Content Menu

● Introduction to SMT Plastic Reels

>> Key Features of SMT Plastic Reels

● Benefits of Using SMT Plastic Reels

>> Enhanced Efficiency

>> Cost Savings

>> Quality and Reliability

● Challenges and Considerations

>> Environmental Considerations

>> Technological Advancements

● Comparison of Paper and Plastic SMT Reels

● Additional Applications of SMT Plastic Reels

>> Automotive Industry

>> Consumer Electronics

● Future Trends in SMT Reel Technology

>> Sustainable Materials

>> Advanced Automation

● Conclusion

● FAQs

>> 1. What are the primary materials used for SMT plastic reels?

>> 2. How do SMT plastic reels improve production efficiency?

>> 3. What are the key considerations when selecting an SMT plastic reel?

>> 4. How do SMT plastic reels contribute to cost savings?

>> 5. What are the common reel sizes and widths used in SMT manufacturing?

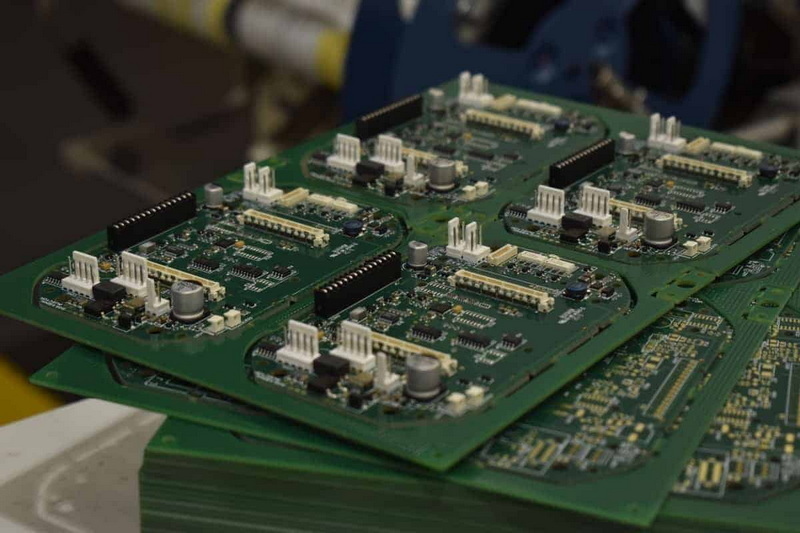

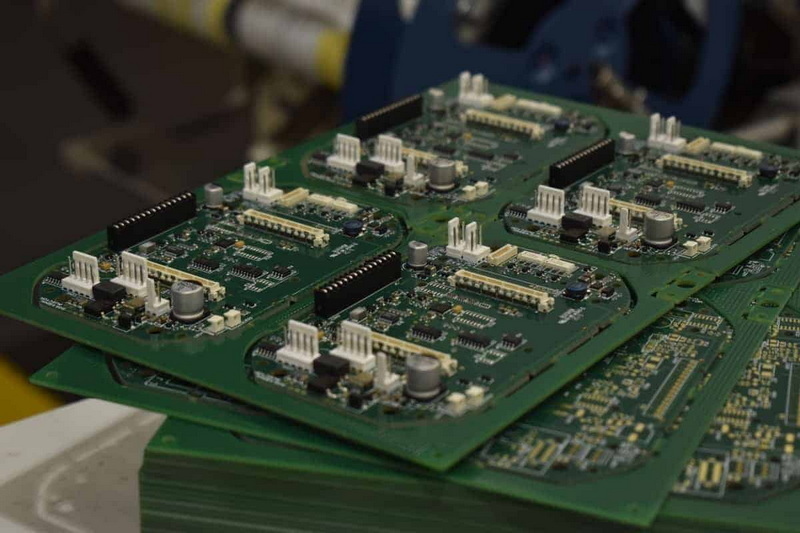

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by enabling the production of smaller, more complex electronic devices with higher component densities. A crucial component in this process is the SMT plastic reel, which plays a significant role in improving efficiency in component handling. This article will delve into the specifics of how SMT plastic reels enhance production efficiency, their key features, and the benefits they offer in modern electronics manufacturing.

Introduction to SMT Plastic Reels

SMT plastic reels are designed to store and dispense surface mount components during the assembly process. These reels are essential for maintaining component organization and facilitating easy pickup and placement onto printed circuit boards (PCBs) by pick-and-place machines. The use of plastic reels in SMT manufacturing offers several advantages, including durability, cost-effectiveness, and compatibility with a wide range of components.

