Content Menu

● How Do Pick and Place SMD Machines Revolutionize PCB Assembly?

>> Understanding Pick and Place SMD Machines

>>> Key Features of Pick and Place SMD Machines

>> The PCB Assembly Process Using Pick and Place SMD Machines

>>> 1. Design Preparation

>>> 2. Solder Paste Application

>>> 3. Component Placement

>>> 4. Reflow Soldering

>>> 5. Inspection

>> Advantages of Using Pick and Place SMD Machines

>> Applications of Pick and Place SMD Machines

>> The Future of Pick and Place Technology

>>> 1. Increased Automation

>>> 2. IoT Integration

>>> 3. Sustainability Initiatives

>> Challenges in Implementing Pick and Place Technology

>> Best Practices for Maximizing Efficiency with Pick and Place Machines

>> Conclusion

>> Frequently Asked Questions

How Do Pick and Place SMD Machines Revolutionize PCB Assembly?

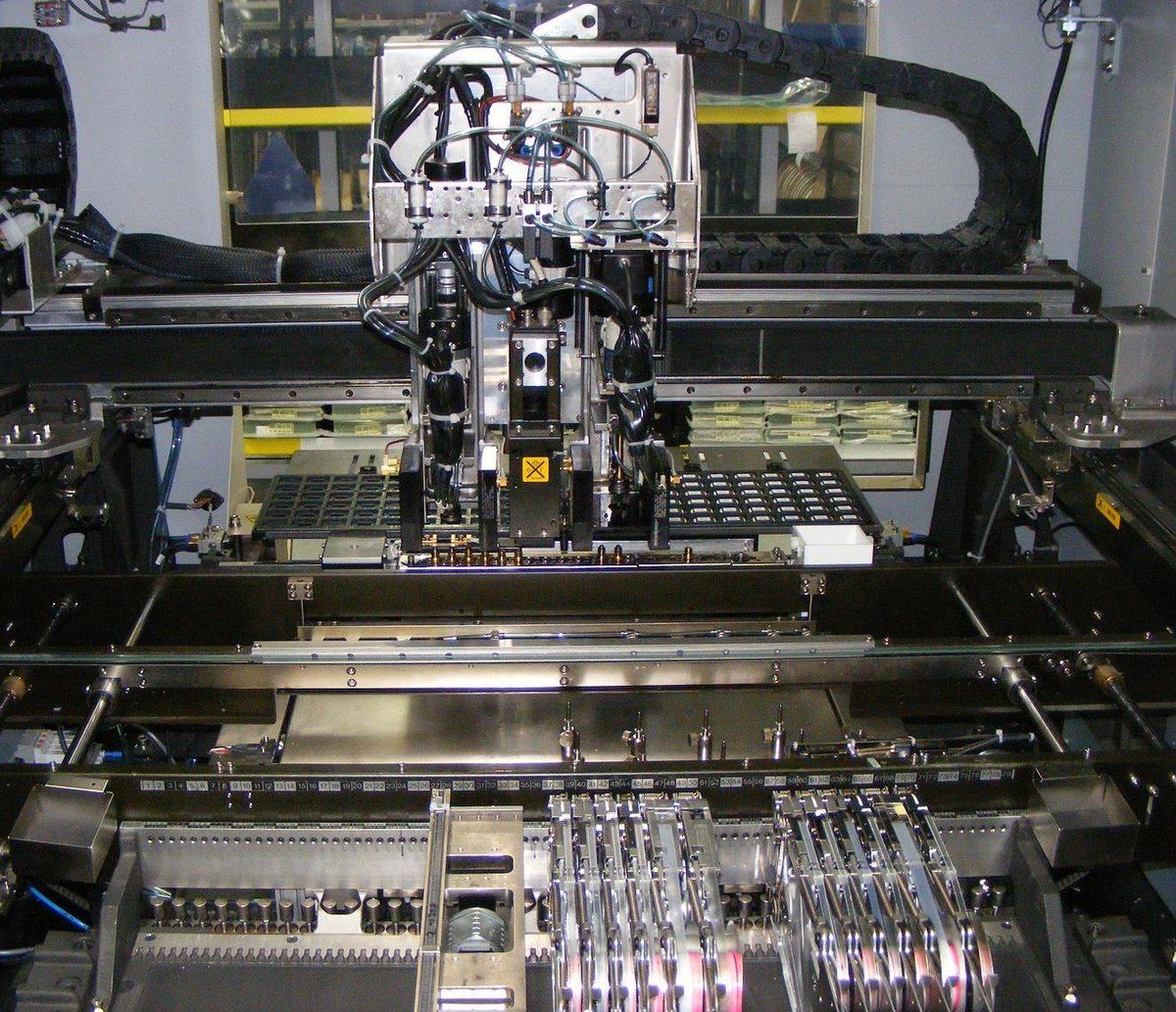

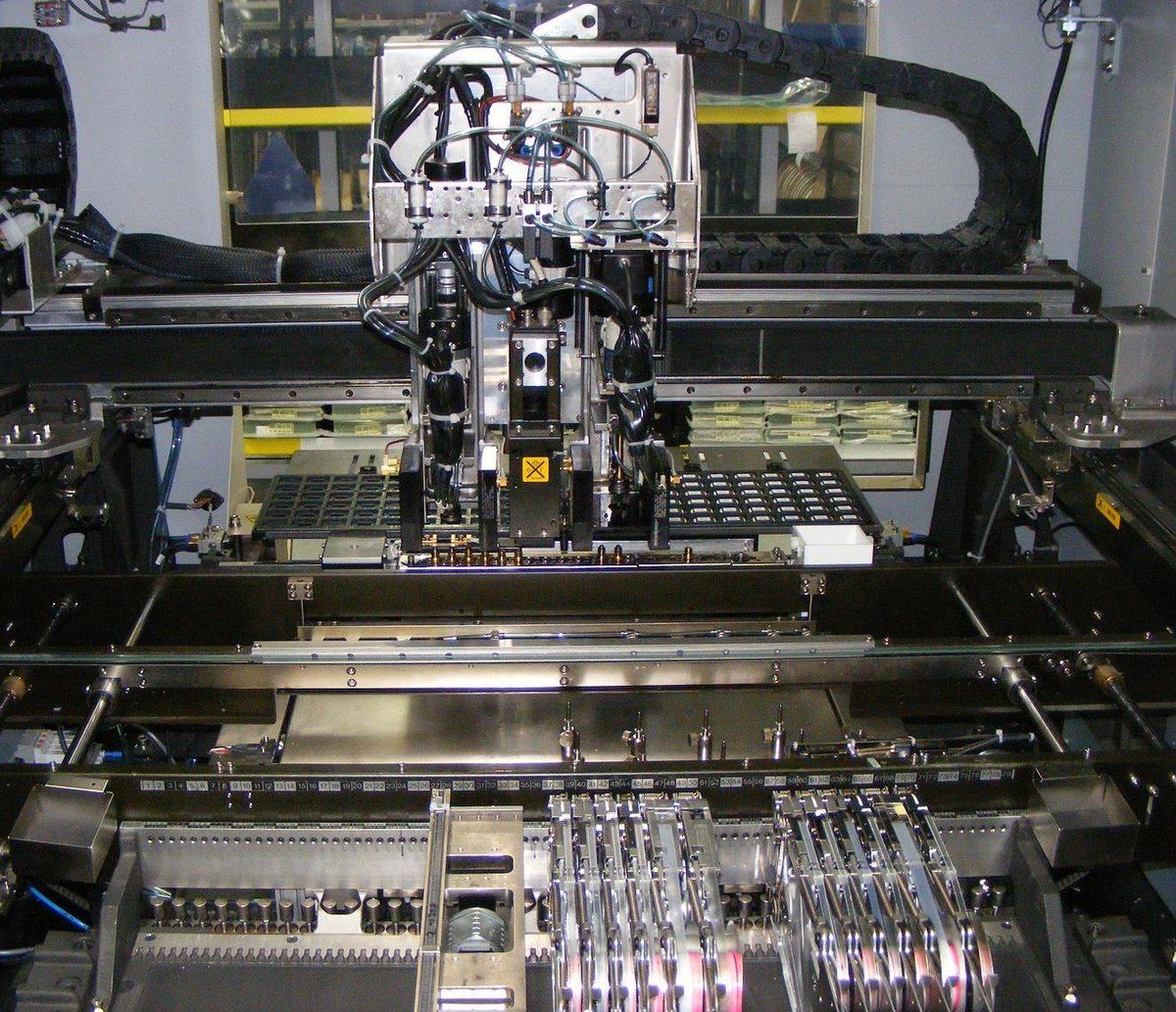

Pick and place SMD machines are automated systems used in the electronics manufacturing industry to position surface mount devices (SMDs) onto PCBs. These machines have transformed traditional assembly processes by significantly increasing speed, accuracy, and efficiency.

Key Features of Pick and Place SMD Machines

1. High-Speed Operation: Modern pick and place machines can place thousands of components per hour, dramatically reducing assembly time compared to manual methods.

2. Precision Placement: Equipped with advanced vision systems, these machines ensure that each component is accurately positioned on the PCB, minimizing errors.

3. Versatility: Pick and place machines can handle a wide variety of component types and sizes, making them suitable for diverse applications.

4. Automated Workflow: These machines integrate seamlessly with other SMT processes such as solder paste application and reflow soldering, creating a streamlined production line.

5. User-Friendly Interfaces: Many pick and place machines come with intuitive software that simplifies programming and operation.

The PCB Assembly Process Using Pick and Place SMD Machines

The assembly process using pick and place machines involves several key steps:

1. Design Preparation

Before production begins, engineers design the PCB layout using computer-aided design (CAD) software. This design specifies where each component will be placed on the board.

2. Solder Paste Application

Solder paste is applied to the PCB using a stencil printer. This paste will act as an adhesive for the components during assembly.

