Content Menu

● Introduction to Laser Cut Mylar SMT Stencils

>> Advantages of Laser Cut Mylar SMT Stencils

● Maintenance Techniques for Laser Cut Mylar SMT Stencils

>> Cleaning the Stencil

>> Storage Methods

>> Handling Precautions

● Tips for Extending Stencil Life

● Common Issues and Solutions

● Advanced Techniques for Laser Cutting Mylar

● Enhancing Stencil Performance

● Best Practices for Solder Paste Application

● Laser Cutting Techniques for Mylar Stencils

● DIY Laser Cut Stencils for SMT Assembly

● Conclusion

● FAQs

>> 1. What is the best material for laser cut SMT stencils?

>> 2. How do I clean laser cut Mylar SMT stencils?

>> 3. What are the common issues with laser cut Mylar stencils?

>> 4. Can I use laser cut Mylar stencils for high-volume production?

>> 5. How do I store laser cut Mylar SMT stencils?

● Citations:

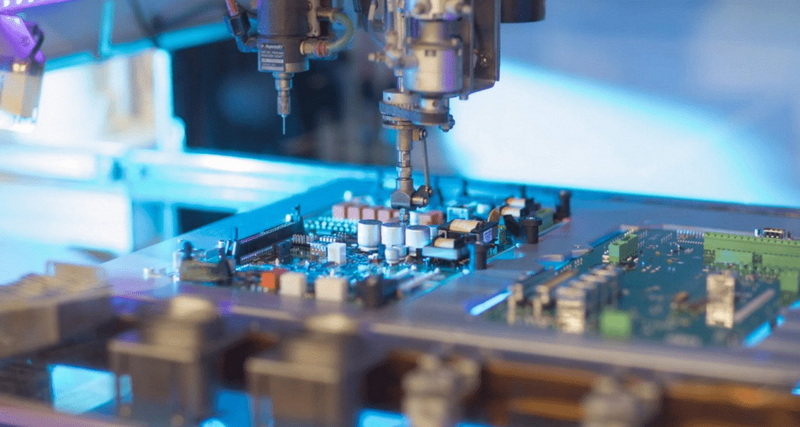

Laser cut Mylar SMT stencils are essential tools in the electronics manufacturing industry, particularly for surface mount technology (SMT) applications. These stencils are made from Mylar, a type of polyester film known for its durability, flexibility, and heat resistance, making them ideal for applying solder paste to printed circuit boards (PCBs). Proper maintenance of these stencils is crucial to ensure their longevity and performance. In this article, we will explore the best practices for maintaining laser cut Mylar SMT stencils.

Introduction to Laser Cut Mylar SMT Stencils

Laser cut Mylar SMT stencils are designed to facilitate the reflow soldering process by accurately applying solder paste to the PCB pads. This method is superior to hand soldering with irons, as it allows for faster assembly and better soldering of components with pads on the bottom of packages. Mylar stencils are economical alternatives to metal stencils and are widely used in prototypes and low-volume manufacturing runs.

Advantages of Laser Cut Mylar SMT Stencils

1. Precision and Accuracy: Laser cutting ensures precise apertures that match the PCB layout, reducing errors in solder paste application.

2. Cost-Effectiveness: Mylar stencils are less expensive than metal stencils, making them ideal for small-scale production.

3. Flexibility: Mylar is flexible and can be easily stored and transported without damage.

4. Heat Resistance: Mylar can withstand the high temperatures involved in the reflow soldering process.

Maintenance Techniques for Laser Cut Mylar SMT Stencils

Proper maintenance is essential to extend the life of your laser cut Mylar SMT stencils and ensure they continue to perform optimally.

Cleaning the Stencil

Cleaning is a critical step in maintaining the stencil. After each use, clean the stencil with isopropyl alcohol (IPA) to remove any solder paste residue. IPA is effective at dissolving solder without damaging the Mylar material.

1. Dampen a lint-free cloth with IPA.

2. Gently wipe the stencil to remove solder residue.

3. Allow the stencil to air dry completely before storing.

Storage Methods

Proper storage protects the stencil from physical damage and environmental factors that could degrade its quality.

