Content Menu

● Introduction to LED SMD Strip Machines

>> Key Components of LED SMD Strip Machines

● Benefits of Using LED SMD Strip Machines

>> Increased Production Efficiency

>> Enhanced Accuracy and Precision

>> Improved Quality Control

>> Flexibility and Versatility

● Manufacturing Process of LED SMD Strips

● Applications and Advantages of LED SMD Strips

>> Energy Efficiency and Longevity

>> Flexibility and Versatility

>> Market Trends and Future Prospects

● Challenges and Solutions in LED SMD Strip Production

>> Cost Reduction Strategies

● Conclusion

● FAQ

>> 1. What is the primary function of an LED SMD strip machine?

>> 2. How does an LED SMD strip machine improve production efficiency?

>> 3. What are the key components of an LED SMD strip machine?

>> 4. What are the benefits of using LED SMD strips?

>> 5. Can LED SMD strips be customized?

The manufacturing of LED strip lights has become increasingly sophisticated with the integration of advanced technologies, particularly the LED SMD strip machine. This machine plays a crucial role in enhancing production efficiency by automating several key processes involved in the creation of LED strips. In this article, we will delve into the specifics of how these machines improve production efficiency and explore their benefits in the context of modern LED strip manufacturing.

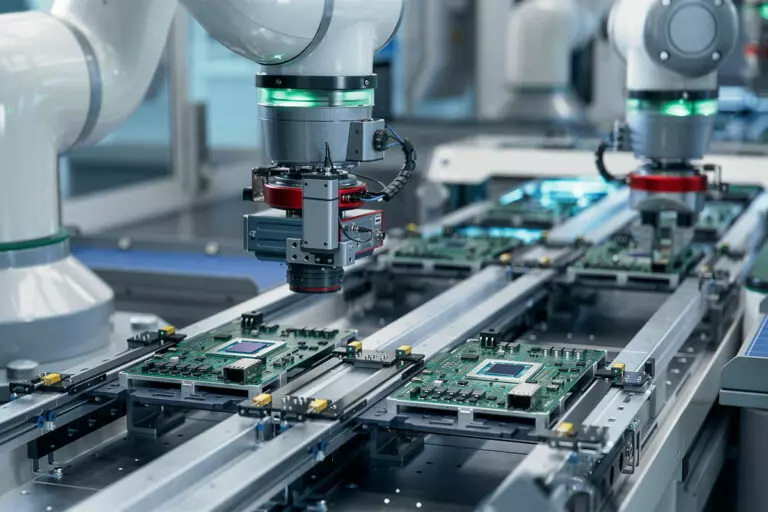

Introduction to LED SMD Strip Machines

LED SMD strip machines are specialized equipment designed to manufacture LED light strips using Surface Mount Technology (SMT). These machines are essential for producing high-quality LED strips efficiently by automating the placement of tiny LED components onto flexible printed circuit boards (PCBs). The precision and speed of these machines significantly reduce manual labor and errors, making them indispensable in modern LED strip production.

