Content Menu

● Understanding SMT and Its Role in PCB Manufacturing

>> The Evolution of SMT in PCB Production

● Key Components of an SMT Machine Line

>> SMT Loader

>> Solder Paste Printing Machine

>> Pick and Place Machine

>> Reflow Oven

>> Automated Optical Inspection (AOI) System

● How SMT Machine Lines Enhance Efficiency

>> Increased Production Speed

>> Improved Accuracy and Consistency

>> Miniaturization Capabilities

>> Reduced Labor Costs

>> Enhanced Quality Control

● Optimizing SMT Line Efficiency

>> Implementing Design for Manufacturability (DFM) Guidelines

>> Continuous Process Improvement

>> Staff Training and Development

>> Supply Chain Management

● The Impact of SMT Lines on PCB Manufacturing Industry

>> Increased Competitiveness

>> Meeting Demand for Smaller, More Complex Electronics

>> Environmental Benefits

● Future Trends in SMT Line Technology

>> Integration of Industry 4.0 Concepts

>> Advancements in Automation

>> Flexibility in Production

● Conclusion

● FAQ

>> 1. What are the main components of an SMT production line?

>> 2. How does SMT improve PCB miniaturization?

>> 3. What are the key factors in optimizing SMT line efficiency?

>> 4. How does automated optical inspection (AOI) contribute to SMT line efficiency?

>> 5. What are the future trends in SMT production line technology?

● Citations:

In the ever-evolving world of electronics manufacturing, efficiency and quality are paramount. Surface Mount Technology (SMT) has revolutionized the production of Printed Circuit Boards (PCBs), offering a streamlined approach to component placement and assembly. This article explores how SMT machine lines significantly enhance PCB manufacturing efficiency, detailing the various aspects of the process and the benefits it brings to the industry.

Understanding SMT and Its Role in PCB Manufacturing

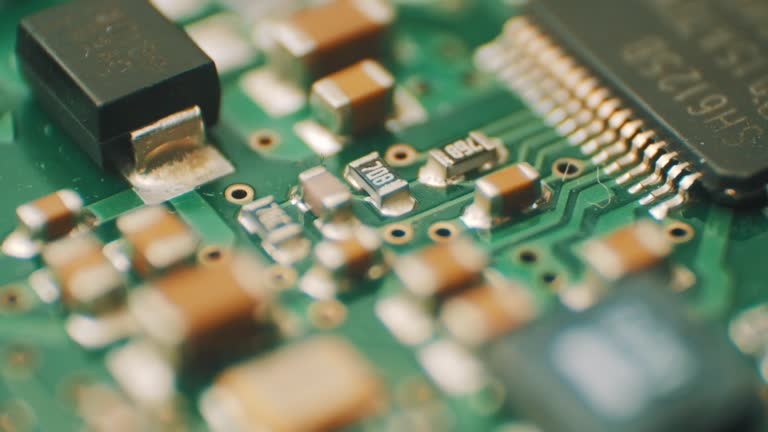

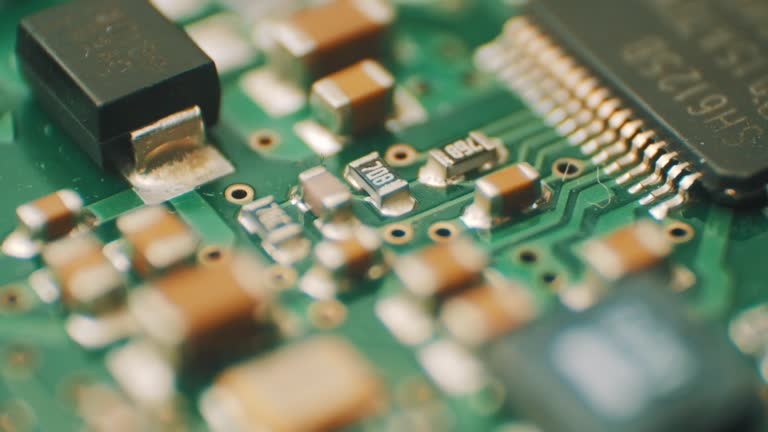

Surface Mount Technology is a method used in PCB manufacturing where electronic components are mounted directly onto the surface of a printed circuit board. This technique has largely replaced the traditional through-hole technology, offering numerous advantages in terms of efficiency, miniaturization, and cost-effectiveness[1].

The Evolution of SMT in PCB Production

SMT has become the standard in modern electronics manufacturing due to its ability to handle smaller components and create more compact designs. As electronic devices continue to shrink in size while increasing in functionality, SMT has proven to be an indispensable technology in meeting these demands[4].

Key Components of an SMT Machine Line

An SMT machine line consists of several specialized pieces of equipment, each playing a crucial role in the efficient production of PCBs. Understanding these components is essential to appreciating how they collectively improve manufacturing efficiency.

