Content Menu

● Understanding SMT and Its Importance in PCB Assembly

● Types of Defects in SMT PCB Assemblies

● How SMT PCB Test Machines Identify Defects

>> 1. Automated Optical Inspection (AOI)

>> 2. In-Circuit Testing (ICT)

>> 3. X-ray Inspection

>> 4. Solder Paste Inspection (SPI)

>> 5. PCB Text and Marking Defect Detection

● Advanced Technologies Enhancing SMT PCB Test Machines

● Benefits of Using SMT PCB Test Machines

● Integration of SMT PCB Test Machines in the Assembly Line

● Challenges and Considerations in SMT PCB Testing

● Future Trends in SMT PCB Test Machines

● Conclusion

● FAQ

>> 1. What is an SMT PCB test machine?

>> 2. How does Automated Optical Inspection (AOI) work in SMT testing?

>> 3. Why is X-ray inspection important for SMT PCB testing?

>> 4. Can SMT PCB test machines detect defects in PCB text areas?

>> 5. What are the advantages of integrating SMT PCB test machines in the assembly line?

● Citations:

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by enabling the direct mounting of electronic components onto the surface of printed circuit boards (PCBs). SMT PCB test machines play a crucial role in ensuring the quality and reliability of these assemblies by identifying defects that can compromise functionality. This article explores how SMT PCB test machines help in detecting PCB defects, the types of defects commonly found, and the technologies involved in the testing process.

Understanding SMT and Its Importance in PCB Assembly

Surface-mount technology (SMT) involves mounting electronic components, called surface-mount devices (SMDs), directly onto the surface of PCBs, replacing the older through-hole technology. SMT allows for smaller components, higher circuit density, and automated assembly processes, which reduce costs and improve product quality.

SMT PCB test machines are specialized equipment designed to inspect and verify the quality of SMT assemblies during or after the manufacturing process. These machines help detect defects early, reducing rework, scrap, and improving overall yield. As the complexity of PCB designs increases and component sizes shrink, the role of SMT PCB test machines becomes even more critical in maintaining manufacturing standards and ensuring product reliability.

Types of Defects in SMT PCB Assemblies

Before delving into how SMT PCB test machines identify defects, it is important to understand the common types of defects that occur in SMT assemblies:

- Soldering Defects: Includes insufficient solder, solder bridges (short circuits), cold solder joints, and dry joints. These defects can cause intermittent or permanent electrical failures.

- Component Placement Defects: Misaligned, missing, or incorrectly oriented components can lead to malfunction or failure of the circuit.

- Component Damage: Cracked, broken, or damaged components during handling or soldering affect the performance and reliability of the PCB.

- PCB Surface Defects: Contamination, corrosion, or damage to the PCB surface can impair electrical connectivity and cause failures.

- Text and Marking Defects: Errors or defects in PCB text areas such as unclear, missing, or shifted characters can cause assembly errors or complicate troubleshooting and maintenance.

Identifying these defects early in the manufacturing process is essential to avoid costly rework and ensure the final product meets quality standards.

How SMT PCB Test Machines Identify Defects

SMT PCB test machines use a combination of advanced technologies and methods to detect defects with high accuracy and speed. These include:

1. Automated Optical Inspection (AOI)

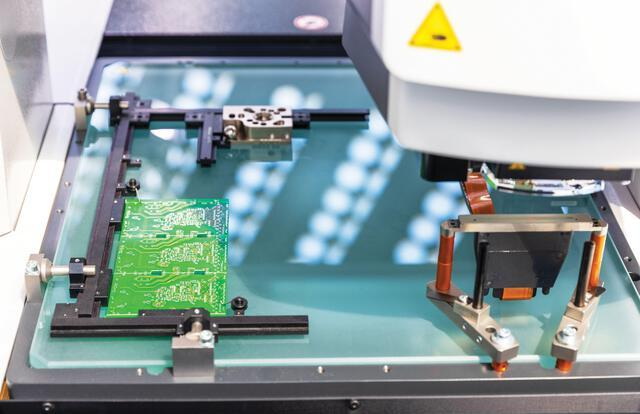

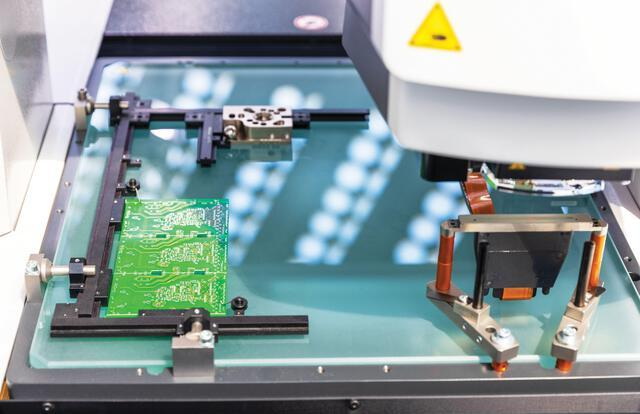

Automated Optical Inspection (AOI) is one of the most widely used SMT PCB test machine technologies. AOI machines use high-resolution cameras to capture detailed images of the PCB surface and components. These images are then compared against a reference design or "golden board" using sophisticated image processing algorithms.

