Content Menu

● What is a PCB Stencil with Frame?

● Types of SMT PCB Stencils

>> Frameless SMT PCB Stencils

>> Framed SMT PCB Stencils

>> Prototype SMT Stencils

● How a PCB Stencil with Frame Improves Your Soldering Process

>> 1. Enhanced Alignment and Precision

>> 2. Consistent Solder Paste Volume

>> 3. Improved Durability and Longevity

>> 4. Faster and More Efficient Printing

>> 5. Reduced Operator Error

● Manufacturing Process of Framed SMT PCB Stencils

>> 1. Laser Cutting

>> 2. Mounting and Stretching

>> 3. Finishing

● Best Practices for Using a SMT PCB Stencil with Frame

>> Pre-Use Inspection

>> Proper Alignment

>> Solder Paste Preparation

>> Printing Technique

>> Cleaning and Maintenance

● Advantages of Using a SMT PCB Stencil with Frame

● Common Challenges Without a Framed SMT PCB Stencil

● Innovations in SMT PCB Stencil Technology

● Conclusion

● FAQ

>> 1. What is the main difference between a framed and frameless SMT PCB stencil?

>> 2. How does the stencil frame help in solder paste printing?

>> 3. Can a framed SMT PCB stencil be reused?

>> 4. How do I clean a PCB stencil with frame after use?

>> 5. Is a framed stencil necessary for small-scale PCB assembly?

In the world of electronics manufacturing, Surface Mount Technology (SMT) has revolutionized the way printed circuit boards (PCBs) are assembled. Central to this SMT process is the use of a smt pcb stencil with frame, a tool that significantly enhances the accuracy, efficiency, and quality of solder paste application. This article explores how framed PCB stencils improve your soldering process, their types, manufacturing, benefits, and practical usage tips, providing a comprehensive understanding of why this tool is indispensable in modern PCB assembly.

What is a PCB Stencil with Frame?

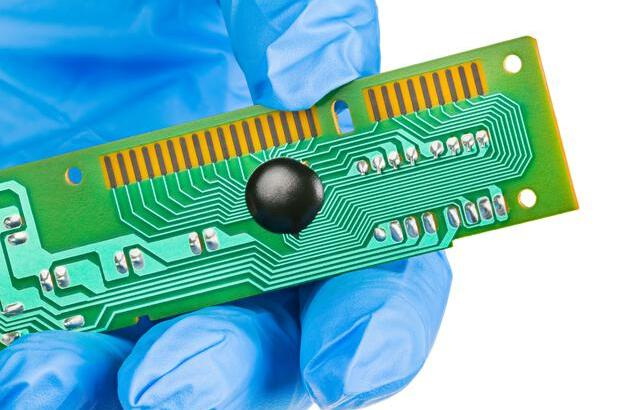

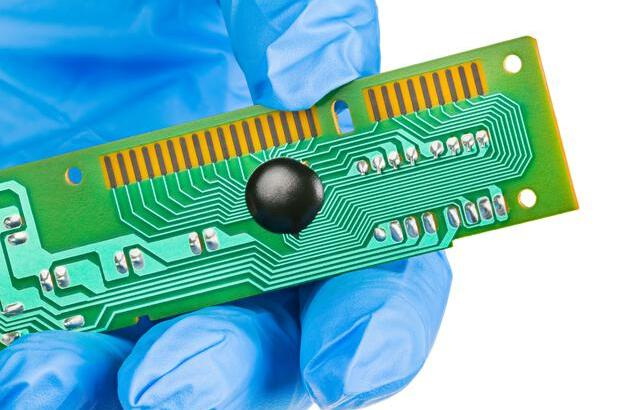

A PCB stencil is a thin sheet, typically made from stainless steel, laser-cut with apertures corresponding precisely to the pads on a PCB where solder paste needs to be applied. When solder paste is spread over the stencil, it deposits exactly on the PCB pads, enabling reliable solder joints during component placement and reflow soldering.

A PCB stencil with frame means that this thin metal sheet is permanently mounted and stretched tightly within a rigid frame, often made of aluminum or steel. This frame maintains consistent tension and alignment during the solder paste printing process, preventing shifting or deformation of the stencil foil. The frame also makes handling easier and enables compatibility with automated stencil printers.

