Content Menu

● Introduction to SMT Manufacturing and PCB Loaders

>> Role of PCB Loaders in SMT Production

● Features of SMT PCB Loaders

● Benefits of Using SMT PCB Loaders

● Types of SMT PCB Loaders

● Future Trends in SMT PCB Loader Technology

● Impact of SMT on PCB Assembly

● Integration of Advanced Technologies in SMT

● Conclusion

● Frequently Asked Questions

>> 1. What is the primary function of an SMT PCB loader?

>> 2. How do SMT PCB loaders improve production efficiency?

>> 3. What types of PCBs can SMT loaders handle?

>> 4. What are the cost benefits of using SMT PCB loaders?

>> 5. How do advanced technologies like IoT and AI enhance SMT PCB loaders?

● Citations:

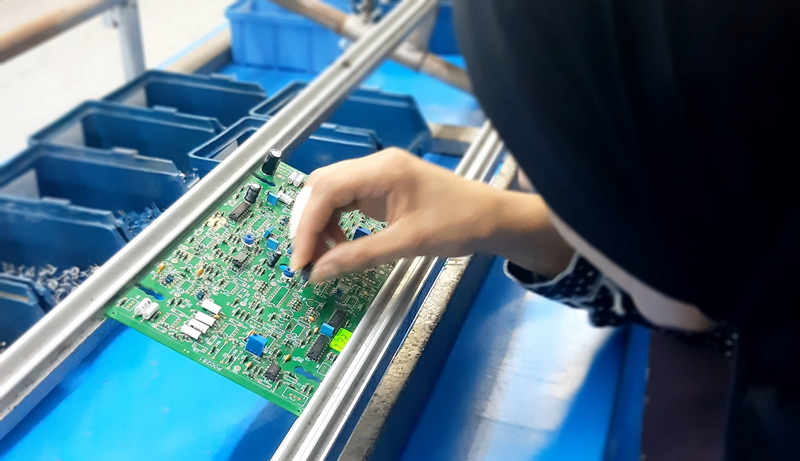

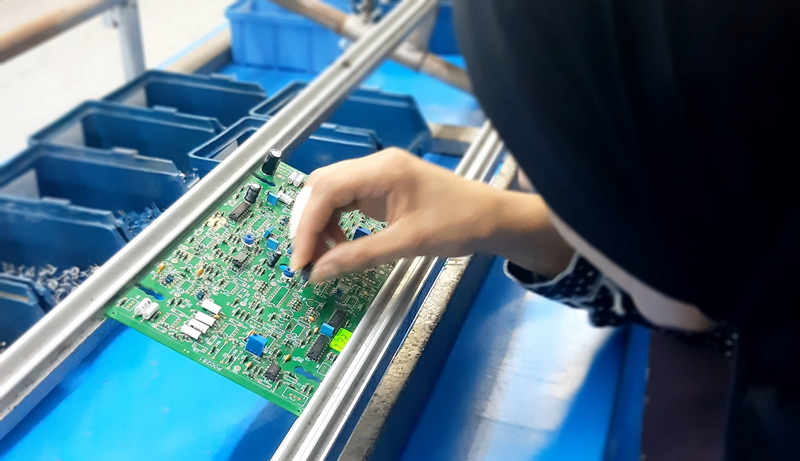

In the realm of Surface Mount Technology (SMT) manufacturing, efficiency and precision are paramount for producing high-quality electronic components. One crucial piece of equipment that significantly enhances production efficiency is the SMT PCB loader. These machines automate the loading process of printed circuit boards (PCBs) onto the production line, ensuring a seamless workflow and minimizing manual errors. This article delves into the role of SMT PCB loaders in improving production efficiency, their features, and how they contribute to the overall optimization of SMT manufacturing processes.

Introduction to SMT Manufacturing and PCB Loaders

SMT manufacturing involves the assembly of electronic components onto PCBs using automated processes. This technology has revolutionized the electronics industry by enabling the production of smaller, lighter, and more efficient devices. A key component in this process is the PCB loader, which is designed to load PCBs onto the production line efficiently and accurately.

Role of PCB Loaders in SMT Production

PCB loaders play a critical role in SMT production by automating the initial stages of the assembly process. They ensure that PCBs are consistently and accurately placed onto the conveyor belt, ready for further processing stages such as solder paste application, component placement, and reflow soldering. This automation not only speeds up the production cycle but also reduces the risk of human error, which can lead to defective products and increased production costs.

