Content Menu

● Understanding the Challenge of Curved Surfaces in SMT

● Key Technologies Enabling Precision SMD on Curved Surfaces

>> 1. Multi-Axis Mounting Heads and Hybrid Machines

>> 2. Advanced Vision and Alignment Systems

>> 3. 3D Scanning and Digital Modeling

>> 4. Specialized Fixturing and Conveyance Systems

>> 5. Temperature Control and Monitoring

● Process Strategies for Precision on Curved Surfaces

>> Component Placement Accuracy

>> Solder Paste Application

>> Adaptive Toolpaths and Motion Control

>> Hybrid Mounting and Dispensing

● Advantages of Using SMD Machines for Curved Surfaces

● Conclusion

● FAQ

>> 1. What makes an SMD machine suitable for curved surfaces?

>> 2. How does 3D scanning improve precision in SMD assembly on curved surfaces?

>> 3. What role does temperature control play in soldering on curved surfaces?

>> 4. Can hybrid SMD machines handle both dispensing and component placement on curved surfaces?

>> 5. How do SMD machines maintain component placement accuracy over time?

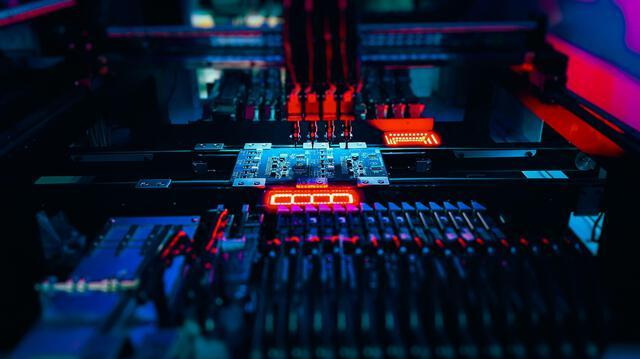

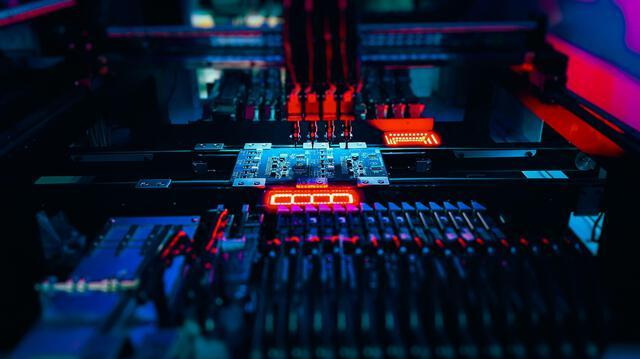

Surface Mount Device (SMD) machines have revolutionized electronics manufacturing by enabling the precise placement and soldering of components on printed circuit boards (PCBs). While traditional SMD assembly typically focuses on flat PCBs, modern applications increasingly require mounting components on curved or irregular surfaces. This presents unique challenges for precision and reliability. This article explores how SMD machines ensure precision on curved surfaces, focusing on the technologies, techniques, and innovations that enable accurate surface mount technology (SMT) on non-flat geometries. The discussion will emphasize the keyword smd machine for curved surface throughout.

Understanding the Challenge of Curved Surfaces in SMT

Curved surfaces introduce complexities that do not exist on flat PCBs:

- Irregular Geometry: Curved surfaces vary in radius and angle, making component placement more difficult.

- Alignment Issues: Maintaining precise alignment of components relative to the surface contour is critical.

- Soldering Consistency: Ensuring uniform solder paste application and reflow on a non-flat surface requires advanced control.

- Mechanical Stability: Holding and moving curved PCBs securely during assembly demands specialized fixturing and machine flexibility.

To overcome these challenges, SMD machines designed for curved surfaces incorporate advanced hardware and software features that adapt to the surface shape while maintaining high precision.

