Content Menu

● The Importance of Quality Control in PCB Assembly

● JLCPCB's Quality Control Measures

>> Pre-Production Quality Assurance

>> SMT Assembly Process Quality Control

>>> Solder Paste Printing

>>> Component Placement

>>> Reflow Soldering

● Post-Assembly Inspection and Testing

>> Automated Optical Inspection (AOI)

>> X-ray Inspection

>> Flying Probe Testing

>> Final Quality Check

● Continuous Improvement and Quality Management

>> ISO Certifications

>> IPC Standards Compliance

>> Data Analysis and Process Improvement

>> Staff Training and Accountability

● Customer Communication and Support

● The Impact of Quality Control on PCB Performance

● Challenges in SMT Assembly Quality Control

● Conclusion

● FAQ

>> 1. What is SMT assembly in PCB manufacturing?

>> 2. How does JLCPCB ensure component quality in SMT assembly?

>> 3. What is the significance of AOI in PCB quality control?

>> 4. How does JLCPCB handle quality issues discovered after shipping?

>> 5. What are the advantages of using JLCPCB's SMT assembly service?

● Citations:

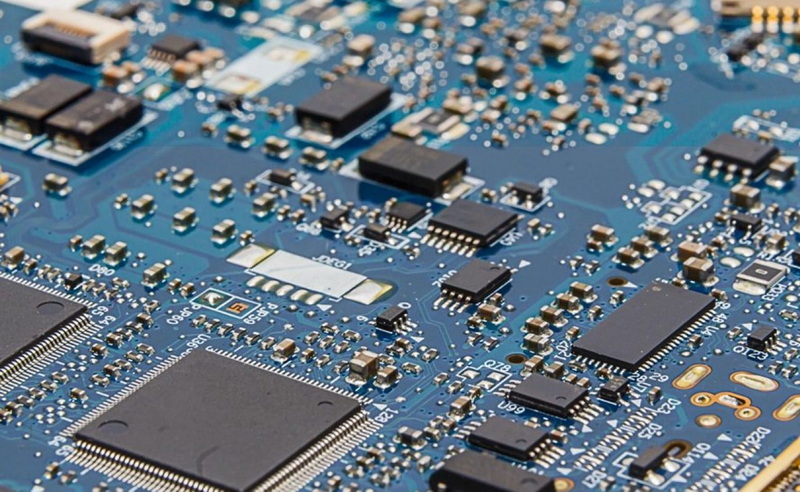

JLCPCB, a leading manufacturer in the PCB industry, has established a robust quality control system for their SMT (Surface Mount Technology) assembly process. This comprehensive approach ensures that every PCB produced meets the highest standards of quality and reliability. In this article, we will explore the various techniques and procedures JLCPCB employs to maintain exceptional quality control in their SMT assembly service.

The Importance of Quality Control in PCB Assembly

Quality control is a critical aspect of PCB manufacturing, especially in SMT assembly. As electronic devices become increasingly complex and miniaturized, the demand for high-quality, reliable PCBs has never been greater. JLCPCB recognizes this need and has implemented a multi-faceted quality control strategy that covers every stage of the SMT assembly process[1][3].

JLCPCB's Quality Control Measures

Pre-Production Quality Assurance

Before the actual assembly process begins, JLCPCB takes several steps to ensure quality:

1. File Review: Every order submitted to JLCPCB undergoes a thorough review by engineers. They check the Gerber files to confirm that the design adheres to tolerance restrictions for board edge clearance, drill holes, and spacing between pads and traces[5].

2. Raw Material Selection: JLCPCB partners with industry-leading suppliers to source top-quality materials. They use premium components such as Nanya FR4 material and TAIYO INK PSR-2000 solder mask[5].

3. Advanced Equipment: To ensure consistent quality, JLCPCB invests in state-of-the-art equipment, including fully-automatic LDI exposure machines, solder mask production lines, and PCB test machines[5].

