Content Menu

● What is a Turnkey SMT Line?

● Benefits of a Turnkey SMT Line

>> 1. Cost Efficiency

>> 2. Enhanced Quality Control

>> 3. Faster Time-to-Market

>> 4. Simplified Management

>> 5. Advanced Technology Integration

● How Does a Turnkey SMT Line Work?

>> Design and Prototyping

>> Component Sourcing

>> Assembly and Testing

● Advantages of Using SMT Technology in Turnkey Lines

● Industry Applications

● Future Trends in Turnkey SMT Lines

>> 1. Increased Automation

>> 2. Sustainable Practices

>> 3. Customization Capabilities

>> 4. Advanced Materials

● Conclusion

● FAQs

>> 1. What is the main advantage of a turnkey SMT line?

>> 2. How does a turnkey SMT line improve quality?

>> 3. Can a turnkey SMT line handle complex PCB designs?

>> 4. Is a turnkey SMT line cost-effective for small businesses?

>> 5. How does a turnkey SMT line reduce time-to-market?

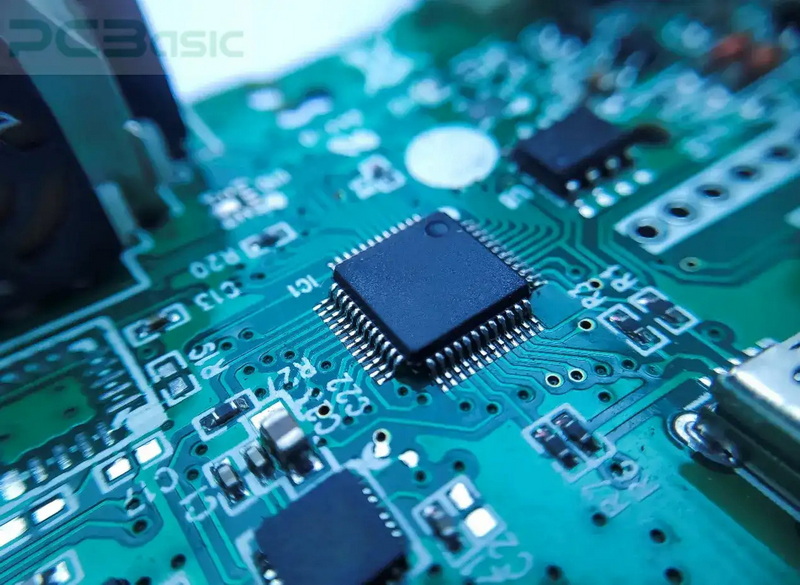

In the rapidly evolving electronics manufacturing industry, efficiency and precision are critical. A turnkey Surface Mount Technology (SMT) line has become a transformative solution in the Printed Circuit Board (PCB) assembly process. This article explores how a turnkey SMT line enhances PCB assembly, highlighting its benefits, operational processes, and its significant impact on the industry.

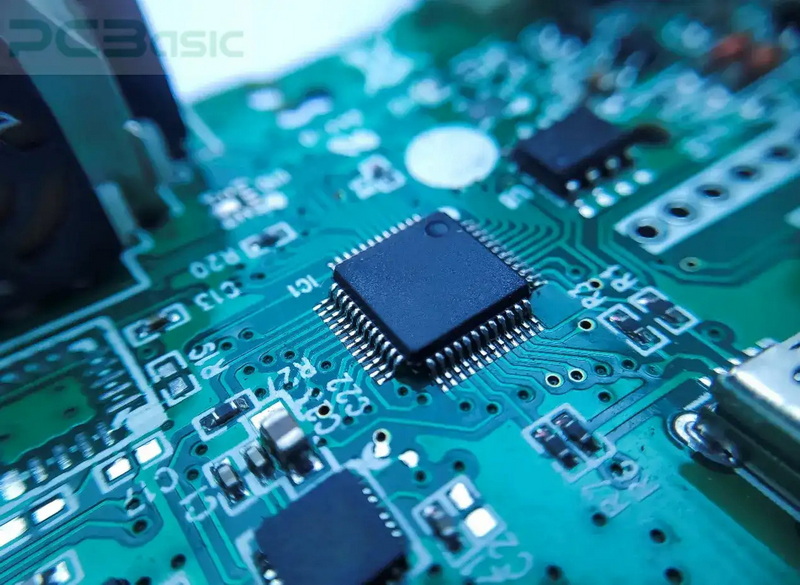

What is a Turnkey SMT Line?