1. Flat Storage: Store the stencil flat in a protective folder or sleeve to prevent bending or warping.

2. Avoid Moisture and Sunlight: Keep the stencil away from moisture and direct sunlight, as these can cause the Mylar to degrade.

3. Use Protective Covers: Cover the stencil with a clear plastic sheet or sleeve to shield it from dust and scratches.

Handling Precautions

- Avoid Overstretching: Handle the stencil gently to prevent stretching or distorting the Mylar.

- Minimize Exposure to Heat: Avoid exposing the stencil to excessive heat, which can cause it to deform.

Tips for Extending Stencil Life

To maximize the lifespan of your laser cut Mylar SMT stencil, consider the following tips:

- Regular Inspection: Check the stencil for any signs of wear or damage before use.

- Avoid Overuse: Limit the number of uses for each stencil to prevent wear and tear.

- Proper Alignment: Ensure the stencil is properly aligned with the PCB during solder paste application to avoid misregistration.

Common Issues and Solutions

Sometimes, issues may arise during the use of laser cut Mylar SMT stencils. Here are some common problems and their solutions:

- Inaccurate Apertures: If the apertures do not match the PCB layout, check the design file and ensure that the laser cutting settings are correct.

- Solder Paste Not Adhering: Ensure the PCB surface is clean and free of debris. Also, check the solder paste viscosity and expiration date.

Advanced Techniques for Laser Cutting Mylar

For those interested in creating their own laser cut Mylar stencils, here are some advanced techniques:

- Raster Engraving: Use raster engraving for cutting small holes to allow the material more time to cool and prevent overheating.

- Low Power and Speed Settings: Adjust laser settings to prevent burning or melting the Mylar.

Enhancing Stencil Performance

To further enhance the performance of your laser cut Mylar SMT stencils, consider the following strategies:

- Stencil Thickness: Ensure the stencil thickness is appropriate for the application. Thicker stencils are more durable but may require more solder paste.

- Aperture Design: Optimize aperture shapes and sizes to improve solder paste release and reduce bridging.

- Stencil Frame: Use a stencil frame to improve stencil stability and alignment during the solder paste application process.

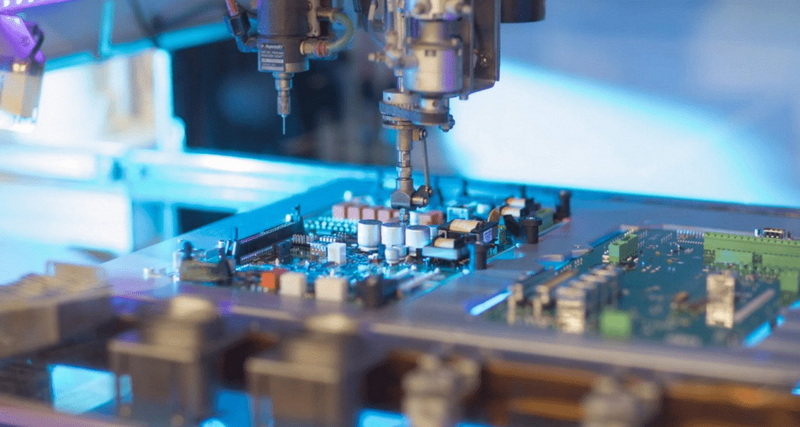

Best Practices for Solder Paste Application

Effective solder paste application is crucial for achieving high-quality solder joints. Here are some best practices:

- Solder Paste Selection: Choose a solder paste with the right viscosity and type (e.g., no-clean, water-soluble) for your application.

- Stencil Alignment: Ensure precise alignment of the stencil with the PCB to prevent solder paste misregistration.

- Squeegee Technique: Use a smooth, consistent squeegee motion to apply solder paste evenly.

Laser Cutting Techniques for Mylar Stencils

Laser cutting is a precise method for creating detailed stencil designs. Here are some key considerations when laser cutting Mylar:

- Material Selection: Mylar is a popular choice due to its durability and flexibility, but other materials like paper, card, vinyl, and thin plastics can also be used[1].