Key Features of SMT Plastic Reels

1. Material and Durability: High-quality SMT plastic reels are typically made from materials like polystyrene (PS) or polycarbonate (PC), which provide strength and resistance to wear and tear. These materials ensure that the reels can withstand the rigors of the manufacturing environment without compromising the integrity of the components.

2. Customization: Manufacturers offer custom plastic reels tailored to specific industry needs, including custom dimensions and spacing for embossed cavities. This customization allows for optimal component protection and efficient handling.

3. ESD Protection: Many SMT plastic reels are designed with electrostatic discharge (ESD) protection to safeguard sensitive electronic components from damage during storage and transport. ESD protection is crucial because it prevents costly defects or failures in finished products.

4. Compatibility with Pick-and-Place Machines: The dimensions of SMT plastic reels, such as reel diameter and width, must align with the specifications of pick-and-place machines to ensure smooth operation and minimize downtime.

Benefits of Using SMT Plastic Reels

Enhanced Efficiency

- Automated Assembly: SMT plastic reels enable the transition from manual to automated assembly processes. This shift significantly reduces labor costs and increases production speed, as components can be quickly picked up from reels and placed onto PCBs.

- Reduced Setup Time: Components packaged on reels allow for faster setup times compared to those stored in trays or tubes. This efficiency is particularly beneficial for high-volume production lines where minimizing setup time can lead to substantial cost savings.

- Increased Component Density: SMT components are smaller and can be placed at higher densities on PCBs, which is facilitated by the organized storage and dispensing provided by plastic reels.

Cost Savings

- Lower Capital Investment: By utilizing SMT plastic reels, manufacturers can avoid the high upfront costs associated with purchasing new SMD lines or tray modules. The efficiency gains from reel-based systems can offset the need for expensive equipment upgrades.

- Reduced Labor Costs: Automated processes reduce the number of shifts and labor required, leading to lower operational costs over time.

Quality and Reliability

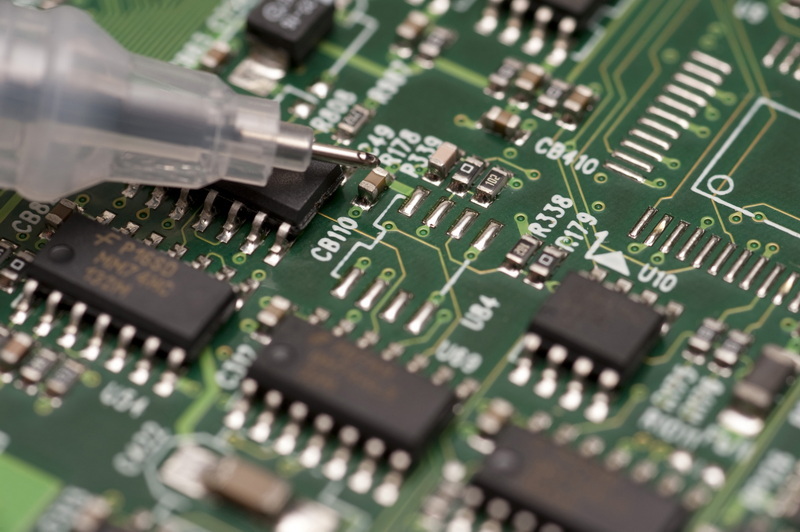

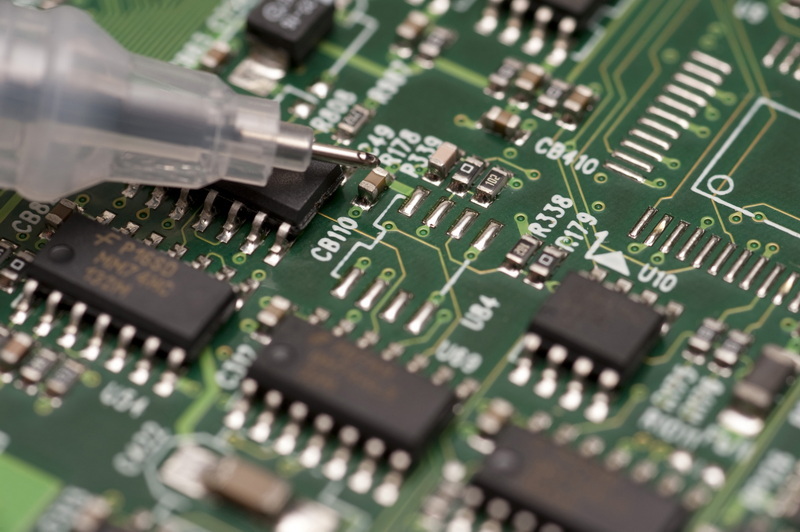

- Minimized Errors: Automated placement using SMT plastic reels reduces the likelihood of human error, ensuring that components are accurately positioned on PCBs. This precision is crucial for maintaining product quality and reliability.

