Content Menu

● The Importance of Consistent Quality in Electronics Manufacturing

● Understanding Automatic SMD Soldering Machines

>> Key Components of an Automatic SMD Soldering Machine

● How Automatic SMD Soldering Machines Ensure Consistency

>> Precise Temperature Control

>> Accurate Component Placement

>> Controlled Solder Paste Application

>> Optimized Reflow Profiles

>> Continuous Monitoring and Adjustment

● Benefits of Consistent Quality from Automatic SMD Soldering Machines

>> Reduced Defect Rates

>> Improved Reliability

>> Increased Productivity

>> Enhanced Traceability

>> Adaptability to Different Products

● Challenges and Considerations

>> Initial Investment

>> Maintenance and Calibration

>> Operator Training

>> Process Optimization

● Future Trends in Automatic SMD Soldering

>> Artificial Intelligence and Machine Learning

>> Integration with Industry 4.0

>> Enhanced Miniaturization Capabilities

● Conclusion

● Frequently Asked Questions

>> 1. What is an automatic SMD soldering machine?

>> 2. How does an automatic SMD soldering machine improve soldering quality?

>> 3. What are the main advantages of using an automatic SMD soldering machine?

>> 4. Are there any challenges associated with implementing automatic SMD soldering machines?

>> 5. What future developments can we expect in automatic SMD soldering technology?

● Citations:

In the ever-evolving world of electronics manufacturing, precision and consistency are paramount. As devices become smaller and more complex, the demand for high-quality soldering processes has never been greater. Enter the automatic SMD (Surface Mount Device) soldering machine, a technological marvel that has revolutionized the industry by ensuring consistent quality in electronic component assembly. This article will delve into the intricacies of how these machines operate and why they are crucial in maintaining the high standards required in modern electronics production.

The Importance of Consistent Quality in Electronics Manufacturing

Before we explore the specifics of automatic SMD soldering machines, it's essential to understand why consistent quality is so critical in electronics manufacturing. In today's high-tech world, electronic devices are expected to perform flawlessly under various conditions. From smartphones to medical devices, and from automotive systems to aerospace equipment, the reliability of electronic components can often be a matter of life and death[1].

Inconsistent soldering quality can lead to a host of problems, including:

- Intermittent connections

- Short circuits

- Component failure

- Reduced product lifespan

- Increased warranty claims

- Damage to brand reputation

By ensuring consistent quality, manufacturers can mitigate these risks and produce reliable, long-lasting electronic products that meet the stringent demands of modern consumers and industries.

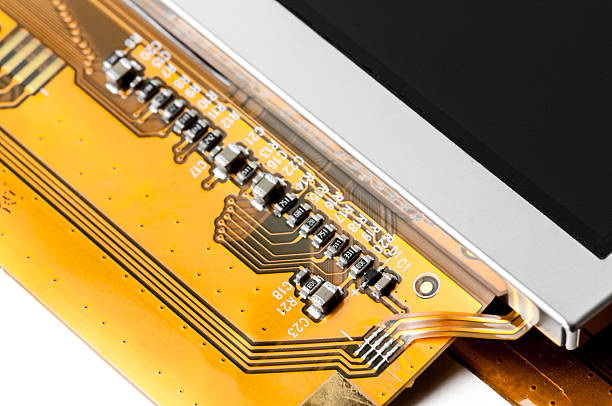

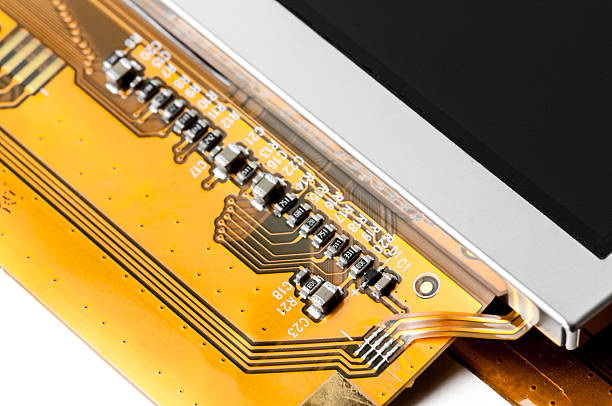

Understanding Automatic SMD Soldering Machines

Automatic SMD soldering machines are sophisticated pieces of equipment designed to place and solder surface mount components onto printed circuit boards (PCBs) with high precision and speed. These machines use advanced technologies such as computer vision, robotics, and precise temperature control to achieve consistent results[1].

