Content Menu

● Introduction

● Understanding Surface Mount Technology (SMT)

>> Key Components of an SMT Assembly Line

● Advantages of Wholesale SMT Assembly Lines

>> 1. Increased Production Speed

>> 2. Enhanced Precision and Quality

>> 3. Cost-Effectiveness

>> 4. Flexibility and Scalability

>> 5. Improved Reliability

● Technological Innovations Driving Efficiency

>> Integration with Industry 4.0

>> Advanced Placement Technologies

>> Inline Inspection Systems

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. How does an SMT assembly line improve production speed?

>> 3. What are the benefits of using automated optical inspection (AOI) in SMT?

>> 4. Can wholesale SMT assembly lines adapt to different product designs?

>> 5. How do Industry 4.0 technologies enhance SMT assembly lines?

● Citations:

Introduction

In the rapidly evolving electronics manufacturing industry, the efficiency of production lines is paramount. One of the most significant advancements in this field is the introduction of wholesale Surface Mount Technology (SMT) assembly lines. These automated systems have transformed how electronic components are produced, offering numerous advantages that enhance production efficiency. This article delves into how a wholesale SMT assembly line improves production efficiency, exploring its key components, benefits, and the technological innovations driving its success.

Understanding Surface Mount Technology (SMT)

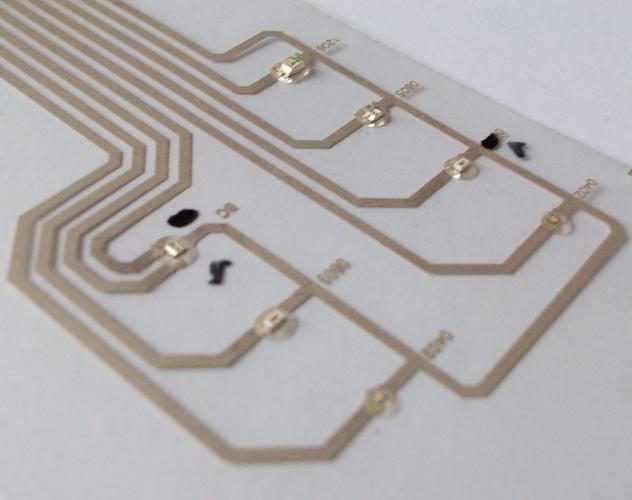

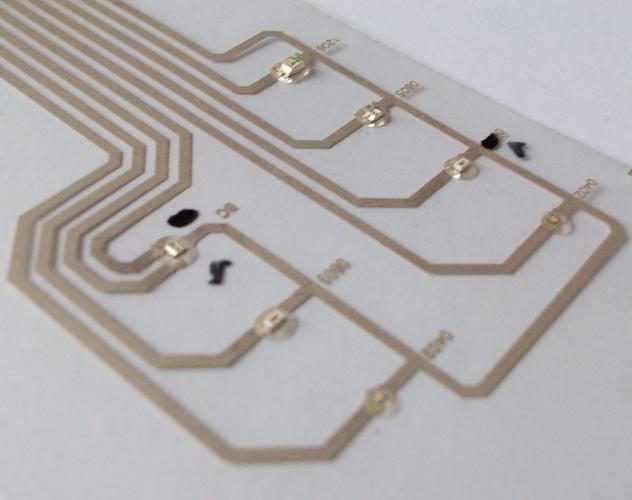

Surface Mount Technology (SMT) is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole technology, where components are inserted into holes drilled in the PCB, SMT allows for a more compact and efficient design. The components used in SMT are smaller and lighter, which not only saves space but also enables higher component density on the boards.

Key Components of an SMT Assembly Line

A typical wholesale SMT assembly line consists of several key components that work in unison to optimize production efficiency:

- Solder Paste Printer: This machine applies solder paste to the PCB in precise locations where components will be placed. Accuracy in this step is crucial for ensuring strong solder joints.

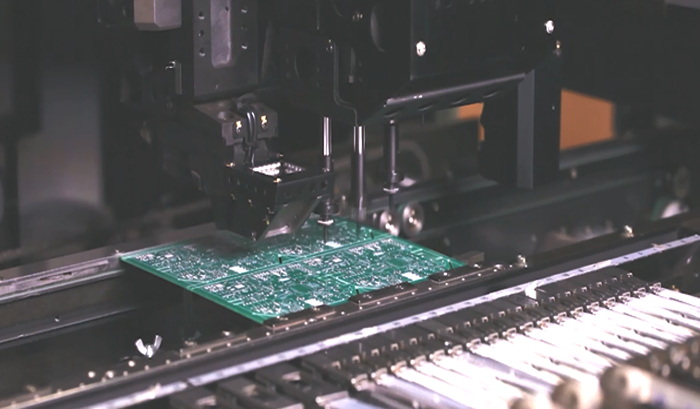

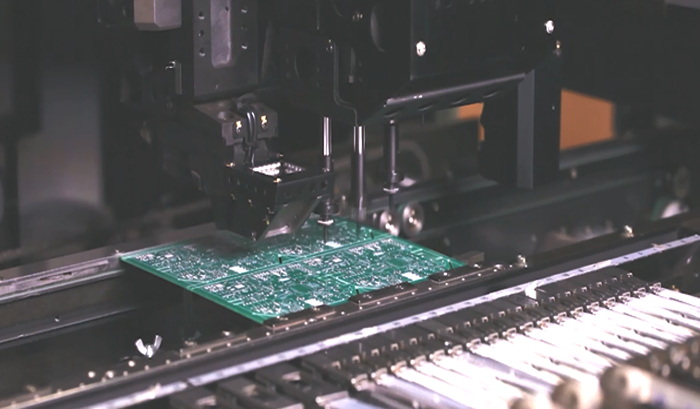

- Pick and Place Machine: This automated system places components onto the PCB with high speed and accuracy. Modern machines can place over 136,000 components per hour, significantly increasing throughput[5].

