Content Menu

● Understanding SMT and Its Importance

● Key Strategies for Ensuring Product Reliability

>> 1. Rigorous Testing Protocols

>> 2. Quality Control Measures

>> 3. Advanced Technology Integration

● Best Practices for SMT Line Test Equipment Suppliers

>> 1. Continuous Improvement Programs

>> 2. Comprehensive Training for Operators

>> 3. Collaboration with Design Engineers

● Design Stage Controls

>> DFA Analysis

>> Process Capability Assessment

● Incoming Quality Control

>> Components

>> Solder Paste

>> PCBs

● Continuous Improvement Strategy

>> Data Analysis

● Idea Generation

● Implementation

● The Role of Inspection Technologies in Ensuring Reliability

>> Automated Optical Inspection (AOI)

>> X-Ray Inspection (AXI)

>> In-Circuit Testing (ICT)

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. Why is product reliability important in electronics?

>> 3. What are common testing methods used in SMT?

>> 4. How do suppliers ensure component quality?

>> 5. What role does technology play in enhancing product reliability?

● Citations:

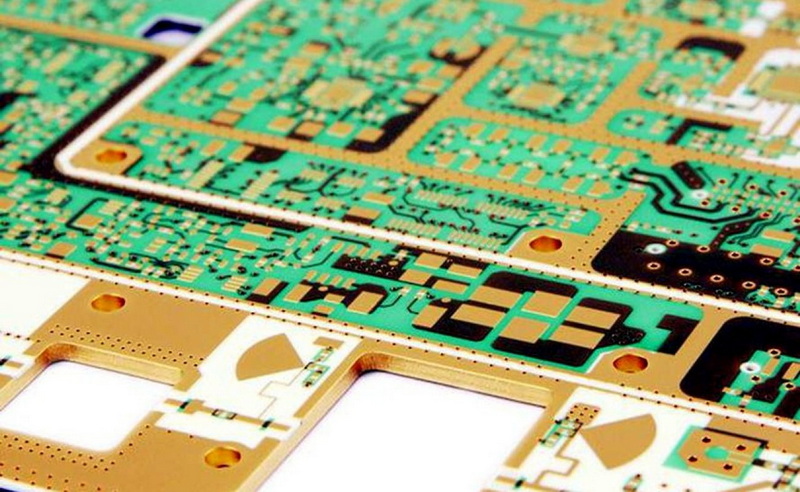

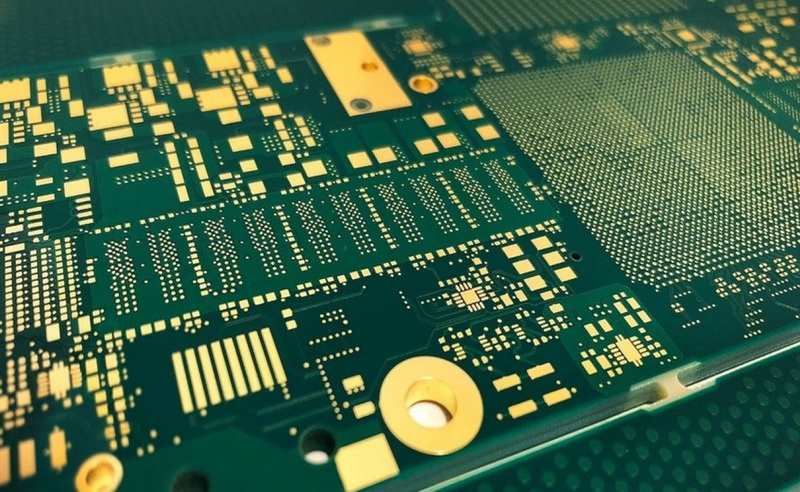

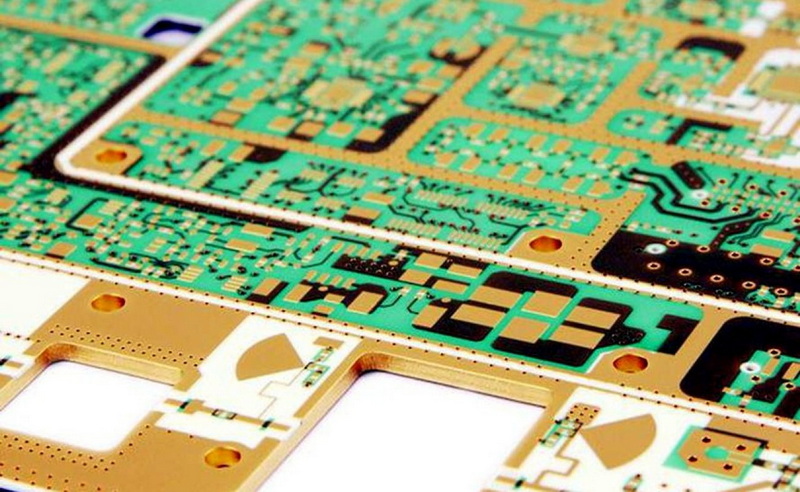

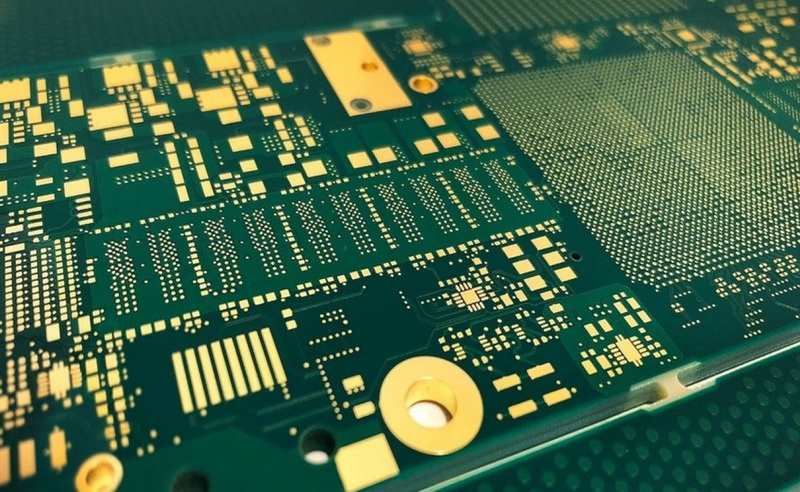

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, enabling the efficient assembly of printed circuit boards (PCBs). The reliability of SMT products is paramount, as it directly affects the performance and longevity of electronic devices. Test equipment suppliers play a crucial role in ensuring this reliability through various strategies and methodologies. This article delves into how these suppliers ensure product reliability, focusing on testing processes, quality control measures, and technological advancements.

Understanding SMT and Its Importance

SMT involves mounting electronic components directly onto the surface of PCBs, which allows for smaller and more complex designs. The transition from traditional through-hole technology to SMT has led to significant improvements in manufacturing efficiency and product performance. However, with these advancements come challenges in maintaining quality and reliability.

The reliability of SMT products is critical for several reasons:

- Performance: Reliable products perform consistently under various conditions.