A turnkey SMT line refers to a comprehensive solution where a single provider manages all aspects of PCB assembly. This includes design, prototyping, component sourcing, assembly, testing, and final delivery. Unlike traditional methods that involve multiple vendors, a turnkey approach consolidates these processes under one roof, streamlining operations and reducing complexities.

Benefits of a Turnkey SMT Line

1. Cost Efficiency

Turnkey SMT lines significantly reduce costs by leveraging established relationships with component suppliers, bulk purchasing, and minimizing logistical expenses. The automation in SMT lines also reduces manual labor costs, further enhancing cost savings.

- Bulk Purchasing: Turnkey providers often buy components in bulk, which lowers the per-unit cost. This is particularly beneficial for companies looking to scale their production without significantly increasing their budget.

- Reduced Waste: Automation minimizes material waste during the production process. Precise placement of components reduces the likelihood of errors that can lead to defective products.

2. Enhanced Quality Control

With a single provider overseeing the entire process, quality control becomes more consistent. Automated inspections and testing at various stages ensure that defects are identified and rectified early in the production process, leading to higher reliability in the final product.

- Automated Testing: Advanced testing equipment can perform checks at various stages of assembly, ensuring that each component functions correctly before moving on to the next stage.

- Real-time Monitoring: Many turnkey SMT lines utilize real-time monitoring systems that provide instant feedback on production quality, allowing for immediate adjustments if issues arise.

3. Faster Time-to-Market

By eliminating the need to coordinate with multiple vendors, a turnkey SMT line accelerates the production process. This is crucial in the competitive electronics market where speed can be a decisive factor for success.

- Streamlined Communication: With one point of contact for all aspects of production, communication is simplified. This leads to quicker decision-making and faster resolution of any issues that may arise during production.

- Efficient Workflow: The integration of all processes allows for a more efficient workflow, reducing downtime between stages and speeding up overall production time.

4. Simplified Management

Managing a single point of contact simplifies communication and project oversight. This reduces the risk of miscommunication and ensures that projects stay on track and within budget.

- Centralized Information: All project-related information is centralized, making it easier for managers to access data and make informed decisions quickly.

- Consistent Project Updates: Clients receive regular updates from one source rather than having to gather information from multiple vendors.