- Reflow Oven: After placement, PCBs pass through a reflow oven where solder paste is melted to create permanent connections between components and the board.

- Automated Optical Inspection (AOI): This machine inspects PCBs for defects such as misalignment or insufficient soldering. Early detection of issues helps maintain quality and reduces rework costs[7].

Advantages of Wholesale SMT Assembly Lines

1. Increased Production Speed

One of the primary benefits of a wholesale SMT assembly line is its ability to significantly increase production speed. The automation involved in SMT allows for rapid component placement and processing times, reducing cycle times compared to manual assembly methods. This speed is critical for meeting high-volume demands in today's fast-paced market.

2. Enhanced Precision and Quality

The precision offered by SMT machinery minimizes human error, ensuring that components are placed accurately on the PCB. Automated systems can consistently achieve high-quality results, leading to fewer defects and higher first-run yields. For instance, companies have reported improvements in first-run yield from 70% to as high as 97% after implementing advanced SMT processes[10].

3. Cost-Effectiveness

Wholesale SMT assembly lines reduce labor costs by minimizing manual intervention. The automation not only speeds up production but also lowers material waste through precise solder paste application and efficient component placement. This cost-effectiveness is particularly beneficial for large-scale production runs where even small savings per unit can add up significantly[8].

4. Flexibility and Scalability

SMT assembly lines are designed to be flexible, allowing manufacturers to quickly adapt to changing production needs or product designs. This flexibility is essential for businesses that need to pivot rapidly in response to market demands or technological advancements.

5. Improved Reliability

The reliability of SMT processes stems from their inherent design advantages. The absence of drilled holes reduces mechanical stress on PCBs, leading to enhanced durability and longevity of electronic devices[4]. Furthermore, automated inspection systems ensure that any defects are caught early in the process, further improving overall reliability.

Technological Innovations Driving Efficiency

Integration with Industry 4.0

The integration of Industry 4.0 technologies into wholesale SMT assembly lines has further enhanced production efficiency. Data analytics provide insights into machine performance and operational bottlenecks, allowing for continuous improvement initiatives[1]. Additionally, IoT connectivity enables real-time monitoring of production processes, facilitating proactive maintenance and reducing downtime.

Advanced Placement Technologies

High-speed placement machines equipped with advanced technologies such as laser alignment and multi-head placement systems have revolutionized component mounting speeds and accuracy[8]. These innovations ensure that even complex PCB designs can be assembled efficiently without compromising quality.

Inline Inspection Systems

Implementing inline inspection systems has become increasingly common in modern SMT lines. These systems utilize cameras and sensors to monitor quality throughout the production process, reducing the need for extensive manual inspections post-production[8]. This not only enhances quality control but also streamlines workflows by identifying issues as they occur.

Conclusion

Wholesale SMT assembly lines represent a significant advancement in electronics manufacturing, offering unparalleled improvements in production efficiency. By leveraging automation, advanced technologies, and data analytics, manufacturers can achieve faster production speeds, enhanced precision, cost-effectiveness, flexibility, and improved reliability. As the industry continues to evolve with new technological innovations, wholesale SMT assembly lines will remain at the forefront of efficient electronic component manufacturing.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method used for mounting electronic components directly onto the surface of printed circuit boards (PCBs), allowing for more compact designs compared to traditional through-hole methods.

2. How does an SMT assembly line improve production speed?

SMT assembly lines utilize automated machines that can place thousands of components per hour, significantly reducing cycle times compared to manual assembly processes.

3. What are the benefits of using automated optical inspection (AOI) in SMT?

Automated Optical Inspection (AOI) helps detect defects such as misalignment or insufficient soldering early in the production process, improving quality control and reducing rework costs.

4. Can wholesale SMT assembly lines adapt to different product designs?

Yes, wholesale SMT assembly lines are designed to be flexible and scalable, allowing manufacturers to quickly adjust their processes for different product designs or changing market demands.

5. How do Industry 4.0 technologies enhance SMT assembly lines?

Industry 4.0 technologies integrate data analytics and IoT connectivity into SMT assembly lines, providing insights into machine performance and enabling real-time monitoring for proactive maintenance.

Citations:

[1] https://www.hct-smt.com/blog/how-to-integrate-industry-4-0-technologies-with-wholesale-smt-line-machines

[2] https://rootsems.com/advantages-and-disadvantages-of-surface-mount-technology/

[3] https://dokumen.pub/manufacturing-engineering-and-technology-in-si-units-8nbsped-9781292422244-1292422246.html

[4] https://www.medicaldesignbriefs.com/component/content/article/46458-surface-mount-technology-for-pcb-assembly-use-case-and-smt-in-healthcare-systems

[5] https://jlcpcb.com/blog/the-characteristics-of-surface-mount-technology

[6] https://dokumen.pub/automation-production-systems-and-computerintegrated-manufacturing-5nbsped-9780134605463.html

[7] https://de.hct-smt.com/blog/wholesale-led-smt-production-line--revolutionizing-the-led-manufacturing-industry

[8] https://www.zjyingxing.com/info/what-are-the-ways-to-improve-the-efficiency-of-88896111.html

[9] https://tech-long.jp/pdf/23.pdf

[10] https://blog.matric.com/smt-production-for-pcbs-matric