- Longevity: High-quality SMT assemblies have longer lifespans, reducing the need for replacements.

- Safety: In critical applications like medical devices or automotive systems, failures can have severe consequences.

Key Strategies for Ensuring Product Reliability

1. Rigorous Testing Protocols

Test equipment suppliers implement comprehensive testing protocols at various stages of the SMT production process. These protocols include:

- In-Circuit Testing (ICT): This method tests electrical properties to identify defects in PCB assemblies. ICT is effective in detecting short circuits, open circuits, and component values, ensuring that each assembly meets specified standards.

- Automated Optical Inspection (AOI): AOI uses advanced imaging technology to inspect solder joints and component placements. By identifying defects early in the production process, AOI minimizes the risk of faulty products reaching the market.

- X-Ray Inspection: Particularly useful for detecting hidden defects in components like Ball Grid Arrays (BGAs), X-ray inspection provides a non-destructive way to ensure solder joint integrity.

2. Quality Control Measures

Quality control is integral to maintaining product reliability. Suppliers adopt several measures to ensure that every component used in SMT assemblies meets high standards:

- Component Traceability: Suppliers implement traceability systems that allow them to track the origin and quality of each component. This ensures that only reliable components are used in production.

- Supplier Audits: Regular audits of component suppliers help verify compliance with quality standards. This proactive approach reduces the risk of incorporating substandard materials into the manufacturing process.

- Environmental Controls: Maintaining optimal environmental conditions during assembly—such as temperature and humidity—helps prevent defects related to moisture-sensitive devices.

3. Advanced Technology Integration

The integration of advanced technologies into SMT testing processes enhances reliability:

- Machine Learning Algorithms: Some suppliers use machine learning algorithms to analyze data from past testing results. This analysis helps predict potential failures and optimize testing parameters.

