Content Menu

● Understanding SMT Pin Connectors

● Preparing for SMT Pin Connector Installation

>> PCB Design Considerations

>> Component Selection

● SMT Pin Connector Installation Process

>> Step 1: Solder Paste Application

>> Step 2: Component Placement

>> Step 3: Reflow Soldering

>> Step 4: Inspection and Quality Control

● Advanced Techniques for SMT Pin Connector Installation

>> Pin-in-Paste Technology

>> Edge-Mount Connectors

● Troubleshooting Common SMT Pin Connector Installation Issues

>> Solder Bridging

>> Insufficient Solder

>> Misalignment

>> Tombstoning

● Best Practices for SMT Pin Connector Installation

● Future Trends in SMT Pin Connector Technology

● Conclusion

● FAQ

>> 1. What are the main advantages of using SMT pin connectors over through-hole connectors?

>> 2. How do you choose the right solder paste for SMT pin connector installation?

>> 3. What are some common causes of SMT pin connector failure, and how can they be prevented?

>> 4. How does the reflow profile affect SMT pin connector installation, and how can it be optimized?

>> 5. What inspection methods are most effective for ensuring proper SMT pin connector installation?

● Citations:

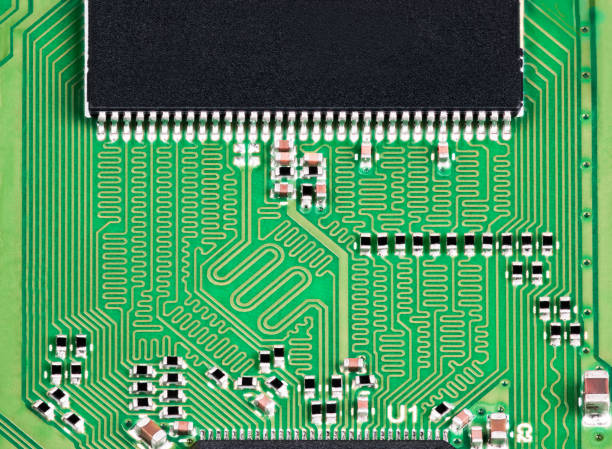

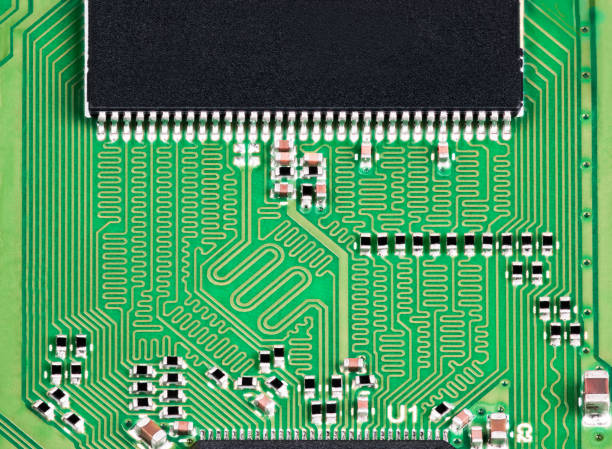

Surface Mount Technology (SMT) has revolutionized the electronics industry, offering numerous advantages over traditional through-hole technology. SMT pin connectors are essential components in modern PCB design, providing a compact and efficient means of connecting various electronic components. This article will explore the proper installation techniques for SMT pin connectors on PCBs, covering everything from preparation to final inspection.

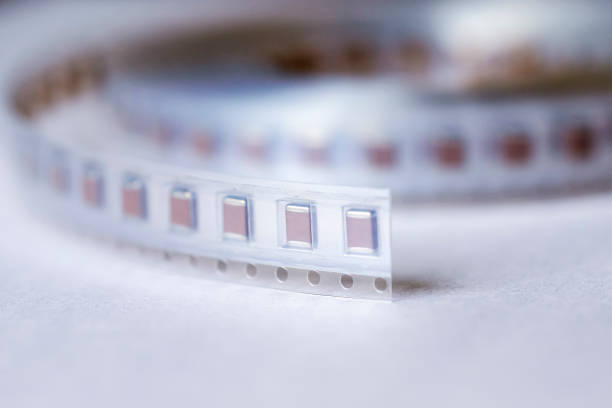

Understanding SMT Pin Connectors

SMT pin connectors are designed to be mounted directly onto the surface of a PCB without the need for through-holes[1]. These connectors come in various shapes, sizes, and configurations, making them versatile for different applications. Unlike through-hole connectors, SMT pin connectors offer several advantages:

1. Increased component density

2. Reduced board size

3. Improved electrical performance

4. Lower production costs

5. Faster assembly process

Preparing for SMT Pin Connector Installation

PCB Design Considerations

Before installing SMT pin connectors, it's crucial to ensure that your PCB design is optimized for these components. Consider the following factors:

1. Footprint Design: Ensure that the PCB footprint matches the specifications of the chosen SMT pin connector[1]. This includes the correct number of pins, pitch, and pad size.

