Content Menu

● Introduction to SMT and PCB Symbols

>> Understanding SMT

>> PCB Symbols

● Impact of SMT PCB Symbols on Circuit Design

>> Enhanced Visualization

>> Improved Communication

>> Design Efficiency

>> Component Selection

>> Manufacturing Considerations

● Best Practices for Using SMT PCB Symbols

>> Standardization

>> Component Library Management

>> Design for Manufacturability (DFM)

● Challenges and Limitations

● Advanced Applications of SMT PCB Symbols

>> High-Speed Design

>> IoT and Wearable Devices

>> Automotive Electronics

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary advantages of using SMT in PCB design?

>> 2. How do SMT PCB symbols aid in component selection?

>> 3. What are some common SMT component packages?

>> 4. Why is standardization important for SMT PCB symbols?

>> 5. How do SMT PCB symbols impact the manufacturing process?

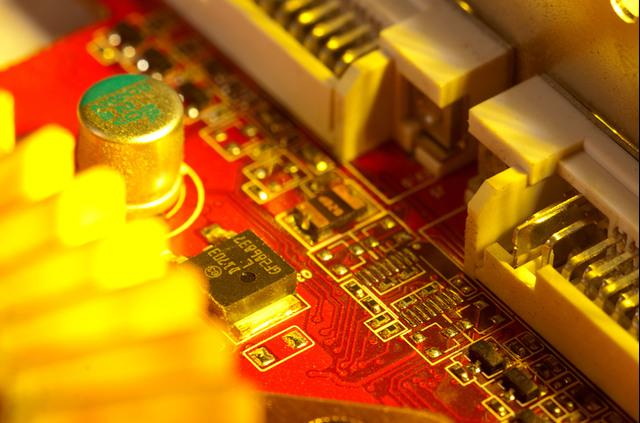

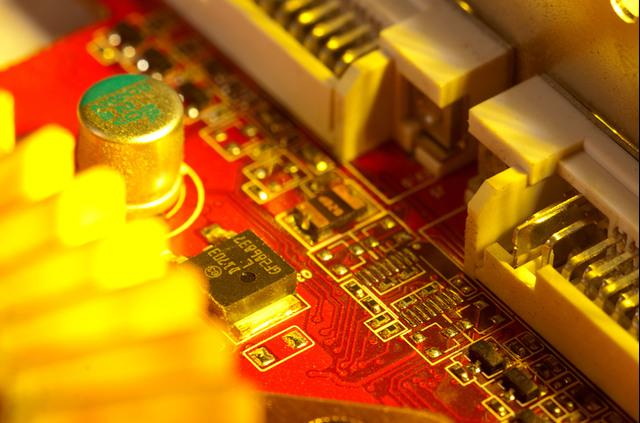

In the realm of electronics manufacturing, Surface Mount Technology (SMT) has revolutionized the way components are integrated into printed circuit boards (PCBs). SMT PCB symbols play a crucial role in the design process, enabling engineers to visualize and communicate complex circuitry effectively. This article delves into the impact of SMT PCB symbols on circuit design, exploring their significance, applications, and best practices.

Introduction to SMT and PCB Symbols

Understanding SMT

Surface Mount Technology (SMT) involves mounting electronic components directly onto the surface of a PCB, eliminating the need for through-hole components. This method has become indispensable in modern electronics due to its ability to miniaturize components, increase circuit density, and reduce production costs. SMT components are smaller and lighter, allowing for more efficient use of space on the PCB, which is crucial for compact electronic devices.

PCB Symbols

PCB symbols are graphical representations of electronic components used in schematic diagrams and PCB layouts. These symbols help engineers visualize complex circuitry and wiring connections during the design process. They are abstract and not drawn to scale, using shapes like rectangles, circles, and triangles to depict different components. Lines between symbols show electrical connectivity, and each symbol includes information such as component name, value, and other identifiers.

Impact of SMT PCB Symbols on Circuit Design

Enhanced Visualization

SMT PCB symbols enhance the visualization of circuit designs by providing a clear and concise representation of components and their connections. This clarity is essential for identifying potential issues early in the design phase, reducing the likelihood of errors during manufacturing. For instance, visualizing the layout helps designers ensure that components are placed in a way that minimizes electromagnetic interference (EMI) and optimizes thermal dissipation.

Improved Communication

The use of standardized SMT PCB symbols facilitates communication among design teams and manufacturers. These symbols ensure that all stakeholders have a consistent understanding of the circuit layout, which is vital for ensuring that the final product meets specifications. This consistency also helps in troubleshooting and debugging, as any discrepancies can be quickly identified and addressed.

