Content Menu

● What is an SMD Tape and Reel Machine?

● Components of an SMD Tape and Reel Machine

● Working Principle of an SMD Tape and Reel Machine

>> 1. Component Feeding

>> 2. Component Placement

>> 3. Inspection and Quality Control

>> 4. Sealing the Tape

>> 5. Counting and Monitoring

>> 6. Winding the Tape

● Advanced Features of Modern SMD Tape and Reel Machines

● Benefits of Using an SMD Tape and Reel Machine

● Applications of SMD Tape and Reel Machines

● Maintenance and Operational Tips for SMD Tape and Reel Machines

● Future Trends in SMD Tape and Reel Technology

● Conclusion

● FAQ

>> 1. What types of components can an SMD tape and reel machine handle?

>> 2. How does the machine ensure components are not missing or incorrectly placed?

>> 3. What is the difference between hot sealing and cold sealing in tape and reel machines?

>> 4. Can the SMD tape and reel machine perform quality inspections?

>> 5. What are the common feeding methods for components in these machines?

In the electronics manufacturing industry, the efficient handling and packaging of Surface Mount Device (SMD) components are crucial for streamlined assembly and quality assurance. The SMD tape and reel machine plays a pivotal role in this process by automating the packaging of tiny electronic components into carrier tapes, which are then wound onto reels for easy handling, storage, and feeding into pick-and-place machines. This article provides an in-depth exploration of how an SMD tape and reel machine operates, its components, working principles, and significance in modern electronics manufacturing.

What is an SMD Tape and Reel Machine?

An SMD tape and reel machine is a specialized automation device designed to package surface mount electronic components into carrier tapes sealed with a cover tape, which are then wound onto reels. This packaging method protects components from damage, contamination, and misplacement, while also facilitating automated assembly processes.

The machine can handle various SMD components such as resistors, capacitors, inductors, and semiconductors, transforming them from bulk or loose states into neatly organized tapes that can be directly fed into automated assembly lines. This packaging standard is widely adopted globally, making it a cornerstone of modern SMT (Surface Mount Technology) manufacturing.

Components of an SMD Tape and Reel Machine

The typical SMD tape and reel machine consists of several key components:

- Feeding System: Usually a vibratory bowl feeder or other automatic feeding devices that supply bulk components to the machine. The feeder ensures components are oriented correctly before placement.

- Carrier Tape: A tape with pockets designed to hold individual SMD components. The tape is typically made of plastic with embossed cavities sized to fit specific components.

- Cover Tape: A protective tape that seals the components inside the carrier tape pockets. It prevents contamination, moisture ingress, and mechanical damage during handling.

- Vacuum Manipulator or Handler: Picks components from the feeder and places them accurately into the carrier tape pockets using vacuum suction or mechanical grippers.

- Sensors: Optical or other sensors monitor component presence, count components, and detect any missing parts to ensure quality control.

- Sealing Mechanism: Can be hot sealing (heat-based) or cold sealing (adhesive-based) to seal the cover tape onto the carrier tape.

- Motor and Drive System: Pulls the tape forward and controls the movement of the carrier and cover tapes in precise increments.

- Reel System: Rolls the sealed tape onto reels for storage and transportation. The reels are standardized to fit automated assembly machines.

Working Principle of an SMD Tape and Reel Machine

The operation of an SMD tape and reel machine can be broken down into several stages:

