Content Menu

● Introduction

● Understanding Surface Mount Technology (SMT)

>> Advantages of SMT

● Types of Surface Mount Assembly Tools

>> Solder Paste Printers

>> Pick and Place Machines

>> Reflow Ovens

>> Inspection Systems

>> Manual Assembly Tools

● Enhancing Precision with Surface Mount Assembly Tools

>> Improved Accuracy in Component Placement

>> Consistent Solder Application

>> Controlled Reflow Process

>> Enhanced Quality Control

>> Flexibility in Design

● Challenges in Surface Mount Assembly

>> Complexity of Designs

>> Equipment Costs

>> Training Requirements

● Conclusion

● FAQ

>> 1. What are surface mount assembly tools?

>> 2. How do pick and place machines enhance precision?

>> 3. Why is consistent solder application important?

>> 4. What role do inspection systems play in PCB assembly?

>> 5. Are there challenges associated with using surface mount assembly tools?

Introduction

In the rapidly evolving world of electronics, the demand for high-quality printed circuit boards (PCBs) has never been greater. As devices become smaller and more complex, the need for precision in PCB assembly is paramount. Surface mount technology (SMT) has emerged as a preferred method for assembling PCBs due to its efficiency and ability to accommodate high-density components. Central to this process are surface mount assembly tools, which play a critical role in enhancing the precision of PCB assembly. This article delves into the various types of surface mount assembly tools, their functionalities, and how they contribute to achieving high precision in PCB manufacturing.

Understanding Surface Mount Technology (SMT)

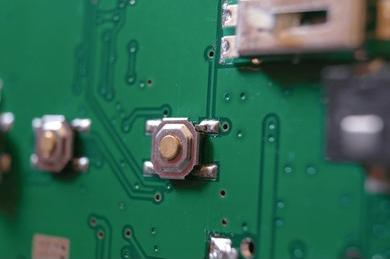

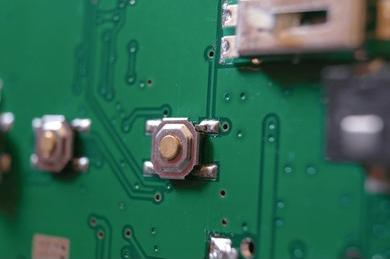

Before exploring surface mount assembly tools, it is essential to understand what surface mount technology entails. SMT is a method where electronic components are mounted directly onto the surface of PCBs rather than through holes. This technique allows for smaller components and increased circuit density, which is crucial in modern electronic devices.

Advantages of SMT

- Space Efficiency: SMT enables the design of compact circuits, allowing for more components to fit on a single board.

- Improved Performance: The shorter electrical paths in SMT can lead to better performance and reduced signal loss.

- Automated Assembly: SMT is highly compatible with automated assembly processes, which increases production speed and reduces labor costs.

Types of Surface Mount Assembly Tools

Surface mount assembly tools are essential for the successful implementation of SMT. These tools can be categorized into several types, each serving a specific purpose in the assembly process.

Solder Paste Printers

Solder paste printers are crucial in applying solder paste onto PCBs before component placement. The precision of solder paste application directly affects the quality of solder joints.

- Functionality: These printers use stencils to deposit solder paste accurately onto designated pads on the PCB.

- Benefits: High-quality solder paste printers ensure that the right amount of paste is applied, reducing defects such as bridging or insufficient solder.

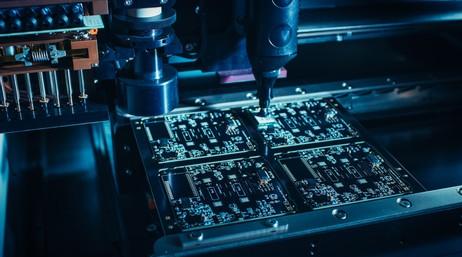

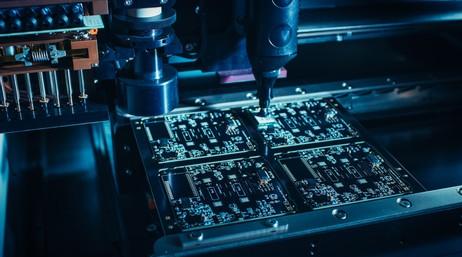

Pick and Place Machines

Pick and place machines are automated devices that position surface mount components onto PCBs with high accuracy.

- Functionality: These machines use vacuum suction to pick components from reels or trays and place them precisely on the PCB.

- Benefits: The speed and accuracy of pick and place machines significantly enhance production efficiency while minimizing human error.

Reflow Ovens

Reflow ovens are used to melt solder paste after components have been placed on the PCB, creating permanent connections.

- Functionality: The oven heats the PCB in a controlled manner, ensuring that solder reaches the appropriate temperature for melting.