Features of SMT PCB Loaders

SMT PCB loaders are equipped with advanced features that make them indispensable in modern SMT manufacturing:

- PLC Control Systems: These systems provide precise control over the loading process, allowing for easy operation and maintenance. PLCs can be programmed to handle different types of PCBs and production scenarios, ensuring flexibility and adaptability in the production line.

- Advanced Vision Systems: Some loaders are equipped with vision systems that enable accurate detection of component positions and orientations. This ensures that components are placed correctly on the PCB, enhancing overall product quality.

- Adaptability: SMT loaders are designed to accommodate various PCB sizes and types. This adaptability allows manufacturers to integrate these machines into existing production lines without significant modifications, thereby enhancing overall manufacturing efficiency.

- Real-Time Monitoring and Predictive Maintenance: Modern loaders often incorporate smart technologies like IoT and AI, enabling real-time monitoring and predictive maintenance. This reduces downtime and optimizes production capabilities, ensuring that the manufacturing process runs smoothly and efficiently.

Benefits of Using SMT PCB Loaders

The integration of SMT PCB loaders into production lines offers several benefits that contribute to improved efficiency and productivity:

- Increased Efficiency: By automating the loading process, manufacturers can handle multiple PCBs simultaneously, saving time and reducing the risk of damage to delicate components. This leads to higher production volumes in less time.

- Cost Savings: Automating the loading and unloading processes reduces the need for manual labor, resulting in savings on wages and related expenses. Additionally, increased efficiency allows for higher production volumes, further enhancing cost-effectiveness.

- Enhanced Quality Control: SMT PCB loaders minimize errors during the loading and unloading process, leading to improved customer satisfaction and fewer returns or warranty claims. This is crucial in maintaining high-quality standards in electronics manufacturing.

- Versatility: These machines can handle different types of PCBs, making them a versatile solution for large-scale manufacturing operations. This adaptability ensures that manufacturers can easily switch between different production runs without significant setup changes.

Types of SMT PCB Loaders

There are various types of SMT PCB loaders designed to meet different production needs:

- SMT Magazine Loaders: These loaders take PCBs stored in magazines and individually feed them to pick-and-place machines. They are ideal for high-speed automated processes in SMT assembly lines.

- Vacuum Loaders: These use vacuum absorption to handle PCBs, ensuring precise control and minimizing the risk of damage. They are particularly useful in environments where dust and debris must be minimized.

Future Trends in SMT PCB Loader Technology

The field of SMT manufacturing continues to evolve, and advancements in PCB loader set technology are on the horizon. Here are some trends to watch:

- Enhanced Automation and AI Integration: Future SMT PCB loader sets are likely to incorporate advanced automation features and artificial intelligence (AI). These enhancements will enable loaders to adapt to varying PCB designs and production requirements dynamically.

- Improved Connectivity and IoT: Integration with the Internet of Things (IoT) will allow PCB loader sets to communicate seamlessly with other equipment in the assembly line. This connectivity will facilitate real-time data sharing and process optimization.

- Eco-Friendly Designs: As sustainability becomes a priority, manufacturers will develop SMT PCB loader sets with eco-friendly features. These designs will focus on reducing energy consumption and minimizing waste.

Impact of SMT on PCB Assembly

SMT technology has significantly impacted PCB assembly by offering several advantages over traditional through-hole technology (THT):

- Compact and Lightweight Designs: SMT components are smaller and lighter than their THT counterparts, enabling the production of compact devices like smartphones and wearables.

- Increased Production Speed: SMT assembly is highly automated, reducing production times. High-speed pick-and-place machines can mount thousands of components per hour with precision.

- Enhanced Reliability and Performance: SMT components are soldered directly onto the PCB surface, resulting in better electrical performance and fewer mechanical failures.

- Cost-Effectiveness: While initial setup costs for SMT machinery may be high, the overall production costs are lower due to reduced labor, faster assembly times, and efficient use of materials.

Integration of Advanced Technologies in SMT

The integration of advanced technologies such as AI, machine learning, and IoT is transforming the SMT industry. These technologies enable real-time monitoring, predictive maintenance, and process optimization, further enhancing production efficiency and product quality.

- Artificial Intelligence (AI): AI algorithms can optimize the manufacturing process by analyzing extensive datasets to predict potential defects. Machine learning models power automated inspection systems that identify soldering issues and other defects with unparalleled accuracy.

