Content Menu

● Introduction to SMT Stencils

>> Importance of Stencil Cleaning

● Stencil Cleaning Methods

>> Manual Cleaning

>> Automatic Cleaning

● Best Practices for Stencil Maintenance

● Challenges in Stencil Cleaning

>> Advanced Stencil Materials

● Prototype SMT Stencil Considerations

>> Environmental Considerations

● Stencil Storage and Handling

● Conclusion

● FAQ

>> 1. What are the primary reasons for cleaning SMT stencils?

>> 2. How often should SMT stencils be cleaned?

>> 3. What are the best methods for cleaning small apertures in SMT stencils?

>> 4. What are the advantages of automatic stencil cleaning systems?

>> 5. How should SMT stencils be stored and maintained when not in use?

Proper maintenance and cleaning of SMT (Surface Mount Technology) stencils are crucial for ensuring high-quality PCB (Printed Circuit Board) assembly. SMT stencils play a pivotal role in applying solder paste accurately onto PCB pads, and their cleanliness directly affects the yield and reliability of electronic assemblies. In this article, we will delve into the importance of stencil cleaning, the methods used, and best practices for maintaining these critical tools.

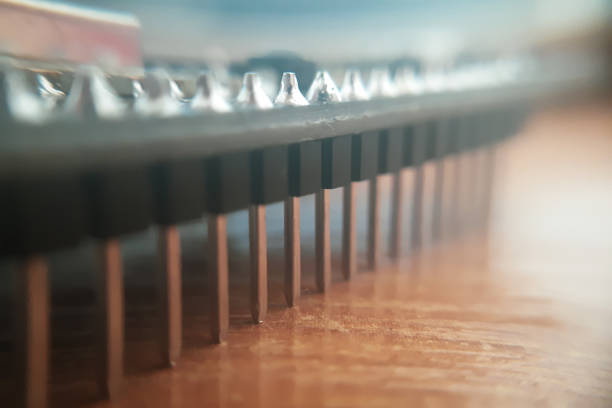

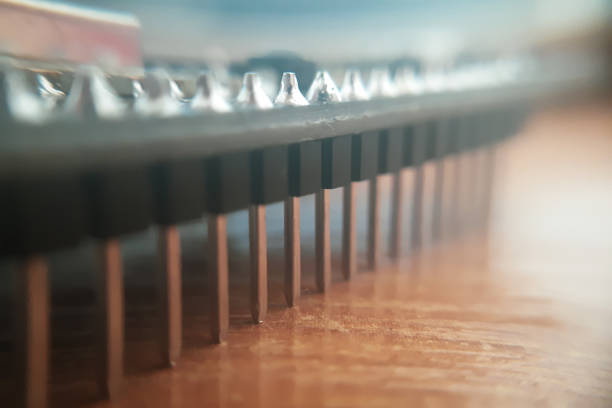

Introduction to SMT Stencils

SMT stencils are thin, metal sheets with precision-cut apertures that correspond to the solder paste patterns required for PCB assembly. These stencils are used in the solder paste printing process, which is a critical step in SMT assembly. The quality of the solder paste application significantly influences the final product's performance and reliability. Stencils are typically made from stainless steel or other durable materials to withstand the rigors of repeated use.

Importance of Stencil Cleaning

Regular cleaning of SMT stencils is essential for several reasons:

- Prevents Print Defects: Residual solder paste in stencil apertures can lead to insufficient or inaccurate solder deposition, causing poor prints and missing joints. This results in reduced assembly yield and increased rework costs.

- Maintains Print Quality: Dust, flux, and other contaminants on the stencil surface can lower print quality and affect solder paste release. Clogged apertures due to dried paste alter print definition and reduce stencil lifespan.

- Reduces Solder Balls and Beads: Paste residues can result in solder balls and mid-chip solder beads, further impacting assembly yield.

Stencil Cleaning Methods

There are primarily two methods for cleaning SMT stencils: manual and automatic.

Manual Cleaning

Manual cleaning is often preferred for low-volume or prototype PCB assembly. The process involves several steps:

1. Visual Inspection: Inspect the stencil for dried solder paste, debris, and contamination.

2. Preparation: Clean hands and wear lint-free gloves to prevent fingerprints. Prepare cleaning solvents, swabs, and wipes.

3. Loosening Dry Paste: Use adhesive tape to remove large chunks of dried paste. Gently roll non-abrasive swabs across the underside to loosen residues.

4. Cleaning Apertures: Use a soft brass brush and solvent to clean apertures.

5. Bottom and Top Side Cleaning: Wipe the stencil with solvent-soaked wipes and swabs.

6. Final Cleaning: Thoroughly clean both sides with solvent and wipe with lens cleaning tissue.

7. Drying: Allow the stencil to air dry or use compressed air.

Manual cleaning is cost-effective and suitable for small-scale operations but requires skill and attention to detail to avoid damaging the stencil.

Automatic Cleaning

Automatic stencil cleaners are more efficient for high-volume production. They typically use a combination of spray cleaning solutions and ultrasonic technology to remove solder paste and particles from stencils. Automatic systems ensure consistent cleaning quality and reduce labor costs. These systems can be programmed to optimize cleaning cycles based on the type of solder paste and stencil material.

