Content Menu

● Introduction to SMT PCB Assembly Defects

>> Common SMT PCB Assembly Defects

● Impact on Product Quality

● Impact on Product Reliability

● Mitigation Strategies

● Advanced Technologies in Defect Detection

● Industry Standards and Compliance

● Economic Implications

● Conclusion

● Frequently Asked Questions

>> 1. What are the most common SMT PCB assembly defects?

>> 2. How do SMT PCB assembly defects affect product reliability?

>> 3. What strategies can be used to mitigate SMT PCB assembly defects?

>> 4. How important is testing in detecting SMT PCB assembly defects?

>> 5. What are the implications of SMT PCB assembly defects on product appearance?

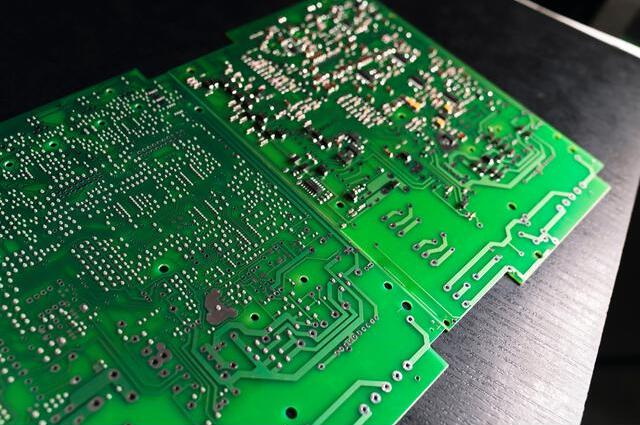

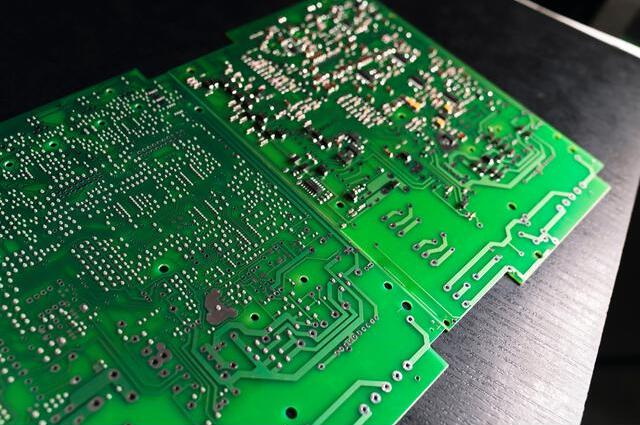

Surface Mount Technology (SMT) is a widely used method in the electronics manufacturing industry for assembling components onto printed circuit boards (PCBs). Despite its advantages, such as increased automation and higher circuit density, SMT PCB assembly can be prone to various defects. These defects not only affect the appearance of the product but also significantly impact its reliability and performance. Understanding and addressing these defects are crucial for ensuring the quality and longevity of electronic devices.

Introduction to SMT PCB Assembly Defects

SMT PCB assembly defects can arise from several stages of the manufacturing process, including solder paste printing, component placement, and reflow soldering. The most common defects include solder opens, solder shorts (bridging), and component misalignment. These defects can lead to electrical failures, reduced product lifespan, and increased maintenance costs.

Common SMT PCB Assembly Defects

1. Open Solder Joints: This occurs when there is no integral bond between the component lead and the PCB pad. It can happen if solder appears only on the PCB pad and not on the component lead, or vice versa.

2. Solder Shorts (Bridging): This defect involves solder connecting two or more adjacent pads, causing a short circuit. It is often due to issues in the solder paste printing process or excessive solder paste deposition.

3. Component Misalignment: Components may shift during reflow due to surface tension, leading to incorrect placement. This can be particularly problematic for components with multiple pads, such as Ball Grid Arrays (BGAs).

4. Cold Solder Joints: These occur when the solder does not fully melt during reflow, resulting in a weak bond. Cold solder joints can be identified by their irregular shape or black color.

5. Insufficient Solder: This defect arises when there is not enough solder to form a reliable bond between the component and the PCB pad. It can lead to weak connections and circuit failures.

Impact on Product Quality

SMT PCB assembly defects can significantly compromise the quality of electronic products. For instance:

- Electrical Performance: Defects like solder opens and shorts can disrupt electrical continuity, leading to malfunctioning circuits and reduced product performance.

- Reliability: Defects increase the likelihood of premature failures, which can result in costly repairs and maintenance. In critical applications, such as life support systems, reliability is paramount.

- Appearance: Visible defects can affect the aesthetic appeal of the product, potentially impacting consumer confidence and brand reputation.

Impact on Product Reliability

Reliability is a critical aspect of electronic products, especially in high-performance or safety-critical applications. SMT PCB assembly defects can compromise reliability in several ways:

- Increased Failure Rate: Defects like cold solder joints and insufficient solder can lead to early component failures, reducing the overall lifespan of the product.

- Environmental Stress: Defects can make products more susceptible to environmental stresses such as temperature fluctuations and humidity, further reducing reliability.

- Safety Risks: In critical systems, defects can pose safety risks by causing unexpected failures, which could lead to accidents or injuries.

