Content Menu

● Understanding SMT Nozzle Cleaning Machines

● The Importance of Cleaning Nozzles

● How SMT Nozzle Cleaning Machines Work

● Benefits of Using SMT Nozzle Cleaning Machines

>> 1. Enhanced Production Efficiency

>> 2. Cost Savings

>> 3. Improved Quality Control

● Challenges Addressed by SMT Nozzle Cleaning Machines

● Types of SMT Nozzle Cleaning Machines

● Best Practices for Using SMT Nozzle Cleaning Machines

● Future Trends in SMT Nozzle Cleaning Technology

● Conclusion

● FAQ

>> 1. What is an SMT nozzle cleaning machine?

>> 2. How does an SMT nozzle cleaning machine improve efficiency?

>> 3. What types of contaminants do these machines remove?

>> 4. Are there different types of SMT nozzle cleaning machines available?

>> 5. How often should I use an SMT nozzle cleaning machine?

● Citations:

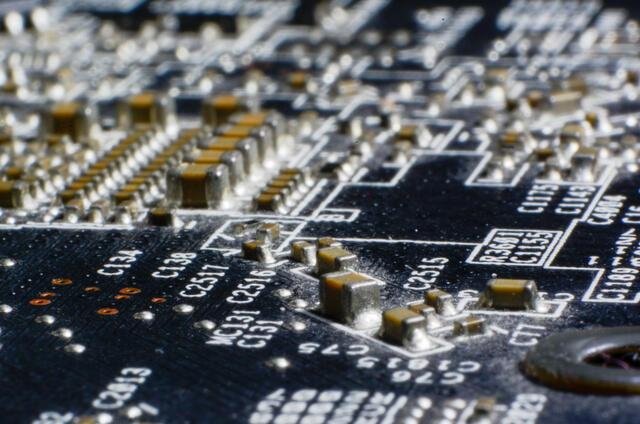

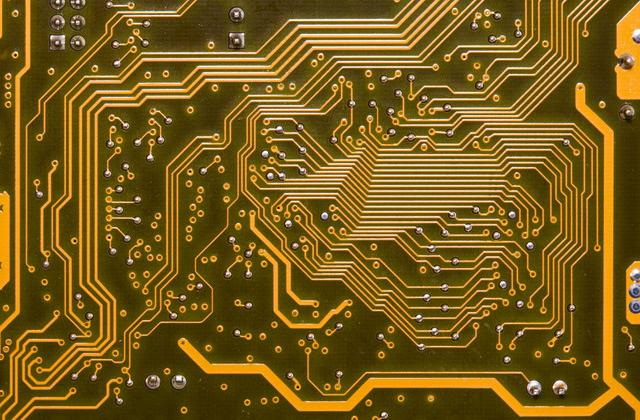

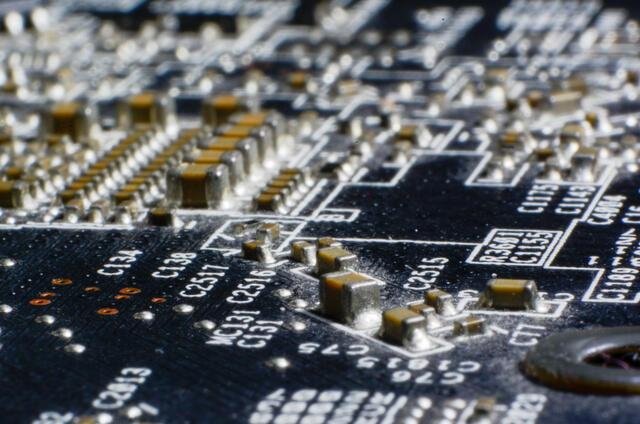

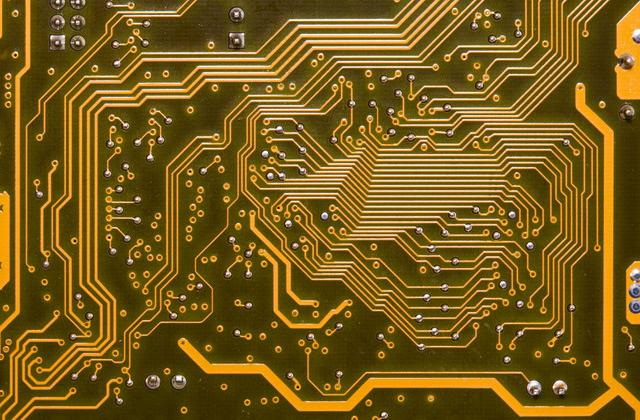

In the fast-paced world of electronics manufacturing, efficiency is paramount. Surface Mount Technology (SMT) plays a crucial role in this field, enabling the placement of electronic components onto printed circuit boards (PCBs) with precision and speed. A key component in this process is the nozzle used in pick-and-place machines. However, as components become smaller and more intricate, the nozzles are prone to clogging due to solder, flux, and other contaminants. This is where an SMT nozzle cleaning machine becomes essential for enhancing production efficiency.

Understanding SMT Nozzle Cleaning Machines

An SMT nozzle cleaning machine is specifically designed to clean the nozzles used in SMT pick-and-place machines. These machines employ advanced cleaning technologies that ensure nozzles remain free from contaminants that can lead to defects in the assembly process. By maintaining clean nozzles, manufacturers can significantly reduce product defect rates and improve overall operational efficiency.

The Importance of Cleaning Nozzles

The nozzles in SMT machines are critical for ensuring accurate placement of components. When these nozzles become clogged, several issues can arise:

- Component Misplacement: Blocked nozzles can lead to improper suction and placement of components, resulting in misalignments.

- Increased Defect Rates: Contaminated nozzles contribute to higher defect rates in products, leading to increased rework and scrap costs.

- Reduced Lifespan of Nozzles: Dirt and debris can cause wear and tear on nozzles, necessitating more frequent replacements.

By using an SMT nozzle cleaning machine, manufacturers can mitigate these issues effectively.

How SMT Nozzle Cleaning Machines Work

The operation of an SMT nozzle cleaning machine typically involves several key processes:

