Content Menu

● The Evolution of PCB Assembly

● Key Components of SMT Machines for PCB Assembly

● Enhancing Speed and Throughput

● Precision and Accuracy in Component Placement

● Flexibility and Adaptability

● Reducing Labor Costs and Human Error

● Optimizing Material Usage

● Integration with Industry 4.0 Technologies

● Quality Assurance and Defect Reduction

● Environmental Benefits

● Challenges and Considerations

● Future Trends in SMT Technology

● Conclusion

● FAQ

>> 1. What is the primary advantage of using SMT machines for PCB assembly?

>> 2. How do SMT machines contribute to miniaturization in electronics?

>> 3. What are the environmental benefits of using SMT machines in PCB manufacturing?

>> 4. How do SMT machines integrate with Industry 4.0 technologies?

>> 5. What are the main challenges in implementing SMT machines for PCB assembly?

● Citations:

In the rapidly evolving world of electronics manufacturing, efficiency and precision are paramount. Surface Mount Technology (SMT) has revolutionized the production of Printed Circuit Boards (PCBs), and at the heart of this transformation are SMT machines. These sophisticated devices have become indispensable in modern PCB assembly, dramatically enhancing productivity, accuracy, and overall manufacturing quality. This article delves into the multifaceted ways SMT machines boost efficiency in PCB manufacturing, exploring their impact on various aspects of the production process.

The Evolution of PCB Assembly

Before we dive into the specifics of SMT machines, it's crucial to understand the context of their development. Traditionally, PCB assembly relied on through-hole technology, where component leads were inserted through holes in the board and soldered on the opposite side. While effective, this method was labor-intensive and limited in terms of component density and miniaturization.

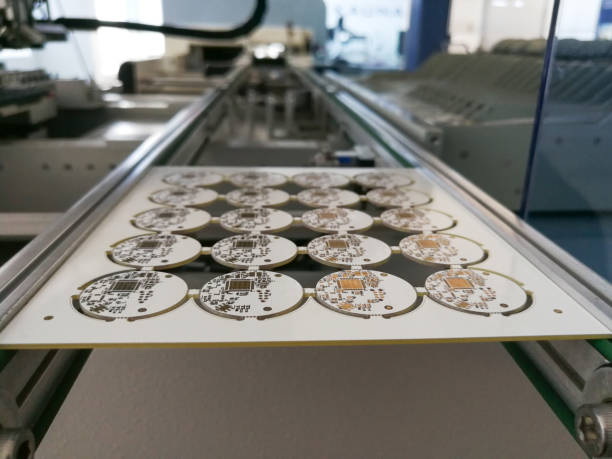

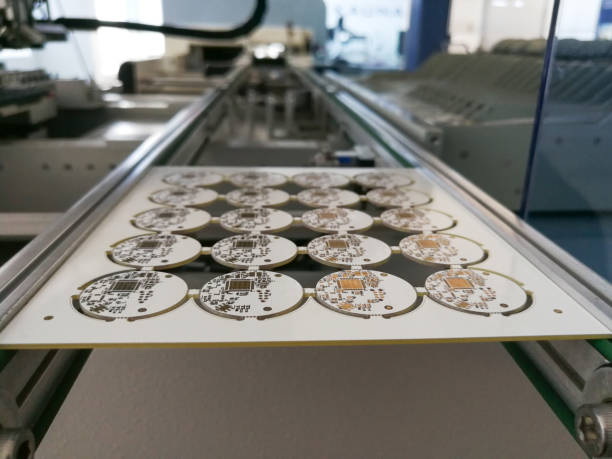

The advent of SMT marked a significant leap forward. In SMT, components are mounted directly onto the surface of the PCB, allowing for more compact designs and automated assembly processes. This shift laid the groundwork for the development of SMT machines, which have become the cornerstone of modern PCB manufacturing[1].

Key Components of SMT Machines for PCB Assembly

SMT machines for PCB assembly comprise several critical components, each contributing to the overall efficiency of the manufacturing process:

1. Pick and Place Machines: These are the workhorses of SMT assembly lines. They rapidly and precisely place components onto the PCB surface.

2. Solder Paste Printers: These machines apply a precise amount of solder paste to the PCB before component placement.

3. Reflow Ovens: After component placement, reflow ovens heat the board to melt the solder paste, creating permanent connections.