Mitigation Strategies

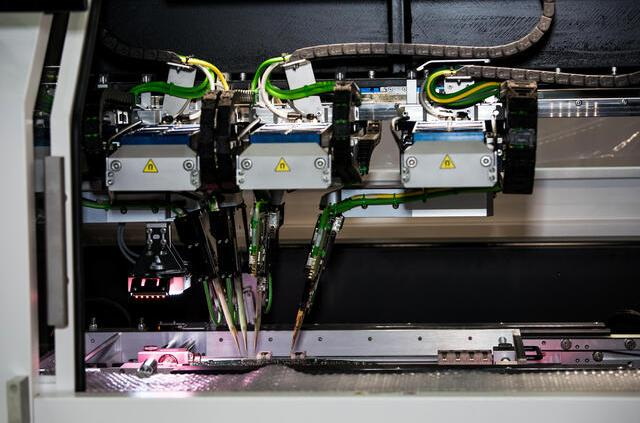

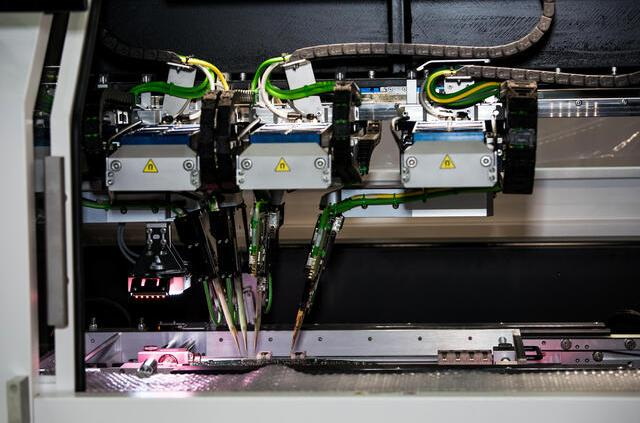

To minimize SMT PCB assembly defects and enhance product quality and reliability, manufacturers can implement several strategies:

- Precision Solder Paste Application: Ensuring the correct amount and distribution of solder paste is crucial for preventing bridging and open joints. Advanced stencil design and precise printing techniques help achieve this goal.

- Automated Component Placement: Using high-precision pick-and-place machines can reduce misalignment errors. These machines are equipped with vision systems that ensure accurate component placement.

- Optimized Reflow Profiles: Maintaining a precise reflow temperature profile helps prevent cold solder joints and ensures strong bonds. This involves carefully controlling the heating and cooling rates during the reflow process.

- Rigorous Testing: Implementing comprehensive testing protocols, including Automated Optical Inspection (AOI) and X-ray inspection, can detect defects early in the manufacturing process. AOI is effective for detecting surface-level defects, while X-ray inspection is used for inspecting components like BGAs.

Advanced Technologies in Defect Detection

Recent advancements in inspection technologies have significantly improved the detection and analysis of SMT PCB assembly defects. For example:

- Machine Learning (ML) in AOI: By integrating ML algorithms into AOI systems, manufacturers can enhance defect detection accuracy and speed. ML can learn from historical data to identify patterns and anomalies more effectively.

- 3D X-ray Inspection: This technology provides detailed, three-dimensional images of PCB assemblies, allowing for precise analysis of internal defects that are not visible to the naked eye.

Industry Standards and Compliance

Manufacturers must adhere to industry standards and regulations to ensure that their products meet quality and reliability requirements. For instance, standards like IPC-A-610 provide guidelines for the acceptability of electronic assemblies. Compliance with these standards helps ensure that products are free from defects and meet customer expectations.

Economic Implications

The economic impact of SMT PCB assembly defects can be substantial. Defects can lead to increased production costs due to rework and scrap, as well as potential legal liabilities if defective products cause harm. Additionally, defects can damage a company's reputation, leading to lost sales and revenue.

Conclusion

SMT PCB assembly defects have a profound impact on the quality and reliability of electronic products. Understanding these defects and implementing effective mitigation strategies are essential for ensuring that products meet the required standards for performance and longevity. By focusing on precision in every stage of the assembly process and utilizing advanced testing methods, manufacturers can significantly reduce the occurrence of defects and enhance overall product reliability.

Frequently Asked Questions

1. What are the most common SMT PCB assembly defects?

The most common defects include solder opens, solder shorts (bridging), and component misalignment. These defects account for a significant portion of all quality issues in SMT PCB assembly.

2. How do SMT PCB assembly defects affect product reliability?

Defects can lead to premature failures, increased susceptibility to environmental stresses, and safety risks, all of which compromise product reliability. Ensuring defect-free assembly is crucial for maintaining high reliability standards.

3. What strategies can be used to mitigate SMT PCB assembly defects?

Mitigation strategies include precise solder paste application, automated component placement, optimized reflow profiles, and rigorous testing protocols such as AOI and X-ray inspection.

4. How important is testing in detecting SMT PCB assembly defects?

Testing is crucial for detecting defects early in the manufacturing process. Methods like AOI and X-ray inspection help identify issues such as solder opens and shorts, ensuring that only defect-free products reach the market.

5. What are the implications of SMT PCB assembly defects on product appearance?

Visible defects can affect the aesthetic appeal of products, potentially impacting consumer confidence and brand reputation. Ensuring that products are visually flawless is important for maintaining a positive brand image.