Content Menu

● Understanding Small SMD Pick and Place Machines

● Features of Larger SMD Pick and Place Machines

● Comparative Analysis: Small vs. Large SMD Pick and Place Machines

● Applications and Use Cases

>> Small SMD Pick and Place Machines

>> Large SMD Pick and Place Machines

● Key Considerations When Choosing Between Small and Large Machines

● Conclusion

● FAQ

>> 1. What is a small SMD pick and place machine best used for?

>> 2. How does placement accuracy differ between small and large pick and place machines?

>> 3. Can small SMD pick and place machines handle complex PCBs?

>> 4. Are small SMD pick and place machines fully automatic?

>> 5. What factors should I consider when choosing a pick and place machine?

● Citations:

Surface Mount Technology (SMT) pick and place machines are essential in modern electronics manufacturing, automating the precise placement of surface mount devices (SMDs) onto printed circuit boards (PCBs). These machines vary widely in size, capability, and cost, ranging from small desktop models designed for low-volume or prototype work to large, high-speed industrial systems for mass production. This article explores how small SMD pick and place machines compare to larger models, focusing on their features, performance, applications, and cost-effectiveness.

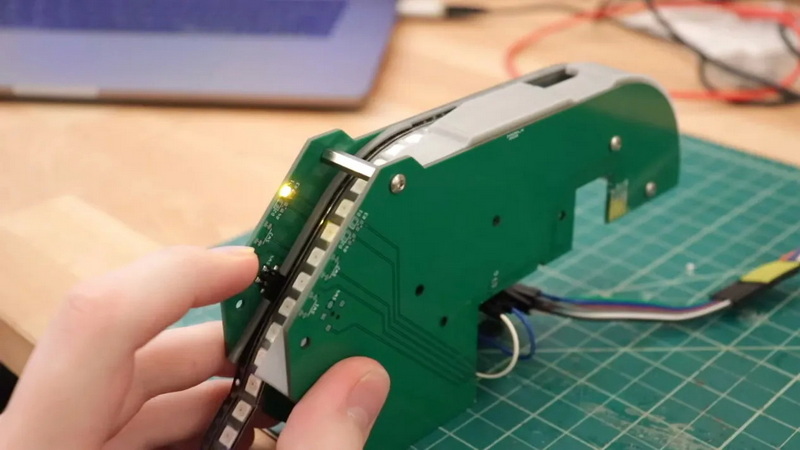

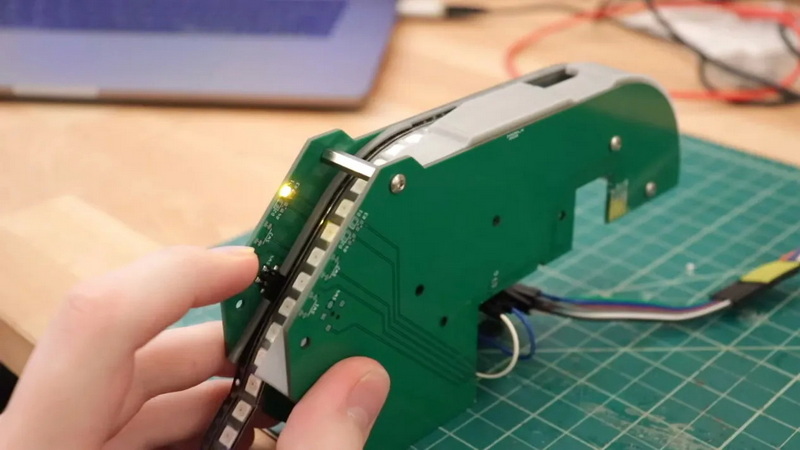

Understanding Small SMD Pick and Place Machines

Small SMD pick and place machines are compact, often desktop-sized devices designed for small-scale production, prototyping, or hobbyist use. They typically feature fewer placement heads, limited feeder capacity, and slower placement speeds compared to larger industrial machines. However, they offer several advantages:

- Affordability: Small machines are significantly less expensive, making them accessible to startups, small businesses, and electronics enthusiasts[5].

- Compact Footprint: Their small size allows them to fit in limited workspace environments, such as labs or small workshops.

- Ease of Use: These machines often come with user-friendly software and simpler setup processes, ideal for users with limited experience[5].

- Flexibility: Small machines are well-suited for handling a variety of small batch jobs, prototypes, and custom assemblies where frequent changeovers are required.

Despite these benefits, small SMD pick and place machines have limitations in speed, accuracy, and component handling capacity compared to larger models.

Features of Larger SMD Pick and Place Machines

Larger pick and place machines are designed for high-volume manufacturing environments. They incorporate advanced technologies to maximize throughput, accuracy, and automation:

- High Placement Speed: Industrial machines can place tens of thousands of components per hour, significantly faster than small machines[1].

- Multiple Placement Heads: Larger models often have multiple heads working simultaneously, increasing efficiency.

- Advanced Vision Systems: These machines use sophisticated cameras and sensors for precise component recognition and placement verification[1][7].

- Large Feeder Capacity: They support numerous feeder slots, allowing continuous operation with minimal downtime for reloading components[1].

