Content Menu

● Understanding SMT Stencils

● Wholesale SMT Stencils: Features and Advantages

>> Key Features of Wholesale SMT Stencils

>> Benefits of Wholesale SMT Stencils

>> Typical Applications for Wholesale SMT Stencils

● Custom SMT Stencils: Features and Advantages

>> Key Features of Custom SMT Stencils

>> Benefits of Custom SMT Stencils

>> Typical Applications for Custom SMT Stencils

● Comparison Between Wholesale and Custom SMT Stencils

● Factors to Consider When Choosing Between Wholesale and Custom SMT Stencils

>> Production Volume and Frequency

>> PCB Complexity and Component Density

>> Cost Constraints

>> Lead Time Requirements

>> Material and Quality Requirements

● Advantages of Using Wholesale SMT Stencils

● Limitations of Wholesale SMT Stencils

● Advantages of Using Custom SMT Stencils

● Limitations of Custom SMT Stencils

● Best Practices for Using Wholesale and Custom SMT Stencils

>> For Wholesale SMT Stencils

>> For Custom SMT Stencils

● Conclusion

● FAQ

>> 1. What is the main difference between wholesale SMT stencils and custom SMT stencils?

>> 2. Can wholesale SMT stencils be used for fine-pitch or high-density PCB assemblies?

>> 3. How does stencil thickness affect solder paste application?

>> 4. Are there material differences between wholesale and custom SMT stencils?

>> 5. How should manufacturers decide between wholesale and custom SMT stencils?

In the electronics manufacturing industry, Surface Mount Technology (SMT) stencils are indispensable tools used to apply solder paste onto printed circuit boards (PCBs) with precision and consistency. Choosing the right type of SMT stencil can significantly influence the quality, efficiency, and cost-effectiveness of the PCB assembly process. Among the options available, wholesale SMT stencils and custom SMT stencils are two popular choices, each with distinct characteristics and advantages. This article explores how wholesale SMT stencils compare to custom stencils, focusing on their features, benefits, limitations, and suitability for different manufacturing needs.