4. Automated Optical Inspection (AOI) Systems: These systems check for errors in component placement and soldering quality.

5. Conveyor Systems: They transport PCBs between different stages of the assembly process.

Each of these components plays a crucial role in streamlining the PCB assembly process, contributing to the overall efficiency gains provided by SMT technology[2].

Enhancing Speed and Throughput

One of the most significant advantages of SMT machines in PCB assembly is the dramatic increase in production speed. Modern pick and place machines can place thousands of components per hour with remarkable precision. This high-speed operation translates directly into increased throughput, allowing manufacturers to meet demanding production schedules and respond quickly to market demands[3].

The speed advantage of SMT machines extends beyond just component placement. The entire SMT process, from solder paste application to reflow soldering, is designed for rapid throughput. Conveyor systems seamlessly move PCBs between different stages of production, minimizing downtime and maximizing efficiency.

Precision and Accuracy in Component Placement

SMT machines excel in placing components with exceptional accuracy. This precision is crucial for several reasons:

1. Miniaturization: As electronic devices become smaller, PCBs must accommodate more components in less space. SMT machines can place tiny components with pinpoint accuracy, enabling the production of compact, high-density boards.

2. Consistency: Machine placement eliminates human error, ensuring consistent quality across large production runs.

3. Complex Designs: Modern PCBs often feature intricate designs with components placed on both sides of the board. SMT machines can handle these complex layouts with ease.

The precision offered by SMT machines not only improves the quality of the final product but also reduces waste and rework, further enhancing manufacturing efficiency[4].

Flexibility and Adaptability

SMT machines for PCB assembly offer remarkable flexibility, adapting to various production requirements:

1. Component Variety: They can handle a wide range of component types and sizes, from tiny resistors to large integrated circuits.

2. Quick Changeovers: Modern SMT machines can be quickly reprogrammed for different PCB designs, reducing downtime between production runs.

3. Scalability: SMT assembly lines can be scaled up or down to meet changing production volumes, making them suitable for both small-batch and high-volume manufacturing.

This adaptability allows manufacturers to respond quickly to market demands and product changes, a crucial advantage in the fast-paced electronics industry[5].

Reducing Labor Costs and Human Error

By automating the PCB assembly process, SMT machines significantly reduce the need for manual labor. This automation has several benefits:

1. Cost Reduction: Fewer human operators are required, leading to lower labor costs.

2. Consistency: Machines don't suffer from fatigue or distraction, ensuring consistent quality throughout long production runs.

3. Error Reduction: Automated processes minimize the risk of human errors in component placement and soldering.

4. Improved Working Conditions: Automation of repetitive tasks allows human workers to focus on more complex, value-added activities.

The reduction in labor-intensive processes not only improves efficiency but also enhances overall product quality and reliability[6].

Optimizing Material Usage

SMT machines contribute to material efficiency in several ways:

1. Precise Solder Paste Application: SMT machines apply solder paste with extreme precision, reducing waste and ensuring optimal joint formation.

2. Component Handling: Automated feeders and placement systems minimize component loss and damage during the assembly process.

3. Reduced Rework: The accuracy of SMT machines means fewer defects and less need for rework, saving both materials and time.

By optimizing material usage, SMT machines help reduce manufacturing costs and environmental impact, contributing to more sustainable production practices[7].

