Content Menu

● Introduction to SMD Mounting Machines

>> Key Features of Wholesale SMD Mounting Machines

● Benefits of Using Wholesale SMD Mounting Machines

>> Advantages of Surface Mount Technology (SMT)

● Applications of Wholesale SMD Mounting Machines

● Operational Aspects of Wholesale SMD Mounting Machines

>> Future Developments in SMT

● Challenges and Future Developments

● Conclusion

● FAQ

>> 1. What is the primary advantage of using wholesale SMD mounting machines in PCB assembly?

>> 2. How do wholesale SMD mounting machines handle different types of components?

>> 3. What maintenance is required for wholesale SMD mounting machines?

>> 4. Can wholesale SMD mounting machines be integrated with existing production lines?

>> 5. What factors should be considered when purchasing a wholesale SMD mounting machine?

● Citations:

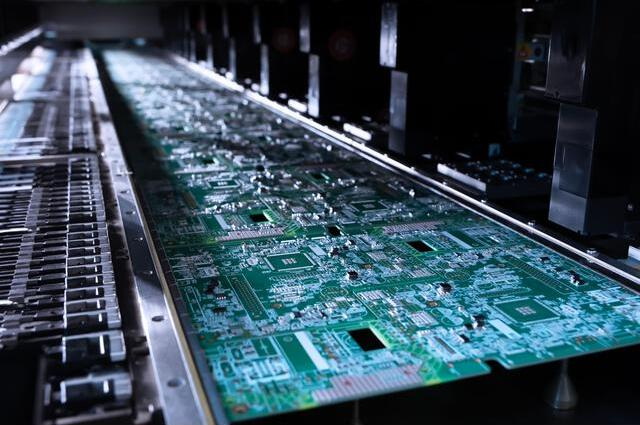

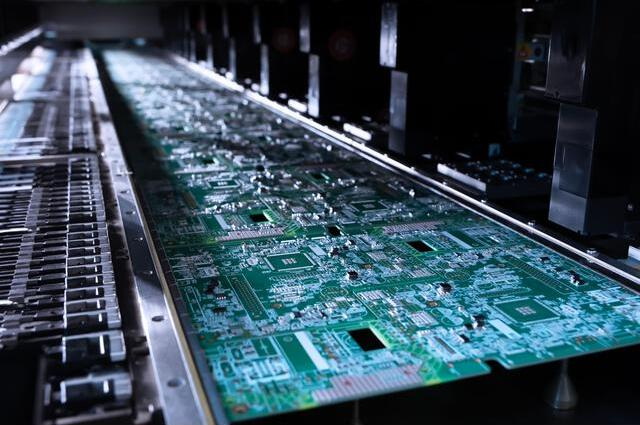

In the rapidly evolving electronics industry, efficiency and speed are crucial for maintaining a competitive edge. One of the key technologies driving this efficiency is the use of wholesale SMD (Surface Mount Device) mounting machines in PCB (Printed Circuit Board) assembly. These machines are designed to automate the process of placing SMD components onto PCBs, significantly enhancing production speed and reducing manual labor errors. This article will delve into how wholesale SMD mounting machines increase PCB assembly speed and explore their benefits, applications, and operational aspects.

Introduction to SMD Mounting Machines

SMD mounting machines, also known as pick-and-place machines, are essential components of modern PCB assembly lines. They are capable of handling a wide range of SMD components, from small resistors and capacitors to complex ICs and BGAs (Ball Grid Arrays). These machines use advanced vision systems and precision nozzles to accurately place components on the PCB, ensuring high-quality assembly with minimal defects.

Key Features of Wholesale SMD Mounting Machines

Wholesale SMD mounting machines are designed with several key features that contribute to increased PCB assembly speed:

- High-Speed Placement: These machines can place thousands of components per hour, significantly faster than manual assembly methods. For example, some advanced models can achieve placement rates of over 40,000 components per hour (CPH).

- Automation and Precision: Automated systems reduce human error and ensure consistent quality. The use of advanced vision systems allows for precise alignment and placement of components, even at high speeds.

- Flexibility and Adaptability: Modern SMD mounting machines can handle a variety of component sizes and types, making them versatile for different production needs.

- User-Friendly Interface: Many machines come with intuitive software interfaces that simplify setup and operation, reducing the need for extensive technical expertise.

Benefits of Using Wholesale SMD Mounting Machines

The integration of wholesale SMD mounting machines into PCB assembly processes offers several benefits:

- Increased Efficiency: By automating the component placement process, these machines significantly reduce assembly time and increase production throughput.

- Improved Quality: Automated placement minimizes errors, leading to higher reliability and longevity of the assembled PCBs.

- Cost Savings: While the initial investment in SMD mounting machines is high, they offer long-term cost savings through reduced labor costs and improved efficiency.

- Design Flexibility: SMD components allow for denser PCB designs, enabling the creation of smaller, more complex electronic devices.

Advantages of Surface Mount Technology (SMT)

Surface Mount Technology (SMT) is the backbone of modern PCB assembly, offering several advantages over traditional through-hole methods:

- Higher Component Density: SMT allows for much higher component densities, enabling the miniaturization of electronic devices. This is particularly beneficial in mobile, handheld, and portable electronics where small form factors are crucial[1][5].

- Smaller and Lighter Assemblies: The compact size and low weight of SMT assemblies make them ideal for applications requiring reduced size and weight[1].