Key Components of an Automatic SMD Soldering Machine

1. Conveyor System: Transports PCBs through the soldering process.

2. Vision System: Ensures accurate component placement and alignment.

3. Pick-and-Place Mechanism: Precisely positions SMD components on the PCB.

4. Solder Paste Dispenser: Applies the correct amount of solder paste to each pad.

5. Reflow Oven: Heats the PCB to melt the solder paste and create permanent connections.

6. Cooling System: Gradually cools the PCB to solidify solder joints.

7. Control System: Manages all aspects of the soldering process, including temperature profiles and timing.

How Automatic SMD Soldering Machines Ensure Consistency

Precise Temperature Control

One of the most critical factors in achieving consistent soldering quality is temperature control. Automatic SMD soldering machines excel in this area by utilizing advanced heating systems and temperature sensors[3]. These systems can:

- Maintain precise temperatures throughout the soldering process

- Create and follow complex temperature profiles for different components

- Adjust heating rates and cooling periods to optimize solder joint formation

By maintaining consistent temperatures, these machines ensure that each solder joint is formed under optimal conditions, reducing the risk of defects such as cold joints or overheating damage.

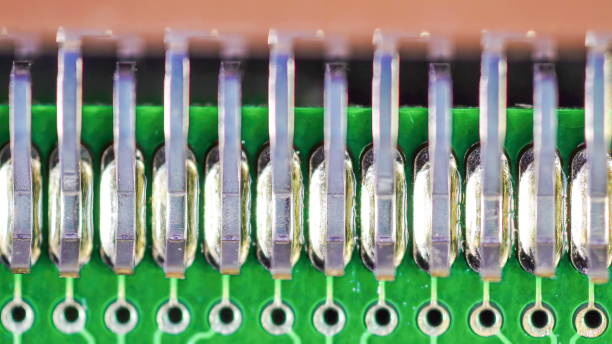

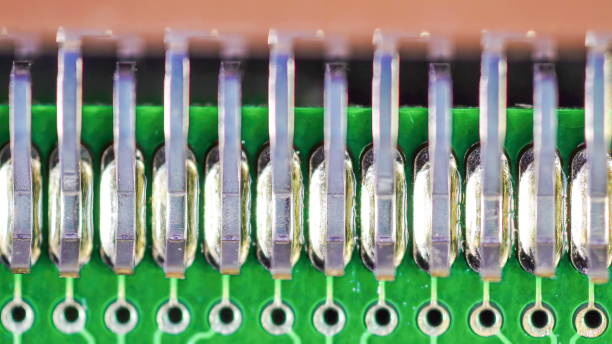

Accurate Component Placement

Consistency in soldering begins with accurate component placement. Automatic SMD soldering machines use sophisticated vision systems and robotic arms to place components with micrometer-level precision[1]. This ensures that:

- Components are correctly aligned with their corresponding pads

- There is no misalignment that could lead to bridging or open circuits

- The correct amount of solder paste is applied to each pad

The precision of component placement is crucial for creating reliable solder joints and minimizing the risk of defects.

Controlled Solder Paste Application

The amount and distribution of solder paste play a significant role in the quality of solder joints. Automatic SMD soldering machines use advanced dispensing systems to apply solder paste with exceptional accuracy[3]. These systems can:

- Dispense precise volumes of solder paste

- Adjust dispensing parameters based on pad size and component requirements

- Ensure even distribution of solder paste across all pads

By controlling the solder paste application, these machines reduce the likelihood of issues such as insufficient solder, excess solder, or solder balls.