1. Component Feeding

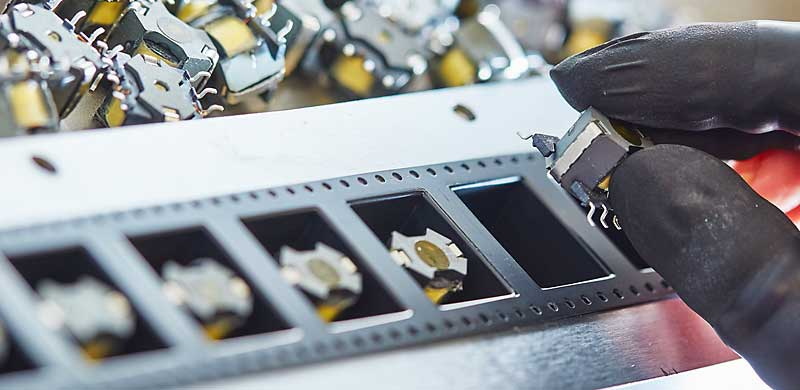

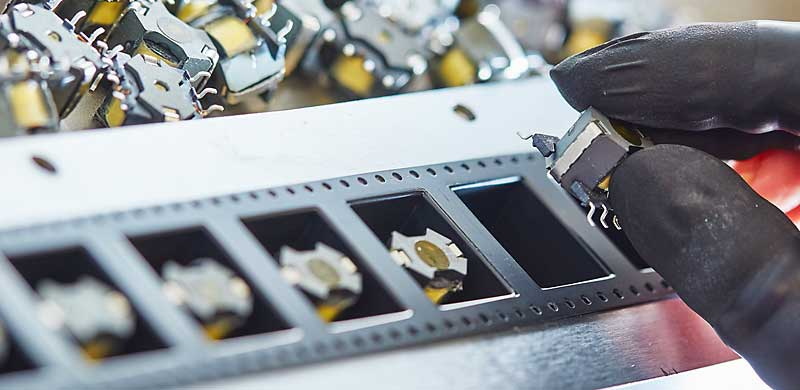

Bulk SMD components are loaded into the vibratory bowl feeder or other feeding devices. The feeder uses vibrations to orient and move components along a track to the pick-up point. This ensures components are presented in a consistent orientation for accurate placement. The vibratory feeder is designed to separate components and align them so that the vacuum manipulator can pick them up efficiently.

2. Component Placement

A vacuum manipulator or robotic handler picks components from the feeder and places each component into the corresponding pocket of the carrier tape. The carrier tape moves incrementally to position empty pockets for component placement. The manipulator's precision is critical because even a slight misalignment can cause defects in packaging or assembly failures downstream.

3. Inspection and Quality Control

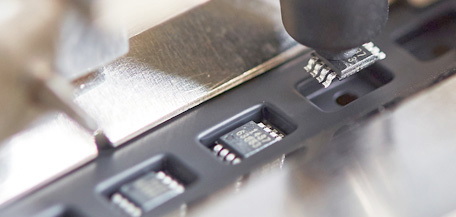

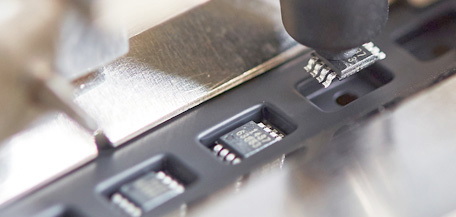

Before sealing, sensors and inspection stations may check for correct component presence, orientation, polarity, and appearance. Some machines incorporate CCD cameras or optical sensors for detailed inspection, ensuring defective or incorrectly oriented components are removed or flagged. This step is vital for maintaining the integrity of the packaging process and minimizing errors during assembly.

4. Sealing the Tape

Once components are placed, the cover tape is aligned over the carrier tape. The machine then seals the cover tape onto the carrier tape pockets to secure the components. There are two main sealing methods:

- Hot Sealing: The machine heats blades or sealing elements to melt adhesive on the cover tape, bonding it to the carrier tape. This method provides a strong, durable seal suitable for high-speed production.

- Cold Sealing: Uses adhesive-coated cover tape that sticks to the carrier tape without heat. This method is preferred for heat-sensitive components or materials.

The sealing process ensures components are protected from environmental factors and mechanical damage during transportation and storage.

5. Counting and Monitoring

Optical sensors count the number of components packaged by detecting the sprocket holes or grooves on the carrier tape. Material control sensors check for missing components in the pockets. If any missing components are detected, the machine stops automatically to prevent defective packaging. This automated monitoring improves yield and reduces waste.

6. Winding the Tape

After sealing, the encapsulated carrier tape is wound onto reels. These reels are then ready for shipment or direct use in automated pick-and-place machines. The winding tension and speed are carefully controlled to avoid tape deformation or component displacement.

Advanced Features of Modern SMD Tape and Reel Machines

Modern SMD tape and reel machines are equipped with advanced features to enhance performance, flexibility, and reliability:

- Multi-Component Handling: Some machines can handle multiple component types simultaneously by switching feeder trays or adjusting placement parameters.

- Automatic Tape Loading and Unloading: Reduces manual labor and speeds up production cycles.

- Integrated Data Logging: Tracks production data such as component counts, machine status, and fault reports for quality management and traceability.

- User-Friendly Interfaces: Touchscreen controls and programmable settings allow operators to quickly adjust parameters for different component sizes and production runs.