- Greater Placement Accuracy: High-end machines achieve placement accuracy as tight as ±25 microns, essential for fine-pitch and complex components[1].

- Automation and Integration: Larger machines integrate seamlessly into automated production lines, including solder paste printing, inspection, and reflow soldering[1][5].

The trade-off is that these machines require significant investment, larger floor space, and skilled operators.

Comparative Analysis: Small vs. Large SMD Pick and Place Machines

| Feature | Small SMD Pick and Place Machine | Large SMD Pick and Place Machine |

| Cost | Low to moderate, suitable for startups and hobbyists5 | High capital investment, suited for mass production1 |

| Placement Speed | Slower, suitable for low to medium volume5 | Very high, capable of 100,000+ components per hour1 |

| Placement Accuracy | Moderate accuracy, sufficient for prototypes and small runs | High precision (±25 µm or better), critical for complex PCBs1 |

| Feeder Capacity | Limited feeder slots, frequent reloading needed | Large feeder capacity, supports continuous operation1 |

| Machine Size and Footprint | Compact, desktop or benchtop size5 | Large, requires dedicated floor space1 |

| Ease of Use | User-friendly, simple software interfaces5 | Complex software, requires trained operators1 |

| Automation Level | Semi-automatic or manual assistance common8 | Fully automatic with integrated inspection and feedback17 |

| Application Suitability | Prototyping, small batch production, hobbyists5 | High-volume manufacturing, OEMs, contract manufacturers |

Applications and Use Cases

Small SMD Pick and Place Machines

- Ideal for electronics startups developing prototypes or small product runs.

- Suitable for educational institutions and research labs.

- Hobbyists and DIY electronics enthusiasts benefit from affordability and ease of use.

- Small contract manufacturers handling custom or low-volume orders.

Large SMD Pick and Place Machines

- Used by Original Equipment Manufacturers (OEMs) for mass production.

- High-volume contract manufacturers requiring fast turnaround.

- Production of complex PCBs with fine-pitch components and high component density.

- Facilities implementing smart factory solutions with integrated automation[1][5].

Key Considerations When Choosing Between Small and Large Machines

- Production Volume: Small machines are cost-effective for low volumes; large machines are necessary for high throughput.

- Budget Constraints: Initial investment and operating costs differ significantly.

- Space Availability: Larger machines require more floor space.

- Component Complexity: Fine-pitch and high-density boards benefit from larger machines' precision.

- Operator Expertise: Larger machines may require specialized training.

- Future Scalability: Consider potential growth in production needs.

Conclusion

Small SMD pick and place machines offer an accessible, flexible, and affordable solution for prototyping, small batch production, and hobbyist projects. They provide sufficient accuracy and ease of use for these applications but are limited in speed, feeder capacity, and automation. Larger pick and place machines excel in high-speed, high-precision, and high-volume manufacturing environments, offering advanced features and integration capabilities at a higher cost and complexity. Selecting the right machine depends on your production scale, budget, and technical requirements.

FAQ

1. What is a small SMD pick and place machine best used for?

Small SMD pick and place machines are best suited for prototyping, small batch production, educational purposes, and hobbyist projects due to their affordability, compact size, and ease of use[5].

2. How does placement accuracy differ between small and large pick and place machines?

Large machines typically achieve higher placement accuracy (as precise as ±25 microns), essential for fine-pitch components, while small machines offer moderate accuracy suitable for less complex assemblies[1].

3. Can small SMD pick and place machines handle complex PCBs?

While small machines can handle many standard components, they may struggle with very fine-pitch or high-density PCBs that require the precision and speed of larger industrial machines[1][5].

4. Are small SMD pick and place machines fully automatic?

Many small machines are semi-automatic or require some manual assistance, whereas larger models are usually fully automatic with integrated vision and inspection systems[8].

5. What factors should I consider when choosing a pick and place machine?

Consider production volume, budget, required placement accuracy, component complexity, available space, and operator expertise to select the machine that best fits your needs[5].

Citations:

[1] https://www.nextpcb.com/blog/top-10-smt-machines-worldwide

[2] https://www.reddit.com/r/ECE/comments/po8qbj/any_recommendations_for_cheap_pick_and_place/

[3] https://www.smtmachine.eu/top-9-best-smt-pick-and-place-machine-of-2024/

[4] https://www.eevblog.com/forum/manufacture/choosing-a-desktop-pick-and-place-machine/

[5] https://www.manufacturingtomorrow.com/news/2024/06/24/choosing-the-right-smt-pick-and-place-machine-a-comprehensive-guide-for-different-buyers/22957/

[6] https://www.eevblog.com/forum/manufacture/choosing-a-desktop-pick-and-place-machine/75/

[7] https://www.itechsmt.com/blogs/news/how-pick-and-place-machine-works-1

[8] https://patents.google.com/patent/WO2003034802A1/en

[9] https://yourpcb.com/best-pick-and-place-machines/

[10] https://www.restronics.com/blog/everything-you-need-to-know-about-smt-pick-and-place-machines

[11] https://www.alibaba.com/showroom/small-smd-pick-and-place-machine.html