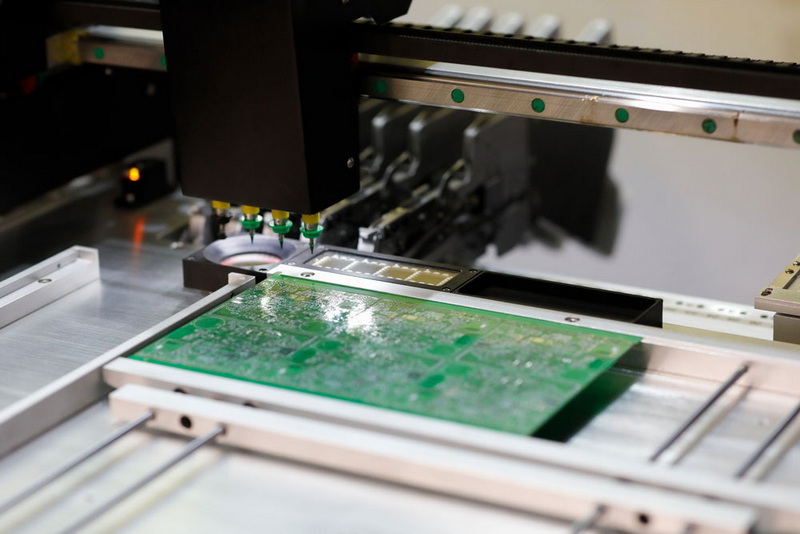

5. Advanced Technology Integration

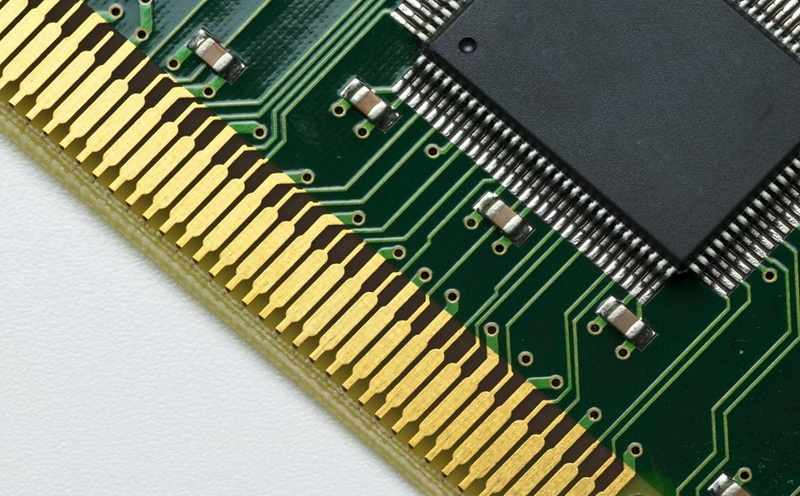

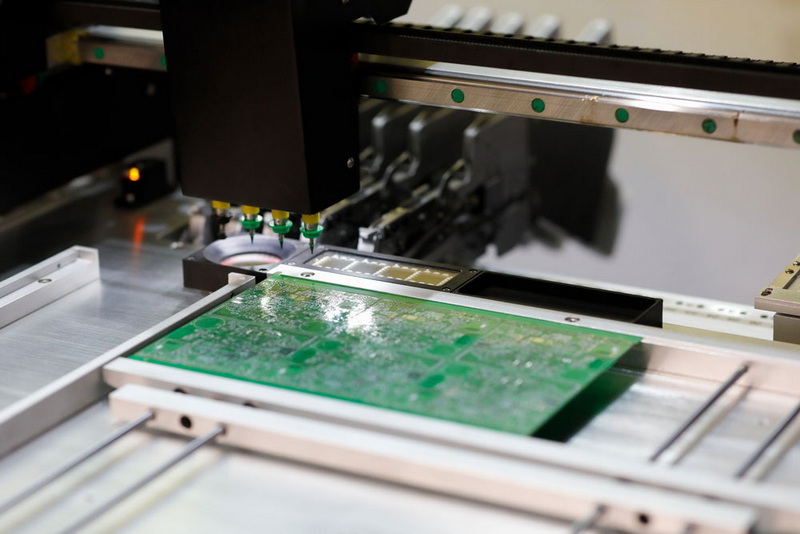

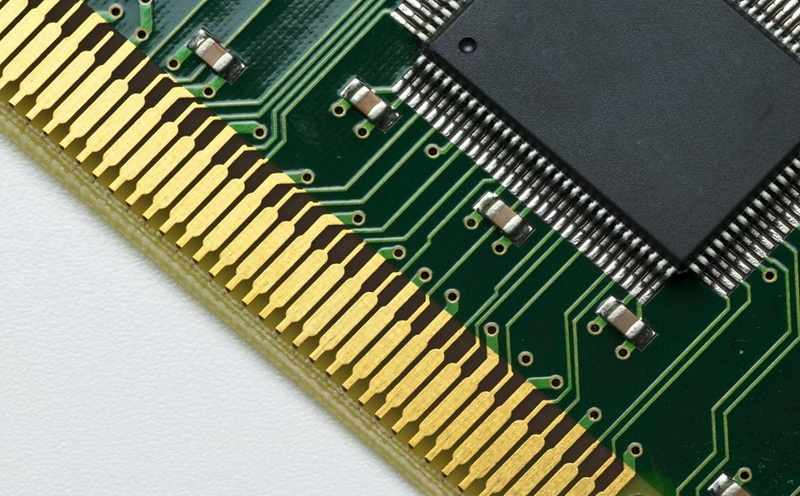

Turnkey SMT lines utilize state-of-the-art equipment and techniques, such as pick-and-place machines and automated soldering processes. This integration allows for high precision and efficiency, particularly beneficial for complex and high-density PCB designs.

- High-Speed Placement: Automated pick-and-place machines can place thousands of components per hour with high accuracy, significantly increasing throughput.

- Lead-free Soldering Techniques: Many modern SMT lines use lead-free soldering methods that comply with environmental regulations while maintaining product quality.

How Does a Turnkey SMT Line Work?

