Content Menu

● Introduction to SMT PCB Coating Machines

>> Types of Coatings

● Cost Factors of SMT PCB Coating Machines

>> Initial Investment

>> Operational Costs

● Benefits of SMT PCB Coating Machines

>> Enhanced Reliability

>> Cost Savings

>> Flexibility and Efficiency

● SMT PCB Connectors in Coating Processes

>> Types of SMT Connectors

>> Advantages of SMT Connectors

● Advanced Features and Technologies

>> Integration with Other Manufacturing Processes

>> Environmental Considerations

● Conclusion

● FAQs

>> 1. What is the primary purpose of using an SMT PCB coating machine?

>> 2. How do SMT PCB connectors affect the coating process?

>> 3. What are the key cost factors associated with SMT PCB coating machines?

>> 4. What benefits does using an SMT PCB coating machine offer?

>> 5. How does automation impact the cost of SMT PCB coating?

Investing in an SMT PCB coating machine is a significant decision for any electronics manufacturing company. This type of equipment is crucial for protecting printed circuit boards (PCBs) from environmental factors such as moisture, dust, and chemicals, thereby enhancing their reliability and lifespan. However, understanding the cost implications of such an investment is essential for budget planning and strategic decision-making. In this article, we will delve into the various cost factors associated with SMT PCB coating machines, including initial investment, operational costs, and potential savings.