Understanding SMT Stencils

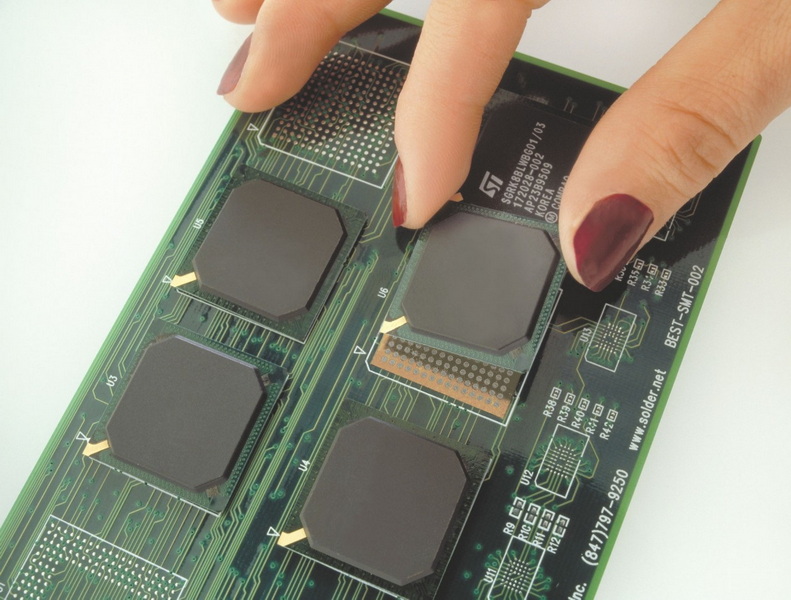

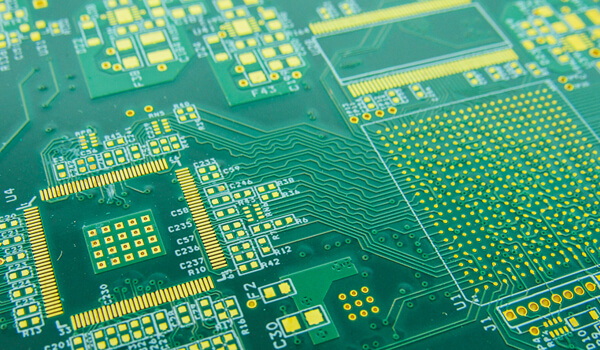

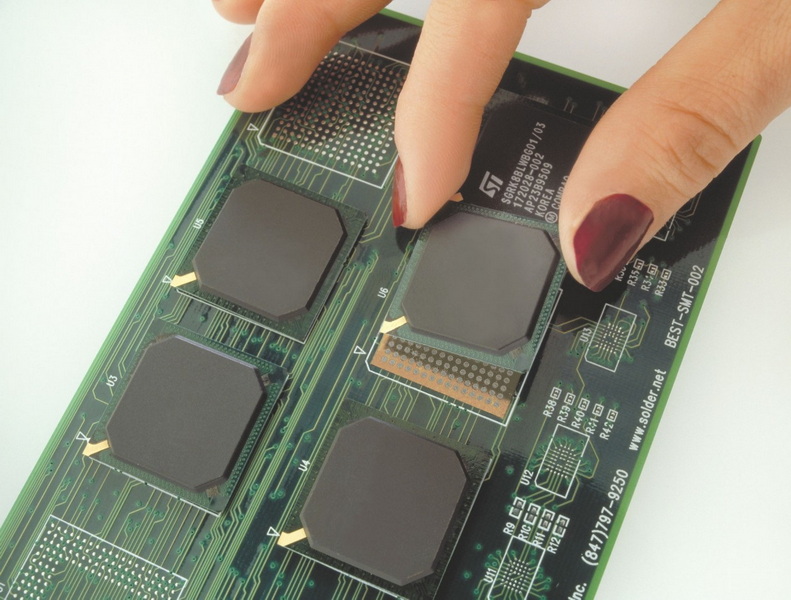

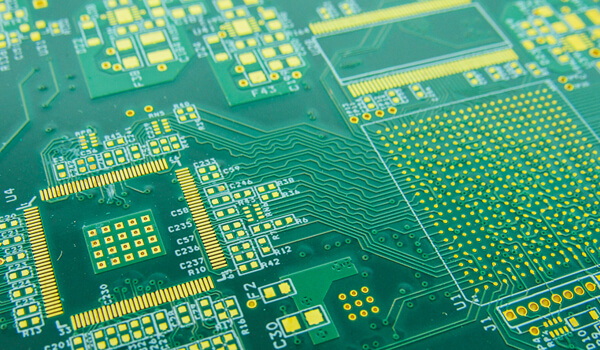

An SMT stencil is a thin metal sheet, usually made of stainless steel or nickel, with precisely cut apertures that correspond to the pads on a PCB where solder paste needs to be applied. The stencil acts as a template, allowing solder paste to be deposited accurately on the board, ensuring proper solder joints and reliable electronic connections. SMT stencils are critical for achieving high-quality soldering, especially in high-density and fine-pitch PCB assemblies.

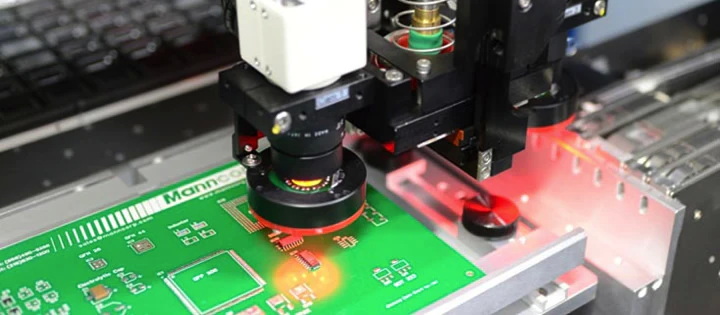

The manufacturing of SMT stencils involves designing the stencil pattern based on the PCB layout, selecting appropriate materials and thickness, and employing precision cutting methods such as laser cutting or chemical etching. The stencil must be durable, corrosion-resistant, and capable of delivering consistent solder paste deposition throughout its usage.

