Content Menu

● Understanding SMD Mount Machines and Their Role in PCB Production

● Key Ways an SMD Mount Machine Boosts PCB Production Efficiency

>> Exceptional Speed and Throughput

>> Enhanced Precision and Accuracy

>> Automation and Reduced Labor Costs

>> Support for High-Density PCB Designs

>> Consistency and Repeatability

>> Integration with Other SMT Processes

● Additional Benefits of Using an SMD Mount Machine in PCB Production

>> Smaller and Thinner PCBs

>> Reduced Material and Handling Costs

>> Improved Electrical Performance

>> Flexibility in Design

● Challenges and Considerations

● Conclusion

● FAQ

>> 1. What is an SMD mount machine, and how does it work?

>> 2. How does an SMD mount machine improve production speed?

>> 3. Can SMD mount machines handle very small components?

>> 4. What are the cost benefits of using an SMD mount machine?

>> 5. Are SMD mount machines suitable for all types of PCBs?

Surface Mount Device (SMD) mount machines have transformed the way printed circuit boards (PCBs) are manufactured by greatly enhancing speed, accuracy, and scalability. These automated machines place surface-mount components onto PCBs with remarkable precision, enabling manufacturers to produce smaller, more complex, and higher-quality electronic products efficiently. This article delves into how an SMD mount machine improves PCB production efficiency, the benefits it offers, and why it is essential in modern electronics manufacturing.

Understanding SMD Mount Machines and Their Role in PCB Production

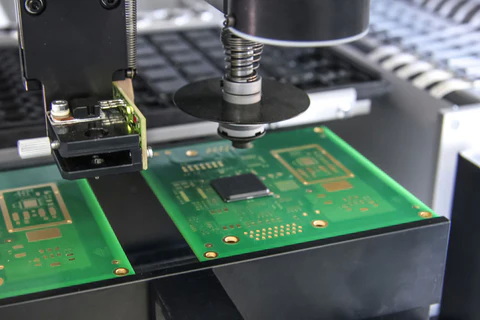

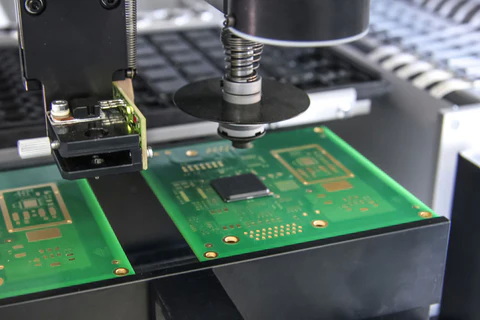

An SMD mount machine, also known as a pick-and-place machine, is an automated device designed to pick electronic components from reels or trays and place them accurately onto the surface of a PCB. Unlike traditional through-hole mounting, which requires manual insertion of components into drilled holes, SMD machines handle components that are soldered directly onto the PCB surface. This shift in assembly technology allows for faster, more precise, and more compact PCB designs.

The machine uses robotic arms equipped with nozzles to pick components, align them precisely according to the PCB layout, and place them onto solder paste applied on the board. After placement, the PCB undergoes a soldering process where the solder paste melts and solidifies, securing the components and creating reliable electrical connections.

Key Ways an SMD Mount Machine Boosts PCB Production Efficiency

Exceptional Speed and Throughput

One of the most significant improvements brought by SMD mount machines is their incredible speed. These machines can place a very large number of components per hour, far surpassing manual assembly capabilities. This rapid placement drastically reduces the time required to assemble a PCB, enabling manufacturers to increase production volumes and meet tight deadlines.

The ability to handle very small components at high speeds means that even the most compact and complex PCBs can be assembled quickly without sacrificing quality. This speed advantage is crucial for industries requiring mass production of electronics, such as consumer electronics, automotive, and telecommunications.

Enhanced Precision and Accuracy

SMD mount machines are equipped with advanced vision systems and alignment technologies that ensure components are placed with micron-level accuracy. This precision reduces errors such as misalignment, tombstoning, or component damage, which are common in manual assembly.

Accurate placement directly correlates with higher first-pass yields, meaning fewer boards require rework or scrapping. This not only saves time but also reduces material waste and labor costs associated with fixing defects.