Best Practices for Stencil Maintenance

To maintain stencil quality and extend their lifespan, follow these best practices:

- Use Lint-Free Gloves: Prevent fingerprints on the stencil.

- Apply Solvent Judiciously: Use just enough solvent to avoid waste.

- Replace Cleaning Tools Frequently: Prevent spreading contamination.

- Clean in One Direction: Follow the stencil tensioning direction.

- Avoid Excessive Brushing: Prevent damage to the stencil surface.

- Maintain a Separate Cleaning Area: Prevent solvent contamination in the production area.

- Regular Inspection: Regularly inspect stencils for wear and tear, and replace them when necessary.

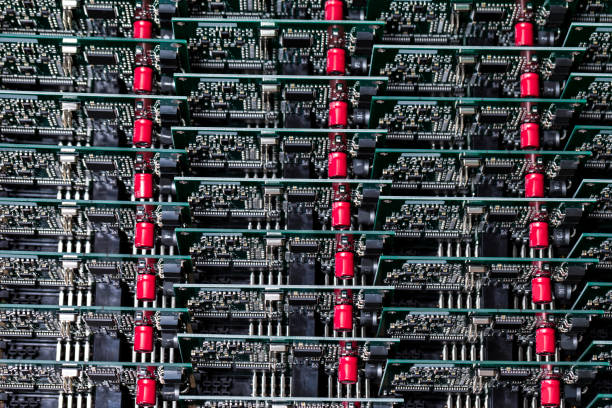

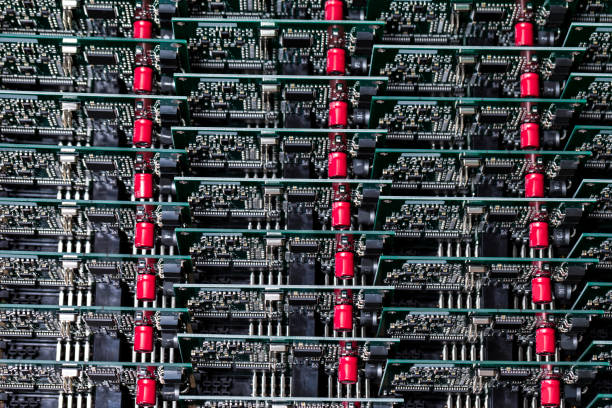

Challenges in Stencil Cleaning

As PCBAs become denser and more sophisticated, cleaning stencils effectively becomes more challenging. Narrower pitches require precise cleaning methods to remove solder particles from small apertures. Manual cleaning may not be sufficient for such complex designs, making automatic cleaning systems more appealing for high-density PCB assembly.

Advanced Stencil Materials

The development of new stencil materials, such as laser-cut stencils with enhanced aperture shapes, has improved solder paste release and reduced cleaning challenges. These advanced materials are designed to minimize paste residue and make cleaning easier.

Prototype SMT Stencil Considerations

For prototype PCB assembly, manual cleaning is often more practical due to lower volumes. However, it's crucial to optimize the cleaning process to ensure high-quality prints. Frequent cleaning is necessary to check the process and adjust the cleaning procedure as needed. Prototypes often require quick turnaround times, so efficient cleaning methods are vital to meet these deadlines.

Environmental Considerations

Environmental factors, such as temperature and humidity, can affect stencil cleaning. High humidity can lead to faster paste drying, making cleaning more difficult. Maintaining a controlled environment helps ensure consistent cleaning results.

Stencil Storage and Handling

Proper storage and handling of SMT stencils are essential to maintain their integrity. Stencils should be stored in a clean, dry environment away from direct sunlight and moisture. Always handle stencils with care to prevent damage and maintain their precision.

Conclusion

Proper maintenance and cleaning of SMT stencils are vital for achieving high-quality PCB assemblies. Regular cleaning prevents print defects, maintains print quality, and extends stencil lifespan. Whether using manual or automatic methods, following best practices and optimizing cleaning frequencies based on production volume and environmental conditions are essential. As electronics manufacturing continues to evolve with denser and more complex PCB designs, effective stencil cleaning will remain a critical factor in ensuring assembly reliability and yield.

FAQ

1. What are the primary reasons for cleaning SMT stencils?

Cleaning SMT stencils is essential to prevent print defects, maintain print quality, and extend stencil lifespan. Residual solder paste can cause insufficient solder deposition and lead to assembly defects.

2. How often should SMT stencils be cleaned?

The frequency of cleaning depends on the volume of PCBs produced. For low volumes (1-5 boards per day), clean after each print. For higher volumes, clean after every 2-3 prints or more frequently as needed.

3. What are the best methods for cleaning small apertures in SMT stencils?

For small apertures, using a soft brass brush with solvent and foam swabs can be effective. For stubborn residues, ultrasonic cleaning may be necessary.

4. What are the advantages of automatic stencil cleaning systems?

Automatic systems provide consistent cleaning quality, reduce labor costs, and are more efficient for high-volume production. They can also handle complex stencil designs more effectively.

5. How should SMT stencils be stored and maintained when not in use?

Stencils should be stored in a clean, dry environment. Regular inspection for damage or contamination is recommended. Always handle stencils with care to prevent damage and maintain their precision.