Optimized Reflow Profiles

The reflow process, where the solder paste is melted to form permanent connections, is critical for joint quality. Automatic SMD soldering machines use sophisticated reflow ovens with multiple heating zones to create optimized temperature profiles[4]. These profiles are designed to:

- Gradually preheat components to reduce thermal shock

- Rapidly heat to the peak temperature for proper solder melting

- Maintain the peak temperature for the correct duration

- Cool at a controlled rate to ensure proper solder joint formation

By following these carefully crafted profiles, the machines ensure that each solder joint is formed under ideal conditions, promoting consistency across the entire PCB.

Continuous Monitoring and Adjustment

To maintain consistency over time, automatic SMD soldering machines incorporate advanced monitoring and feedback systems. These systems continuously track various parameters, including:

- Component placement accuracy

- Solder paste volume and distribution

- Reflow oven temperatures

- Conveyor speed

- Cooling rates

When deviations are detected, the machine can make real-time adjustments to maintain optimal performance. This constant monitoring and adjustment ensure that consistency is maintained not just within a single PCB, but across entire production runs.

Benefits of Consistent Quality from Automatic SMD Soldering Machines

The use of automatic SMD soldering machines offers numerous benefits that contribute to overall product quality and manufacturing efficiency:

Reduced Defect Rates

By maintaining consistent soldering conditions, these machines significantly reduce the occurrence of defects such as:

- Solder bridges

- Cold joints

- Tombstoning (where components stand on end)

- Insufficient solder

- Component misalignment

This reduction in defects leads to higher yield rates and fewer rejected PCBs, ultimately reducing production costs.

Improved Reliability

Consistent soldering quality translates directly into improved product reliability. When all solder joints are formed under optimal conditions, they are more likely to withstand thermal cycling, vibration, and other stresses that electronic devices encounter during their lifetime[1].

Increased Productivity

Automatic SMD soldering machines can work continuously without fatigue, maintaining consistent quality even during long production runs. This leads to:

- Higher throughput

- Reduced labor costs

- Faster time-to-market for new products

Enhanced Traceability

Many automatic SMD soldering machines include advanced tracking and logging features. These systems record detailed information about each PCB processed, including:

- Temperature profiles

- Component placement data

- Solder paste volumes

- Any detected anomalies

This data can be invaluable for quality control, process improvement, and compliance with industry standards.

Adaptability to Different Products

Modern automatic SMD soldering machines are highly adaptable and can be quickly reconfigured for different PCB designs. This flexibility allows manufacturers to:

- Produce a wide range of products on the same equipment

- Quickly switch between different production runs

- Easily incorporate design changes or new components

Challenges and Considerations

While automatic SMD soldering machines offer numerous benefits, there are some challenges and considerations to keep in mind:

Initial Investment

The cost of acquiring and setting up an automatic SMD soldering machine can be substantial. However, the long-term benefits in terms of quality, productivity, and reduced labor costs often outweigh the initial investment[4].

Maintenance and Calibration

To ensure consistent performance, these machines require regular maintenance and calibration. This includes:

- Cleaning of conveyor systems and reflow ovens

- Replacement of worn components

- Regular calibration of vision systems and pick-and-place mechanisms

- Software updates

Operator Training

While automatic SMD soldering machines reduce the need for manual soldering skills, they require operators who are trained in their setup, operation, and maintenance. Investing in comprehensive training programs is essential for maximizing the benefits of these machines.

