Content Menu

● Introduction

● What is an SMT Line?

>> Key Components of an SMT Line

● Benefits of SMT Lines in PCBA Manufacturing

>> 1. Increased Production Speed

>> 2. Enhanced Precision and Quality

>> 3. Cost Efficiency

>> 4. Compact and Lightweight Designs

>> 5. Environmental Benefits

● How SMT Lines Improve Efficiency

>> Real-Time Monitoring and Adjustments

>> Standardization and Automation

>> High Component Density

● Challenges and Limitations

● The Role of Automation in SMT Lines

● Innovations Shaping the Future of SMT Lines

>> 1. Miniaturization of Components

>> 2. Advanced Materials

>> 3. Integration with Additive Manufacturing

>> 4. AI-Powered Process Optimization

● Conclusion

● FAQ

>> 1. What is the primary function of an SMT line?

>> 2. How does an SMT line reduce production costs?

>> 3. What are the environmental benefits of SMT lines?

>> 4. Can SMT lines handle different types of components?

>> 5. What are some challenges associated with using SMT lines?

● Citations:

Introduction

Surface Mount Technology (SMT) lines have fundamentally transformed the landscape of Printed Circuit Board Assembly (PCBA) manufacturing. By automating and optimizing various stages of production, SMT lines have become essential in the electronics industry. This article delves into how SMT lines enhance PCBA manufacturing, highlighting their benefits, operational mechanisms, and the impact they have on efficiency, quality, and cost-effectiveness.

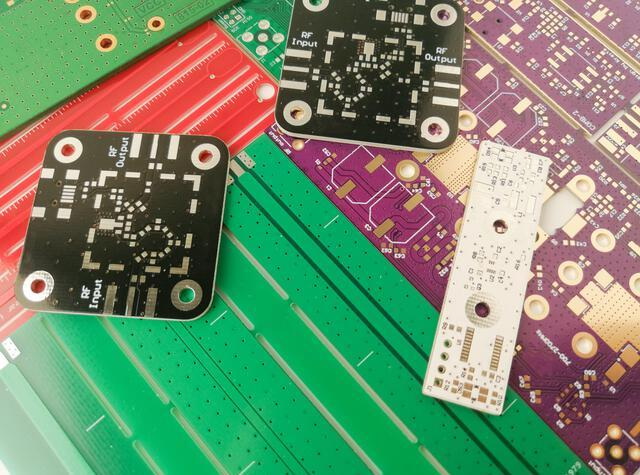

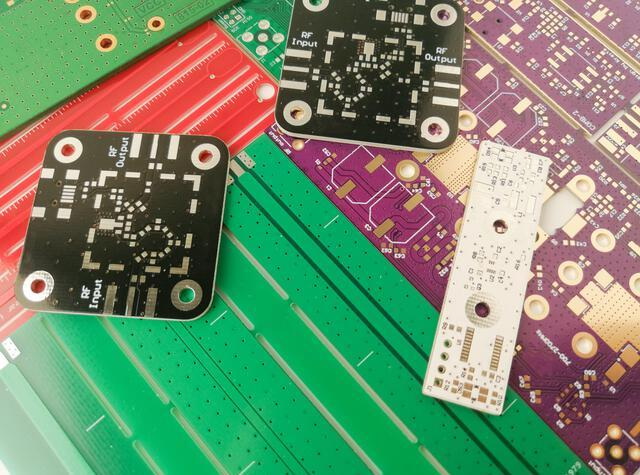

What is an SMT Line?

An SMT line is an automated assembly system designed to place surface mount devices (SMDs) onto printed circuit boards (PCBs). The line typically comprises several key components, including:

- Solder Paste Printers: These machines apply a uniform layer of solder paste to the PCB pads where components will be placed.

