Content Menu

● Introduction to SMT Stencils

>> Types of SMT Stencils

● Importance of SMT Stencil Racks

● Efficiency Improvements with SMT Stencil Racks

● Advanced Features of Modern SMT Stencil Racks

● Environmental and Cost Benefits

● Role of SMT Stencils in PCB Assembly

● Integration with Emerging Technologies

● Case Studies: Successful Implementation

● Future Developments in SMT Stencil Technology

● Conclusion

● FAQs

>> 1. What is the primary function of SMT stencil racks in PCB assembly?

>> 2. How do SMT stencil racks contribute to quality control in PCB manufacturing?

>> 3. What are some advanced features of modern SMT stencil racks?

>> 4. How do SMT stencil racks support environmental sustainability?

>> 5. What cost benefits do SMT stencil racks provide to manufacturers?

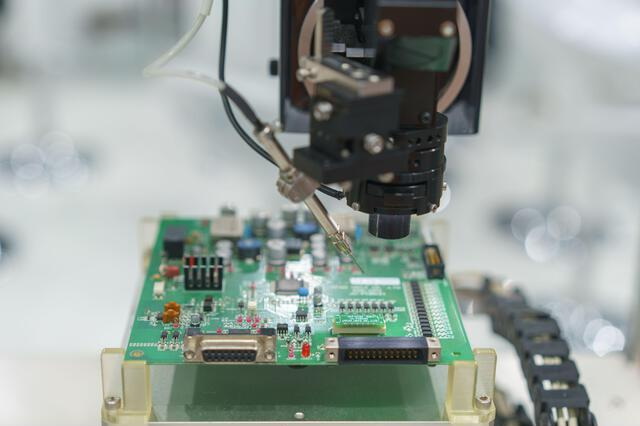

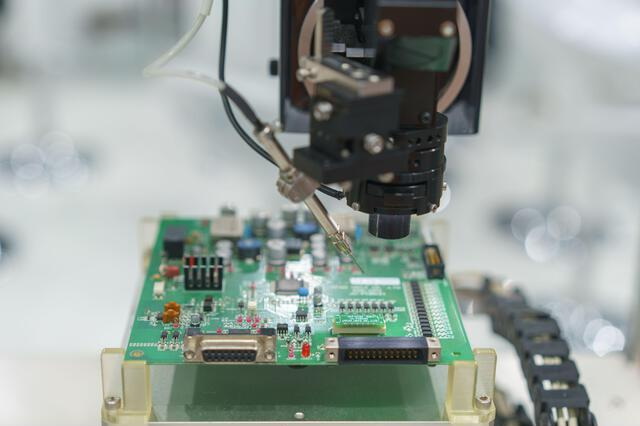

In the realm of electronics manufacturing, Surface Mount Technology (SMT) plays a pivotal role in enhancing efficiency and precision during the assembly of printed circuit boards (PCBs). A crucial component in this process is the SMT stencil, which ensures precise solder paste application onto PCB pads. However, managing these stencils effectively is equally important for maintaining production efficiency. This is where SMT stencil racks come into play, offering a systematic way to store and organize stencils, thereby optimizing the PCB assembly workflow.

Introduction to SMT Stencils

SMT stencils are thin, precision-cut templates used to apply solder paste onto PCBs. They are essential for ensuring that the correct amount of solder is deposited in the right locations, which is critical for reliable electrical connections and overall product quality. The use of SMT stencils streamlines the solder paste application process, making it faster and more consistent compared to manual methods.

Types of SMT Stencils

SMT stencils come in various forms to cater to different production needs:

- Frameless SMT Stencils: These stencils are flexible and cost-effective, ideal for prototypes and small-scale production. Made from materials like stainless steel or nickel alloys, they are easy to handle and store, adapting well to evolving PCB designs. Frameless SMT stencils are particularly useful in environments where quick changes and adjustments are necessary, providing manufacturers with the ability to rapidly switch between different PCB designs without significant downtime.

- Framed SMT Stencils: Known for their durability, framed stencils are perfect for high-volume manufacturing. The rigid frame provides stability during solder paste application, ensuring consistent results across multiple PCBs. They are preferred in mass production lines where precision and repeatability are essential. The framed SMT stencils offer robustness and reliability, critical for maintaining quality in long production runs where any deviation can lead to significant losses.