Key Components of LED SMD Strip Machines

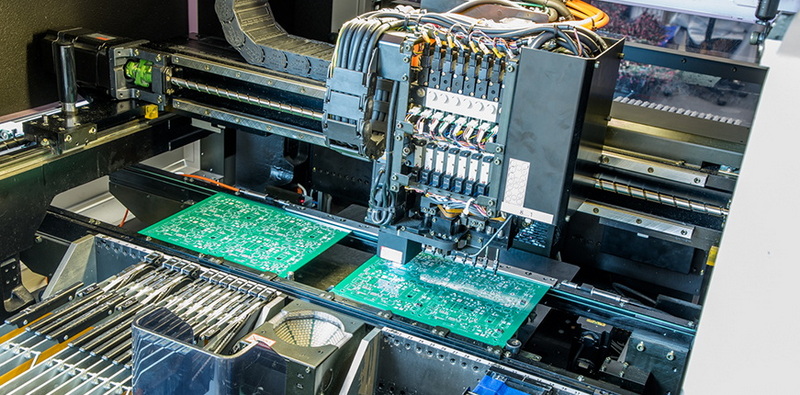

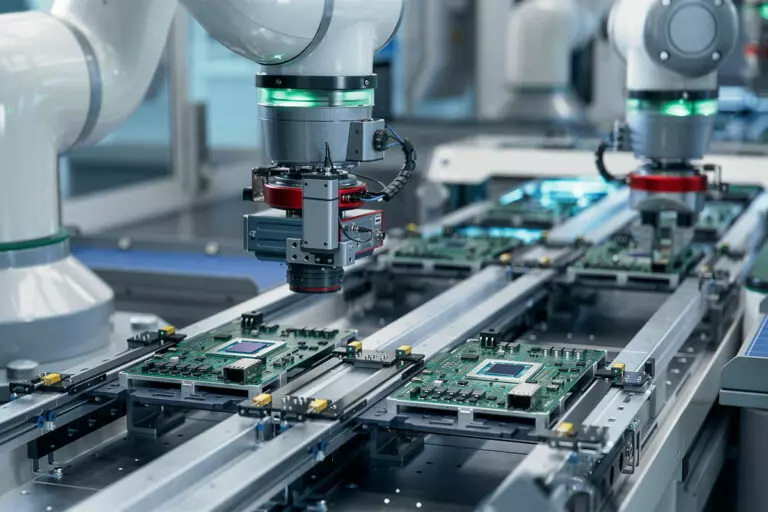

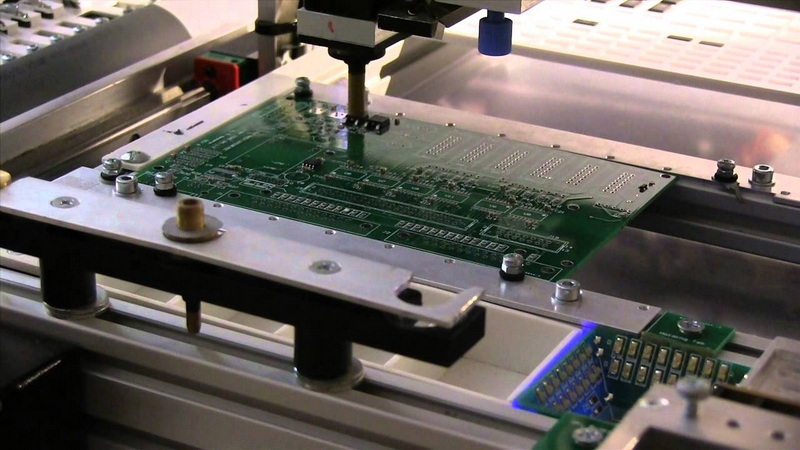

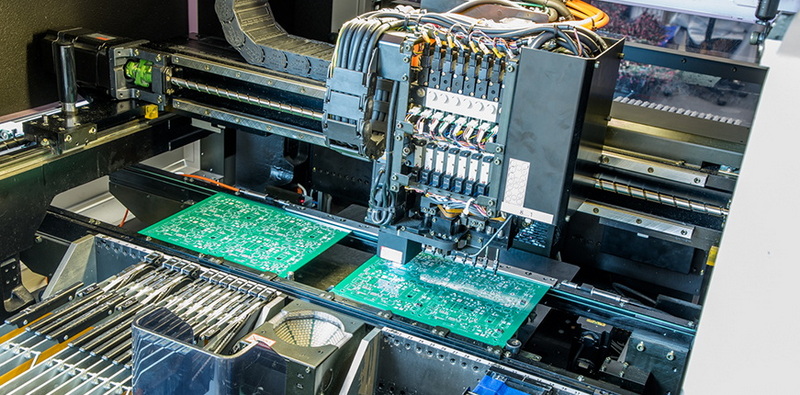

1. Pick-and-Place Machines: These are the core components of SMT technology, capable of placing thousands of components per hour with high accuracy. They ensure that LEDs and other components are precisely aligned and mounted onto the PCBs.

2. Reflow Ovens: After component placement, the PCBs are passed through reflow ovens where solder paste is melted to secure the components firmly to the board. This process ensures strong electrical connections and minimizes defects.

3. Quality Control Systems: Integrated quality control systems monitor the assembly process, detecting any defects or misplacements. This ensures that only high-quality LED strips are produced, reducing rework and waste.

Benefits of Using LED SMD Strip Machines

Increased Production Efficiency

- High-Speed Component Placement: LED SMD strip machines can handle large volumes of components at high speeds, significantly increasing production rates compared to manual assembly. This capability allows manufacturers to meet higher demands while maintaining consistent product quality.

- Reduced Cycle Times: By automating the assembly process, these machines reduce the time required to produce each unit, enabling faster turnaround times and increased overall productivity.

Enhanced Accuracy and Precision

- Advanced Vision Systems: The machines utilize advanced vision systems to accurately position and solder components onto PCBs, ensuring proper electrical connectivity and minimizing errors. This level of precision is crucial for the functionality and aesthetics of LED strip lights.

- Consistent Quality: The precision placement and soldering ensure that each LED strip meets high standards of quality, reducing the need for rework and improving customer satisfaction.

Improved Quality Control

- Extensive Quality Checks: These machines perform rigorous quality checks during the assembly process, verifying the correct placement and soldering of each component. Any defects are detected and faulty products are rejected, ensuring that only high-quality LED strips reach the market.

Flexibility and Versatility

- Customization Options: LED SMD strip machines can accommodate various types and sizes of LED components, allowing for different strip lengths, color variations, and customized designs. Quick changeover capabilities enable manufacturers to easily switch between production runs, enhancing adaptability and customization to meet diverse customer demands.