Types of SMT PCB Stencils

Understanding the different types of SMT PCB stencils helps in selecting the right one for your soldering process.

Frameless SMT PCB Stencils

- Description: Flexible, cost-effective stencils made from stainless steel or nickel alloys without a permanent frame.

- Usage: Suitable for small-scale or prototype production.

- Advantages: Easy to store, lightweight, and adaptable to frequent design changes.

- Limitations: Require manual tensioning or use of reusable tension frames; less stable during printing, which can affect paste deposition consistency.

Framed SMT PCB Stencils

- Description: Stainless steel stencils permanently bonded to a rigid frame.

- Usage: Ideal for medium to high-volume manufacturing.

- Advantages: Provide superior stability and tension, ensuring consistent solder paste deposition and alignment. Compatible with automated printing machines.

- Limitations: Slightly higher initial cost and less flexible for rapid design changes compared to frameless stencils.

Prototype SMT Stencils

- Description: Designed for rapid prototyping and testing new PCB layouts.

- Usage: Used in R&D or small batch runs.

- Advantages: Quick turnaround time, can be frameless or framed.

- Limitations: May not be as durable for long production runs.

How a PCB Stencil with Frame Improves Your Soldering Process

The use of a smt pcb stencil with frame offers multiple advantages that directly impact the quality and efficiency of your soldering process.

1. Enhanced Alignment and Precision

One of the biggest challenges in SMT assembly is ensuring that solder paste is deposited precisely on the PCB pads. The frame holds the stencil foil taut and fixed, preventing any movement during solder paste application. This ensures that the apertures align perfectly with the PCB pads, reducing the risk of solder bridging (where solder creates unintended connections between pads) or insufficient solder joints caused by misalignment. This precision is crucial for fine-pitch components where pad spacing is minimal.

2. Consistent Solder Paste Volume

The thickness and tension of the stencil foil within the frame control the amount of solder paste deposited. A framed stencil maintains uniform tension, which helps achieve consistent paste volume across all pads, critical for reliable electrical and mechanical connections. Inconsistent solder paste volume can lead to defects such as tombstoning (where one end of a chip lifts off the pad) or cold solder joints.

3. Improved Durability and Longevity

Framed stencils are less prone to warping or damage because the frame protects the delicate stencil foil and maintains its shape. This durability is especially important for high-volume production runs where the stencil is reused multiple times. The frame also facilitates easier handling and storage, reducing the risk of accidental bending or damage.

4. Faster and More Efficient Printing

The rigid frame allows the stencil to be securely mounted on stencil printers or screen printing machines, enabling automated, high-speed solder paste application. This reduces manual labor, increases throughput, and improves overall process efficiency. Automated printing also ensures repeatability and reduces variability caused by human operators.

5. Reduced Operator Error

The frame's stability simplifies the handling and positioning of the stencil, minimizing human errors during alignment and solder paste application. This leads to higher first-pass yields and less rework, saving time and cost in production.

Manufacturing Process of Framed SMT PCB Stencils

The quality of a smt pcb stencil with frame depends heavily on its manufacturing process, which involves several precise steps:

1. Laser Cutting

The stencil foil, usually made of stainless steel with thicknesses ranging from 75 to 150 microns, is laser-cut with high precision. The apertures correspond exactly to the PCB pads where solder paste needs to be deposited. Laser cutting ensures clean, burr-free edges, which are essential for smooth solder paste release.

2. Mounting and Stretching

The cut stencil foil is stretched tightly and permanently bonded onto a rigid frame, typically made of aluminum or steel. The stretching process ensures uniform tension across the entire stencil surface, preventing sagging or deformation during printing. The foil is often bonded using adhesives or mesh borders designed to maintain tension over time.

3. Finishing

After mounting, the stencil edges and apertures are polished to remove any burrs or roughness. This step improves solder paste flow and prevents paste from sticking inside the apertures. Some stencils receive special nano-coatings that enhance paste release, reduce wear, and extend stencil life.

Best Practices for Using a SMT PCB Stencil with Frame

To maximize the benefits of using a framed stencil, follow these best practices:

Pre-Use Inspection

Before each use, inspect the stencil for any clogged apertures, damage, or contamination. Use dust-free wipes and isopropyl alcohol to clean the stencil surface and apertures.