Process Optimization

Achieving optimal results with automatic SMD soldering machines often requires careful process optimization. This may involve:

- Fine-tuning temperature profiles for different component types

- Adjusting solder paste formulations

- Optimizing component placement sequences

Future Trends in Automatic SMD Soldering

As technology continues to advance, we can expect to see further improvements in automatic SMD soldering machines:

Artificial Intelligence and Machine Learning

AI and machine learning algorithms are being incorporated into these machines to:

- Predict and prevent potential defects

- Optimize process parameters in real-time

- Improve component recognition and placement accuracy

Integration with Industry 4.0

Automatic SMD soldering machines are becoming increasingly connected, allowing for:

- Remote monitoring and control

- Integration with factory-wide data systems

- Predictive maintenance based on real-time performance data

Enhanced Miniaturization Capabilities

As electronic components continue to shrink, automatic SMD soldering machines are evolving to handle even smaller and more delicate parts with precision.

Conclusion

Automatic SMD soldering machines have revolutionized the electronics manufacturing industry by ensuring consistent quality in the critical process of component assembly. Through precise temperature control, accurate component placement, optimized reflow profiles, and continuous monitoring, these machines significantly reduce defect rates and improve overall product reliability.

The benefits of using automatic SMD soldering machines extend beyond just quality improvement. They also enhance productivity, increase manufacturing flexibility, and provide valuable data for process optimization and traceability. While there are challenges associated with their implementation, including initial costs and the need for ongoing maintenance and training, the long-term advantages make them an indispensable tool in modern electronics production.

As technology continues to advance, we can expect automatic SMD soldering machines to become even more sophisticated, incorporating AI, machine learning, and Industry 4.0 capabilities. These advancements will further enhance their ability to ensure consistent quality, cementing their role as a cornerstone of high-quality electronics manufacturing.

Frequently Asked Questions

1. What is an automatic SMD soldering machine?

An automatic SMD (Surface Mount Device) soldering machine is a sophisticated piece of equipment designed to place and solder surface mount components onto printed circuit boards (PCBs) with high precision and speed. It uses advanced technologies such as computer vision, robotics, and precise temperature control to achieve consistent results in electronics manufacturing.

2. How does an automatic SMD soldering machine improve soldering quality?

An automatic SMD soldering machine improves soldering quality through several mechanisms:

- Precise temperature control ensures optimal soldering conditions

- Accurate component placement reduces alignment errors

- Controlled solder paste application prevents issues like insufficient or excess solder

- Optimized reflow profiles create ideal conditions for solder joint formation

- Continuous monitoring and adjustment maintain consistency throughout production runs

3. What are the main advantages of using an automatic SMD soldering machine?

The main advantages of using an automatic SMD soldering machine include:

- Reduced defect rates and improved product reliability

- Increased productivity and throughput

- Enhanced traceability through detailed process logging

- Adaptability to different PCB designs and components

- Consistent quality even during long production runs

4. Are there any challenges associated with implementing automatic SMD soldering machines?

Yes, there are some challenges to consider:

- The initial investment can be substantial

- Regular maintenance and calibration are required

- Operator training is necessary to maximize the machine's potential

- Process optimization may be needed for different component types or PCB designs

5. What future developments can we expect in automatic SMD soldering technology?

Future developments in automatic SMD soldering technology may include:

- Integration of artificial intelligence and machine learning for predictive maintenance and process optimization

- Enhanced connectivity and integration with Industry 4.0 systems

- Improved capabilities for handling increasingly miniaturized components

- Advanced vision systems for even more precise component placement and inspection

Citations:

[1] https://www.seamarkzm.com/automatic-smd-soldering-machine-in-the-defense-industry-ensuring-national-security.html

[2] https://www.youtube.com/watch?v=fYInlAmPnGo

[3] https://www.seamarkzm.com/medical-device-manufacturing-made-easy-with-automatic-smd-soldering.html

[4] https://sumitron.com/automatic-soldering-machine-revolutionizing-electronics-manufacturing/

[5] https://www.aixuntech.com/newsinfo/5%20Frequently%20Asked%20Questions%20about%20SMD%20soldering/

[6] https://patents.google.com/patent/WO2021032455A1/en

[7] https://www.neodensmt.com/news/pros-and-cons-of-manual-and-auto-soldering-71484593.html

[8] https://www.instructables.com/SMD-surface-Mount-Device-101-for-the-Beginner/