- Laser Settings: Adjust the laser cutter's settings according to the material. This includes cutting speed, laser power, and blade settings. Different materials require specific settings to achieve optimal cuts[1].

- Ventilation: Ensure good ventilation when cutting materials like Mylar that produce smoke or particulates[1].

DIY Laser Cut Stencils for SMT Assembly

For makers and electronics enthusiasts, creating DIY laser cut stencils can be a cost-effective and efficient way to produce high-quality stencils for SMT assembly. Here are some tips:

- Material Alternatives: Consider using laser printer transparencies as an alternative to Mylar for DIY projects[2].

- Thermal Management: Use thermal management techniques to prevent melting during cutting. A sandwich method involving cardboard and copier paper can help[2].

- Optimal Laser Settings: Adjust laser air assist settings, movement speed, and power level to achieve precise cuts[2].

Conclusion

Maintaining laser cut Mylar SMT stencils is crucial for ensuring their longevity and performance in electronics manufacturing. By following proper cleaning, storage, and handling practices, you can extend the life of your stencils and achieve consistent results in solder paste application. Whether you are working on prototypes or small-scale production, these stencils offer a cost-effective and precise solution for SMT applications.

FAQs

1. What is the best material for laser cut SMT stencils?

- Mylar (BoPET) is widely used due to its durability, flexibility, and heat resistance.

2. How do I clean laser cut Mylar SMT stencils?

- Use isopropyl alcohol (IPA) to gently remove solder paste residue.

3. What are the common issues with laser cut Mylar stencils?

- Common issues include inaccurate apertures and solder paste not adhering properly. Check the design file and PCB surface cleanliness.

4. Can I use laser cut Mylar stencils for high-volume production?

- While Mylar stencils are cost-effective for prototypes and low-volume runs, metal stencils are generally preferred for high-volume production due to their durability.

5. How do I store laser cut Mylar SMT stencils?

- Store them flat in a protective sleeve or folder, away from moisture and direct sunlight.

Citations:

[1] https://shop.machinemfg.com/how-to-make-stencil-designs-using-laser-cutting/

[2] https://www.youtube.com/watch?v=WfyZK2GO3Sc

[3] https://www.pcbway.com/blog/Engineering_Technical/Laser_Cut_Stenciling_for_SMT_PCB_DIY_Solder_Pasting.html

[4] https://www.hygradelaser.com.au/can-you-cut-mylar-with-a-laser

[5] https://razorlab.online/guide-to-laser-cut-stencils/

[6] https://hackaday.com/2014/06/27/how-to-laser-cut-mylar-solder-stencils/

[7] https://www.pololu.com/product/446

[8] https://www.reddit.com/r/lasercutting/comments/bk6kc5/cutting_mylar_for_pcb_stencils_with_a_5w_450nm/

[9] http://www.trainboard.com/highball/index.php?threads%2Fmylar-6-mil-laser-cut-issues.157483%2F

[10] https://www.stentech.com/products/stencils/laser-cut-smt-stencils

[11] https://www.raypcb.com/how-to-choose-the-correct-stencil-that-suits-your-smt-requirement/

[12] https://sawmillcreek.org/showthread.php?241350-Laser-cut-mylar

[13] https://www.reddit.com/r/lasercutting/comments/1epl0tb/laser_cutting_clear_polyester/

[14] https://www.pnconline.com/blog/advantages-of-laser-cut-smt-stencils-for-smt-assembly/

[15] https://razorlab.online/clean-laser-stencils/

[16] https://www.xometry.com/resources/sheet/stencil-designs/

[17] https://www.eevblog.com/forum/manufacture/laser-cutter-for-stainless-steel-stencils/

[18] https://electronics.stackexchange.com/questions/101817/whats-a-good-plastic-for-self-cutting-solder-paste-stencils-on-a-laser

[19] https://www.youtube.com/watch?v=zyB-01p7AtI

[20] https://www.youtube.com/watch?v=BYRK7hGFOb8