2. Pad Layout: Design the pads to provide adequate surface area for soldering while maintaining proper spacing between adjacent pads.

3. Solder Mask: Apply solder mask between pads to prevent solder bridging and improve the overall appearance of the board.

4. Silkscreen: Include clear markings on the silkscreen layer to indicate the orientation and position of the SMT pin connector.

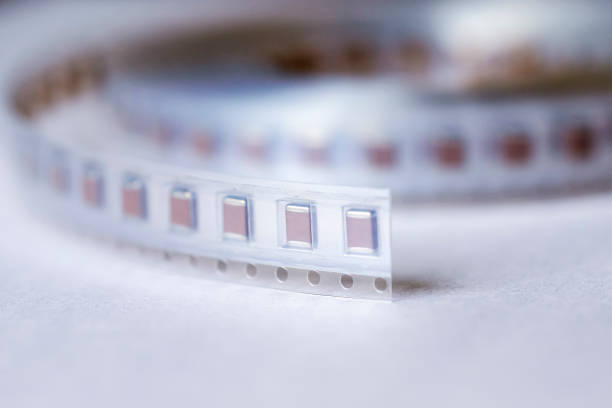

Component Selection

Choosing the right SMT pin connector is crucial for successful installation and long-term reliability. Consider the following factors when selecting your connector:

1. Pin Count: Determine the number of pins required for your application.

2. Pitch: Select the appropriate pitch (distance between adjacent pins) based on your PCB design and space constraints.

3. Current and Voltage Ratings: Ensure that the connector can handle the required electrical specifications of your circuit.

4. Environmental Considerations: Choose connectors that can withstand the expected operating conditions, such as temperature, humidity, and vibration.

5. Mating Cycles: Consider the number of times the connector will be mated and unmated throughout its lifecycle.

SMT Pin Connector Installation Process

Step 1: Solder Paste Application

The first step in installing SMT pin connectors is applying solder paste to the PCB pads. This process is crucial for creating strong and reliable solder joints.

1. Stencil Design: Use a stencil with apertures that match the connector's footprint[2]. The stencil thickness should be appropriate for the amount of solder paste required.

2. Solder Paste Selection: Choose a solder paste that is compatible with your PCB and connector materials, as well as your reflow profile.

3. Paste Application: Apply the solder paste using a stencil printer or manual application method. Ensure even coverage across all pads.

Step 2: Component Placement

Accurate placement of SMT pin connectors is essential for proper alignment and electrical connection.

1. Pick and Place: Use automated pick and place equipment for high-volume production, or place the connectors manually for smaller batches[7].

2. Alignment: Ensure that the connector pins are correctly aligned with the PCB pads. Many SMT pin connectors have alignment features to assist with this process.

3. Placement Pressure: Apply gentle pressure to seat the connector onto the solder paste. Avoid excessive force, which can displace the paste or damage the component.

Step 3: Reflow Soldering

Reflow soldering is the most common method for attaching SMT pin connectors to PCBs.

1. Reflow Profile: Follow the recommended reflow profile for your specific solder paste and components[2]. This typically involves a pre-heat stage, soak stage, reflow stage, and cooling stage.

2. Temperature Control: Maintain precise temperature control throughout the reflow process to ensure proper solder joint formation and prevent component damage.

3. Atmosphere: Consider using an inert nitrogen atmosphere during reflow to improve solder joint quality and reduce oxidation[2].