Automation and Reduced Labor Costs

Automation is central to the efficiency of SMD mount machines. By automating the component placement process, manufacturers reduce their reliance on manual labor, which is slower, more error-prone, and costlier over time. Automated lines can run continuously with minimal human intervention, increasing uptime and throughput.

Moreover, automated inspection systems integrated with SMD mount machines can detect placement defects in real-time, allowing immediate correction and minimizing downstream quality issues.

Support for High-Density PCB Designs

The compact nature of surface-mount components allows for much higher component density on PCBs compared to through-hole technology. SMD mount machines can place components on both sides of the board and handle very fine-pitch devices, enabling the production of smaller, lighter, and more complex electronic assemblies.

This capability supports the miniaturization trend in electronics, where space savings are critical for portable and wearable devices, medical electronics, and advanced computing hardware.

Consistency and Repeatability

SMD mount machines deliver consistent placement quality across large production runs. Unlike manual assembly, which can vary depending on operator skill and fatigue, automated machines maintain uniformity, ensuring every PCB meets the same high standards.

This repeatability is essential for industries with strict quality requirements, such as aerospace, medical devices, and automotive electronics, where reliability is paramount.

Integration with Other SMT Processes

SMD mount machines seamlessly integrate with other surface-mount technology (SMT) processes, such as solder paste printing, soldering, and automated optical inspection. This integration creates a streamlined production line that minimizes handling time and maximizes throughput.

The synergy between these processes enhances overall production efficiency by reducing bottlenecks and enabling real-time quality control.

Additional Benefits of Using an SMD Mount Machine in PCB Production

Smaller and Thinner PCBs

By enabling the use of tiny surface-mount components, SMD mount machines facilitate the production of ultra-thin and miniature PCBs. This is essential for modern electronics that demand compact form factors without sacrificing functionality.

Reduced Material and Handling Costs

Automated placement reduces the need for manual handling, which can introduce contamination or damage. It also lowers material waste by ensuring precise component placement and soldering, reducing scrap rates.

Improved Electrical Performance

The shorter leads and smaller size of surface-mount components reduce parasitic inductance and capacitance, enhancing signal integrity and high-frequency performance. This is critical for high-speed digital and RF circuits.

Flexibility in Design

SMD mount machines support a wide variety of component types and sizes, enabling flexible PCB designs, including rigid, flexible, and rigid-flex boards. This versatility allows manufacturers to innovate and customize products efficiently.

Challenges and Considerations

While SMD mount machines offer many advantages, they require significant initial investment and skilled operators for programming and maintenance. Proper setup and calibration are essential to maximize efficiency and avoid production downtime.

Additionally, very small components and ultra-fine pitch devices demand high-precision machines and advanced vision systems, which can increase costs.

Conclusion

An SMD mount machine dramatically improves PCB production efficiency through its high speed, precision, automation, and ability to handle high-density, complex designs. By automating the placement of surface-mount components, these machines reduce labor costs, minimize errors, and support the production of smaller, lighter, and more reliable electronic devices. The integration of SMD mount machines into SMT production lines has become a cornerstone of modern electronics manufacturing, enabling companies to meet the demands of fast-paced, high-volume markets while maintaining quality and cost-effectiveness.

FAQ

1. What is an SMD mount machine, and how does it work?

An SMD mount machine is an automated device that picks surface-mount components from reels or trays and places them accurately onto a PCB. It uses robotic arms and vision systems to align components and place them on solder paste applied to the board before soldering.

2. How does an SMD mount machine improve production speed?

By automating the placement process, SMD mount machines can place a very large number of components per hour, far faster than manual assembly, which significantly reduces PCB assembly time and increases throughput.

3. Can SMD mount machines handle very small components?

Yes, modern SMD mount machines can handle extremely small components with high precision, enabling the production of compact and high-density PCBs.

4. What are the cost benefits of using an SMD mount machine?

Although the initial investment is high, SMD mount machines reduce labor costs, minimize rework and scrap, and increase production speed, leading to lower overall production costs, especially in medium to high-volume runs.

5. Are SMD mount machines suitable for all types of PCBs?

SMD mount machines are highly versatile and support rigid, flexible, and rigid-flex PCBs. They are ideal for high-density and complex PCB assemblies but may require specific models or configurations depending on production volume and component types.