Content Menu

● Introduction

● Importance of Stencil Maintenance and Cleaning

>> Role of SMT Stencils in PCB Assembly

>> Challenges in Stencil Maintenance

● Best Practices for Maintaining Hard Frame SMT Stencils

>> Handling and Storage

>> Cleaning Methods

>>> Manual Cleaning

>>> Ultrasonic Cleaning

>>> Automated Cleaning Systems

>> Choice of Cleaning Agents

● Common Mistakes in Stencil Maintenance

>> Worst Practices

>> Best Practices

● Advanced Technologies in Stencil Cleaning

>> Ultrasonic Cleaning Innovations

>> Automated Cleaning Machines

>> Innovative Cleaning Solutions

● Future Trends in SMT Stencil Technology

>> Nano-Coating Technology

● Conclusion

● FAQs

>> 1. What is the best method for cleaning fine-pitch SMT stencils?

>> 2. How often should SMT stencils be cleaned?

>> 3. What are the common mistakes in storing SMT stencils?

>> 4. Can manual cleaning effectively remove solder paste from fine-pitch stencils?

>> 5. What are the environmental considerations for cleaning SMT stencils?

● Citations:

Introduction

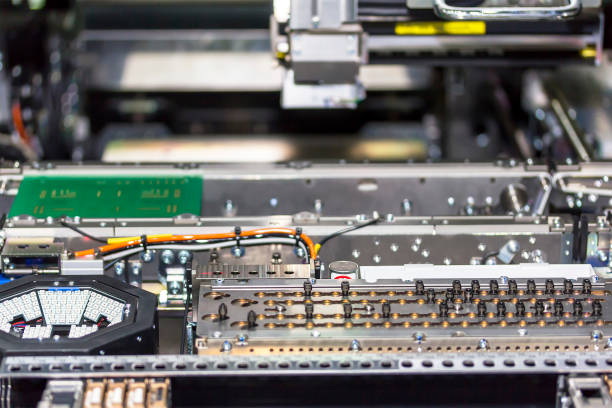

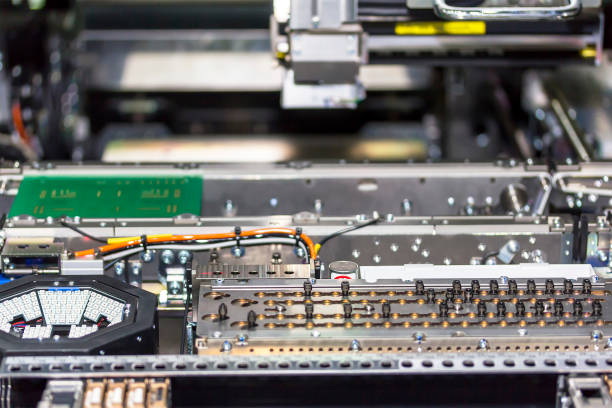

In the realm of Surface Mount Technology (SMT), hard frame SMT stencils play a pivotal role in ensuring the precise application of solder paste onto printed circuit boards (PCBs). These stencils, typically made from stainless steel or nickel alloys, are encased in a rigid frame that provides stability and consistency during the solder paste printing process. Proper maintenance and cleaning of these stencils are crucial to maintain their performance and extend their lifespan. This article will delve into the best practices for maintaining and cleaning hard frame SMT stencils, highlighting the importance of these processes in achieving high-quality PCB assembly.

Importance of Stencil Maintenance and Cleaning

Role of SMT Stencils in PCB Assembly

SMT stencils act as templates for applying solder paste to specific locations on a PCB. The precision of these stencils ensures that the correct amount of solder paste is applied, which is essential for forming reliable solder joints between components and the PCB. Over time, solder paste residues and other contaminants can accumulate on the stencil, clogging its apertures and affecting print quality. Therefore, regular cleaning and maintenance are vital to prevent defects such as bridging, insufficient solder joints, and misaligned components.

Challenges in Stencil Maintenance

- Material Sensitivity: SMT stencils are made from thin materials that can be easily damaged by improper handling or cleaning methods. The use of harsh chemicals or excessive force can lead to delamination of the epoxy bonds in framed stencils or damage to the nanocoatings that enhance paste release.

