Content Menu

● Introduction to SMT and Stencil Printing

>> Role of Stencil Printers

● Key Factors in High-Quality Solder Paste Printing

● Benefits of Using Stencil Printers in SMT

● Innovations in Solder Paste Printing Technology

● Challenges and Future Developments

● Step Stencil Technologies

● Advanced Solder Paste Materials

● Integration with Industry 4.0

● Conclusion

● FAQ

>> 1. What is the primary function of a stencil printer in SMT?

>> 2. How do stencil printers ensure precision in solder paste application?

>> 3. What are the benefits of using automated stencil printers in SMT assembly?

>> 4. How does environmental stability affect stencil printing quality?

>> 5. What role do stencils play in the solder paste printing process?

Stencil printers play a crucial role in the Surface Mount Technology (SMT) assembly process by ensuring high-quality soldering. These printers are responsible for applying solder paste onto printed circuit boards (PCBs) with precision, which is essential for achieving reliable electrical connections and minimizing defects. In this article, we will explore how stencil printers contribute to high-quality soldering in SMT and discuss key factors that influence their performance.

Introduction to SMT and Stencil Printing

SMT is a widely used method for assembling electronic components onto PCBs. It involves mounting components directly onto the surface of the board, as opposed to through-hole technology, where components are inserted through holes in the board. The first step in the SMT process is solder paste printing, which involves using a stencil printer to apply solder paste onto the PCB pads where components will be placed.

Role of Stencil Printers

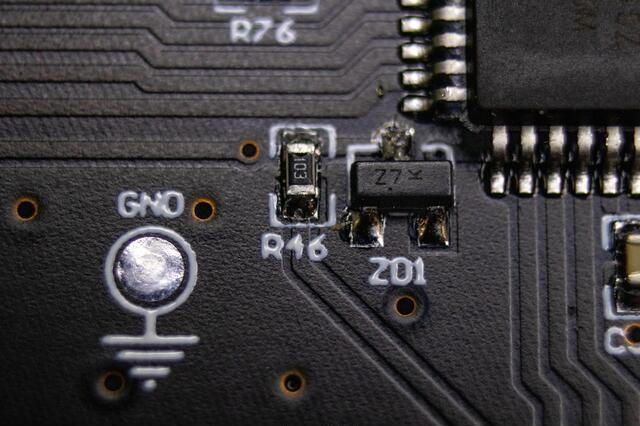

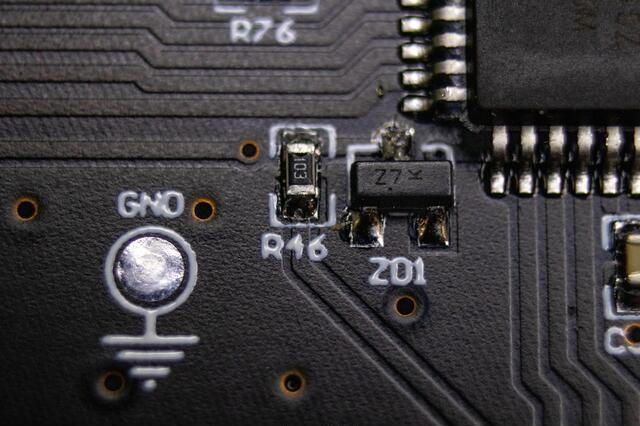

Stencil printers are specialized machines designed to accurately deposit solder paste onto PCB pads through apertures in a stencil. The stencil acts as a template, ensuring that the solder paste is applied only where needed, which is critical for achieving high-quality solder joints and preventing defects such as short circuits.

Key Factors in High-Quality Solder Paste Printing

Several factors contribute to the effectiveness of stencil printers in ensuring high-quality soldering:

1. Stencil Design and Quality: The stencil is a critical component in the solder paste printing process. It must be designed to match the PCB layout precisely, with apertures that correspond to the component pads. High-quality stencils are typically made from materials like stainless steel and are laser-cut to ensure precise aperture sizes and shapes. Recent innovations include advanced coating technologies like StenTech's BluPrint™ CVD treatment, which enhances stencil performance and longevity by providing a smooth, high-gloss surface with improved corrosion resistance.

2. Printer Precision and Accuracy: Modern stencil printers are equipped with advanced technologies such as precision motion control systems and high-resolution vision systems. These features enable accurate alignment of the stencil with the PCB and ensure that the solder paste is deposited with micron-level precision. For instance, Mycronic's MYPro S series stencil printers utilize advanced vision systems to maintain precise alignment and climate control to ensure consistent solder paste quality.