SMT Assembly Process Quality Control

During the SMT assembly process, JLCPCB implements several quality control measures:

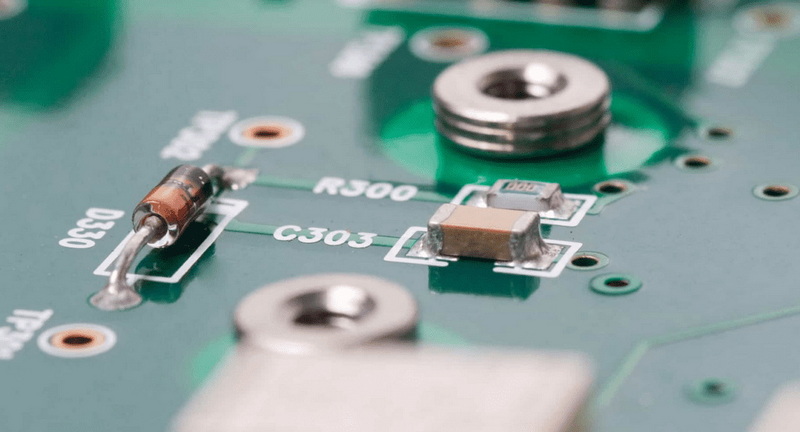

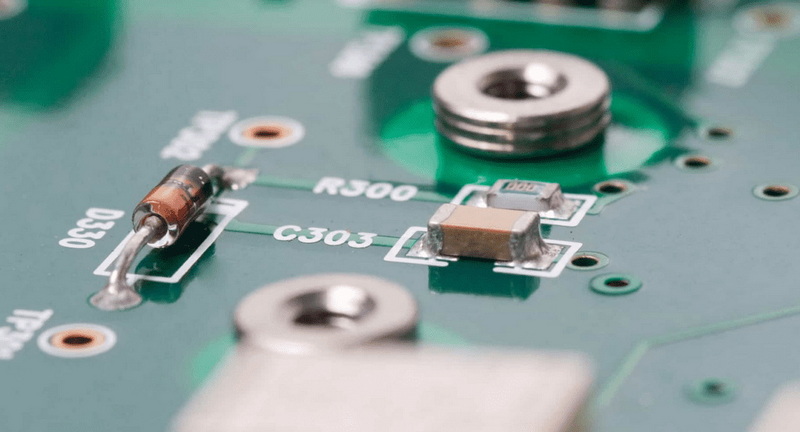

Solder Paste Printing

1. Stencil Design: JLCPCB uses high-quality stencils designed to match the PCB layout precisely. This ensures accurate solder paste deposition[6].

2. Paste Inspection: After printing, the solder paste is inspected using automated systems to verify its volume, position, and shape[6].

3. Environmental Control: The assembly area is maintained at a controlled temperature and humidity to prevent solder paste degradation[1].

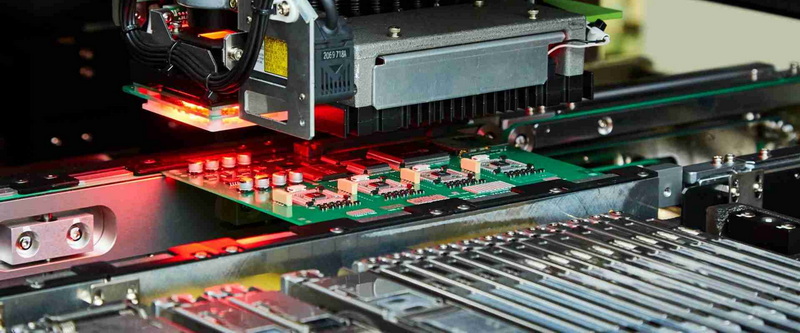

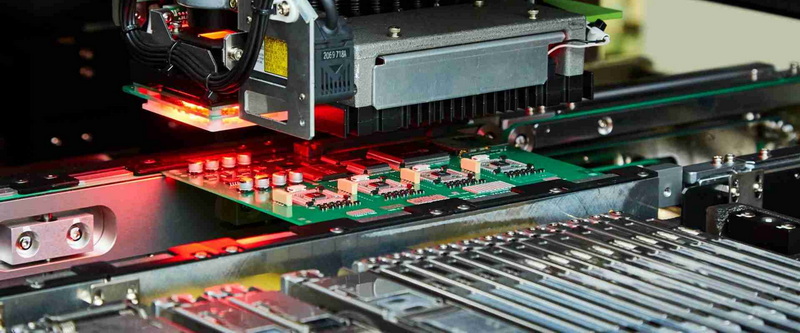

Component Placement

1. Automated Placement: JLCPCB uses advanced pick-and-place machines for precise and consistent component placement[3].

2. Vision Systems: These machines are equipped with high-resolution cameras that verify component polarity and positioning[3].

3. Component Verification: Before placement, components are verified against the bill of materials (BOM) to ensure the correct parts are used[1].