3. Component Placement

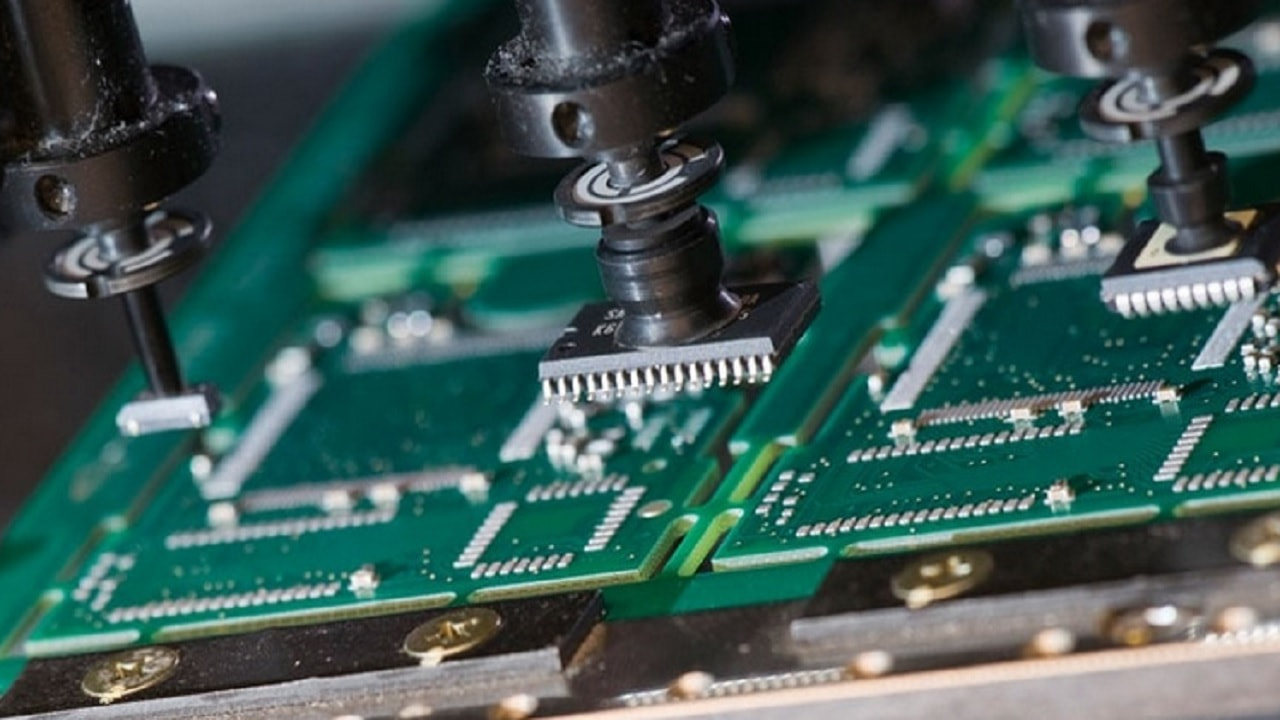

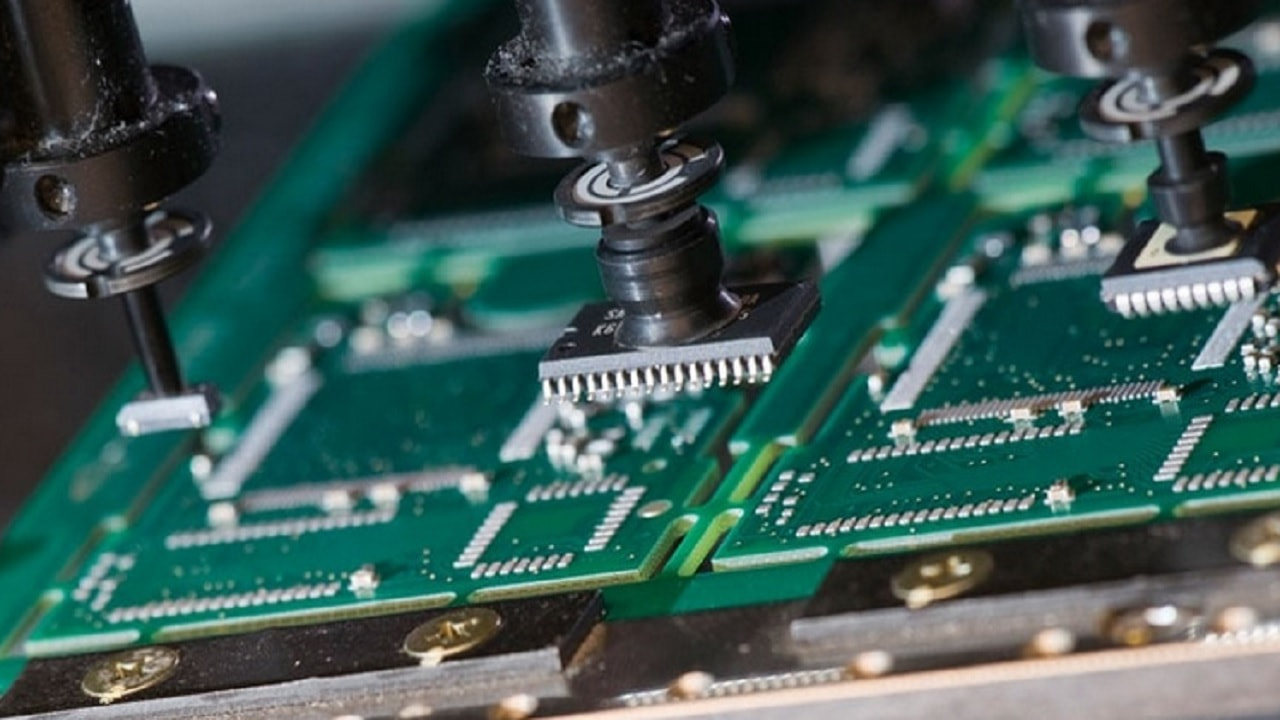

Once the solder paste is applied, the PCB is fed into the pick and place machine. The machine uses vacuum nozzles to pick up components from feeders and accurately places them onto the solder paste-covered pads on the PCB.