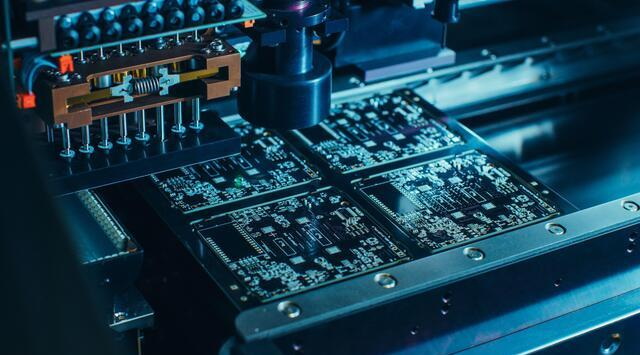

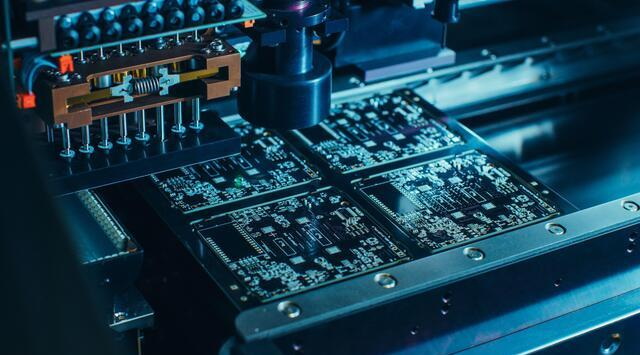

- Pick-and-Place Machines: These machines accurately position components onto the solder paste with high precision.

- Reflow Ovens: After component placement, the boards pass through reflow ovens that heat the solder paste to create reliable solder joints.

- Automated Optical Inspection (AOI): This system inspects the assembled boards to ensure correct component placement and solder quality.

Key Components of an SMT Line

1. Solder Paste Printer: Ensures consistent application of solder paste.

2. Pick-and-Place Machine: Rapidly places components with high accuracy.

3. Reflow Oven: Melts solder paste to secure components.

4. Automated Optical Inspection (AOI): Detects defects and ensures quality control.

Benefits of SMT Lines in PCBA Manufacturing

1. Increased Production Speed

SMT lines can assemble thousands of components per hour, making them ideal for high-volume production. The automation provided by these systems drastically reduces production times compared to manual assembly methods, enabling manufacturers to meet market demands swiftly.

2. Enhanced Precision and Quality

The use of automated machinery ensures precise placement of components, significantly reducing errors and enhancing product reliability. Features like AOI are crucial for early defect detection, allowing for immediate corrective actions before further processing.

3. Cost Efficiency

By minimizing manual labor and reducing material waste, SMT lines lower overall production costs. They allow manufacturers to scale operations without a corresponding increase in workforce size, leading to greater profitability.

4. Compact and Lightweight Designs

SMT technology enables the placement of components on both sides of the PCB, resulting in smaller and lighter products. This capability is especially important for modern electronics like smartphones and wearables, where space is at a premium.

5. Environmental Benefits

The efficient use of materials and reduced waste associated with SMT lines make them more environmentally friendly than traditional methods. Additionally, they consume less energy throughout the manufacturing process.

How SMT Lines Improve Efficiency

Real-Time Monitoring and Adjustments

Integration with Industry 4.0 technologies such as IoT and AI allows for real-time monitoring and predictive maintenance within SMT lines. This leads to optimal performance and minimizes downtime by anticipating potential issues before they disrupt production.

Standardization and Automation

Standardized panel designs combined with automated processes streamline production workflows. This standardization reduces setup times and enhances consistency across different production runs.

High Component Density

SMT lines support high-density component placement, enabling manufacturers to produce complex and compact PCBs that meet the demands of advanced electronic applications.

Challenges and Limitations

Despite their numerous advantages, SMT lines also face challenges:

- High Initial Setup Costs: The investment required for advanced machinery can be significant.

- Need for Skilled Operators: Although automation reduces labor needs, skilled technicians are still necessary for machine operation and maintenance.

- Fragility of Components: Small SMDs can be delicate, requiring careful handling during assembly processes.

The Role of Automation in SMT Lines

Automation is a driving force behind the efficiency gains seen in SMT lines. With advancements in robotics and AI technologies:

- Robotic Pick-and-Place Systems: These systems can operate continuously without fatigue, allowing for higher throughput while maintaining precision in component placement.

- Automated Quality Control: Systems equipped with machine vision can inspect boards at various stages of production, ensuring that defects are caught early in the process.

- Data Analytics: The integration of data analytics allows manufacturers to analyze production metrics in real time, leading to continuous improvements in efficiency and quality.

Innovations Shaping the Future of SMT Lines

The future of SMT technology is being shaped by several key innovations:

1. Miniaturization of Components

As electronic devices continue to shrink in size, manufacturers are producing smaller SMDs that require advanced handling techniques. Innovations such as micro-SMT are allowing for even denser packing on PCBs without compromising performance.

2. Advanced Materials

The development of new materials such as lead-free solder alloys has improved environmental compliance while maintaining reliability in solder joints. These materials are crucial as regulations around hazardous substances continue to tighten globally.

3. Integration with Additive Manufacturing

The combination of SMT with additive manufacturing techniques allows for more complex designs that were previously impossible with traditional methods. This integration enables rapid prototyping and customization options tailored to specific client needs.