- Environmental Controls: Some machines include humidity and temperature control to protect sensitive components during packaging.

- Remote Monitoring and Diagnostics: Enables maintenance teams to monitor machine health and troubleshoot issues remotely, minimizing downtime.

Benefits of Using an SMD Tape and Reel Machine

Using an SMD tape and reel machine offers numerous benefits for electronics manufacturers:

- Increased Productivity: Automates a previously manual and time-consuming process, significantly increasing packaging speed.

- Improved Accuracy: Precision placement and sealing reduce errors and component damage.

- Enhanced Component Protection: Proper sealing and packaging protect components from moisture, dust, and mechanical shocks.

- Standardized Packaging: Ensures compatibility with automated pick-and-place machines and industry standards.

- Cost Savings: Reduces labor costs, material waste, and rework expenses.

- Scalability: Machines can be scaled up or customized to meet production volume requirements.

Applications of SMD Tape and Reel Machines

- Electronics Manufacturing: Preparing components for surface mount technology (SMT) assembly lines.

- Semiconductor Packaging: Handling sensitive semiconductor devices in bulk.

- Quality Control Labs: For inspection and repackaging of components.

- Component Distribution: Packaging for shipment to customers or other manufacturing facilities.

- Repair and Rework Centers: Repackaging components removed during repair processes.

Maintenance and Operational Tips for SMD Tape and Reel Machines

To ensure optimal performance and longevity of an SMD tape and reel machine, regular maintenance and proper operation are essential:

- Routine Cleaning: Keep the feeding system, sensors, and sealing mechanisms free of dust and debris.

- Lubrication: Apply lubricants to moving parts as recommended by the manufacturer.

- Calibration: Regularly calibrate sensors and placement tools to maintain accuracy.

- Component Compatibility Checks: Verify that carrier tapes and cover tapes are compatible with the machine and components.

- Operator Training: Ensure operators are trained to handle setup, troubleshooting, and emergency stops.

- Spare Parts Inventory: Maintain an inventory of critical spare parts to minimize downtime during repairs.

Future Trends in SMD Tape and Reel Technology

As electronics manufacturing continues to evolve, SMD tape and reel machines are expected to incorporate new technologies and capabilities:

- Artificial Intelligence and Machine Learning: For predictive maintenance, defect detection, and process optimization.

- IoT Integration: Enabling real-time data collection and remote control.

- Enhanced Inspection Systems: Using 3D vision and AI to detect even subtle defects.

- Flexible Packaging Solutions: Machines capable of handling increasingly diverse and miniaturized components.

- Sustainability Improvements: Using recyclable materials and energy-efficient designs.

Conclusion

The SMD tape and reel machine is an indispensable tool in the electronics manufacturing industry, enabling the efficient, accurate, and protective packaging of tiny surface mount components. By automating the feeding, placement, inspection, sealing, and winding processes, these machines significantly enhance production efficiency and product quality. Their flexibility and reliability make them essential for modern SMT assembly lines, ensuring components are delivered in optimal condition for high-speed automated assembly.

With ongoing advancements in automation, inspection, and connectivity, the role of the SMD tape and reel machine will only grow more critical in supporting the demands of increasingly complex and miniaturized electronic devices.

FAQ

1. What types of components can an SMD tape and reel machine handle?

An SMD tape and reel machine can handle a wide variety of surface mount components such as resistors, capacitors, inductors, semiconductors, and other small electronic parts, typically with cavity depths up to 5mm and widths up to 24mm.

2. How does the machine ensure components are not missing or incorrectly placed?

The machine uses optical sensors and material control sensors to detect the presence and correct placement of components in the carrier tape pockets. If any missing components are detected, the machine stops automatically to prevent defective packaging.

3. What is the difference between hot sealing and cold sealing in tape and reel machines?

Hot sealing uses heat to activate adhesive on the cover tape, bonding it to the carrier tape, while cold sealing uses pre-applied adhesive on the cover tape that sticks without heat. The choice depends on the materials used and production requirements.

4. Can the SMD tape and reel machine perform quality inspections?

Yes, many machines include inspection stations with CCD cameras or optical sensors to check component orientation, polarity, appearance, and even perform electrical tests as per customer requirements.

5. What are the common feeding methods for components in these machines?

Common feeding methods include vibratory bowl feeders, pallet feeding, vibrating disc feeding, and belt feeding. These can be customized based on the type and size of components and production needs.