Design Efficiency

SMT PCB symbols streamline the design process by allowing engineers to focus on the logical connections between components rather than their physical appearance. This abstraction enables faster iteration and refinement of designs, leading to more efficient development cycles. Additionally, symbols can be easily reused across different projects, reducing the time spent on creating new designs from scratch.

Component Selection

SMT PCB symbols aid in the selection of appropriate components by providing a visual representation of how components will fit on the PCB. This helps designers ensure that the chosen components are compatible with the available space and can be efficiently assembled using SMT techniques. For example, symbols can highlight potential issues with component sizes or lead types, allowing designers to make informed decisions about component selection.

Manufacturing Considerations

The choice of SMT components and their symbols must consider manufacturing constraints. For instance, smaller components like 0402 or 0603 packages require precise placement and soldering techniques, which can be challenging in high-volume production. Symbols help designers assess these challenges early on, ensuring that the design is optimized for manufacturability. This includes considerations for pick-and-place machines, solder paste application, and reflow oven settings.

Best Practices for Using SMT PCB Symbols

Standardization

Adhering to standardized symbol conventions, such as those from IEC and IEEE, ensures consistency across different schematics and layouts. This standardization reduces confusion and facilitates collaboration among designers and manufacturers. Standardization also helps in maintaining a uniform component library, which is essential for efficient design and production.

Component Library Management

Maintaining an up-to-date component library with accurate symbols is crucial. This library should include detailed information about each component, such as package type, footprint, and electrical characteristics. A well-managed library helps designers quickly find suitable components for their designs and ensures that the selected components are compatible with the manufacturing process.

Design for Manufacturability (DFM)

Designers should consider manufacturability when selecting SMT components and creating symbols. Factors such as component size, lead type, and soldering requirements must be evaluated to ensure that the design can be efficiently produced. DFM principles also involve optimizing the PCB layout to reduce assembly costs and improve yield rates. This includes strategies like minimizing component density in areas prone to thermal stress and ensuring adequate spacing for easy inspection and repair.

Challenges and Limitations

While SMT PCB symbols offer numerous benefits, there are challenges associated with their use. One of the primary concerns is the complexity of managing a large number of small components, which can increase the risk of errors during assembly. Additionally, the high density of SMT components can lead to thermal management issues if not properly addressed. For example, densely packed components can generate excessive heat, affecting the reliability and lifespan of the device. Designers must carefully plan heat dissipation paths and possibly incorporate thermal management solutions like heat sinks or thermal vias.

Advanced Applications of SMT PCB Symbols

High-Speed Design

In high-speed designs, SMT PCB symbols play a critical role in ensuring signal integrity. Symbols help designers visualize and manage signal paths, allowing them to optimize trace lengths and minimize signal degradation. This is particularly important in applications like high-speed data transmission, where even small delays can significantly impact performance.

IoT and Wearable Devices

The Internet of Things (IoT) and wearable devices require compact, low-power electronics. SMT PCB symbols are essential in these applications, enabling designers to create highly integrated circuits that fit within tight space constraints. Symbols help ensure that components are selected and placed to maximize efficiency and minimize power consumption.

Automotive Electronics

In automotive electronics, reliability and durability are paramount. SMT PCB symbols help designers create robust circuits that can withstand harsh environmental conditions. By carefully selecting components and optimizing their placement, designers can ensure that automotive systems meet stringent reliability standards.

Conclusion

SMT PCB symbols are indispensable tools in modern electronics design, offering enhanced visualization, improved communication, and design efficiency. By understanding the role of these symbols and adhering to best practices, engineers can optimize their circuit designs for better performance and manufacturability. As electronics continue to evolve towards smaller, more complex systems, the importance of SMT PCB symbols will only grow.

Frequently Asked Questions

1. What are the primary advantages of using SMT in PCB design?

The primary advantages of using SMT in PCB design include a smaller footprint, lower production costs, higher component density, quicker turnaround times, and improved design flexibility.

2. How do SMT PCB symbols aid in component selection?

SMT PCB symbols aid in component selection by visually representing how components will fit on the PCB, ensuring compatibility with available space and assembly requirements.

3. What are some common SMT component packages?

Common SMT component packages include 0402, 0603, QFN (Quad Flat No-Lead), and BGA (Ball Grid Array), each suited to different applications based on size and complexity.

4. Why is standardization important for SMT PCB symbols?

Standardization is important for SMT PCB symbols because it ensures consistency across different designs and manufacturers, facilitating collaboration and reducing errors.

5. How do SMT PCB symbols impact the manufacturing process?

SMT PCB symbols impact the manufacturing process by providing clear instructions for component placement and soldering, which is crucial for efficient and error-free assembly.