Reflow Soldering

1. Thermal Profiling: JLCPCB carefully controls the reflow oven's temperature profile to ensure optimal soldering for all components[6].

2. Nitrogen Atmosphere: Some reflow ovens use a nitrogen atmosphere to improve solder joint quality and reduce oxidation[6].

3. Cooling Control: After reflow, boards are cooled at a controlled rate to prevent thermal shock and ensure solder joint reliability[6].

Post-Assembly Inspection and Testing

JLCPCB employs a multi-stage inspection and testing process to catch any defects that may have occurred during assembly:

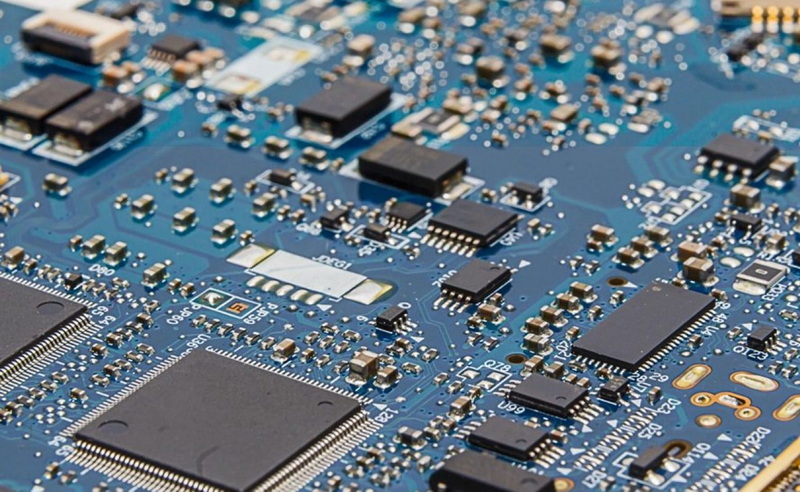

Automated Optical Inspection (AOI)

AOI is a crucial step in JLCPCB's quality control process. It uses advanced cameras and algorithms to inspect each board for defects such as:

- Missing or misaligned components

- Solder bridges

- Insufficient solder

- Component polarity errors

The AOI system can detect issues that might be missed by human inspectors, ensuring a high level of accuracy and consistency[1][3][5].

X-ray Inspection

For more complex boards or those with hidden solder joints (such as BGA components), JLCPCB uses X-ray inspection. This technology allows for the examination of solder joints that are not visible from the surface, ensuring proper connection and alignment[6].

Flying Probe Testing

JLCPCB uses flying probe testing to verify the electrical integrity of the assembled PCBs. This method uses electro-mechanically controlled probes to access various points on the board, testing for:

- Open circuits

- Short circuits

- Component values

- Functionality of certain circuits[5]

Final Quality Check

Before shipping, each board undergoes a final visual inspection by trained quality control personnel. This step serves as a last line of defense against any defects that may have been missed by automated systems[5].

Continuous Improvement and Quality Management

JLCPCB's commitment to quality extends beyond individual board inspections. They have implemented several systemic approaches to maintain and improve their quality standards:

ISO Certifications

JLCPCB's manufacturing facilities are ISO 9001 and ISO 14001 certified, demonstrating their commitment to quality management and environmental responsibility[1].

IPC Standards Compliance

JLCPCB adheres to IPC standards, including IPC-A-600F for bare PCB acceptability and J-STD-001 for soldered electrical and electronic assemblies[1][3].

Data Analysis and Process Improvement

JLCPCB continuously analyzes defect data and customer feedback to identify areas for improvement. This data-driven approach allows them to refine their processes and reduce defect rates over time[1].

Staff Training and Accountability

JLCPCB invests in ongoing training for their staff to ensure they are up-to-date with the latest quality control techniques. They also implement a strict accountability system, where staff members are responsible for any errors they make during the production process[5].

Customer Communication and Support

Quality control doesn't end when the boards leave JLCPCB's facility. They maintain open lines of communication with customers to address any issues that may arise:

1. Transparent Reporting: JLCPCB provides detailed inspection reports and images from each inspection step for customer review[1].

2. Design for Manufacturing (DFM) Analysis: For complex designs, JLCPCB's engineering team offers DFM analysis and recommendations to improve manufacturability and minimize assembly issues[1].

3. Responsive Support: In case of any quality concerns, JLCPCB's support team is ready to assist customers and resolve issues promptly[2].