- Real-Time Monitoring Systems: Implementing real-time monitoring allows for immediate detection of anomalies during production, enabling quick corrective actions.

- Automated Data Collection: Automated systems streamline data collection from testing equipment, facilitating better analysis and reporting on product quality.

Best Practices for SMT Line Test Equipment Suppliers

To further enhance product reliability, SMT line test equipment suppliers follow best practices:

1. Continuous Improvement Programs

Suppliers should establish continuous improvement programs that focus on refining testing processes and equipment performance. This can involve:

- Regular training for personnel on the latest testing technologies.

- Implementing feedback loops where data from failed tests inform process improvements.

2. Comprehensive Training for Operators

Well-trained operators are essential for maintaining high-quality standards. Suppliers should invest in training programs that cover:

- Equipment operation and maintenance.

- Quality control procedures.

- Troubleshooting techniques for common issues encountered during testing.

3. Collaboration with Design Engineers

Close collaboration between test equipment suppliers and design engineers can lead to better product outcomes. By involving engineers in the testing phase, suppliers can ensure that test protocols align with design specifications, ultimately enhancing reliability.

Design Stage Controls

Delivering quality SMT production begins in the design stages of product development:

DFA Analysis

Conduct design for assembly (DFA) analysis during board layout to identify any problematic areas for manufacturability and quality. Address issues like:

- Component spacing and density

- Placement sequence optimization

- Accessibility for inspection and rework

- Test point integration

Early DFA allows optimizing the design for ease of error-free SMT assembly.

Process Capability Assessment

Evaluate process capabilities against all design requirements during engineering prototyping. Verify the selected factory can achieve requirements like:

- Component sizes and pitches

- Solder joint sizes

- Component and board warpage control

- Placement precision

Incoming Quality Control

Rigorously controlling the quality of incoming parts and materials prevents defects from entering the production line:

Components

Certificates of compliance– Review for acceptability from trusted distributors

Sample inspections– Check component markings, lead forms, correctness

X-ray inspection– Detect hidden issues like broken wire bonds

Solder Paste

Mill/use by date tracking– First in first out (FIFO) usage

Thawing/cooling logs– Monitor against specifications

Paste viscosity tests– Confirm viscosity within limits

PCBs

Netlist testing– Validate against approved data

Visual inspection– Check for blemishes, scratches, missing markings

AOI verification– Use automated optical inspection to catch board defects

Continuous Improvement Strategy

Steadily improving quality requires instilling a culture and mindset of continuous improvement.

Data Analysis

Collect comprehensive metrics on rework, yield, defects, reliability field failures

Analyze for patterns indicating chronic issues

Prioritize worst pain points for correction

Idea Generation

Empower production teams to suggest improvements

Leverage programs like Kaizen and Lean to stimulate ideas

Brainstorm solutions to longstanding problems

Implementation

Standardize solutions into procedures and training

Update documentation like work instructions and drawings

Close the feedback loop by measuring impact

Continuous improvement delivers compounded gains over time.

The Role of Inspection Technologies in Ensuring Reliability

Inspection technologies play a vital role in maintaining product reliability throughout the SMT process. Key inspection methods include:

Automated Optical Inspection (AOI)

AOI systems utilize high-resolution cameras to capture images of PCBs at various stages of production. They can detect defects such as:

- Missing components

- Misaligned parts

- Insufficient solder

- Solder bridging

The use of AOI significantly reduces manual inspection time while increasing accuracy in defect detection.

X-Ray Inspection (AXI)

X-ray inspection is crucial when dealing with components that are not visually accessible after soldering, such as BGAs. AXI can reveal issues like voids or insufficient solder joints that could lead to failure in operational conditions.

In-Circuit Testing (ICT)

ICT is a powerful method used post-manufacturing to ensure all components are correctly placed and functioning as intended. It checks for electrical continuity between points on a PCB and identifies faults such as shorts or opens effectively.

Conclusion

The reliability of SMT products is a multifaceted challenge that requires a comprehensive approach from test equipment suppliers. By implementing rigorous testing protocols, maintaining stringent quality control measures, integrating advanced technologies, following best practices, and utilizing effective inspection methods throughout the entire production process, these suppliers can significantly enhance product reliability. As technology continues to evolve, ongoing adaptation and innovation will be essential in meeting the growing demands of the electronics manufacturing industry.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method used in electronics manufacturing where components are mounted directly onto the surface of PCBs instead of through holes.