Pick and Place Process

4. Reflow Soldering

After all components are placed, the PCB moves to a reflow oven where heat is applied to melt the solder paste, forming strong electrical connections between components and pads.

5. Inspection

Finally, automated optical inspection (AOI) systems check for defects such as misaligned components or insufficient solder joints.

Advantages of Using Pick and Place SMD Machines

Investing in pick and place SMD machines offers numerous benefits for electronics manufacturers:

- Increased Efficiency: The high-speed operation of these machines allows for rapid production cycles.

- Reduced Labor Costs: Automation decreases reliance on manual labor, leading to lower operational costs.

- Improved Quality Control: Advanced vision systems enhance placement accuracy, reducing defects.

- Flexibility: Manufacturers can easily switch between different product lines without significant downtime.

- Scalability: As demand increases, manufacturers can scale up production by adding more machines or upgrading existing ones.

Applications of Pick and Place SMD Machines

Pick and place SMD machines are used across various industries due to their versatility:

- Consumer Electronics: Smartphones, tablets, and laptops require precise assembly of numerous small components.

- Automotive Electronics: Modern vehicles rely heavily on electronic systems that demand high reliability.

- Medical Devices: Precision in medical electronics is crucial; thus, pick and place machines are essential for this sector.

- Industrial Automation: Robotics and automation systems often utilize PCBs assembled with pick and place technology.

The Future of Pick and Place Technology

As technology continues to advance, several trends are shaping the future of pick and place SMD machines:

1. Increased Automation

The trend towards fully automated factories is growing. Future pick and place machines will likely incorporate more robotics to enhance efficiency further.

2. IoT Integration

The Internet of Things (IoT) is becoming more prevalent in manufacturing processes. Smart factories equipped with connected devices can monitor performance metrics in real-time.

3. Sustainability Initiatives

There is a growing emphasis on sustainable manufacturing practices. Companies are looking for ways to reduce waste during production processes.

Challenges in Implementing Pick and Place Technology

While there are many advantages to adopting pick and place technology, challenges also exist:

- Initial Investment Costs: The upfront costs for advanced machinery can be significant.

- Training Requirements: Staff may need training to operate new equipment effectively.

- Integration with Existing Systems: Ensuring new machines work seamlessly with existing processes can be complex.

Best Practices for Maximizing Efficiency with Pick and Place Machines

To get the most out of your investment in pick and place SMD machines, consider these best practices:

1. Regular Maintenance: Schedule routine maintenance checks to keep machinery running smoothly.

2. Continuous Training: Invest in ongoing training programs for staff to keep them updated on best practices.

3. Data Analysis: Utilize data analytics tools to monitor production efficiency.

4. Collaboration with Suppliers: Work closely with suppliers like GS-SMT LTD to stay informed about new technologies.

Conclusion

In conclusion, pick and place SMD machines play a crucial role in modern electronics manufacturing by enhancing efficiency, accuracy, and flexibility in PCB assembly processes. As a leading pick place SMD manufacturer, Global Soul Limited recognizes the importance of these advanced technologies in driving quality within the industry. By understanding their benefits and applications, manufacturers can make informed decisions that will shape their future success.

---

Frequently Asked Questions

1. What is a pick and place SMD machine?

- A pick and place SMD machine is an automated system used in electronics manufacturing to position surface mount devices onto printed circuit boards accurately.

2. How does a pick and place machine work?

- It uses vacuum nozzles to pick components from feeders and places them onto solder paste-covered pads on PCBs.

3. What industries use pick and place technology?

- Industries such as consumer electronics, automotive manufacturing, medical devices, and industrial automation utilize this technology.

4. What are the benefits of using pick and place machines?

- Benefits include increased efficiency, reduced labor costs, improved quality control, flexibility in production lines, and scalability.

5. What challenges might manufacturers face when implementing this technology?

- Challenges include high initial investment costs, training requirements for staff, and integration issues with existing systems.