Integration with Industry 4.0 Technologies

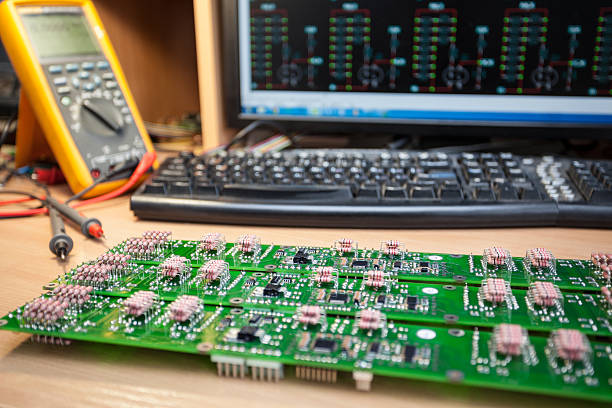

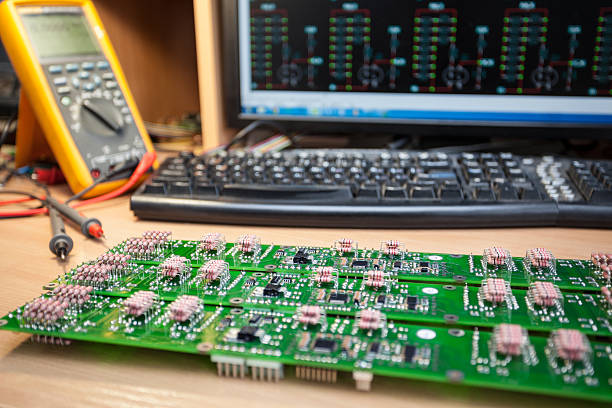

Modern SMT machines are at the forefront of Industry 4.0 integration. They incorporate advanced technologies that further enhance manufacturing efficiency:

1. Data Collection and Analysis: SMT machines can collect and analyze production data in real-time, allowing for continuous process optimization.

2. IoT Connectivity: Connected SMT machines can communicate with other systems, enabling seamless production flow and predictive maintenance.

3. AI and Machine Learning: Advanced algorithms can optimize component placement strategies and predict potential issues before they occur.

4. Digital Twin Technology: Virtual models of SMT machines and assembly lines can be used for simulation and optimization without disrupting actual production.

This integration with cutting-edge technologies positions SMT machines as key enablers of smart manufacturing, driving continuous improvements in efficiency and quality[8].

Quality Assurance and Defect Reduction

SMT machines incorporate advanced quality assurance features that significantly reduce defects in PCB assembly:

1. In-line Inspection: Many SMT machines include built-in optical inspection systems that can detect placement errors or solder joint issues in real-time.

2. Automated Optical Inspection (AOI): Dedicated AOI systems can perform thorough checks of assembled PCBs, identifying even minor defects.

3. X-ray Inspection: For complex or multi-layer boards, X-ray inspection can verify internal connections and hidden solder joints.

4. Statistical Process Control: SMT machines can collect and analyze data to identify trends and potential quality issues before they become significant problems.

By catching and correcting defects early in the production process, SMT machines help reduce waste, improve yield rates, and ensure consistently high-quality output[9].

Environmental Benefits

The efficiency gains provided by SMT machines also translate into environmental benefits:

1. Reduced Energy Consumption: Automated processes are often more energy-efficient than manual assembly methods.

2. Minimized Waste: Precise component placement and solder application reduce material waste.

3. Smaller Footprint: The compact nature of SMT assembly lines means less factory floor space is required, potentially reducing the overall environmental impact of manufacturing facilities.

4. Longevity of Products: The precision and reliability of SMT-assembled PCBs can lead to longer-lasting electronic products, reducing electronic waste.

These environmental advantages align with growing consumer and regulatory demands for more sustainable manufacturing practices[10].

Challenges and Considerations

While SMT machines offer numerous benefits, their implementation does come with certain challenges:

1. Initial Investment: High-quality SMT machines represent a significant capital investment.

2. Maintenance and Upkeep: Regular maintenance is crucial to ensure optimal performance and longevity of SMT equipment.

3. Training Requirements: Operators and technicians need specialized training to effectively use and maintain SMT machines.

4. Rapid Technological Advancements: The fast pace of technological change in SMT equipment can make it challenging to stay current.

Manufacturers must carefully consider these factors when planning to implement or upgrade SMT assembly lines[11].

Future Trends in SMT Technology

The field of SMT technology continues to evolve, with several exciting trends on the horizon:

1. Increased Automation: Future SMT machines may incorporate even more automated features, potentially leading to lights-out manufacturing scenarios.

2. Enhanced AI Integration: Advanced AI algorithms could further optimize component placement, predict maintenance needs, and adapt to changing production requirements in real-time.

3. Improved Miniaturization Capabilities: As electronic devices continue to shrink, SMT machines will need to handle even smaller components with greater precision.

4. Sustainability Focus: Future SMT machines may incorporate features specifically designed to reduce energy consumption and material waste.

5. Flexible Manufacturing: SMT technology may evolve to handle an even wider range of component types and board designs, enabling greater manufacturing flexibility.

These trends suggest that SMT machines will continue to play a crucial role in driving efficiency and innovation in PCB manufacturing for years to come[12].