- Prototype SMT Stencils: These stencils are designed for rapid prototyping, allowing engineers to quickly test new PCB layouts. They support agility in product development, enabling fast adjustments based on initial tests and feedback. Prototype SMT stencils are designed to handle the iterative nature of product development, where frequent changes and updates are part of the process. Their adaptability ensures that any modifications in design are easily accommodated, facilitating a smooth transition from concept to final product.

Importance of SMT Stencil Racks

SMT stencil racks are specialized storage solutions designed to safely store and organize stencils used in the SMT assembly process. These racks are essential for maintaining efficiency and quality in PCB assembly by:

- Organizing Stencils: They systematically store stencils, making it easy to locate specific ones when needed. This organization reduces downtime and enhances workflow operations during PCB assembly.

- Protecting Stencils: Stencil racks provide a secure environment that shields stencils from physical damage, dust, moisture, and other potential sources of damage. This protection extends the lifespan of the stencils and ensures they remain in optimal condition for use.

- Enhancing Accessibility: Many stencil racks feature adjustable shelves or dividers, allowing users to customize storage space for stencils of different sizes. This flexibility optimizes storage efficiency and maximizes the use of available space.

- Minimizing ESD Damage: Some racks incorporate anti-static materials or coatings to prevent electrostatic discharge (ESD) damage to sensitive stencil materials. This is crucial in electronics manufacturing where ESD can cause significant harm to components.

Efficiency Improvements with SMT Stencil Racks

The integration of SMT stencil racks into the PCB assembly process offers several efficiency improvements:

- Reduced Downtime: By organizing stencils systematically, operators can quickly locate and retrieve the needed stencils, reducing the time spent searching for them. This streamlined process minimizes production downtime and accelerates assembly throughput.

- Improved Quality Control: Proper storage and handling of stencils help maintain their quality, ensuring consistent solder paste application and reducing defects in the final product. This consistency is vital for meeting industry standards for performance and reliability.

- Enhanced Production Flow: SMT stencil racks often feature mobility, allowing them to be easily moved around the production floor. This mobility facilitates efficient stencil changeovers during assembly line operations, contributing to a smoother production flow.

Advanced Features of Modern SMT Stencil Racks

Modern SMT stencil racks incorporate advanced features to further enhance efficiency and productivity:

- Smart Stencil Racks: These racks use sensors and pick-to-light systems to expedite the retrieval process. Operators can insert stencils into any available slot, and the system illuminates the precise location of the desired stencil, reducing search time significantly.

- Customizable Storage: Many racks offer adjustable shelves or dividers, allowing users to customize storage space according to their specific needs. This flexibility supports the efficient storage of stencils of varying sizes and types.

- Digital Management Systems: Some advanced racks integrate with warehouse management systems (WMS), enterprise resource planning (ERP), or manufacturing execution systems (MES) to provide full data traceability and error-proof operations. This integration enhances inventory management and reduces errors during storage and retrieval.

Environmental and Cost Benefits

The use of SMT stencil racks also contributes to environmental sustainability and cost savings:

- Environmental Sustainability: By optimizing resource use and reducing material waste, SMT stencil racks support more sustainable manufacturing practices. Improved efficiency and minimized defects reduce energy consumption and carbon emissions.

- Cost Savings: Accurate solder paste application and reduced defects lead to lower rework costs. Higher first-pass yield rates enhance profitability for manufacturers by minimizing material wastage and reducing the need for repairs.

Role of SMT Stencils in PCB Assembly

SMT stencils play a crucial role in ensuring precision and efficiency during PCB assembly:

- Precision Deposition: SMT stencils ensure precise and uniform solder paste deposition on PCB pads, minimizing solder bridging and ensuring consistent solder joint quality. This precision is essential for reliable electrical connections, enhancing product performance and longevity.

- Enhanced Efficiency: Stencils streamline the PCB assembly process by enabling simultaneous solder paste application across multiple PCBs. This reduces assembly time, accelerates production throughput, and helps manufacturers meet tight deadlines and delivery schedules.

- Consistency and Quality Control: Consistent solder paste deposition improves product quality and reliability. Uniform solder joints enhance electrical conductivity and mechanical stability, meeting industry standards for performance and reliability.