Key Technologies Enabling Precision SMD on Curved Surfaces

1. Multi-Axis Mounting Heads and Hybrid Machines

Modern SMD machines for curved surfaces often feature multi-axis mounting heads that can tilt, rotate, and move in multiple directions. This flexibility allows the placement nozzle to approach the curved PCB at the correct angle, ensuring accurate component placement.

For example, Yamaha's 3D hybrid mounters S10 and S20 combine mounting, dispensing, and inspection functions in one unit. These machines support mounting on irregular, sloped, and curved surfaces by using a hybrid mounting head that performs both dispensing and component placement with high accuracy.

2. Advanced Vision and Alignment Systems

Precision placement on curved surfaces requires real-time feedback and alignment correction. High-resolution optical systems with multi-angle cameras and laser alignment sensors detect the exact position and orientation of the PCB and components.

Some machines integrate optical alignment with servo-controlled motion systems, allowing automatic adjustment of the nozzle position in three dimensions. For example, the ZM-R8000B BGA rework station uses a 2-million-pixel HD digital imaging system combined with automatic optical zoom and laser red-dot indicators to achieve alignment accuracy as fine as ±0.01 mm.

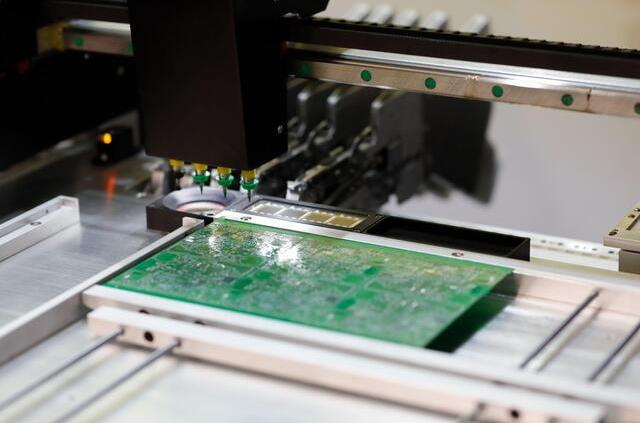

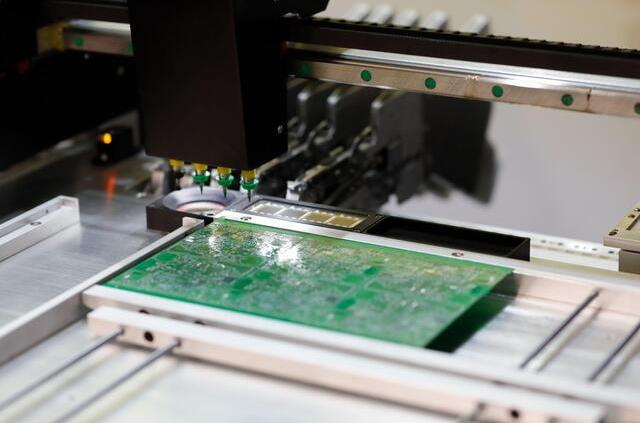

3. 3D Scanning and Digital Modeling

Before the assembly process, 3D scanning technologies create precise digital models of the curved PCB surface. These models guide the SMD machine's toolpath and placement strategy, ensuring components are positioned exactly where needed despite the surface curvature.

Adaptive milling and machining techniques use similar approaches to ensure precision on curved surfaces by dynamically adjusting toolpaths based on real-time data. SMD machines employ analogous software algorithms to compensate for surface irregularities.

4. Specialized Fixturing and Conveyance Systems

Holding curved PCBs securely during assembly is essential. Machines use custom-designed fixtures and conveyor belts that conform to the PCB's shape, preventing movement or vibration that could cause misalignment.

NeoDen's automatic SMD soldering machine, for example, features a stainless steel mesh belt that is durable and resistant to deformation, ensuring stable transport of PCBs during soldering. Such conveyance systems can be adapted to hold curved boards firmly.

5. Temperature Control and Monitoring

Soldering on curved surfaces requires precise temperature control to avoid thermal distortion or uneven solder joints. Machines employ multi-zone heating systems with independent temperature control for upper and lower zones, combined with real-time temperature monitoring.