- Internet of Things (IoT): IoT integration allows SMT machines to communicate with other equipment in the assembly line, facilitating seamless data exchange and optimizing production processes.

- 3D Printing Technology: Integrating 3D printing into PCB assembly processes has unlocked new dimensions for creating intricate and customized structures. This technology enables the fabrication of three-dimensional circuitry, providing enhanced design flexibility for complex applications.

Conclusion

In conclusion, SMT PCB loaders are essential components in modern SMT manufacturing, offering significant improvements in production efficiency, quality, and cost-effectiveness. By automating the loading process, these machines reduce manual errors, increase throughput, and enhance overall product quality. As technology continues to evolve, the strategic integration of advanced SMT PCB loaders will remain crucial for achieving operational excellence in the electronics manufacturing industry.

Frequently Asked Questions

1. What is the primary function of an SMT PCB loader?

An SMT PCB loader is primarily used to automate the loading of PCBs onto the production line. It ensures that PCBs are consistently and accurately placed onto the conveyor belt for further processing stages.

2. How do SMT PCB loaders improve production efficiency?

SMT PCB loaders improve production efficiency by automating the initial stages of the assembly process, reducing manual errors, and increasing throughput. They also minimize downtime and optimize production capabilities through advanced technologies like IoT and AI.

3. What types of PCBs can SMT loaders handle?

SMT loaders are designed to handle various PCB sizes and types, making them versatile for large-scale manufacturing operations. They can accommodate different configurations without significant setup changes.

4. What are the cost benefits of using SMT PCB loaders?

Using SMT PCB loaders reduces labor costs by minimizing manual handling and increases production volumes, leading to significant cost savings. Additionally, they enhance product quality, reducing returns and warranty claims.

5. How do advanced technologies like IoT and AI enhance SMT PCB loaders?

Advanced technologies like IoT and AI enable real-time monitoring and predictive maintenance in SMT PCB loaders. This reduces downtime, optimizes production capabilities, and ensures that the manufacturing process runs smoothly and efficiently.

Citations:

[1] https://www.hct-smt.com/blog/maximizing-efficiency-with-the-smd-pcb-loader-set--a-comprehensive-guide

[2] https://www.hwgcsmt.com/news/new-technological-trends-in-the-smt-machine-in-84515003.html

[3] https://www.zjyingxing.com/info/what-are-the-advantages-of-advanced-smt-machin-82695955.html

[4] https://www.linkedin.com/pulse/latest-advancements-pcb-assembly-technologies-whats-new-2024-xo2qf

[5] https://www.mordorintelligence.com/industry-reports/surface-mount-technology-market

[6] https://www.pcbgogo.com/Article/Why_SMT_Technology_Benefit_PCB_Assembly_.html

[7] https://www.zetwerk.com/resources/knowledge-base/electronics-manufacturing-services-ems/how-smt-pcb-assembly-enhances-efficiency-in-electronics-production/

[8] https://www.andwinpcb.com/smt-pcb/

[9] https://www.1stsmt.com/blog/the-advantages-of-using-a-fully-automatic-pcb-loader

[10] https://www.hct-smt.com/blog/the-ultimate-guide-to-led-smd-pcb-loaders--everything-you-need-to-know

[11] https://novaenginc.com/future-of-circuit-board-assembly/

[12] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[13] https://www.youtube.com/watch?v=0PVE0wqVhBw

[14] https://www.smtmachine.eu/top-10-pcb-coating-machines-the-ultimate-guide-to-best-picks-in-2025/

[15] https://www.smtsite.com/resources/pcb-loader-unloader-improve-efficiency-and-accuracy.html

[16] https://www.zetwerk.com/resources/knowledge-base/electronics-manufacturing-services-ems/smt-assembly-revolutionizing-pcb-production-process/

[17] https://highpcb.com/top-5-emerging-trends-in-pcb-technology-for-2025/

[18] https://www.zetwerk.com/resources/knowledge-base/electronics-manufacturing-services-ems/smt-pcb-assembly-processes-benefits-and-applications/

[19] https://www.smtfactory.com/Optimizing-Efficiency-Strategies-for-A-Smooth-SMT-Line-Production-Process-id47463586.html

[20] https://www.zetwerk.com/resources/knowledge-base/electronics-manufacturing-services-ems/top-trends-in-pcb-manufacturing-for-2025-and-beyond/