Wholesale SMT Stencils: Features and Advantages

Wholesale SMT stencils are pre-manufactured stencils available in bulk quantities, often produced to standard specifications that fit common PCB designs or industry-standard sizes. These stencils are typically offered by suppliers who specialize in providing a wide range of stencil types and materials at competitive prices.

Key Features of Wholesale SMT Stencils

- Standardized Designs: Wholesale stencils are usually designed to accommodate common PCB layouts or popular component footprints, making them suitable for manufacturers with recurring or less complex assembly needs.

- Bulk Availability: They are produced in large quantities, which reduces the per-unit cost and ensures quick availability for high-volume production runs.

- Cost-Effectiveness: Purchasing wholesale SMT stencils can lower procurement costs due to economies of scale and streamlined manufacturing processes.

- Material Options: Wholesale suppliers often offer stencils made from durable materials like stainless steel or nickel, with options for coatings that enhance paste release and stencil longevity.

Benefits of Wholesale SMT Stencils

- Reduced Lead Times: Since wholesale stencils are pre-made or produced in large batches, they are generally available faster than custom stencils, which require design and manufacturing time.

- Lower Initial Investment: For manufacturers with standard PCB designs or those starting production, wholesale stencils provide an affordable entry point without the need for custom tooling.

- Reliable Quality: Established wholesale suppliers maintain quality control to ensure stencils meet industry standards, offering consistent solder paste application and durability.

- Simplified Procurement: Bulk purchasing from wholesale sources streamlines supply chain management, reducing administrative overhead.

Typical Applications for Wholesale SMT Stencils

Wholesale SMT stencils are particularly well-suited for manufacturers who produce high volumes of PCBs with standardized designs. For example, companies manufacturing consumer electronics, automotive parts, or other products with consistent PCB layouts can benefit from the economies of scale and quick turnaround times offered by wholesale SMT stencils. Additionally, these stencils serve well in environments where the PCB design does not change frequently, allowing the same stencil to be reused over multiple production cycles.

Custom SMT Stencils: Features and Advantages

Custom SMT stencils are tailored specifically to the unique design and requirements of a particular PCB. They are manufactured based on the exact layout, component placement, and solder paste volume specifications provided by the client.

Key Features of Custom SMT Stencils

- Tailored Design: Custom stencils are precisely cut to match the PCB's pad configuration, thickness requirements, and aperture shapes, ensuring optimal solder paste deposition.

- Material and Thickness Selection: Clients can specify stencil material, thickness (commonly between 0.1mm and 0.25mm), and surface treatments to suit their assembly process and component types.

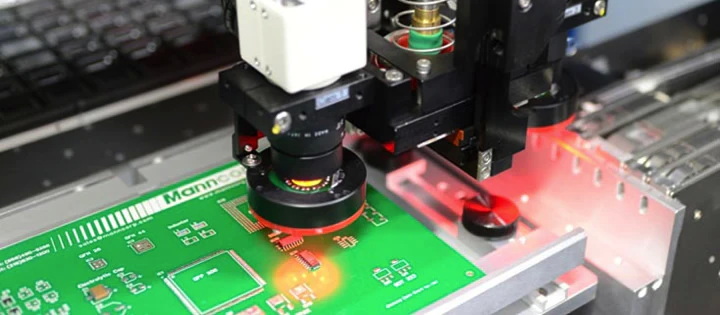

- Advanced Cutting Techniques: Custom stencils often employ high-precision laser cutting or electroforming to achieve fine apertures needed for complex or fine-pitch components.

- Additional Features: Custom stencils can include enhancements such as electro-polishing, anti-sticking coatings, and reinforced frames to improve durability and print quality.

Benefits of Custom SMT Stencils

- High Precision and Accuracy: Custom stencils ensure the exact amount of solder paste is applied to each pad, reducing defects such as bridging, insufficient solder, or tombstoning.

- Optimized for Complex Designs: For PCBs with high-density layouts, fine-pitch components, or unique geometries, custom stencils provide the necessary precision that wholesale stencils may not offer.

- Enhanced Product Quality: By matching the stencil perfectly to the PCB design, manufacturers can achieve superior solder joint reliability and overall product performance.

- Flexibility: Custom stencils allow modifications and iterations to accommodate design changes or process improvements.