- Benefits: Properly calibrated reflow ovens prevent issues such as cold solder joints or overheating components, enhancing overall assembly quality.

Inspection Systems

Inspection systems are vital for ensuring that assembled PCBs meet quality standards.

- Functionality: These systems can include automated optical inspection (AOI) machines that check for defects such as misaligned components or insufficient solder.

- Benefits: Early detection of defects allows for corrective actions before further processing, reducing waste and rework costs.

Manual Assembly Tools

While automation plays a significant role in modern PCB assembly, manual tools remain essential for certain tasks.

- Functionality: Manual tools include soldering irons, tweezers, and magnifying glasses used by technicians for hand-soldering or component placement.

- Benefits: Skilled technicians can address complex assemblies or repairs that require a human touch, ensuring high precision where automation may fall short.

Enhancing Precision with Surface Mount Assembly Tools

The integration of surface mount assembly tools into PCB manufacturing processes significantly enhances precision in several ways:

Improved Accuracy in Component Placement

The use of advanced pick and place machines allows for precise placement of components on PCBs. These machines utilize sophisticated vision systems to detect component orientation and alignment, ensuring that each component is positioned accurately on its designated pad. This level of precision minimizes misalignment issues that can lead to circuit failures.

Consistent Solder Application

Solder paste printers ensure that solder paste is applied uniformly across all pads on the PCB. Consistency in solder application reduces variability in solder joint quality, leading to more reliable connections between components. This uniformity is crucial in preventing defects such as cold joints or shorts caused by excessive solder.

Controlled Reflow Process

Reflow ovens provide a controlled environment for melting solder paste. By carefully managing temperature profiles during the reflow process, manufacturers can achieve optimal melting conditions for different types of solder alloys. This control minimizes thermal stress on components and ensures that solder flows correctly into joints, enhancing overall reliability.

Enhanced Quality Control

The incorporation of inspection systems into the assembly process allows for real-time monitoring of quality. Automated optical inspection systems can quickly identify defects that may go unnoticed during manual inspections. By catching issues early in the production process, manufacturers can reduce scrap rates and improve overall product quality.

Flexibility in Design

Surface mount assembly tools enable manufacturers to work with a wide variety of component sizes and types. This flexibility allows for innovative designs that push the boundaries of what is possible with traditional through-hole technology. Designers can create more compact circuits without sacrificing performance or reliability.

Challenges in Surface Mount Assembly

Despite the advantages offered by surface mount assembly tools, there are challenges associated with their use:

Complexity of Designs

As electronic devices become more complex, so do PCB designs. High-density layouts can lead to difficulties in component placement and soldering if not managed properly.

Equipment Costs

Investing in advanced surface mount assembly tools can be costly for manufacturers, particularly small businesses. The initial capital expenditure may be a barrier to entry for some companies looking to adopt SMT processes.

Training Requirements

Operating sophisticated surface mount assembly tools requires skilled personnel who understand both the technology and best practices for PCB assembly. Ongoing training is necessary to keep staff updated on new equipment and techniques.

Conclusion

Surface mount assembly tools play an indispensable role in enhancing the precision of PCB assembly processes. From solder paste printers to automated inspection systems, these tools contribute significantly to improving accuracy, consistency, and overall quality in electronic manufacturing. While challenges exist, such as equipment costs and training requirements, the benefits offered by these tools far outweigh potential drawbacks. As technology continues to advance, we can expect further innovations in surface mount assembly techniques that will continue to drive precision in PCB manufacturing forward.

FAQ

1. What are surface mount assembly tools?

Surface mount assembly tools are specialized equipment used in the process of assembling printed circuit boards using surface mount technology (SMT). They include solder paste printers, pick and place machines, reflow ovens, inspection systems, and manual assembly tools.

2. How do pick and place machines enhance precision?

Pick and place machines enhance precision by using advanced vision systems to accurately position components on PCBs. They minimize human error by automating the placement process at high speeds while maintaining accuracy.

3. Why is consistent solder application important?

Consistent solder application is crucial because it ensures uniformity across all solder joints on a PCB. This uniformity reduces variability in joint quality and prevents defects such as cold joints or shorts caused by excessive or insufficient solder.

4. What role do inspection systems play in PCB assembly?

Inspection systems play a critical role by monitoring assembled PCBs for defects during production. Automated optical inspection (AOI) systems quickly identify misaligned components or insufficient solder joints, allowing for early corrective actions that improve overall product quality.

5. Are there challenges associated with using surface mount assembly tools?

Yes, challenges include managing complex designs that may lead to difficulties in placement and soldering, high initial equipment costs that may deter small manufacturers from adopting SMT processes, and the need for ongoing training to ensure personnel are skilled in operating advanced equipment effectively.