1. High-Pressure Cleaning: Many machines utilize high-pressure water mist or jets to dislodge contaminants from the nozzle surfaces. This method is particularly effective for stubborn debris that traditional cleaning methods cannot remove.

2. Automated Processes: Modern cleaning machines are fully automated, allowing for continuous operation without the need for dedicated personnel. This automation not only saves labor costs but also ensures consistent cleaning results.

3. Environmentally Friendly Solutions: Most SMT nozzle cleaning machines use deionized or distilled water as their cleaning medium, which is non-toxic and environmentally friendly. This approach minimizes the environmental impact compared to traditional solvents.

4. Drying Mechanisms: After cleaning, these machines often incorporate air-drying features that ensure no moisture remains on the nozzles, preventing any potential contamination during subsequent production runs.

Benefits of Using SMT Nozzle Cleaning Machines

Implementing an SMT nozzle cleaning machine offers numerous benefits that directly impact production efficiency:

1. Enhanced Production Efficiency

With clean nozzles, pick-and-place machines operate at optimal efficiency. This leads to:

- Fewer Downtime Events: Regular cleaning prevents blockages that would otherwise require machine stoppages for manual cleaning.

- Increased Throughput: Clean nozzles facilitate faster placement speeds without the risk of misplacement or defects.

2. Cost Savings

Investing in an SMT nozzle cleaning machine can lead to significant cost savings over time:

- Reduced Nozzle Replacement Costs: By extending the lifespan of nozzles through regular cleaning, manufacturers can avoid costly replacements.

- Lower Labor Costs: Automation reduces the need for manual intervention in the cleaning process, allowing staff to focus on more critical tasks.

3. Improved Quality Control

Maintaining clean nozzles directly contributes to higher product quality:

- Lower Defect Rates: With effective cleaning, the likelihood of component misplacement decreases significantly.

- Consistency in Production: Automated cleaning ensures that every nozzle is cleaned uniformly, leading to consistent performance across production runs.

Challenges Addressed by SMT Nozzle Cleaning Machines

As electronic components continue to shrink in size (e.g., 0402 and 0201), traditional cleaning methods have become inadequate. The challenges include:

- Miniaturization of Components: Smaller components require equally small and precise nozzles that are harder to clean using conventional methods like ultrasonic cleaners or manual scrubbing.

- Increased Density on PCBs: As circuit boards become more densely populated with components, even minor misalignments can lead to significant failures.

SMT nozzle cleaning machines address these challenges effectively by employing advanced technologies that cater specifically to modern manufacturing needs.