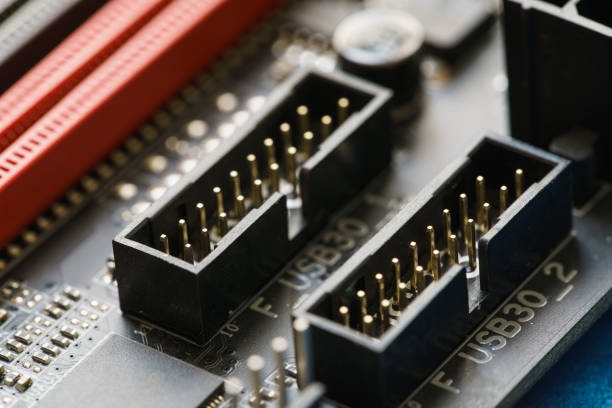

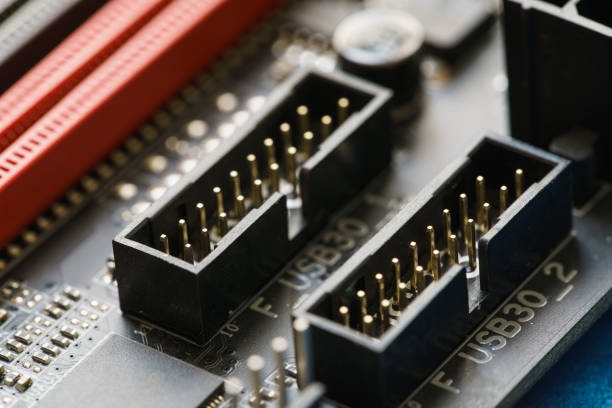

SMT Loader

The SMT loader is the starting point of the production line. It automatically stacks and loads PCBs onto the conveyor system, ensuring a steady and consistent flow of boards into the production process[3].

Solder Paste Printing Machine

This machine applies solder paste to the blank PCBs with high precision. The accuracy of this step is crucial for ensuring proper component adhesion and electrical connections[1].

Pick and Place Machine

Perhaps the most critical component of the SMT line, the pick and place machine accurately positions surface mount components onto the PCB. These machines can place thousands of components per hour with remarkable precision[1][3].

Reflow Oven

After component placement, the PCBs pass through a reflow oven. This machine applies controlled heat to melt the solder paste, creating permanent connections between the components and the board[3].

Automated Optical Inspection (AOI) System

AOI systems scan the assembled PCBs for defects, ensuring quality control throughout the production process. These systems can detect issues such as misaligned components or soldering defects with high accuracy[6].

How SMT Machine Lines Enhance Efficiency

The integration of these specialized machines into a cohesive production line significantly boosts manufacturing efficiency in several ways.

Increased Production Speed

SMT lines are capable of assembling PCBs at a much faster rate than manual or traditional assembly methods. Pick and place machines, in particular, can place components at speeds that far exceed human capabilities, dramatically reducing production time[1].

Improved Accuracy and Consistency

Automated SMT processes ensure a high level of accuracy in component placement and soldering. This precision leads to fewer errors and defects, reducing the need for rework and improving overall product quality[5].

Miniaturization Capabilities

SMT allows for the placement of smaller components in higher densities on PCBs. This capability is crucial for producing compact electronic devices with advanced functionality[4].

Reduced Labor Costs

By automating much of the assembly process, SMT lines reduce the need for manual labor. This not only cuts costs but also minimizes the risk of human error in the production process[9].

Enhanced Quality Control

Integrated inspection systems like AOI provide real-time quality checks throughout the production process. This immediate feedback allows for quick corrections and minimizes the production of defective units[6].

Optimizing SMT Line Efficiency

While SMT lines inherently improve efficiency, there are several strategies manufacturers can employ to further optimize their production processes.

Implementing Design for Manufacturability (DFM) Guidelines

Adhering to DFM principles during the PCB design phase can significantly streamline the manufacturing process. This includes considerations for component placement, board layout, and material selection[2].

Continuous Process Improvement

Regularly analyzing production data and implementing improvements is crucial for maintaining and enhancing efficiency. This may involve adjusting machine settings, optimizing component placement sequences, or upgrading equipment[5].

Staff Training and Development

While SMT lines are highly automated, skilled operators are still essential for smooth operation. Investing in comprehensive training programs ensures that staff can effectively manage and maintain the SMT equipment[5].

Supply Chain Management

Efficient management of the component supply chain is critical for maintaining continuous production. Implementing just-in-time inventory systems can help reduce storage costs and minimize production delays[2].

The Impact of SMT Lines on PCB Manufacturing Industry

The widespread adoption of SMT lines has had a profound impact on the PCB manufacturing industry as a whole.

Increased Competitiveness

Manufacturers who have embraced SMT technology can produce PCBs faster and more cost-effectively, giving them a competitive edge in the market[9].

Meeting Demand for Smaller, More Complex Electronics

SMT lines enable the production of increasingly complex and miniaturized electronic devices, meeting the growing consumer demand for smaller, more powerful gadgets[4].

Environmental Benefits

SMT processes often use less material and energy compared to traditional manufacturing methods, contributing to more sustainable production practices[10].