- Reduced Waste and Rework: The precision of custom stencils reduces the likelihood of solder paste defects, which in turn decreases the need for costly rework or scrap.

Typical Applications for Custom SMT Stencils

Custom SMT stencils are ideal for prototype development, low-volume production runs, or products with complex and evolving PCB designs. They are especially valuable in industries like aerospace, medical devices, and telecommunications, where reliability and precision are paramount. Additionally, custom stencils are preferred when working with fine-pitch components, BGA packages, or when specific solder paste volume control is necessary.

Comparison Between Wholesale and Custom SMT Stencils

| Aspect | Wholesale SMT Stencils | Custom SMT Stencils |

| Design Specificity | Standardized designs for common PCB layouts | Tailored precisely to individual PCB designs |

| Cost | Lower per unit cost due to bulk production | Higher cost due to customization and smaller runs |

| Lead Time | Shorter lead times; readily available in many cases | Longer lead times due to design and manufacturing |

| Precision | Suitable for general applications with standard pads | High precision for complex, fine-pitch, or unique PCBs |

| Material Options | Standard materials and coatings | Wide range of materials and thicknesses based on needs |

| Flexibility | Limited flexibility; fixed designs | High flexibility for design changes and optimizations |

| Suitability | Best for high-volume, repetitive production runs | Ideal for prototypes, specialized products, or complex boards |

| Storage and Handling | Requires storage for bulk quantities | Typically smaller quantities, easier to manage |

Factors to Consider When Choosing Between Wholesale and Custom SMT Stencils

Production Volume and Frequency

For manufacturers with large-scale, repetitive production runs of standard PCB designs, wholesale SMT stencils offer a cost-effective and efficient solution. Their availability in bulk and lower cost per unit make them suitable for high-volume assembly lines.

Conversely, for low-volume production, prototypes, or products with frequent design changes, custom SMT stencils provide the necessary precision and adaptability despite higher costs and longer lead times.

PCB Complexity and Component Density

Complex PCBs with fine-pitch components, high-density layouts, or unique pad geometries benefit significantly from custom SMT stencils. The precision and tailored apertures help ensure solder paste is deposited accurately, reducing defects and improving yield.

Wholesale stencils may suffice for simpler or standardized PCB designs where extreme precision is less critical.

Cost Constraints

Wholesale SMT stencils generally offer better cost savings due to economies of scale. However, the potential for defects or rework with less precise stencils can offset initial savings.

Custom stencils, while more expensive upfront, can reduce scrap rates, rework, and improve product reliability, potentially lowering overall production costs.

Lead Time Requirements

If rapid turnaround is essential, wholesale SMT stencils may be preferable due to their immediate availability or shorter manufacturing times.

Custom stencils require design finalization and manufacturing, which may extend lead times but provide better alignment with specific production needs.

Material and Quality Requirements

Custom stencils allow for selection of specific materials, thicknesses, and coatings that can enhance stencil life, paste release, and print quality.

Wholesale stencils typically offer standard material options, which may be sufficient for many applications but less optimized for specialized needs.

Advantages of Using Wholesale SMT Stencils

- Efficiency in Procurement: Buying wholesale SMT stencils simplifies supply chain management, especially for companies producing standard PCBs.

- Cost Savings: Bulk purchasing reduces per-unit costs, making them attractive for large-scale manufacturers.

- Consistent Quality: Reputable wholesale suppliers maintain quality standards ensuring reliable stencil performance.

- Quick Availability: Ready stock or faster production cycles help meet tight production schedules.

- Material Durability: Commonly made from stainless steel or nickel, wholesale stencils offer durability for multiple uses.

- Ease of Replacement: Having multiple identical stencils on hand allows quick replacement if a stencil is damaged or worn.

Limitations of Wholesale SMT Stencils

- Less Customization: Limited ability to tailor stencil thickness, aperture shapes, or materials to specific PCB requirements.

- Potential for Reduced Precision: May not meet the stringent demands of complex or fine-pitch PCB assemblies.

- Storage Requirements: Bulk quantities require adequate storage space and inventory management.

- Limited Adaptability: Not suitable for PCBs undergoing frequent design changes or requiring unique solder paste volumes.