Types of SMT Nozzle Cleaning Machines

Different types of SMT nozzle cleaning machines are available on the market, each offering unique features:

- High-Pressure Water Mist Machines: These use high-pressure jets of water to clean nozzles quickly and effectively without damaging them.

- Ultrasonic Cleaning Machines: While effective for some applications, they may not be suitable for all types of nozzles due to potential damage from overlapping during cleaning.

- Combination Machines: Some models combine ultrasonic and high-pressure methods for a more thorough clean while ensuring safety and effectiveness.

Best Practices for Using SMT Nozzle Cleaning Machines

To maximize the benefits of an SMT nozzle cleaning machine, manufacturers should consider implementing best practices:

- Regular Maintenance Schedules: Establish a routine maintenance schedule based on production volume and specific operational conditions to ensure optimal performance.

- Training Personnel: Ensure that staff operating these machines are properly trained on their use and maintenance procedures to prevent mishandling or damage.

- Monitoring Performance Metrics: Track key performance indicators such as defect rates and downtime incidents before and after implementing a nozzle cleaning solution to measure its effectiveness accurately.

Future Trends in SMT Nozzle Cleaning Technology

As technology continues to evolve, so do the capabilities of SMT nozzle cleaning machines. Some future trends include:

- Integration with Industry 4.0 Technologies: The adoption of IoT (Internet of Things) technology will enable real-time monitoring and data collection from nozzle cleaning machines, allowing manufacturers to optimize their operations further based on data-driven insights.

- Advanced Materials for Nozzle Construction: Research into new materials that resist contamination will enhance the longevity and performance of nozzles themselves, reducing reliance on frequent cleanings.

- Eco-Friendly Innovations: As sustainability becomes a priority across industries, future designs may incorporate even more environmentally friendly practices, such as using biodegradable cleaning agents or energy-efficient systems.

Conclusion

In conclusion, an SMT nozzle cleaning machine significantly improves efficiency in electronics manufacturing by ensuring that nozzles remain clean and functional. The benefits include enhanced production efficiency, cost savings through reduced labor and replacement costs, and improved product quality with lower defect rates. As technology continues to advance and components become smaller and more complex, the importance of maintaining clean nozzles cannot be overstated. Investing in a reliable SMT nozzle cleaning machine is a strategic move for manufacturers looking to optimize their production processes and maintain high standards of quality control.

FAQ

1. What is an SMT nozzle cleaning machine?

An SMT nozzle cleaning machine is a specialized device designed to clean the nozzles used in surface mount technology pick-and-place machines, ensuring they remain free from contaminants that could affect production quality.

2. How does an SMT nozzle cleaning machine improve efficiency?

By keeping nozzles clean, these machines reduce downtime caused by blockages, lower defect rates from misplacements, extend nozzle lifespan, and minimize labor costs through automation.

3. What types of contaminants do these machines remove?

SMT nozzle cleaning machines effectively remove solder residue, flux buildup, dust particles, and other debris that can clog or impair nozzle function during assembly processes.

4. Are there different types of SMT nozzle cleaning machines available?

Yes, there are various types including high-pressure water mist cleaners, ultrasonic cleaners, and combination units that utilize both technologies for thorough cleaning without damaging the nozzles.

5. How often should I use an SMT nozzle cleaning machine?

The frequency of use depends on production volume and specific operational conditions; however, regular maintenance—ideally after every production run—ensures optimal performance and minimizes contamination risks.

Citations:

[1] https://silmantech.com/working-principle-of-fully-automatic-nozzle-cleaning-machine/

[2] https://silmantech.com/why-do-you-need-automatic-nozzle-cleaning-machine/

[3] https://www.joysmt.com/technique/398.html

[4] https://www.obsmt.com/product/smt-nozzle-cleaning-machine/

[5] https://www.neodensmt.com/news/what-is-used-to-clean-smt-nozzle-48216762.html

[6] https://www.odm-technology.com/mobile/prod/auto-smt-nozzle-cleaner

[7] https://smt.fuji.co.jp/en/topics/2806

[8] https://smtnova.com/practices-for-cleaning-smt-nozzles/

[9] https://www.smtmountingmachine.com/sale-36248336-economic-smt-nozzle-cleaner-reduce-unnecessary-labor-655-l-x-560-w-x-475-h.html