2. Why is product reliability important in electronics?

Product reliability is crucial because it affects performance, longevity, and safety; unreliable products can lead to failures that may have serious consequences in critical applications.

3. What are common testing methods used in SMT?

Common testing methods include In-Circuit Testing (ICT), Automated Optical Inspection (AOI), X-Ray Inspection, and functional testing to verify the performance of assembled PCBs.

4. How do suppliers ensure component quality?

Suppliers ensure component quality through traceability systems, regular audits of component sources, and strict adherence to environmental controls during assembly.

5. What role does technology play in enhancing product reliability?

Technology plays a significant role by enabling real-time monitoring, automated data collection, and machine learning algorithms that predict failures and optimize testing processes.

Citations:

[1] https://www.raypcb.com/smt-production/

[2] https://www.7pcb.com/blog/smt-assembly-quality-related-standards

[3] https://www.prideindustries.com/our-stories/electronics-testing

[4] https://www.pcbonline.com/blog/good-smt-manufacturers.html

[5] https://www.raypcb.com/surface-mount-technology/

[6] https://blog.intraratio.com/traceability-for-surface-mount-technology-process

[7] https://www.pcbcart.com/article/content/process-control-in-smt-assembly.html

[8] https://www.raypcb.com/pcb-inspection-in-smt-assembly-process-ict-aoi-and-axi/

[9] https://asselems.com/en/best-practices-in-smt-assembly

[10] https://www.raypcb.com/effective-measures-to-improve-smt-assembly-quality/

[11] https://www.jycircuitboard.com/news/inspection-and-test-in-smt-assembly-process-289.html

[12] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[13] https://www.linkedin.com/pulse/latest-advancements-pcb-assembly-technologies-whats-new-2024-xo2qf

[14] https://smtnet.com/news/index.cfm?fuseaction=view_news&company_id=58069&news_id=30605

[15] https://www.smtfactory.com/Enhancing-Reliability-in-Electronics-Manufacturing-id66335007.html

[16] https://www.myemssolutions.com/smt-assembly-inspection-processes-and-test-technologies/

[17] https://forums.parallax.com/discussion/124449/best-practices-and-basic-techniques-used-for-short-run-smt-of-boards

[18] https://www.pcbgogo.com/Article/Innovations_in_printed_circuit_board_assembly__trends_and_techniques.html

[19] https://smt.asmpt.com/en/news-center/press/minimizing-process-risks-in-smt-production/

[20] https://www.pcbcart.com/article/content/measures-to-improve-smt-assembly-quality.html

[21] https://rootsems.com/the-importance-of-pcb-assembly-testing-in-electronics-manufacturing/

[22] https://www.linkedin.com/pulse/comprehensive-guide-smt-machines-what-how-choose-%E6%97%AD%E4%B8%9C-%E8%A2%81-wm4hc

[23] https://sfxpcb.com/exploring-advanced-techniques-next-level-pcb-smt-assembly-solutions/

[24] https://www.linkedin.com/pulse/inspections-tests-applied-smt-assembly-process-tina-raypcb-jidpf

[25] https://www.ipcb.com/pcba-tech/9915.html

[26] https://www.elecrow.com/blog/why-is-smt-pcba-first-article-inspection-so-important.html

[27] https://www.smithsinterconnect.com/smiths-interconnect-blog/best-practices-in-installation-and-testing-of-board-level-passive-components-for-applications-at-fre/

[28] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[29] https://www.viasion.com/blog/must-have-qualities-of-a-reliable-smt-pcb-assembly-supplier/

[30] https://www.ablcircuits.co.uk/blog/what-is-the-smt-process-and-why-should-oems-care/

[31] https://www.ocmmanufacturing.com/resources/resource/dfm-tip-best-practices-for-surface-mount-technology-smt-design/

[32] https://www.unmannedsystemstechnology.com/feature/mpl-explains-the-evolution-of-smt-technology/

[33] https://www.linkedin.com/pulse/importance-types-smt-inspection-electronics-manufacturing-rzfac

[34] https://www.viasion.com/blog/how-to-choose-the-right-smt-pcb-assembly-supplier/

[35] https://www.andwinpcb.com/innovations-in-surface-mount-technology-for-enhanced-electronics/

[36] https://www.linkedin.com/pulse/exciting-developments-surface-mount-technology-snehal-kale

[37] https://apps.dtic.mil/sti/tr/pdf/ADA267598.pdf