production while maintaining quality standards.

2. Versatility: These machines can handle various types of substrates, including FR4 and aluminum, making them versatile tools for different PCB applications.

3. Reduced Operator Workload: The automated nature of SMT PCB cutting machines significantly reduces the workload of operators, allowing for more efficient production processes.

4. Durable Components: The use of high-quality materials, such as Sweden SKH-9 high-speed steel for cutters, ensures durability and longevity of the machine.

Enhancing PCB Design Flexibility

Design Considerations for SMT PCBs

When designing PCBs for SMT manufacturing, several factors must be considered to ensure compatibility with cutting machines:

1. PCB Pattern and Size: The design must account for the cutting process, ensuring that the PCB pattern and size are optimized for efficient cutting and minimal waste.

2. Material Selection: The choice of PCB material affects the cutting process. Materials like FR4 and aluminum require different cutting techniques and tools.

3. Clamping Edge and Panel Design: Proper design of the clamping edge and panel layout is crucial for secure handling during the cutting process, preventing damage to components or the PCB itself.

Impact on Manufacturing Efficiency

The integration of SMT PCB cutting machines into the manufacturing process enhances efficiency in several ways:

1. Automated Processes: By automating the cutting process, these machines reduce manual errors and increase production speed, allowing for higher volumes of PCBs to be processed in less time.

2. Improved Quality Control: The precision cutting capability ensures that PCBs are accurately sized and shaped, reducing defects and improving overall product quality.

3. Flexibility in Production: The ability to handle various substrates and PCB designs allows manufacturers to adapt production lines to different projects without significant retooling.

SMT PCB Assembly Process

The SMT assembly process involves several stages, each critical to ensuring the quality and functionality of the final product:

1. Stencil Printing: Applying solder paste to the PCB using stencils to ensure uniform distribution.

2. Component Placement: Using pick-and-place machines to accurately position components on the PCB.

3. Reflow Soldering: Melting the solder paste to form connections between components and the PCB.

Role of SMT PCB Cutting Machines in Assembly

After the assembly process, SMT PCB cutting machines are used to separate individual PCBs from panels. This step is crucial for preparing PCBs for final inspection, testing, and packaging.

Flexible PCBs and SMT Assembly

Flexible PCBs offer additional design flexibility due to their ability to bend and fold, allowing for innovative product designs:

1. Rigid-Flex PCBs: These combine rigid and flexible sections, enabling complex geometries and reducing the need for connectors.

2. Assembly Challenges: Flexible PCBs require specialized handling and assembly techniques to prevent deformation and ensure reliable connections.

SMT PCB Cutting Machines for Flexible PCBs

While traditional SMT PCB cutting machines are primarily designed for rigid PCBs, advancements in technology are enabling the adaptation of these machines for flexible PCBs. The key challenge is ensuring that the cutting process does not damage the flexible material or compromise its integrity.

Advanced Technologies in SMT PCB Cutting Machines

Recent advancements in SMT PCB cutting machines include the integration of advanced technologies such as laser cutting and CNC (Computer Numerical Control) systems. These technologies enhance precision, reduce material waste, and improve the overall efficiency of the cutting process.

Laser Cutting Technology

Laser cutting offers high precision and can handle complex shapes with ease, making it ideal for cutting flexible PCBs without causing damage. This technology also reduces the risk of mechanical stress on the PCB material.

CNC Systems

CNC systems provide precise control over the cutting process, allowing for intricate designs and complex shapes to be cut accurately. This level of precision is crucial for maintaining quality standards in high-volume production environments.

Environmental Considerations

As the electronics industry continues to grow, environmental considerations are becoming increasingly important. SMT PCB cutting machines can contribute to sustainable manufacturing practices by minimizing waste and optimizing material usage. Additionally, the use of automated processes reduces energy consumption compared to manual cutting methods.

Future Developments

The future of SMT PCB cutting machines will likely involve further integration with Industry 4.0 technologies, such as AI and IoT, to enhance automation and real-time monitoring of production processes. This integration will enable predictive maintenance, reduce downtime, and improve overall manufacturing efficiency.

Conclusion

SMT PCB cutting machines play a vital role in enhancing PCB design flexibility by providing precision cutting capabilities, handling various substrates, and automating the cutting process. This automation and precision are crucial for maintaining high-quality standards in PCB manufacturing, especially in high-volume production environments. As technology continues to evolve, the integration of SMT PCB cutting machines with flexible PCB assembly processes will further expand design possibilities in the electronics industry.

FAQs

1. What are the primary benefits of using SMT PCB cutting machines?

The primary benefits include high precision, speed, and the ability to handle various substrates, which enhance manufacturing efficiency and product quality.

2. How do SMT PCB cutting machines support flexible PCB assembly?

While primarily designed for rigid PCBs, advancements in SMT PCB cutting machines are adapting to handle flexible PCBs by ensuring precise cutting without damaging the material.

3. What design considerations are crucial for SMT PCBs intended for cutting machines?

Key considerations include PCB pattern, size, material selection, and clamping edge design to ensure efficient and accurate cutting.

4. Can SMT PCB cutting machines be used for different types of PCB materials?

Yes, these machines can handle various materials such as FR4 and aluminum, making them versatile for different applications.

5. How does automation in SMT PCB cutting machines impact manufacturing efficiency?

Automation significantly reduces manual errors, increases production speed, and allows for higher volumes of PCBs to be processed efficiently.