Design and Prototyping

The process begins with design and prototyping, where manufacturers collaborate with clients to optimize the PCB design for manufacturability and performance. Prototyping allows for early detection of design flaws, saving time and resources in later stages.

- Design for Manufacturing (DFM): Engineers work closely with clients to ensure that designs are not only functional but also easy to manufacture. This collaboration can lead to innovative solutions that improve performance while reducing costs.

Component Sourcing

Turnkey providers leverage extensive supplier networks to source high-quality components at competitive prices. This ensures availability of even hard-to-find parts while reducing lead times significantly.

- Supplier Relationships: Established relationships with suppliers enable turnkey providers to negotiate better prices and secure priority access to components during shortages.

Assembly and Testing

The assembly process involves automated equipment for placing components on the PCB, soldering them in place, and conducting thorough testing to ensure that the final product meets all specifications and quality standards.

- Solder Paste Printing: The first step in assembly typically involves applying solder paste to the PCB using precision printers that ensure accurate placement on pads.

- Reflow Soldering: After component placement, PCBs undergo reflow soldering where heat is applied to melt solder paste, creating strong electrical connections between components and the board.

- Final Testing: Once assembled, PCBs go through rigorous testing procedures including functional tests, electrical tests, and visual inspections to guarantee quality before shipment.

Advantages of Using SMT Technology in Turnkey Lines

The Surface Mount Technology (SMT) approach offers several advantages over traditional through-hole technology:

| Advantages | Description |

| Higher Component Density | SMT allows for more components to be placed on a PCB due to their smaller size. |

| Reduced Manufacturing Costs | Automation reduces labor costs significantly while enhancing production speed. |

| Improved Electrical Performance | Shorter interconnection lengths lead to better signal integrity and reduced electromagnetic interference. |

| Greater Reliability | Automated processes minimize human error, ensuring consistent quality throughout production. |

Industry Applications

Turnkey SMT lines are utilized across various industries due to their versatility:

- Consumer Electronics: High demand for compact devices drives manufacturers towards efficient PCB assembly methods.

- Automotive Industry: As vehicles become increasingly electronic with advanced driver-assistance systems (ADAS), reliable PCBs are crucial.

- Medical Devices: Precision and reliability are paramount in medical applications; thus, turnkey solutions offer stringent quality controls.

- Telecommunications: With rapid advancements in technology requiring constant upgrades in hardware, efficient PCB assembly becomes essential.

Future Trends in Turnkey SMT Lines

As technology continues to advance, several trends are shaping the future of turnkey SMT lines:

1. Increased Automation

The move towards Industry 4.0 emphasizes automation through smart factories equipped with IoT devices that monitor production processes in real time.

2. Sustainable Practices

Environmental concerns are leading manufacturers to adopt sustainable practices such as using eco-friendly materials and reducing waste throughout the production cycle.

3. Customization Capabilities

As consumer preferences shift towards personalized products, turnkey providers will need to adapt their processes for small-batch runs while maintaining efficiency.

4. Advanced Materials

The development of new materials such as flexible PCBs will require turnkey lines to incorporate technologies capable of handling these innovations effectively.

Conclusion

A turnkey SMT line revolutionizes PCB assembly by offering a streamlined, efficient, and high-quality solution. Its benefits—cost efficiency, enhanced quality control, faster time-to-market—make it an invaluable asset in the electronics manufacturing industry. As technology continues to evolve, the role of turnkey SMT lines in shaping the future of PCB assembly is expected to grow even further.

FAQs

1. What is the main advantage of a turnkey SMT line?

The main advantage is the integration of all processes under one provider, leading to cost savings, faster production times, and improved quality control.

2. How does a turnkey SMT line improve quality?

By consolidating processes under one provider, it ensures consistent quality control through automated inspections and testing at various stages of production.

3. Can a turnkey SMT line handle complex PCB designs?

Yes, advanced equipment and techniques used in turnkey SMT lines are well-suited for handling complex and high-density PCB designs effectively.

4. Is a turnkey SMT line cost-effective for small businesses?

Absolutely! The cost savings from bulk purchasing, reduced labor costs, and streamlined processes make it an attractive option for businesses of all sizes.

5. How does a turnkey SMT line reduce time-to-market?

By eliminating the need to coordinate with multiple vendors, it accelerates the production process significantly, allowing products to reach the market faster.