Future Trends in SMT Line Technology

As technology continues to advance, SMT lines are expected to become even more efficient and capable.

Integration of Industry 4.0 Concepts

The incorporation of smart manufacturing principles, including IoT sensors and real-time data analytics, is set to further optimize SMT line performance[10].

Advancements in Automation

Continued improvements in robotics and artificial intelligence are likely to lead to even more automated and precise SMT processes[6].

Flexibility in Production

Future SMT lines may offer greater flexibility, allowing for easier switching between different product types and faster adaptation to market demands[10].

Conclusion

SMT machine lines have revolutionized PCB manufacturing, offering unprecedented levels of efficiency, accuracy, and quality. By automating critical assembly processes, these production lines enable manufacturers to meet the increasing demands for smaller, more complex electronic devices while maintaining high production volumes and reducing costs.

The integration of advanced technologies such as automated optical inspection and sophisticated pick and place machines has not only accelerated production speeds but also significantly improved the consistency and reliability of PCB assemblies. Furthermore, the ability to handle miniaturized components has opened up new possibilities in electronic device design and functionality.

As the electronics industry continues to evolve, SMT lines will play an increasingly crucial role in meeting the challenges of future technological advancements. The ongoing development of SMT technology, coupled with the integration of Industry 4.0 principles, promises even greater efficiencies and capabilities in PCB manufacturing.

For manufacturers looking to stay competitive in the rapidly changing landscape of electronics production, investing in and optimizing SMT machine lines is not just beneficial—it's essential. The efficiency gains, quality improvements, and cost reductions offered by these advanced production systems make them an indispensable tool in modern PCB manufacturing.

FAQ

1. What are the main components of an SMT production line?

The main components of an SMT production line typically include:

- SMT loader

- Solder paste printing machine

- Pick and place machine

- Reflow oven

- Automated Optical Inspection (AOI) system

- SMT unloader

These machines work together to automate the PCB assembly process, from loading blank boards to inspecting the final product[1][3].

2. How does SMT improve PCB miniaturization?

SMT improves PCB miniaturization by allowing for the placement of smaller components directly on the surface of the board. This technique eliminates the need for through-holes, enabling higher component density and more compact designs. SMT can handle components as small as 0201 (0.6 mm × 0.3 mm) or even 01005 (0.4 mm × 0.2 mm), which is crucial for producing smaller, more advanced electronic devices[4].

3. What are the key factors in optimizing SMT line efficiency?

Key factors in optimizing SMT line efficiency include:

- Implementing Design for Manufacturability (DFM) principles

- Regular maintenance and calibration of equipment

- Optimizing component placement sequences

- Efficient supply chain management

- Continuous staff training and development

- Real-time monitoring and data analysis for process improvement

By focusing on these areas, manufacturers can significantly enhance their SMT line performance and overall production efficiency[2][5].

4. How does automated optical inspection (AOI) contribute to SMT line efficiency?

Automated Optical Inspection (AOI) contributes to SMT line efficiency by:

- Providing real-time quality control checks

- Detecting defects such as misaligned components or soldering issues

- Reducing the need for manual inspection

- Allowing for immediate corrections, minimizing waste and rework

- Improving overall product quality and consistency

AOI systems can inspect PCBs much faster and more accurately than human inspectors, significantly speeding up the quality control process and reducing the likelihood of defective products reaching customers[6].

5. What are the future trends in SMT production line technology?

Future trends in SMT production line technology include:

- Integration of Industry 4.0 concepts, such as IoT sensors and big data analytics

- Advanced automation and robotics for even greater precision and speed

- Artificial intelligence for predictive maintenance and process optimization

- Increased flexibility to handle a wider variety of PCB designs and components

- Enhanced environmental sustainability through more efficient use of materials and energy

These advancements are expected to further improve the efficiency, flexibility, and quality of PCB manufacturing processes[10].

Citations:

[1] https://www.quick-pcba.com/the-main-equipment-in-an-smt-line/

[2] https://www.jycircuitboard.com/news/streamlining-the-pcb-manufacturing-process-for-efficiency-and-quality-465.html

[3] https://minearc.com/what-is-an-smt-line/

[4] https://www.wevolver.com/article/smt-process

[5] https://www.smtfactory.com/Optimizing-Efficiency-Strategies-for-A-Smooth-SMT-Line-Production-Process-id47463586.html

[6] https://profabelectronics.com/posts/how-automated-pcb-assembly-improves-efficiency/

[7] https://www.pcbasic.com/blog/smt_production_line.html

[8] https://pmc.ncbi.nlm.nih.gov/articles/PMC9228397/

[9] https://itchronicles.com/manufacturing/why-is-line-efficiency-a-vital-business-metric-in-the-pcb-manufacturing-industry/

[10] https://www.andwinpcb.com/optimizing-pcb-assembly-and-manufacturing-for-efficiency-and-quality/

[11] https://rushpcb.com/line-efficiency-of-a-pcb-manufacturer/

[12] https://www.ourpcb.com/smt-line.html