3. Process Parameters: The printing process involves several adjustable parameters, including squeegee speed, pressure, and print gap. Optimizing these parameters is crucial for achieving consistent and high-quality solder paste deposits. Manncorp's stencil printers, for example, feature dual squeegees for consistent paste deposits and parallel stencil lifting for uniform print quality.

4. Environmental Control: Maintaining a stable environment, including temperature and humidity levels, is important for preventing changes in solder paste viscosity and stencil dimensions, which can affect print quality. Mycronic's MYPro S series includes climate control features to maintain optimal conditions during printing.

5. Automated Inspection and Feedback: Many modern stencil printers integrate with automated inspection systems that monitor the printing process in real-time. This allows for immediate feedback and adjustments to ensure consistent quality. For example, Mycronic's printers can perform 2D inspections of printed boards and stencils to ensure validity for production.

Benefits of Using Stencil Printers in SMT

The use of stencil printers in SMT offers several benefits:

- Precision and Consistency: Stencil printers ensure precise and consistent application of solder paste, reducing the risk of defects and improving overall assembly quality.

- Efficiency and Cost Savings: By automating the solder paste application process, stencil printers increase production efficiency and reduce labor costs compared to manual methods.

- Adaptability: Modern stencil printers can handle a wide range of PCB designs and component types, making them versatile tools in SMT assembly.

Innovations in Solder Paste Printing Technology

Recent innovations in solder paste printing technology include the use of smart stencils and nano-coating technology. Smart stencils contain sensors that detect pressure and temperature during printing, providing real-time feedback to optimize the process. They also have a longer lifespan than traditional stencils, reducing replacement costs. Nano-coating technology involves applying a hydrophobic coating to the stencil, which helps prevent solder paste from sticking to the stencil, reducing bridging and improving print consistency.

Challenges and Future Developments

As electronic components continue to shrink in size and complexity increases, stencil printers must evolve to meet these demands. Emerging trends include the use of finer pitch components and advanced packaging technologies like MicroBGAs and Wafer Level Chip Scale Packages (WLCSPs), which require even higher precision in solder paste printing.

To address these challenges, manufacturers are focusing on improving stencil design, material quality, and printer technology. This includes developing more precise motion control systems, advanced vision inspection capabilities, and optimized process parameters for different solder paste types. Additionally, new stencil manufacturing techniques such as laser welding and micro-machining are being explored to create step stencils that can handle varying component sizes efficiently.

Step Stencil Technologies

Step stencils are designed to accommodate components with different solder paste volume requirements. They feature varying thicknesses across the stencil to ensure the correct amount of solder paste is applied for each component type. Traditional methods for creating step stencils include photochemical etching, while newer techniques like laser welding and micro-machining offer improved precision and flexibility.

Advanced Solder Paste Materials

The development of advanced solder paste materials is also crucial for improving soldering quality. Modern solder pastes are formulated to have better wetting properties, higher thermal stability, and reduced oxidation, which enhance the reliability of solder joints. For example, lead-free solder pastes are becoming more prevalent due to environmental regulations, and their performance is continually being optimized to match or exceed that of traditional lead-based pastes.

Integration with Industry 4.0

The integration of stencil printers with Industry 4.0 technologies is another significant trend. This involves connecting stencil printers to broader manufacturing networks, enabling real-time data exchange and process optimization. By leveraging IoT sensors and AI-driven analytics, manufacturers can monitor production in real-time, predict potential issues, and make adjustments to improve efficiency and quality.

Conclusion

Stencil printers are indispensable in ensuring high-quality soldering in SMT by providing precise and consistent solder paste application. Their role is critical in achieving reliable electrical connections and minimizing defects in PCB assemblies. As technology advances, the importance of stencil printers will only grow, driving innovations in stencil design, printer technology, and process optimization.

FAQ

1. What is the primary function of a stencil printer in SMT?

- The primary function of a stencil printer in SMT is to apply solder paste onto PCB pads through a stencil, ensuring precise and consistent paste deposition for reliable solder joints.

2. How do stencil printers ensure precision in solder paste application?

- Stencil printers ensure precision through advanced technologies such as precision motion control, high-resolution vision systems, and optimized process parameters like squeegee speed and pressure.

3. What are the benefits of using automated stencil printers in SMT assembly?

- Automated stencil printers offer benefits such as increased production efficiency, reduced labor costs, and improved consistency in solder paste application, leading to higher quality PCB assemblies.

4. How does environmental stability affect stencil printing quality?

- Environmental stability is crucial for maintaining consistent solder paste viscosity and preventing dimensional changes in the stencil, which can affect print quality. Stable temperature and humidity levels help ensure reliable solder paste deposition.

5. What role do stencils play in the solder paste printing process?

- Stencils act as precise templates, guiding the solder paste onto specific areas of the PCB. Their design and quality directly impact the accuracy and consistency of solder paste application.