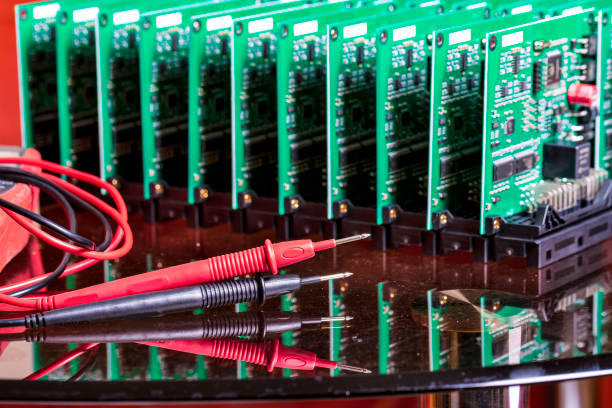

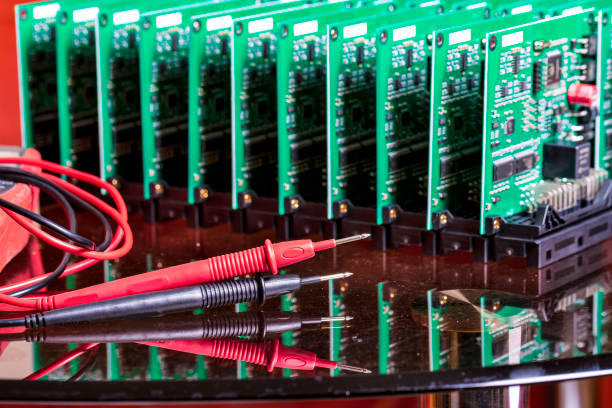

Step 4: Inspection and Quality Control

After reflow soldering, it's essential to inspect the SMT pin connector installation to ensure proper alignment and solder joint quality.

1. Visual Inspection: Perform a visual inspection to check for misalignment, solder bridging, or insufficient solder.

2. X-ray Inspection: For high-density or BGA-style connectors, use X-ray inspection to verify solder joint integrity beneath the component.

3. Electrical Testing: Conduct electrical tests to verify proper connectivity and functionality of the installed connector.

Advanced Techniques for SMT Pin Connector Installation

Pin-in-Paste Technology

For applications requiring both SMT and through-hole components, pin-in-paste technology can be an effective solution.

1. Process: Apply solder paste to both SMT pads and through-holes using a stencil.

2. Component Placement: Place SMT components and insert through-hole pins into the paste-filled holes.

3. Reflow: Perform a single reflow cycle to solder both SMT and through-hole components simultaneously[5].

Edge-Mount Connectors

Edge-mount SMT connectors offer unique challenges and benefits for certain PCB designs.

1. Board Preparation: Ensure that the PCB edge is properly prepared and within specified tolerances.

2. Fixture Usage: Use specialized fixtures to hold the connector in place during reflow soldering[2].

3. Solder Application: Apply solder paste to both the PCB pads and the connector's edge-mount contacts.

Troubleshooting Common SMT Pin Connector Installation Issues

Solder Bridging

Solder bridging occurs when excess solder creates unwanted connections between adjacent pins.

Solution: Adjust solder paste volume, improve pad design, or use a finer pitch stencil to reduce the risk of bridging.

Insufficient Solder

Insufficient solder can lead to weak or unreliable connections.

Solution: Increase solder paste volume, adjust reflow profile, or check for proper wetting of the connector pins.

Misalignment

Misaligned connectors can result in poor electrical connections or mechanical instability.

Solution: Improve placement accuracy, use alignment features on the connector, or implement fiducial marks on the PCB for automated placement.

Tombstoning

Tombstoning occurs when one end of a component lifts off the PCB during reflow.

Solution: Balance the thermal mass on both sides of the component, adjust pad sizes, or modify the reflow profile to prevent uneven heating.

Best Practices for SMT Pin Connector Installation

1. Design for Manufacturability: Consider the manufacturing process when designing your PCB layout and selecting components.

2. Use Quality Materials: Invest in high-quality solder paste, flux, and cleaning agents to ensure reliable connections.

3. Maintain Clean Equipment: Regularly clean and maintain all equipment used in the SMT process to prevent contamination and ensure consistent results.

4. Train Personnel: Provide comprehensive training to all personnel involved in the SMT pin connector installation process.

5. Document Procedures: Develop and maintain detailed documentation of your SMT installation procedures for consistency and troubleshooting.

6. Implement Process Controls: Use statistical process control methods to monitor and improve your SMT installation process over time.

Future Trends in SMT Pin Connector Technology

As electronics continue to evolve, so do SMT pin connector technologies. Some emerging trends include:

1. Miniaturization: Development of even smaller pitch connectors for high-density applications.

2. High-Speed Designs: Connectors optimized for high-frequency and high-speed data transmission.

3. Environmentally Friendly Materials: Increased use of lead-free and halogen-free materials in connector manufacturing.

4. Smart Connectors: Integration of sensors and diagnostic capabilities within SMT connectors.

5. Automated Assembly: Advancements in automated placement and inspection technologies for improved efficiency and accuracy.