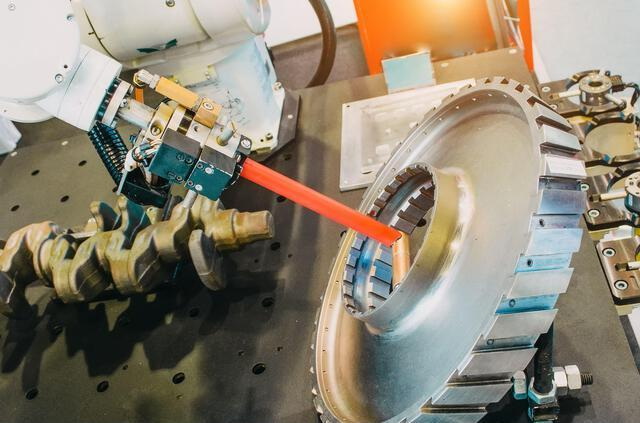

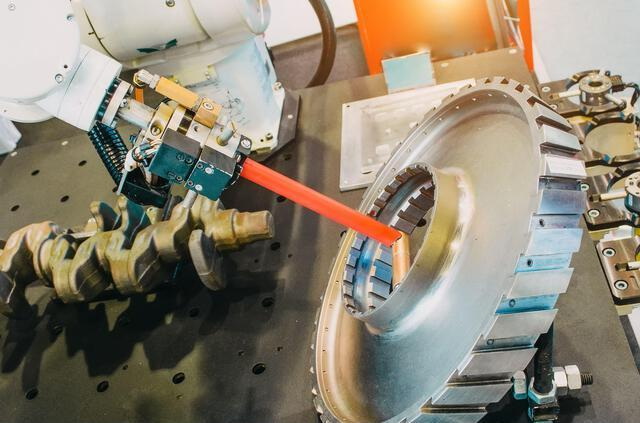

Integration with Emerging Technologies

The future of SMT stencil racks lies in their integration with emerging technologies like robotics and artificial intelligence (AI). By combining stencil racks with robotic systems, manufacturers can automate the retrieval and placement of stencils, further reducing manual labor and increasing precision. AI can be used to optimize storage and retrieval processes based on real-time production data, ensuring that the most frequently used stencils are easily accessible and that storage space is maximized.

Case Studies: Successful Implementation

Including case studies of companies that have successfully implemented SMT stencil racks can provide valuable insights into the practical benefits of these systems. For example, a company might highlight how the use of smart stencil racks reduced their production downtime by 30% and improved product quality by minimizing defects related to improper stencil handling. These real-world examples demonstrate the tangible impact of SMT stencil racks on manufacturing efficiency and product quality.

Future Developments in SMT Stencil Technology

Discussing future developments in SMT stencil technology, such as the use of advanced materials and coatings, can also enhance the article. These advancements are crucial for improving solder paste transfer efficiency and reducing defects in PCB assembly. For instance, the development of nano-coatings can enhance stencil performance by improving solder paste release and reducing underside wiping. These advancements support higher transfer efficiency and better solder joint quality, contributing to improved product reliability and performance.

Conclusion

SMT stencil racks play a vital role in enhancing efficiency in PCB assembly by providing organized storage, protecting stencils, and improving accessibility. These racks are essential for maintaining quality control, reducing downtime, and supporting sustainable manufacturing practices. As technology continues to evolve, integrating advanced features into SMT stencil racks will remain crucial for optimizing production workflows in the electronics manufacturing industry.

FAQs

1. What is the primary function of SMT stencil racks in PCB assembly?

SMT stencil racks are used to organize and store stencils, ensuring they are easily accessible and protected from damage. This organization helps reduce downtime and enhance workflow operations during PCB assembly.

2. How do SMT stencil racks contribute to quality control in PCB manufacturing?

SMT stencil racks help maintain the quality of stencils by storing them securely, which ensures consistent solder paste application and reduces defects in the final product. This consistency is vital for meeting industry standards for performance and reliability.

3. What are some advanced features of modern SMT stencil racks?

Modern SMT stencil racks often include features like sensors, pick-to-light systems, and customizable storage options. These features expedite stencil retrieval, optimize storage space, and enhance overall production efficiency.

4. How do SMT stencil racks support environmental sustainability?

By optimizing resource use and reducing material waste, SMT stencil racks contribute to more sustainable manufacturing practices. Improved efficiency and minimized defects reduce energy consumption and carbon emissions.

5. What cost benefits do SMT stencil racks provide to manufacturers?

SMT stencil racks help reduce costs by minimizing material wastage, lowering rework costs, and enhancing first-pass yield rates. These factors contribute to increased profitability for manufacturers by optimizing production efficiency.