Content Menu

● Introduction

● Understanding Surface Mount Technology

● The Role of a Surface Mount Technology Operator

● Key Quality Assurance Practices

>> 1. Proper Training and Certification

>> 2. Equipment Calibration and Maintenance

>> 3. Process Control

>> 4. Component Inspection

>> 5. In-Line Inspection

>> 6. Final Testing

● Continuous Improvement Strategies

● The Importance of Documentation

● Conclusion

● FAQ

>> 1. What qualifications are needed to become a Surface Mount Technology Operator?

>> 2. How does Automated Optical Inspection work?

>> 3. What are common defects found during inspection?

>> 4. Why is documentation important in SMT operations?

>> 5. How can continuous improvement be implemented in SMT processes?

Introduction

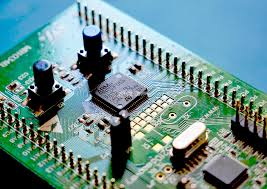

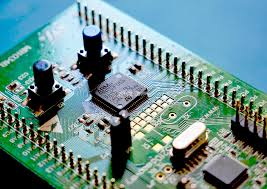

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by allowing for the efficient assembly of electronic components onto printed circuit boards (PCBs). As the demand for high-quality electronic devices continues to rise, the role of a Surface Mount Technology Operator has become increasingly vital. This article explores the various methods and practices employed by SMT operators to ensure quality throughout the manufacturing process.

Understanding Surface Mount Technology

Surface Mount Technology involves mounting electronic components directly onto the surface of PCBs. This method contrasts with traditional through-hole technology, where components are inserted into holes drilled in the PCB. The advantages of SMT include:

- Higher component density: SMT allows for more components to be placed in a smaller area.

- Improved performance: Shorter electrical paths reduce inductance and resistance.

- Cost-effectiveness: Reduced material costs and lower labor expenses contribute to overall savings.

The Role of a Surface Mount Technology Operator

A Surface Mount Technology Operator is responsible for overseeing the SMT assembly process, which includes several key tasks:

- Loading PCBs into machines

- Programming machines for component placement

- Monitoring the soldering process

- Conducting inspections and testing

To ensure quality, SMT operators must possess a thorough understanding of both the technology and the specific requirements of each production run.

Key Quality Assurance Practices

1. Proper Training and Certification

Quality begins with well-trained operators. SMT operators should undergo comprehensive training programs that cover:

- Machine operation: Understanding how to operate and troubleshoot SMT equipment.

- Component handling: Learning how to properly handle sensitive electronic components to prevent damage.

- Quality standards: Familiarity with industry standards such as IPC-A-610 for electronic assemblies.

2. Equipment Calibration and Maintenance

Regular maintenance and calibration of SMT equipment are essential for ensuring quality. Operators should:

- Perform routine checks on placement machines, soldering equipment, and inspection tools.

- Keep detailed logs of maintenance activities to track equipment performance over time.

3. Process Control

Implementing strict process control measures helps maintain consistency in production. Key aspects include:

- Setting parameters: Operators must set appropriate parameters for temperature, time, and pressure during soldering.

- Monitoring conditions: Environmental factors such as humidity and temperature can affect solder quality; maintaining optimal conditions is crucial.

4. Component Inspection

Before components are placed on PCBs, operators should perform thorough inspections to ensure quality. This includes:

- Checking for physical damage or defects in components.

- Verifying that components match specifications (e.g., size, type).

5. In-Line Inspection

In-line inspection is a critical step in ensuring quality during production. Operators can utilize various techniques:

- Automated Optical Inspection (AOI): This technology uses cameras to inspect solder joints and component placements in real-time.

Automated Optical Inspection

- X-ray inspection: For complex assemblies, X-ray inspection can reveal hidden defects in solder joints.

6. Final Testing

After assembly, final testing is essential to verify that the product meets quality standards. Testing methods may include:

- Functional testing: Ensuring that the assembled device operates as intended.

Functional Testing

- Burn-in testing: Running devices under stress conditions to identify early failures.

Continuous Improvement Strategies

To maintain high-quality standards, SMT operators should engage in continuous improvement strategies such as:

- Feedback loops: Establishing communication channels between operators and engineers to discuss issues and improvements.

Feedback Loop

- Lean manufacturing principles: Implementing lean practices can help reduce waste and improve efficiency.

The Importance of Documentation

Documentation plays a crucial role in quality assurance. Operators should maintain detailed records of:

- Production processes

- Inspection results

- Equipment maintenance logs

This documentation serves as a reference for future production runs and helps identify trends or recurring issues.

Conclusion

The role of a Surface Mount Technology Operator is pivotal in ensuring the quality of electronic assemblies. Through proper training, rigorous inspection processes, equipment maintenance, and continuous improvement strategies, operators can significantly enhance product quality. As technology evolves, so too must the practices employed by SMT operators to meet the demands of an increasingly competitive market.

FAQ

1. What qualifications are needed to become a Surface Mount Technology Operator?

A high school diploma is typically required, along with specialized training in electronics or manufacturing processes. Certification programs can further enhance an operator's skills.

2. How does Automated Optical Inspection work?

Automated Optical Inspection uses cameras to capture images of assembled PCBs and compares them against predefined standards to detect defects such as misaligned components or insufficient solder.

3. What are common defects found during inspection?

Common defects include solder bridging, insufficient solder, misaligned components, and physical damage to components.

4. Why is documentation important in SMT operations?

Documentation provides a historical record of production processes, helps identify trends or issues over time, and ensures compliance with industry standards.

5. How can continuous improvement be implemented in SMT processes?

Continuous improvement can be achieved through regular feedback from operators, adopting lean manufacturing principles, and investing in ongoing training for staff.