The NeoDen IN12 SMD soldering machine includes a 4-way board surface temperature monitoring system that provides comprehensive feedback during operation, effectively managing complex thermal profiles on irregular surfaces. Similarly, advanced rework stations use multi-loop heating and PID closed-loop control to maintain stable temperatures.

Process Strategies for Precision on Curved Surfaces

Component Placement Accuracy

Ensuring accurate component placement is fundamental. High-precision machines with multi-axis heads and vision systems calibrate the component position relative to the curved surface in real time. Operators also benefit from automated calibration and maintenance routines to sustain accuracy over time.

Solder Paste Application

Consistent solder paste deposition on curved surfaces is challenging. Specialized stencils and dispensing heads designed for 3D surfaces are used. Automated solder paste inspection (SPI) systems verify paste volume and placement before component mounting, reducing defects like bridging or tombstoning.

Adaptive Toolpaths and Motion Control

SMD machines use adaptive motion control algorithms that adjust the nozzle path dynamically to follow the curved surface contours. This reduces mechanical stress and ensures smooth placement without damaging components or the PCB.

Hybrid Mounting and Dispensing

Combining dispensing and mounting in one machine unit allows for precise application of adhesives or solder paste tailored to the surface curvature, followed immediately by component placement. This hybrid approach minimizes handling errors and improves throughput.

Advantages of Using SMD Machines for Curved Surfaces

- Higher Precision: Multi-axis control and advanced vision systems ensure components are placed with micron-level accuracy.

- Improved Yield: Consistent soldering and placement reduce defects such as misalignment, bridging, and open circuits.

- Flexibility: Ability to handle a variety of curved and irregular surface geometries expands product design possibilities.

- Efficiency: Hybrid machines combining multiple functions reduce cycle times and manual intervention.

- Quality Control: Real-time monitoring of temperature, position, and solder paste application enhances reliability.

Conclusion

SMD machines designed for curved surfaces achieve precision through a combination of multi-axis mounting heads, advanced vision and alignment systems, 3D scanning, specialized fixturing, and precise temperature control. These technologies enable accurate component placement and soldering on irregular geometries, overcoming the unique challenges posed by curved PCBs. The integration of adaptive motion control and hybrid mounting capabilities further enhances efficiency and quality. As electronics design increasingly incorporates complex shapes, the role of smd machine for curved surface technology becomes indispensable for manufacturers aiming for high precision and reliability.

FAQ

1. What makes an SMD machine suitable for curved surfaces?

An SMD machine suitable for curved surfaces typically features multi-axis mounting heads, advanced vision and alignment systems, and adaptive motion control to accurately place components on irregular geometries. It also includes specialized fixturing and temperature control to handle the unique challenges of curved PCBs.

2. How does 3D scanning improve precision in SMD assembly on curved surfaces?

3D scanning creates a detailed digital model of the curved PCB, allowing the SMD machine to generate precise toolpaths and placement strategies that conform exactly to the surface shape. This reduces errors and ensures accurate component positioning.

3. What role does temperature control play in soldering on curved surfaces?

Precise temperature control ensures uniform heating of the PCB and components, preventing thermal distortion and ensuring consistent solder joint quality. Multi-zone heating and real-time temperature monitoring are essential for maintaining optimal soldering conditions on curved surfaces.

4. Can hybrid SMD machines handle both dispensing and component placement on curved surfaces?

Yes, hybrid machines like Yamaha's S10 and S20 combine dispensing and mounting functions in one unit, enabling precise application of adhesives or solder paste followed by component placement. This hybrid approach improves accuracy and efficiency on curved surfaces.

5. How do SMD machines maintain component placement accuracy over time?

SMD machines maintain accuracy through regular calibration, automated vision system feedback, and maintenance routines. High-precision servo motors and adaptive control algorithms compensate for any mechanical drift or variations during production.