- Aperture Clogging: Fine-pitch stencils are particularly susceptible to clogging due to their small apertures. Effective cleaning methods must be employed to remove solder paste residues without damaging these delicate structures.

- Environmental and Safety Concerns: Cleaning agents used for stencils must be environmentally friendly and safe for operators. The choice of cleaning method and agent is critical to minimize environmental impact and ensure operator safety.

Best Practices for Maintaining Hard Frame SMT Stencils

Handling and Storage

- Handle with Care: Always handle stencils with gloves to prevent oils from skin from affecting the stencil surface. Avoid touching the stencil surface directly.

- Vertical Storage: Store stencils in a vertical position in a dedicated stencil rack to prevent bending or creasing. This helps maintain the stencil's flatness and prevents damage to the frame.

- Pre-Use Inspection: Before using a stencil, inspect it for any damage or debris. Use a microscope to check fine-pitch apertures for cleanliness.

Cleaning Methods

Manual Cleaning

- Lint-Free Cloths and Solvents: Use lint-free cloths soaked in a suitable solvent such as isopropyl alcohol (IPA) or deionized water to wipe down the stencil. This method is simple and cost-effective but may not be thorough enough for fine-pitch stencils.

- Limitations: Manual cleaning can be time-consuming and may not effectively remove solder paste from small apertures. It also relies heavily on operator skill and attention to detail.

Ultrasonic Cleaning

- Effectiveness: Ultrasonic cleaning uses high-frequency sound waves to agitate cleaning solutions, effectively removing contaminants from even the smallest apertures. It is highly recommended for fine-pitch stencils.

- Types: There are spray-type and immersion-type ultrasonic cleaners. The immersion type is more effective but requires careful handling to avoid damaging the stencil.

Automated Cleaning Systems

- Efficiency: Automated systems combine solvents, vacuum drying, and air-jet technology to provide consistent and efficient cleaning. They reduce operator involvement and are ideal for high-volume production.

- Advantages: Automated systems ensure repeatable results, minimize human error, and are well-suited for demanding production environments.

Choice of Cleaning Agents

- Safety and Effectiveness: The ideal cleaning agent must be safe for operators and the environment while effectively removing solder paste residues. Specialized stencil cleaning agents are available, but caution is advised as they may damage certain stencil materials.

- Common Agents: IPA and deionized water are commonly used due to their safety and effectiveness. However, for stubborn residues, more specialized agents may be required.

Common Mistakes in Stencil Maintenance

Worst Practices

- Delayed Cleaning: Allowing solder paste to dry on the stencil makes it much harder to clean. Cleaning should be done immediately after use.

- Inadequate Storage: Stacking stencils horizontally can cause damage to the foil, and storing them without cleaning can lead to residue buildup.

- Improper Installation: Installing the stencil before the squeegees can lead to accidental damage during setup.

Best Practices

- Immediate Cleaning: Clean the stencil immediately after use to prevent solder paste from drying.

- Proper Storage: Store stencils in a clean, dry environment, and use protective covers to prevent damage.

- Correct Installation: Install squeegees before the stencil to avoid accidental damage.

Advanced Technologies in Stencil Cleaning

Ultrasonic Cleaning Innovations

Ultrasonic cleaning has become a standard method for removing stubborn solder paste residues from stencils. Recent innovations include the use of handy-type ultrasonic cleaners, which offer portability and efficiency for small-scale operations. These cleaners can be used in conjunction with specialized cleaning agents to enhance their effectiveness[1].

Automated Cleaning Machines

Automated cleaning machines are designed to streamline the cleaning process, offering simultaneous cleaning and drying capabilities. These machines are particularly beneficial for large-scale operations, ensuring consistent results and reducing the time from cleaning to drying[1]. The integration of ultrasonic cleaning heads and vacuum drying nozzles into a single unit has significantly improved the efficiency of these systems.

Innovative Cleaning Solutions

Companies like ROCKA Solutions have developed innovative products such as the SMT Stencil Clean Roll, which enhances vacuum performance and cleaning cycle times. This technology is tailored to accommodate different printer specifications, providing a customized solution for manufacturers[3].