Introduction to SMT PCB Coating Machines

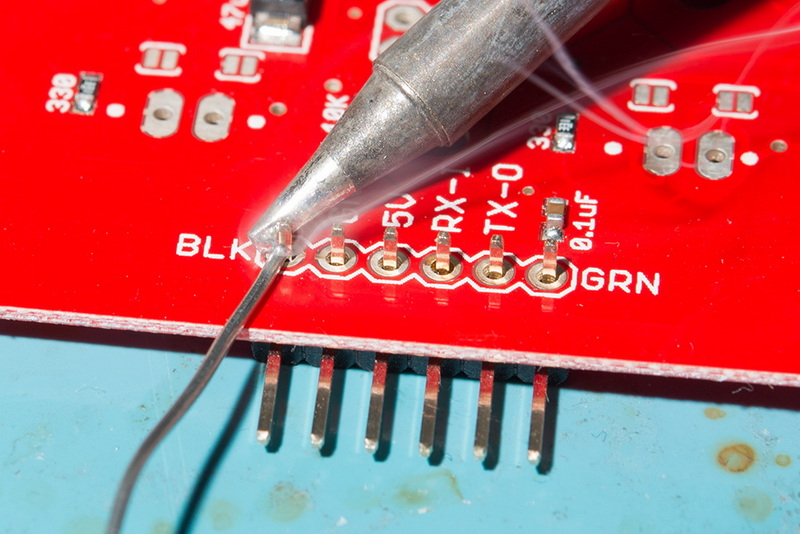

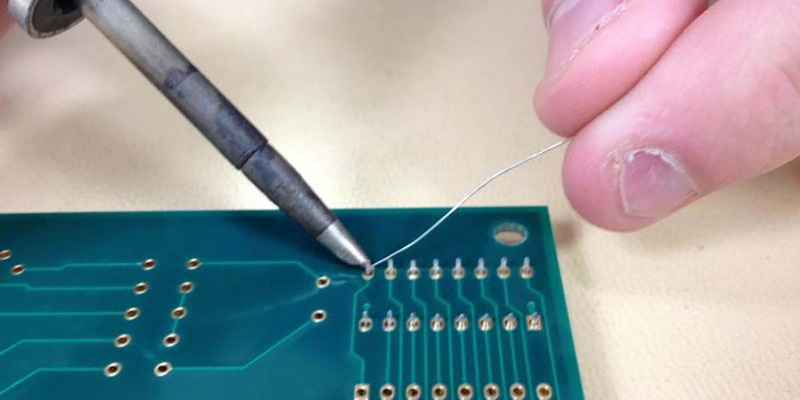

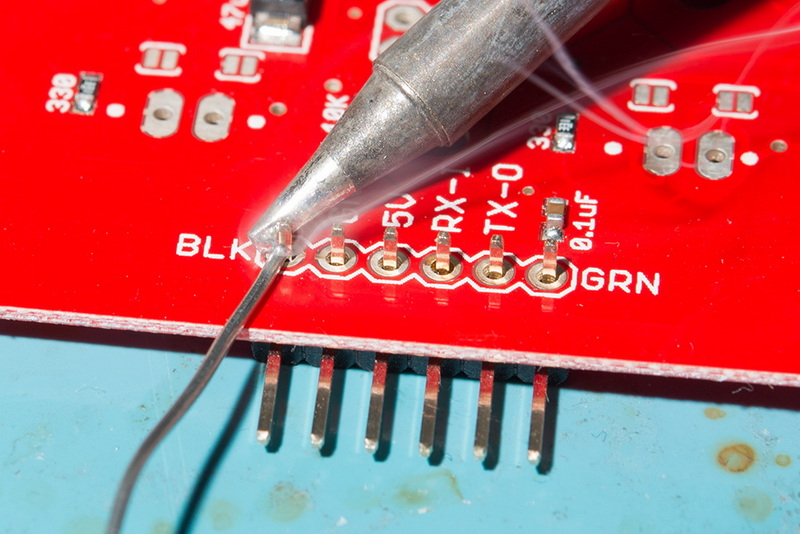

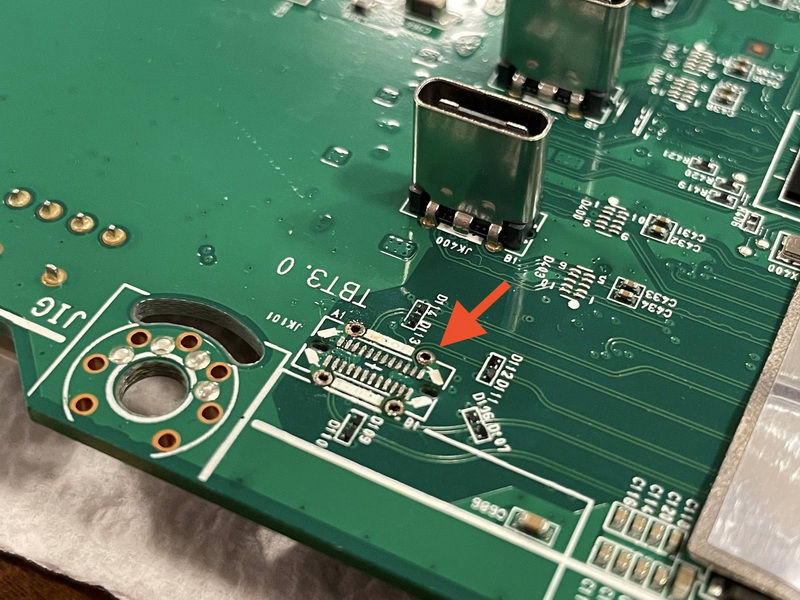

SMT PCB coating machines are designed to apply a protective layer of conformal coating to PCBs. This process involves using specialized machines that can precisely apply coatings to specific areas of the board, ensuring that sensitive components are protected while maintaining the functionality of connectors and other interfaces. The use of SMT PCB connectors in these boards is common, as they provide compact and reliable connections essential for modern electronic devices.

Types of Coatings

There are several types of coatings used in PCB protection, including acrylic, epoxy, silicone, and urethane. Each type has its own advantages and is chosen based on the specific requirements of the PCB application. For instance, acrylic coatings are easy to apply and remove, making them suitable for prototypes or development stages, while epoxy coatings offer high chemical resistance and are often used in harsh environments.