Advantages of Using Custom SMT Stencils

- Perfect Fit for PCB Design: Custom stencils ensure solder paste is applied exactly where needed, improving solder joint quality.

- Adaptability: Easily accommodate design changes, new components, or process improvements.

- Enhanced Print Quality: Tailored aperture shapes and sizes improve paste release and reduce defects.

- Material and Coating Options: Ability to select advanced materials and coatings for longer stencil life and better performance.

- Improved Process Control: Custom stencils allow better control over solder paste volume, critical for sensitive or high-reliability applications.

Limitations of Custom SMT Stencils

- Higher Cost: Customization and smaller production runs increase the cost per stencil.

- Longer Lead Times: Design and manufacturing processes take more time compared to wholesale options.

- Complex Ordering Process: Requires detailed design files and specifications, which may add complexity for some manufacturers.

- Potential for Over-Specification: In some cases, the level of customization may exceed actual production needs, leading to unnecessary expense.

Best Practices for Using Wholesale and Custom SMT Stencils

For Wholesale SMT Stencils

- Standardize PCB Designs: To maximize benefits, maintain consistent PCB layouts that match available wholesale stencil designs.

- Maintain Inventory: Keep an adequate stock of wholesale stencils to avoid production delays.

- Regular Inspection: Periodically check stencil condition to prevent print defects caused by wear or damage.

- Optimize Cleaning: Use appropriate cleaning methods to extend stencil life and maintain print quality.

For Custom SMT Stencils

- Collaborate with Suppliers: Work closely with stencil manufacturers to optimize design for print quality and manufacturability.

- Update Designs Promptly: When PCB revisions occur, update stencil designs to maintain alignment and performance.

- Invest in Quality Materials: Choose materials and coatings that suit your production environment and solder paste characteristics.

- Implement Process Monitoring: Track stencil performance and solder paste deposition to identify opportunities for improvement.

Conclusion

Wholesale SMT stencils and custom SMT stencils each serve important roles in the PCB assembly process. Wholesale SMT stencils offer a cost-effective, readily available solution for manufacturers with standard PCB designs and high-volume production needs. They provide consistent quality and durability, making them suitable for many general applications.

On the other hand, custom SMT stencils deliver unmatched precision and flexibility, essential for complex, fine-pitch, or specialized PCB assemblies. Although they come with higher costs and longer lead times, the benefits in product quality, reduced defects, and adaptability often justify the investment.

Ultimately, the choice between wholesale and custom SMT stencils depends on factors such as production volume, PCB complexity, budget, lead time, and quality requirements. Manufacturers should carefully evaluate these considerations to select the stencil type that best aligns with their operational goals and product specifications.

FAQ

1. What is the main difference between wholesale SMT stencils and custom SMT stencils?

Wholesale SMT stencils are pre-manufactured in bulk with standard designs suitable for common PCB layouts, offering cost savings and quick availability. Custom SMT stencils are specifically designed and manufactured to match unique PCB designs, providing higher precision and adaptability but at a higher cost and longer lead time.

2. Can wholesale SMT stencils be used for fine-pitch or high-density PCB assemblies?

While wholesale SMT stencils can handle many standard applications, they may lack the precision required for very fine-pitch or high-density PCB assemblies. Custom stencils are generally preferred for such complex designs due to their tailored aperture sizes and shapes.

3. How does stencil thickness affect solder paste application?

Stencil thickness influences the volume of solder paste deposited on PCB pads. Thicker stencils deposit more paste, which may be necessary for larger components, while thinner stencils are used for fine-pitch components to prevent solder bridging. Custom stencils allow precise thickness selection to match component requirements.

4. Are there material differences between wholesale and custom SMT stencils?

Both wholesale and custom stencils commonly use stainless steel or nickel. However, custom stencils offer more options for specialized materials or coatings that improve paste release, reduce defects, and extend stencil life.

5. How should manufacturers decide between wholesale and custom SMT stencils?

Manufacturers should consider their production volume, PCB complexity, budget, lead time, and quality requirements. High-volume, standard PCB production benefits from wholesale stencils, while low-volume, complex, or prototype production is better served by custom stencils.