Future Trends in SMT Stencil Technology

As electronics manufacturing continues to evolve, SMT stencil technology is advancing to meet new challenges. Innovations such as 3D-printed stencils and smart stencils with integrated sensors are being explored to enhance precision and efficiency in PCB assembly. Smart stencils, in particular, offer real-time feedback during the printing process, improving stencil lifespan and reducing the need for frequent replacements[6].

Nano-Coating Technology

Nano-coating technology involves applying a thin hydrophobic layer to the stencil, which enhances solder paste release and reduces the need for frequent cleaning. This technology is crucial for maintaining consistent print quality and minimizing defects such as bridging[6].

Conclusion

Proper maintenance and cleaning of hard frame SMT stencils are essential for achieving high-quality PCB assembly. By understanding the importance of these processes and implementing best practices, manufacturers can ensure consistent print quality, extend the lifespan of their stencils, and reduce production costs associated with defects and rework. The choice of cleaning method and agent must be carefully considered to balance effectiveness with safety and environmental responsibility.

FAQs

1. What is the best method for cleaning fine-pitch SMT stencils?

- Ultrasonic cleaning is highly effective for fine-pitch stencils as it can thoroughly remove solder paste residues from small apertures without damaging the stencil.

2. How often should SMT stencils be cleaned?

- SMT stencils should be cleaned before and after each use to prevent residue buildup and ensure consistent print quality. For fine-pitch designs, more frequent cleaning may be necessary[5].

3. What are the common mistakes in storing SMT stencils?

- Common mistakes include storing stencils horizontally, which can cause bending, and not cleaning them before storage, leading to residue buildup.

4. Can manual cleaning effectively remove solder paste from fine-pitch stencils?

- Manual cleaning is generally not effective for fine-pitch stencils due to the difficulty in removing solder paste from small apertures without damaging the stencil.

5. What are the environmental considerations for cleaning SMT stencils?

- Cleaning agents should be environmentally friendly and safe for operators. Automated cleaning systems can help minimize waste and reduce environmental impact.

Citations:

[1] https://www.kaken-tech.co.jp/english/trouble/metalmaskcleaning/

[2] https://rigidflexpcb.org/the-most-important-role-of-stencils-in-pcb-fabrication/

[3] https://iconnect007.com/article/142330/rocka-solutions-wins-mexico-technology-award-for-innovative-smt-stencil-clean-roll/142327/smt

[4] https://www.zestron.com/usa/en/applications/smt/stencil-cleaning

[5] https://www.linkedin.com/pulse/stencil-pcb-assembly-guide-prototype-pcb-assembly-vqmsc

[6] https://www.macrofab.com/blog/innovations-in-solder-paste-printing-technology/

[7] https://olinapcb.com/blog/how-to-maintain-and-clean-smt-stencil/

[8] https://www.youtube.com/watch?v=HC9GQH9VEmg

[9] https://www.multi-circuit-boards.eu/fileadmin/user_upload/downloads/leiterplatten_design-hilfe/ipc-7526.pdf

[10] https://www.elepcb.com/blog/pcb-stencil-smt-assembly/

[11] https://www.wnie.online/rocka-solutions-to-showcase-innovative-smt-stencil-cleaning-products-at-productronica-2023/

[12] https://www.eevblog.com/forum/projects/stencil-cleaning-(framed)-paste-applying/

[13] https://jlcpcb.com/blog/guide-to-smt-stencils-in-pcb-assembly

[14] https://high-techconversions.com/product/globaltech-smt-stencil-cleaner/

[15] https://www.kolb-ct.com/cleaning-tasks/tools-cleaning/stencil-cleaning

[16] https://hilelectronic.com/blog-pcb-stencil/

[17] https://www.microcare.com/en-US/Resources/Resource-Center/FAQs/What-s-the-Technology-Behind-the-SMT-Printing-Qual

[18] https://www.reddit.com/r/AskElectronics/comments/661c41/any_tips_and_tricks_in_cleaning_smd_stencils/

[19] https://www.techspray.com/preventing-pcb-misprints-with-optimized-stencil-cleaning-process

[20] https://www.jycircuitboard.com/news/stencil-classification-effect-on-pcba-smt-processing-283.html