The AOI system inspects solder joints, component placement, polarity, and the presence of components. It can detect a variety of defects such as missing components, misaligned parts, solder bridges, insufficient solder, and foreign objects. AOI machines are non-contact, fast, and capable of inspecting every board in the production line, making them essential for high-volume SMT manufacturing.

2. In-Circuit Testing (ICT)

In-Circuit Testing (ICT) is an electrical testing method where the SMT PCB test machine applies electrical signals to test points on the PCB and measures the response. ICT checks for open circuits, short circuits, incorrect component values, and verifies the functionality of individual components.

ICT machines typically use a "bed-of-nails" fixture that physically contacts the PCB at designated test points. This method is highly effective for functional testing but requires custom fixtures and can be time-consuming for complex boards. ICT complements AOI by verifying electrical integrity beyond visual inspection.

3. X-ray Inspection

X-ray inspection is crucial for detecting defects hidden beneath components, especially in complex SMT packages such as Ball Grid Arrays (BGAs) and Chip Scale Packages (CSPs). These components have solder joints that are not visible to optical systems.

X-ray SMT PCB test machines generate images by passing X-rays through the PCB and capturing the internal structure. This allows detection of solder voids, insufficient solder, bridging, and misalignment under components. X-ray inspection ensures the reliability of solder joints in critical areas and is often used as a secondary inspection after AOI.

4. Solder Paste Inspection (SPI)

Solder Paste Inspection (SPI) machines inspect the solder paste deposits applied to the PCB pads before component placement. Proper solder paste volume, shape, and placement are critical to achieving good solder joints during reflow soldering.

SPI SMT PCB test machines use 3D imaging or laser scanning to measure solder paste height, volume, and area coverage. Detecting solder paste defects early helps prevent soldering issues such as insufficient solder, bridging, or tombstoning of components.

5. PCB Text and Marking Defect Detection

Beyond component and solder joint inspection, SMT PCB test machines increasingly incorporate advanced computer vision and machine learning algorithms to detect defects in PCB text and marking areas. These systems analyze pixels at a granular level to distinguish between normal text variations and actual defects such as missing, blurred, or shifted characters.

This capability is critical because defects in PCB text can lead to assembly errors or difficulties in identifying board revisions and troubleshooting. By accurately classifying text defects, SMT PCB test machines reduce false positives and improve overall defect detection accuracy.

Advanced Technologies Enhancing SMT PCB Test Machines

The continuous evolution of SMT PCB test machines is driven by advancements in artificial intelligence (AI), machine learning, and image processing. Modern SMT PCB test machines leverage these technologies to improve defect detection rates and reduce false alarms.

- Machine Learning Algorithms: These algorithms learn from large datasets of PCB images to differentiate between acceptable variations and true defects. This reduces the need for manual parameter tuning and improves adaptability to new PCB designs.

- 3D Imaging: Some AOI and SPI machines incorporate 3D imaging to better assess solder joint volume and component height, providing more accurate defect identification.

- Cloud-Based Data Analysis: Integration with cloud platforms allows manufacturers to collect, analyze, and benchmark defect data across multiple production lines and sites, enabling continuous process improvement.

These innovations make SMT PCB test machines more intelligent, flexible, and effective in identifying defects that impact product quality.

Benefits of Using SMT PCB Test Machines

- Improved Quality Control: Early detection of defects reduces defective products reaching customers, enhancing brand reputation.

- Increased Production Efficiency: Automated testing speeds up inspection and reduces manual labor, allowing faster throughput.

- Reduced Costs: Minimizes rework, scrap, and warranty claims, saving material and labor costs.

- Enhanced Reliability: Ensures that PCBs meet stringent quality standards for performance and durability, critical in industries such as automotive, aerospace, and medical devices.

- Comprehensive Defect Coverage: Combines visual, electrical, and X-ray inspection for thorough testing, covering a wide range of potential defects.

- Data-Driven Process Improvement: Detailed defect data helps manufacturers identify root causes and optimize manufacturing processes.

Integration of SMT PCB Test Machines in the Assembly Line

SMT PCB test machines are integrated at various stages in the SMT assembly line to provide comprehensive quality control:

- Post-Solder Paste Application: SPI machines verify solder paste quality before component placement, preventing downstream soldering defects.