Cost Factors of SMT PCB Coating Machines

Initial Investment

1. Machine Purchase Cost: The initial cost of purchasing an SMT PCB coating machine can vary widely depending on its features, automation level, and brand. Basic models may start at a few thousand dollars, while advanced systems with high precision and automation capabilities can cost tens of thousands of dollars.

2. Setup and Installation: Beyond the machine itself, there are costs associated with setting up and installing the equipment. This includes modifying the production area to accommodate the machine, ensuring proper ventilation, and connecting it to power and data networks.

3. Training and Support: Employees need training to operate the machine efficiently. Additionally, ongoing technical support from the manufacturer is crucial for maintaining optimal performance and addressing any issues promptly.

Operational Costs

1. Consumables and Materials: The cost of coating materials, such as the conformal coating itself, is a recurring expense. The choice of coating material can significantly impact these costs, with some materials being more expensive than others due to their properties and application requirements.

2. Energy and Maintenance: Running the machine consumes electricity, and regular maintenance is necessary to prevent breakdowns and ensure consistent quality. Maintenance costs include replacement parts and labor for routine checks and repairs.

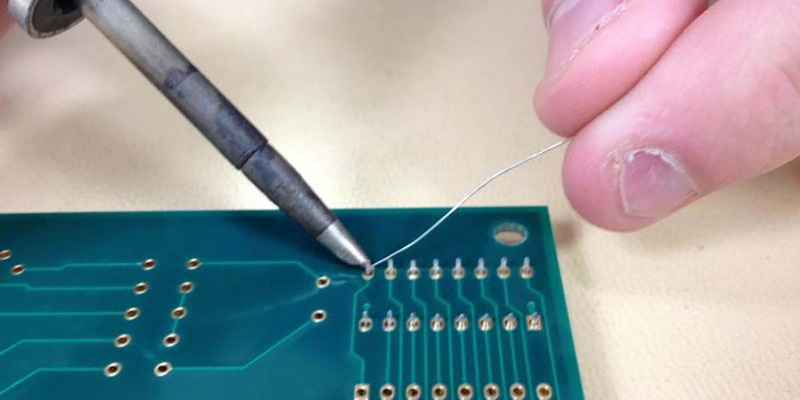

3. Labor Costs: While automated machines reduce labor needs, some manual intervention is still required for setup, monitoring, and troubleshooting. The level of automation influences these costs, with more automated systems generally requiring less human intervention.

Benefits of SMT PCB Coating Machines

Enhanced Reliability

- Environmental Protection: Coating protects PCBs from moisture, dust, and chemicals, reducing the risk of corrosion and electrical failures.

- Increased Lifespan: By shielding components from environmental stressors, coated PCBs can operate reliably over longer periods.

Cost Savings

- Reduced Rework: Proper coating reduces the need for rework due to environmental damage, saving time and resources.

- Improved Yield: Higher reliability means fewer defective units, leading to increased production yields and reduced waste.

Flexibility and Efficiency

- Precision Application: Modern machines allow for selective coating, applying material only where needed, which can reduce material waste and improve efficiency.

- Automated Processes: Automated coating machines enable high-volume production with minimal manual labor, enhancing productivity and reducing labor costs.

SMT PCB Connectors in Coating Processes

SMT PCB connectors play a crucial role in ensuring that PCBs maintain their functionality after coating. These connectors must be carefully selected and positioned to avoid interference with the coating process. The design of the PCB should ensure that connectors are accessible and not covered by the coating, which could prevent proper connections.