Manufacturing Process of LED SMD Strips

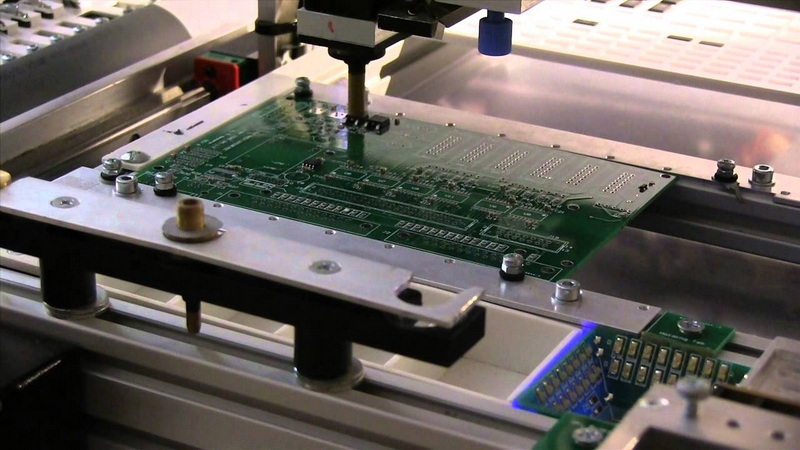

The production of LED SMD strips involves several precise and automated steps:

1. Preparation of Flexible PCBs: The flexible circuit boards are cut and treated to accommodate the SMD LEDs.

2. Component Placement: Using pick-and-place machines, manufacturers place the LED chips and other electrical components onto the board.

3. Reflow Soldering: The assembly undergoes a reflow oven process where solder paste melts to secure components firmly to the PCB.

4. Quality Testing: Once assembled, the strips undergo rigorous testing to check for defects, light output consistency, and color temperature accuracy.

5. Cutting and Packaging: The strips are cut into customizable segments for consumer use.

Applications and Advantages of LED SMD Strips

Energy Efficiency and Longevity

- Energy Efficiency: LED SMD strips are renowned for their energy efficiency, consuming less power while providing brighter light output. This makes them an eco-friendly and cost-effective lighting solution.

- Long Lifespan: With a lifespan of up to 50,000 hours or more, LED SMD strips offer durable and reliable lighting with minimal maintenance.

Flexibility and Versatility

- Flexible Design: The flexible nature of LED SMD strips allows them to be bent or shaped to fit curved or irregular surfaces, making them ideal for unique lighting designs.

- Customization: These strips can be customized to fit specific project requirements, including adjustments in color temperature, length, brightness, and connectors.

Market Trends and Future Prospects

The demand for LED SMD strips is on the rise due to their versatility and energy efficiency. As technology advances, these strips are being integrated into various applications, from residential lighting to commercial and industrial settings. The future of LED SMD strip manufacturing will likely involve further advancements in automation and customization capabilities, enabling manufacturers to meet evolving market demands more effectively.

Challenges and Solutions in LED SMD Strip Production

Despite the benefits of LED SMD strip machines, manufacturers face challenges such as maintaining high-quality output while reducing costs. To address these challenges, manufacturers are focusing on optimizing production processes, investing in advanced quality control systems, and training personnel to operate these sophisticated machines efficiently.

Cost Reduction Strategies

1. Optimization of Production Processes: By streamlining production workflows and minimizing waste, manufacturers can reduce operational costs without compromising product quality.

2. Investment in Advanced Technology: Upgrading to more efficient machinery and automation systems can lead to long-term cost savings by reducing labor costs and improving productivity.

3. Supply Chain Management: Effective management of supply chains ensures timely delivery of components, reducing downtime and associated costs.

Conclusion

In conclusion, LED SMD strip machines significantly enhance production efficiency by automating key processes, improving accuracy, and ensuring consistent quality. Their ability to handle high volumes with precision and speed makes them indispensable in modern LED strip manufacturing. As the demand for energy-efficient and customizable lighting solutions continues to grow, the role of these machines will become even more critical in meeting market needs.

FAQ

1. What is the primary function of an LED SMD strip machine?

An LED SMD strip machine is primarily used to manufacture LED light strips by automating the placement of SMD LEDs onto flexible PCBs using Surface Mount Technology (SMT). This process enhances production efficiency and ensures high-quality output.

2. How does an LED SMD strip machine improve production efficiency?

An LED SMD strip machine improves production efficiency by automating the component placement process, reducing manual labor and errors, and increasing production speeds. It also integrates quality control systems to ensure consistent product quality.

3. What are the key components of an LED SMD strip machine?

The key components include pick-and-place machines for precise component placement, reflow ovens for soldering, and quality control systems for monitoring the assembly process.

4. What are the benefits of using LED SMD strips?

LED SMD strips offer benefits such as energy efficiency, a long lifespan, flexibility, and customization options. They are ideal for various lighting applications due to their compact design and high brightness.

5. Can LED SMD strips be customized?

Yes, LED SMD strips can be customized to fit specific project requirements. Manufacturers can adjust the color temperature, length, brightness, and connectors to meet diverse customer needs.