- Post-Component Placement: AOI machines check component placement accuracy, polarity, and presence to catch placement errors early.

- Post-Reflow Soldering: AOI and X-ray machines inspect solder joints and hidden defects, ensuring assembly integrity.

- Final Testing: ICT machines perform electrical tests to verify circuit functionality and detect electrical faults.

This multi-stage inspection approach ensures defects are caught as early as possible, improving yield and reducing costly rework or scrap. Additionally, feedback loops from test machines to upstream processes enable continuous manufacturing optimization.

Challenges and Considerations in SMT PCB Testing

While SMT PCB test machines provide significant benefits, manufacturers must consider several challenges:

- Cost of Equipment and Fixtures: High-end test machines and custom ICT fixtures can be expensive, especially for low-volume production.

- Complexity of PCB Designs: Increasing PCB complexity requires advanced inspection capabilities and sophisticated programming.

- False Positives and Negatives: Balancing sensitivity and specificity in defect detection is critical to avoid unnecessary rework or missed defects.

- Training and Expertise: Skilled operators and engineers are needed to program, maintain, and interpret test machine results effectively.

- Integration with Manufacturing Execution Systems (MES): Seamless data exchange between test machines and MES enhances traceability and process control.

Addressing these challenges involves careful planning, investment in training, and selecting the right combination of test technologies for each production environment.

Future Trends in SMT PCB Test Machines

The future of SMT PCB test machines is shaped by ongoing technological advancements and market demands:

- Artificial Intelligence and Deep Learning: More sophisticated AI models will enable even higher accuracy in defect classification and predictive maintenance.

- Real-Time Inline Inspection: Faster machines integrated directly into production lines will provide immediate feedback and enable zero-defect manufacturing.

- Miniaturization and 3D PCB Inspection: As PCBs become more compact and multi-layered, test machines will evolve to inspect complex 3D structures.

- Robotics and Automation: Automated handling and sorting systems will work alongside test machines to streamline production flow.

- Sustainability and Energy Efficiency: New machine designs will focus on reducing energy consumption and environmental impact.

These trends will further enhance the role of SMT PCB test machines in delivering high-quality, reliable electronic products.

Conclusion

SMT PCB test machines are indispensable tools in modern electronics manufacturing, providing automated, precise, and comprehensive inspection capabilities. By leveraging technologies such as automated optical inspection, in-circuit testing, X-ray inspection, solder paste inspection, and advanced image processing for text defect detection, these machines significantly enhance the identification of PCB defects.

Their integration into the SMT assembly line improves product quality, reduces costs, and increases production efficiency, making them essential for high-volume and high-reliability PCB manufacturing. As technology advances, SMT PCB test machines will continue to evolve, offering smarter, faster, and more accurate defect detection solutions that meet the demands of increasingly complex electronic assemblies.

FAQ

1. What is an SMT PCB test machine?

An SMT PCB test machine is specialized equipment used to inspect and test printed circuit boards assembled with surface-mount technology. It detects defects in component placement, soldering, and PCB surface quality to ensure product reliability.

2. How does Automated Optical Inspection (AOI) work in SMT testing?

AOI uses cameras to capture images of the PCB and compares them to a reference design to identify visual defects such as missing components, misalignments, and soldering issues. It is fast, non-contact, and widely used in SMT production lines.

3. Why is X-ray inspection important for SMT PCB testing?

X-ray inspection detects hidden defects like solder voids and bridging under components such as BGAs, which are not visible through optical inspection. This ensures the integrity of solder joints in complex assemblies.

4. Can SMT PCB test machines detect defects in PCB text areas?

Yes, advanced SMT PCB test machines use pixel-level classification and machine learning to accurately detect defects in PCB text regions, such as missing or blurred characters, preventing false defect identification caused by normal text variations.

5. What are the advantages of integrating SMT PCB test machines in the assembly line?

Integrating SMT PCB test machines at multiple stages improves defect detection early, enhances product quality, reduces rework and scrap, speeds up production, and ensures high reliability of the final product.

Citations:

1.https://www.mycronic.com/product-areas/pcb-assembly/smt/

2.https://www.pcbunlimited.com/t/smt-equipment

3.https://app.lpkfusa.com/products/pcb_prototyping/smt_assembling/

4.https://www.smtfactory.com/pcb-ict-testing.html

5.https://www.nextpcb.com/blog/top-10-smt-machines-worldwide

6.https://patents.google.com/patent/CN112419260A/zh

7.https://en.wikipedia.org/wiki/Surface-mount_technology

https://www.ednasia.com/top-12-incredible-techniques-to-control-the-quality-of-pcb-smt-assembly/