Types of SMT Connectors

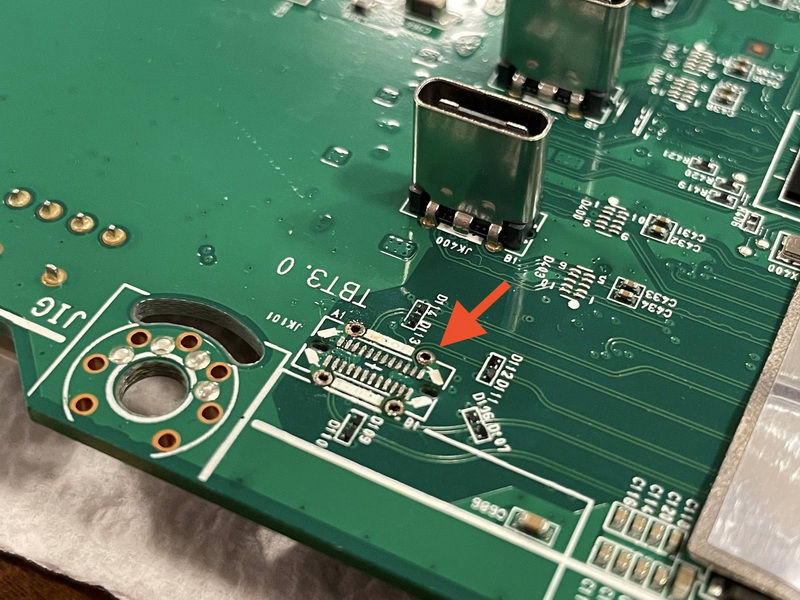

- Header Connectors: These are commonly used for signal and power connections and come in various pitch sizes.

- Terminal Block Connectors: Used for linking wires to PCBs, they offer durability and reliable conductivity.

Advantages of SMT Connectors

- Compact Size: SMT connectors are smaller, allowing for higher component density on PCBs.

- Ease of Assembly: They are easier to assemble than through-hole connectors, reducing production time and errors.

- Cost-Effective: Generally less expensive than through-hole connectors, contributing to lower overall production costs.

Advanced Features and Technologies

Modern SMT PCB coating machines often incorporate advanced features such as computer-controlled dispensing systems, which allow for precise application of coatings. These systems can be programmed to apply coatings in specific patterns or thicknesses, optimizing material usage and ensuring consistent quality.

Integration with Other Manufacturing Processes

For maximum efficiency, SMT PCB coating machines can be integrated with other manufacturing processes, such as pick-and-place machines and reflow ovens. This integration enables a streamlined production line where PCBs can be assembled, coated, and inspected in a continuous workflow, reducing handling errors and increasing throughput.

Environmental Considerations

The choice of coating material and the coating process itself should consider environmental factors. Some coatings may have volatile organic compounds (VOCs) or other chemicals that require special handling and disposal. Manufacturers must ensure compliance with environmental regulations and adopt sustainable practices where possible.

Conclusion

Investing in an SMT PCB coating machine involves significant upfront costs, including the machine purchase, setup, and training. However, these investments can lead to long-term savings through enhanced PCB reliability, reduced rework, and improved production efficiency. Understanding the role of SMT PCB connectors in these processes is crucial for ensuring that PCBs remain functional and reliable after coating. By carefully evaluating these factors, manufacturers can make informed decisions about their coating operations and optimize their production processes.

FAQs

1. What is the primary purpose of using an SMT PCB coating machine?

- The primary purpose is to apply a protective layer to PCBs, enhancing their reliability and lifespan by shielding them from environmental factors.

2. How do SMT PCB connectors affect the coating process?

- SMT PCB connectors must be carefully positioned to avoid interference with the coating process. They should remain accessible and not be covered by the coating to ensure proper connections.

3. What are the key cost factors associated with SMT PCB coating machines?

- Key cost factors include the initial machine purchase, setup and installation costs, ongoing operational expenses (such as consumables and maintenance), and labor costs.

4. What benefits does using an SMT PCB coating machine offer?

- Benefits include enhanced PCB reliability, reduced rework needs, improved production yields, and increased efficiency through automation.

5. How does automation impact the cost of SMT PCB coating?

- Automation reduces labor costs by minimizing manual intervention, improves efficiency, and enhances consistency in the coating process.