- Improved Automation Potential: SMT processes are highly amenable to automation, reducing reliance on manual labor and improving production efficiency[1][4].

- Higher Reliability and Longevity: SMT assemblies generally offer improved reliability and longer lifespans due to robust solder joints and reduced vibration stress[1][7].

Applications of Wholesale SMD Mounting Machines

Wholesale SMD mounting machines are widely used across various industries due to their versatility and efficiency:

- Consumer Electronics: These machines are crucial for producing compact, high-density PCBs used in smartphones, laptops, and other portable devices[1][3].

- Automotive: The automotive industry relies on SMD mounting machines for manufacturing electronic control units and other vehicle electronics[3].

- Medical Devices: In medical applications, precision and reliability are paramount. SMD mounting machines help ensure these standards are met in devices such as diagnostic equipment and medical implants[1].

Operational Aspects of Wholesale SMD Mounting Machines

The operation of wholesale SMD mounting machines involves several key steps:

1. Component Preparation: Components are loaded into feeders, which supply them to the machine.

2. PCB Setup: The PCB is placed on the machine's conveyor system.

3. Component Placement: The machine uses its vision system to identify and pick components from the feeders, placing them accurately on the PCB.

4. Reflow Soldering: After placement, the PCB is passed through a reflow oven where the solder paste melts and solidifies, securing the components.

Future Developments in SMT

The future of SMT is shaped by several key trends and innovations:

- Miniaturization of Electronics: The demand for smaller, lighter devices with higher functionality continues to drive SMT advancements[3].

- Increased Automation: Robotics and advanced soldering techniques are enhancing production speed and accuracy[3][6].

- Integration of AI and Machine Learning: AI is being integrated into SMT production lines to improve quality control and predictive maintenance[3][6].

Challenges and Future Developments

Despite the advantages of wholesale SMD mounting machines, there are challenges to consider:

- Initial Investment: The cost of purchasing and maintaining these machines can be high, making them less accessible to small-scale manufacturers.

- Component Handling: Specialized equipment is required for handling and repairing SMD components due to their small size.

Future developments in SMD mounting technology are expected to focus on improving machine accuracy, increasing placement speeds, and enhancing user interfaces to make these systems more accessible and efficient.

Conclusion

Wholesale SMD mounting machines play a critical role in enhancing PCB assembly speed by automating the placement of SMD components. Their ability to handle high volumes with precision and speed makes them indispensable in modern electronics manufacturing. As technology continues to evolve, these machines will remain at the forefront of PCB assembly, driving innovation and efficiency across various industries.

FAQ

Here are some frequently asked questions about wholesale SMD mounting machines:

1. What is the primary advantage of using wholesale SMD mounting machines in PCB assembly?

- The primary advantage is the significant increase in assembly speed and efficiency, along with improved quality and reduced labor costs.

2. How do wholesale SMD mounting machines handle different types of components?

- These machines are designed to handle a variety of SMD components, from small passive components to complex ICs and BGAs, using adjustable nozzles and flexible feeders.

3. What maintenance is required for wholesale SMD mounting machines?

- Regular maintenance includes cleaning the nozzles, checking vacuum systems, and ensuring proper alignment of the vision system to maintain precision and accuracy.

4. Can wholesale SMD mounting machines be integrated with existing production lines?

- Yes, these machines are designed to be compatible with various production environments. They can be easily integrated into existing assembly lines, enhancing overall efficiency.

5. What factors should be considered when purchasing a wholesale SMD mounting machine?

- Key factors include the machine's placement speed, component handling capacity, user interface complexity, and after-sales support. Additionally, consider the machine's adaptability to future production needs and its cost-effectiveness.

Citations:

[1] https://www.pcbjhy.com/blog/pros-and-cons-of-smt-pcb-assembly/

[2] https://www.altestcorp.com/surface-mount-technology/

[3] https://www.reportsnreports.com/semiconductor-and-electronics/the-future-of-surface-mount-technology-innovations-and-opportunities-in-the-smt-market/

[4] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[5] https://en.wikipedia.org/wiki/Surface-mount_technology

[6] https://www.cognitivemarketresearch.com/articles/surface-mount-technology-smt-market-trends-and-future-opportunities

[7] https://www.pcbelec.com/smt-advantages-and-disadvantages.html

[8] https://www.starengineeringinc.com/the-role-of-smt-assemblies-in-the-future-of-automotive-electronics/

[9] https://www.medicaldesignbriefs.com/component/content/article/46458-surface-mount-technology-for-pcb-assembly-use-case-and-smt-in-healthcare-systems

[10] https://www.pcb-hero.com/blogs/lickys-column/types-and-features-of-excellent-smt-machines

[11] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[12] https://www.globalwellpcba.com/surface-mount-device-smd/

[13] https://www.nextpcb.com/blog/top-10-smt-machines-worldwide

[14] https://www.pcbcart.com/article/content/smt-assembly-development-trend.html

[15] https://ko.hct-smt.com/blog/wholesale-smt-surface-mounting-machines

[16] https://www.wevolver.com/article/smt-process

[17] https://www.neodentech.com/newsinfo/1008374.html

[18] https://www.neodensmt.com/pick-and-place-machine/neoden10-smt-pick-and-place-machine.html

[19] https://goldlandsmt.com/product-item/siemens-d4-high-speed-surface-mounting-system-advanced-smt-solution-for-precision-pcb-assembly/

[20] https://www.hayawin.com/news-smt-machine-types-and-features-of-excellent-smt-machines.html