Conclusion

Proper installation of SMT pin connectors on PCBs is crucial for creating reliable and high-performance electronic devices. By following the steps and best practices outlined in this article, engineers and technicians can ensure successful integration of these essential components. As technology continues to advance, staying informed about the latest developments in SMT connector design and installation techniques will be vital for maintaining a competitive edge in the electronics industry.

FAQ

1. What are the main advantages of using SMT pin connectors over through-hole connectors?

SMT pin connectors offer several advantages over through-hole connectors:

- Increased component density: SMT connectors allow for higher component density on the PCB, enabling more compact designs[1].

- Reduced board size: Without the need for through-holes, PCBs can be smaller and use less material.

- Improved electrical performance: Shorter connection paths can lead to better signal integrity and reduced electromagnetic interference.

- Lower production costs: SMT assembly is generally faster and more cost-effective for high-volume production.

- Dual-sided assembly: SMT allows for components to be placed on both sides of the PCB, further increasing design flexibility.

2. How do you choose the right solder paste for SMT pin connector installation?

Selecting the appropriate solder paste is crucial for successful SMT pin connector installation:

- Alloy composition: Choose a solder alloy compatible with your PCB and component materials, considering factors like melting point and strength.

- Particle size: Select a particle size suitable for your connector's pitch and pad design.

- Flux type: Consider the flux type based on your cleaning requirements and the desired level of activity.

- Viscosity: Choose a viscosity appropriate for your stencil design and printing process.

- Reflow profile compatibility: Ensure the solder paste is compatible with your intended reflow profile and peak temperatures.

3. What are some common causes of SMT pin connector failure, and how can they be prevented?

Common causes of SMT pin connector failure and prevention strategies include:

- Solder joint cracking: Prevent by using appropriate solder alloys and optimizing the reflow profile to reduce thermal stress.

- Connector misalignment: Avoid by improving placement accuracy and using proper alignment features during assembly.

- Insufficient solder: Prevent by ensuring adequate solder paste volume and proper wetting of connector pins.

- Contamination: Avoid by maintaining a clean assembly environment and using appropriate cleaning processes.

- Mechanical stress: Reduce by considering strain relief in the PCB design and using appropriate enclosure designs.

4. How does the reflow profile affect SMT pin connector installation, and how can it be optimized?

The reflow profile significantly impacts SMT pin connector installation:

- Preheat stage: Gradually raises the temperature to activate the flux and prevent thermal shock.

- Soak stage: Allows for even heat distribution and helps remove volatiles from the solder paste.

- Reflow stage: Brings the solder to its liquidus temperature, forming the solder joint.

- Cooling stage: Controls the cooling rate to ensure proper solder joint crystallization.

Optimize the profile by:

- Following manufacturer recommendations for your specific solder paste and components.

- Using thermocouples to monitor actual temperatures on the PCB during reflow.

- Adjusting zone temperatures and conveyor speed to achieve the desired profile.

- Considering the thermal mass of all components on the PCB when designing the profile.

5. What inspection methods are most effective for ensuring proper SMT pin connector installation?

Effective inspection methods for SMT pin connector installation include:

- Visual inspection: Use magnification to check for proper alignment, solder joint shape, and absence of visible defects.

- X-ray inspection: Employ for high-density connectors or BGA-style packages to verify hidden solder joints.

- Automated Optical Inspection (AOI): Utilize for high-volume production to detect issues like misalignment, solder bridging, or insufficient solder.

- In-Circuit Testing (ICT): Perform electrical tests to verify proper connectivity and functionality of installed connectors.

- Flying Probe Testing: Use for low-volume or prototype boards to check electrical connections without the need for custom test fixtures.

Citations:

[1] https://promaxpogopin.com/professional/smt-connectors-in-pcb-everything-you-need-to-know/

[2] https://suddendocs.samtec.com/processing/edge-mount-processing-ch.pdf

[3] https://www.powerelement.com/en/technology/assembly-methods

[4] https://en.wikipedia.org/wiki/Pin_header

[5] https://www.reddit.com/r/PrintedCircuitBoard/comments/1buu37k/connecting_254mm_pin_headers_to_pcb_without/

[6] https://dam-mdc.phoenixcontact.com/asset/156443151564/a597d012129c8f44a327b5f340ddafad/52004352_EN_Steckverbinder_SMT_LoRes.pdf

[7] https://beadelectronics.com/blog/using-custom-headers-in-molded-and-pcb-processes

[8] https://www.wevolver.com/article/types-of-pcb-connectors-an-in-depth-guide