The Impact of Quality Control on PCB Performance

The rigorous quality control measures implemented by JLCPCB have a significant impact on the performance and reliability of the assembled PCBs:

1. Reduced Defect Rates: By catching and correcting issues early in the process, JLCPCB maintains a high yield rate, with soldering joint yields greater than 95% for designs complying with industrial standards[2].

2. Improved Reliability: Thorough testing and inspection ensure that boards will perform as intended in their final application, reducing the risk of field failures.

3. Consistency: The use of automated processes and strict quality control measures results in consistent quality across large production runs.

4. Cost-Effectiveness: While comprehensive quality control may seem costly, it actually reduces overall costs by minimizing rework and warranty claims.

Challenges in SMT Assembly Quality Control

Despite the advanced techniques employed by JLCPCB, SMT assembly quality control faces several challenges:

1. Miniaturization: As components become smaller and PCB designs more dense, inspection and testing become more challenging.

2. Complex Components: Some components, like BGAs with pitches less than 0.5mm, present unique inspection challenges[1].

3. High-Speed Production: Balancing the need for rapid production with thorough quality control can be difficult.

4. Thermal Management: Ensuring proper soldering for components with different thermal requirements on the same board can be challenging.

JLCPCB addresses these challenges through continuous investment in advanced equipment, staff training, and process refinement.

Conclusion

Quality control in JLC PCB SMT assembly is a comprehensive, multi-faceted process that begins with pre-production measures and continues through post-assembly testing and customer support. By implementing advanced inspection technologies, adhering to international standards, and maintaining a culture of continuous improvement, JLCPCB ensures that their SMT assembly service produces high-quality, reliable PCBs.

The combination of automated systems like AOI and X-ray inspection with manual checks and rigorous testing protocols allows JLCPCB to maintain high standards of quality even as PCB designs become more complex and miniaturized. Their commitment to quality not only benefits customers through improved product performance and reliability but also contributes to the advancement of the electronics industry as a whole.

As technology continues to evolve, so too will the challenges and methods of quality control in PCB assembly. JLCPCB's proactive approach to quality management positions them well to meet these future challenges and continue delivering exceptional SMT assembly services to their customers.

FAQ

1. What is SMT assembly in PCB manufacturing?

SMT (Surface Mount Technology) assembly is a method of PCB production where components are mounted directly onto the surface of the board, rather than through holes. This technique allows for more compact designs and is widely used in modern electronics manufacturing.

2. How does JLCPCB ensure component quality in SMT assembly?

JLCPCB ensures component quality through several measures:

- Sourcing from reputable suppliers

- Implementing strict incoming quality control

- Using automated systems to verify component placement and polarity

- Conducting thorough post-assembly testing

3. What is the significance of AOI in PCB quality control?

Automated Optical Inspection (AOI) is crucial in PCB quality control as it:

- Detects defects that may be missed by human inspectors

- Provides consistent and objective inspection results

- Can inspect large volumes of PCBs quickly and accurately

- Helps identify process issues early, allowing for rapid corrective action

4. How does JLCPCB handle quality issues discovered after shipping?

If quality issues are discovered after shipping, JLCPCB:

- Provides responsive customer support

- Investigates the root cause of the issue

- Offers solutions or replacements as necessary

- Uses the feedback to improve their processes and prevent similar issues in the future

5. What are the advantages of using JLCPCB's SMT assembly service?

The advantages of using JLCPCB's SMT assembly service include:

- High-quality results due to comprehensive quality control measures

- Cost-effective production, especially for medium to large volumes

- Access to a wide range of components

- Fast turnaround times

- Professional DFM analysis and support

Citations:

[1] https://prototypepcbassembly.com/jlcpcb-smt-assembly/

[2] https://jlcpcb.com/help/article/Terms-and-Conditions-of-JLCPCB-Assembly-Service

[3] https://jlcpcb.com/blog/electronic-board-manufacturing-efficient-strategy-and-quality-control-processes

[4] https://jlcpcb.com/blog/category/1/375

[5] https://jlcpcb.com/aboutUs/qualityControl

[6] https://www.ednasia.com/top-12-incredible-techniques-to-control-the-quality-of-pcb-smt-assembly/

[7] https://www.youtube.com/watch?v=l9f3yJ3r93Q

[8] https://hackaday.io/project/184378-jlcpcb-smt-assembly-service-complete-guide