Proper Alignment

Use fiducial marks on both the PCB and stencil frame to align the stencil precisely. Many stencil printers have alignment cameras or mechanical guides to assist in this process.

Solder Paste Preparation

Ensure solder paste is at room temperature and mixed properly before use. Stir or knead the paste to restore its viscosity and homogeneity, which affects print quality.

Printing Technique

Apply solder paste evenly using a metal or rubber squeegee at a consistent angle and speed. Avoid excessive pressure, which can cause paste to bleed under the stencil or damage the foil.

Cleaning and Maintenance

After printing, clean the stencil immediately to prevent solder paste from drying and clogging apertures. Use a dry vacuum nozzle or wipe off excess paste, followed by ultrasonic cleaning with alcohol or deionized water. Regular cleaning extends stencil life and maintains print quality.

Advantages of Using a SMT PCB Stencil with Frame

| Advantage | Description |

| Precise Paste Application | Accurate solder paste deposition reduces defects like bridging, opens, and tombstoning. |

| Consistent Quality | Maintains uniform tension for repeatable results across multiple boards. |

| High Throughput | Compatible with automated stencil printers for faster, reliable production. |

| Durability | Frame protects stencil foil, extending stencil life and reducing replacement frequency. |

| Ease of Use | Simplifies alignment and handling, reducing operator errors and training time. |

| Cost Efficiency | Though initial cost is higher, reduced defects and longer stencil life lower overall costs. |

Common Challenges Without a Framed SMT PCB Stencil

Using frameless or poorly tensioned stencils can introduce several problems:

- Stencil Warping: Flexible foils can warp or sag, causing uneven solder paste thickness.

- Misalignment: Without a frame, manual handling may cause stencil shifts, leading to solder bridging or insufficient paste.

- Inconsistent Paste Volume: Variable tension results in uneven paste deposits, increasing defect rates.

- Shorter Stencil Life: Handling damage and deformation reduce stencil usability.

- Lower Throughput: Manual printing with frameless stencils is slower and less repeatable.

By contrast, a smt pcb stencil with frame mitigates these issues effectively.

Innovations in SMT PCB Stencil Technology

Recent advances have enhanced the performance of framed stencils:

- Nano-Coatings: Hydrophobic coatings improve solder paste release and reduce cleaning frequency.

- Laser Etching Improvements: Ultra-fine apertures for micro-BGA and fine-pitch components.

- Hybrid Frames: Frames with adjustable tensioning mechanisms for better control.

- Automated Inspection: Integration with AOI (Automated Optical Inspection) systems to verify stencil aperture quality.

These innovations further improve the soldering process and product quality.

Conclusion

Using a smt pcb stencil with frame significantly enhances the soldering process by ensuring precise, consistent, and efficient solder paste application. The frame maintains stencil tension and alignment, which is vital for high-quality SMT assembly, especially in high-volume manufacturing environments. By improving durability, reducing errors, and enabling faster production, framed stencils are an indispensable tool for modern PCB assembly lines. Investing in a high-quality framed stencil not only improves product reliability but also reduces overall manufacturing costs through fewer defects and reworks.

FAQ

1. What is the main difference between a framed and frameless SMT PCB stencil?

A framed stencil is permanently bonded to a rigid frame providing stability and consistent tension, ideal for high-volume production. Frameless stencils are flexible foils used with tensioning systems, better suited for prototyping or small runs.

2. How does the stencil frame help in solder paste printing?

The frame holds the stencil foil taut and fixed, preventing misalignment and deformation during printing, ensuring precise solder paste deposition on PCB pads.

3. Can a framed SMT PCB stencil be reused?

Yes, framed stencils are designed for repeated use and can withstand multiple printing cycles, making them cost-effective for large production runs.

4. How do I clean a PCB stencil with frame after use?

First, remove residual solder paste with a vacuum nozzle or dry wipe, then use ultrasonic cleaning with alcohol or deionized water to clean apertures thoroughly.

5. Is a framed stencil necessary for small-scale PCB assembly?

For small-scale or prototype work, frameless stencils may suffice. However, framed stencils provide better precision and are recommended if consistent quality and efficiency are priorities.