4. AI-Powered Process Optimization

Artificial intelligence is increasingly being used to optimize various stages of the SMT process—from predicting equipment failures to adjusting parameters in real time based on feedback from production data.

Conclusion

SMT lines have revolutionized PCBA manufacturing by enhancing speed, precision, and cost-effectiveness. Their integration with modern technologies ensures they remain a cornerstone of electronics production as demand for compact and reliable devices continues to grow. As manufacturers strive for greater efficiency and quality in their products, the role of SMT lines will only become more critical in shaping the future of electronics manufacturing.

FAQ

1. What is the primary function of an SMT line?

An SMT line automates the assembly of surface mount devices onto PCBs, improving efficiency and accuracy in manufacturing processes.

2. How does an SMT line reduce production costs?

By automating processes and minimizing manual labor requirements, SMT lines lower production costs while increasing throughput capabilities.

3. What are the environmental benefits of SMT lines?

SMT lines contribute to reduced material waste and energy consumption during production, making them a more sustainable option compared to traditional assembly methods.

4. Can SMT lines handle different types of components?

Yes, SMT lines are highly flexible and can accommodate various component sizes and types, adapting easily to different manufacturing needs.

5. What are some challenges associated with using SMT lines?

Challenges include high initial setup costs, the necessity for skilled operators to manage equipment effectively, and potential fragility issues with small components during handling or assembly.

Citations:

[1] https://www.ourpcb.com/smt-line.html

[2] https://www.mycronic.com/product-areas/pcb-assembly/news-and-press-releases/news/ten-key-smt-trends-you-need-to-know/

[3] https://levisonenterprises.com/5-advantages-to-using-smt/

[4] https://pcbpit.com/what-is-an-smt-line/

[5] https://www.raypcb.com/surface-mount-technology/

[6] https://minearc.com/what-is-an-smt-line/

[7] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[8] https://www.hayawin.com/news-5-advantages-to-using-smt-in-your-electronic-manufacturing-project.html

[9] https://www.criticalmanufacturing.com/blog/material-optimization-in-the-smt-and-electronics-assembly-industries/

[10] https://www.pcbasic.com/blog/smt_production_line.html

[11] https://www.raypcb.com/ems-smt/

[12] https://jhdpcb.com/blog/efficient-smt-assembly/

[13] https://finestpcb.com/smt-assembly/

[14] https://www.wevolver.com/article/smt-process

[15] https://smttoday.com/2024/07/29/smt-component-market-trends-and-win-sources-strategic-responses/

[16] https://www.ultralibrarian.com/2021/08/10/the-impact-of-smt-components-on-pcb-assembly-ulc

[17] https://blog.intraratio.com/revolutionizing-smt-manufacturing-amidst-economic-challenges

[18] https://www.zjyingxing.com/info/what-is-the-future-of-smt-machine-82208106.html

[19] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[20] https://www.globenewswire.com/news-release/2024/10/14/2962707/28124/en/Surface-Mount-Technology-Equipment-SMT-Market-to-Surge-to-8-32-Billion-by-2028-Global-Long-term-Forecast-to-2033.html

[21] https://www.linkedin.com/pulse/impact-smt-printing-pcb-assembly-quality-0c0mc

[22] https://www.electronicdesign.com/technologies/eda/printed-circuit-boards/article/55041417/viasion-technology-top-5-miniaturization-challenges-in-pcb-assembly-and-their-solutions

[23] https://www.pcbcart.com/article/content/smt-assembly-development-trend.html

[24] https://geospacemfg.com/blog/smt-assembly-technology/

[25] https://www.rhsmt.com/news/smt-industrys-future-trends-the-impact-of-ai-and-automation/

[26] https://www.andwinpcb.com/understanding-tht-and-smt-in-modern-electronics-manufacturing/

[27] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[28] https://blog.matric.com/smt-production-for-pcbs-matric

[29] https://www.mordorintelligence.com/industry-reports/surface-mount-technology-market

[30] https://www.bigmateph.com/what-are-the-common-challenges-of-smt-and-how-to-overcome-it/

[31] https://www.pcbjhy.com/blog/pros-and-cons-of-smt-pcb-assembly/

[32] https://smt.fuji.co.jp/en/topics/2858

[33] https://www.nbk1560.com/en-US/resources/mechatronics/article/SMT/

[34] https://m.smt11.com/blog/SMT-Field/SMT-Process-Status-and-Future-Development-Trends-2023.html

[35] https://www.mpe-electronics.co.uk/2024/01/23/future-pcb-industry-trends-to-watch-out-for

[36] https://blueringstencils.com/top-5-smt-industry-trends-for-2019/