- Component Protection: The embossed cavities in carrier tapes protect components from damage during storage and transport, reducing the risk of defective products and costly rework.

Challenges and Considerations

Despite the numerous benefits, there are challenges associated with SMT plastic reels. For instance, improper handling or using the wrong type of reel can lead to assembly errors and defective products. Therefore, it is crucial to maintain and handle SMT reels properly to ensure optimal performance.

Environmental Considerations

While plastic reels offer superior protection and durability, they raise environmental concerns due to their non-biodegradable nature. In contrast, paper reels are more environmentally friendly but may not provide the same level of component protection as plastic reels. Manufacturers must weigh these factors when deciding between paper and plastic SMT reels.

Technological Advancements

The electronics manufacturing industry is continuously evolving, with innovations aimed at improving SMT reel technology. Developments include new plastic formulations to address issues like camber in polystyrene reels and the integration of technologies like RFID tags for better inventory management.

Comparison of Paper and Plastic SMT Reels

| Feature | Paper SMT Reels | Plastic SMT Reels |

| Material | Cardboard | Polystyrene, Polycarbonate |

| Cost | Less expensive | More expensive |

| Environmental Impact | Biodegradable, recyclable | Non-biodegradable |

| Protection | Suitable for small passive components | Better protection against physical damage and ESD |

| Durability | Less durable | More durable, reusable |

Additional Applications of SMT Plastic Reels

SMT plastic reels are not only crucial in the general electronics manufacturing sector but also play significant roles in specialized industries. For instance, in the automotive sector, where reliability and durability are paramount, SMT plastic reels ensure that components are handled with precision, reducing the risk of defects in critical automotive systems. Similarly, in consumer electronics, where high-volume production is common, SMT plastic reels facilitate efficient assembly processes, enabling manufacturers to meet demanding production schedules.

Automotive Industry

In the automotive industry, the use of SMT plastic reels is critical for ensuring the reliability of electronic components in vehicles. These components are often used in safety-critical systems such as airbag controllers and anti-lock braking systems (ABS). The precision and reliability offered by SMT plastic reels help maintain the high standards required in automotive electronics.

Consumer Electronics

Consumer electronics manufacturers benefit from the efficiency and cost-effectiveness of SMT plastic reels. With the rapid pace of innovation in this sector, manufacturers must quickly adapt to new component designs and production volumes. SMT plastic reels enable them to do so by providing a flexible and efficient component handling system.

Future Trends in SMT Reel Technology

As the electronics industry continues to evolve, innovations in SMT reel technology are expected to focus on sustainability and advanced materials. There is a growing interest in developing biodegradable or recyclable materials for SMT reels to reduce environmental impact. Additionally, advancements in automation and inventory management systems will further enhance the efficiency of SMT manufacturing processes.

Sustainable Materials

The development of sustainable materials for SMT reels is becoming increasingly important. Manufacturers are exploring alternatives to traditional plastics, such as bioplastics or recycled materials, which can reduce waste and minimize environmental impact without compromising component protection.

Advanced Automation

Future advancements in automation will likely include more sophisticated pick-and-place machines capable of handling a wider range of components with greater precision. This will further enhance the efficiency of SMT manufacturing lines and reduce the need for manual intervention.

Conclusion

SMT plastic reels play a vital role in enhancing efficiency in component handling within the electronics manufacturing industry. By facilitating automated assembly, reducing setup times, and minimizing errors, these reels contribute significantly to cost savings and improved product quality. As technology continues to evolve, the importance of SMT plastic reels in maintaining competitive production lines will only grow.

FAQs

1. What are the primary materials used for SMT plastic reels?

SMT plastic reels are commonly made from materials such as polystyrene (PS) and polycarbonate (PC), which offer durability and cost-effectiveness.

2. How do SMT plastic reels improve production efficiency?

SMT plastic reels improve efficiency by enabling automated assembly processes, reducing setup times, and minimizing manual handling errors. This leads to faster production speeds and lower labor costs.

3. What are the key considerations when selecting an SMT plastic reel?

Key considerations include ensuring compatibility with pick-and-place machines, selecting the appropriate reel size and width for the components, and choosing materials that provide adequate protection against ESD.

4. How do SMT plastic reels contribute to cost savings?

SMT plastic reels contribute to cost savings by reducing the need for expensive equipment upgrades, lowering labor costs through automation, and minimizing errors that lead to rework.

5. What are the common reel sizes and widths used in SMT manufacturing?

Common reel sizes include diameters of 7 inches to 13 inches, while reel widths vary from 4mm to 56mm, depending on the component size and type.