Conclusion

SMT machines have revolutionized PCB manufacturing, offering unprecedented levels of efficiency, precision, and flexibility. By automating complex assembly processes, these machines have enabled the production of increasingly sophisticated electronic devices while simultaneously reducing costs and improving quality.

The benefits of SMT machines extend beyond just speed and accuracy. They contribute to reduced labor costs, optimized material usage, and improved environmental sustainability. Moreover, their integration with Industry 4.0 technologies positions them at the forefront of smart manufacturing initiatives.

As electronic devices continue to evolve, becoming smaller, more complex, and more ubiquitous, the role of SMT machines in PCB assembly will only grow in importance. Manufacturers who invest in and effectively leverage SMT technology will be well-positioned to meet the challenges and opportunities of the rapidly changing electronics industry.

While challenges exist in terms of initial investment and ongoing maintenance, the long-term benefits of SMT machines far outweigh these considerations for most manufacturers. As technology continues to advance, we can expect SMT machines to become even more capable, efficient, and integral to the future of electronics manufacturing.

FAQ

1. What is the primary advantage of using SMT machines for PCB assembly?

The primary advantage of using SMT machines for PCB assembly is the significant increase in production efficiency. These machines can place components at a much faster rate than manual assembly, with some high-speed models capable of placing thousands of components per hour. This speed, combined with high precision and consistency, leads to dramatically increased throughput and reduced production times.

2. How do SMT machines contribute to miniaturization in electronics?

SMT machines contribute to miniaturization in electronics by enabling the placement of very small components with extreme precision. They can handle components as small as 0201 (0.6 mm × 0.3 mm) or even 01005 (0.4 mm × 0.2 mm) size, allowing for the creation of dense, compact PCB designs. This capability is crucial for the development of smaller electronic devices like smartphones, wearables, and IoT devices.

3. What are the environmental benefits of using SMT machines in PCB manufacturing?

SMT machines offer several environmental benefits in PCB manufacturing. They reduce material waste through precise solder paste application and accurate component placement. The automated process is generally more energy-efficient than manual assembly methods. Additionally, the improved quality and reliability of SMT-assembled PCBs can lead to longer-lasting electronic products, potentially reducing electronic waste.

4. How do SMT machines integrate with Industry 4.0 technologies?

SMT machines integrate with Industry 4.0 technologies in several ways. They often include data collection and analysis capabilities, allowing for real-time monitoring and optimization of the production process. Many SMT machines can be connected to IoT networks, enabling communication with other systems for seamless production flow. Advanced models may incorporate AI and machine learning algorithms for predictive maintenance and process optimization.

5. What are the main challenges in implementing SMT machines for PCB assembly?

The main challenges in implementing SMT machines for PCB assembly include the high initial investment cost, the need for specialized training for operators and maintenance staff, and the ongoing maintenance requirements to ensure optimal performance. Additionally, the rapid pace of technological advancement in SMT equipment can make it challenging for manufacturers to stay current with the latest capabilities and features.

Citations:

[1] https://www.smtfactory.com/Optimizing-SMT-Manufacturing-The-Crucial-Impact-of-PCB-Handling-Machines-id41104497.html

[2] https://insightsolutionsglobal.com/smt-surface-mount-technology-manufacturing-process/

[3] https://vectorbluehub.com/smt-assembly

[4] https://www.zetwerk.com/resources/knowledge-base/electronics-manufacturing-services-ems/how-smt-pcb-assembly-enhances-efficiency-in-electronics-production/

[5] https://www.fs-pcba.com/smt-process-flow/

[6] https://www.viasion.com/blog/smt-manufacturing-process-step-by-step-guide/

[7] https://itchronicles.com/manufacturing/why-is-line-efficiency-a-vital-business-metric-in-the-pcb-manufacturing-industry/

[8] https://www.youtube.com/watch?v=T2SK30JRs_E

[9] https://smtnet.com/library/index.cfm?fuseaction=browse_articles&start_at=296

[10] https://www.smtneoden.com/news/how-to-effectively-improve-the-production-efficiency-of-pcb-smt-machine/

[11] https://www.ablcircuits.co.uk/blog/what-is-the-smt-process-and-why-should-oems-care/

[12] https://cn.hayawin.com/resources/smt-manufacturing-line-amp-smt-cb-assembly-process.html

[13] https://www.pcbonline.com/blog/smt-manufacturing-process.html