Content Menu

● Introduction to Tape and Reel Packaging

>> Importance of Tape and Reel Specifications

● Key Considerations for Choosing Tape and Reel

● DIY Tape and Reel Solutions

>> Advantages of DIY Solutions

>> Challenges of DIY Solutions

● Best Practices for Using Tape and Reel

● Tape and Reel Services for Enhanced Efficiency

>> Benefits of Professional Services

● Future Trends in Tape and Reel Technology

● Selecting a Tape and Reel Packaging Vendor

● Conclusion

● FAQs

>> 1. What are the common reel sizes used in SMT assembly?

>> 2. How does component orientation affect the assembly process?

>> 3. What materials are typically used for carrier tapes in tape and reel packaging?

>> 4. What are the advantages of using SMT splicing tape?

>> 5. Can DIY tape and reel feeders be integrated with commercial pick-and-place machines?

● Citations:

Choosing the right tape and reel for Surface Mount Technology (SMT) components is crucial for efficient and accurate assembly processes. The tape and reel system is designed to hold hundreds to thousands of surface mount devices, allowing pick-and-place machines to operate with minimal interruptions. This article will guide you through the process of selecting the appropriate tape and reel for your SMT components, focusing on key considerations such as component size, assembly speed, and environmental factors.

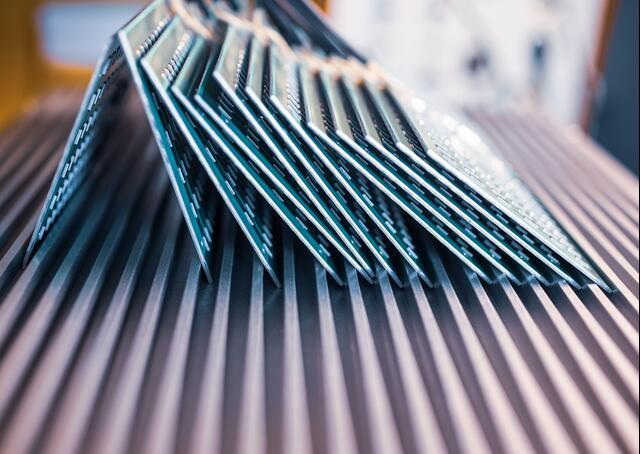

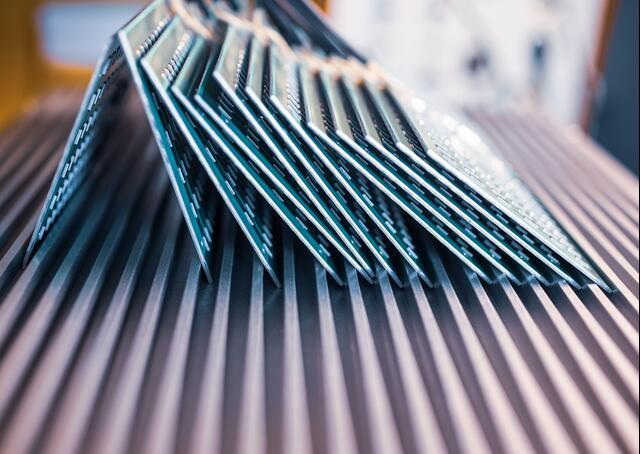

Introduction to Tape and Reel Packaging

Tape and reel packaging is a widely used method in the electronics industry for handling, processing, storing, and transporting electronic components. It provides protection and facilitates precise surface mounting of components. The system consists of a carrier tape with individual pockets, each housing an electronic component, covered by a heat or pressure seal cover tape. This tape is then wrapped around a reel, which can vary in size depending on the component type and quantity.

Importance of Tape and Reel Specifications

Tape and reel specifications are vital for ensuring compatibility with automated assembly equipment. These specifications include reel width, diameter, and pitch (the distance between successive component centers). For instance, reel widths commonly range from 4 mm to 56 mm, and diameters typically include 7 inches and 13 inches[6][8]. These dimensions are crucial for selecting the right feeder types and optimizing the placement process on pick-and-place machines.

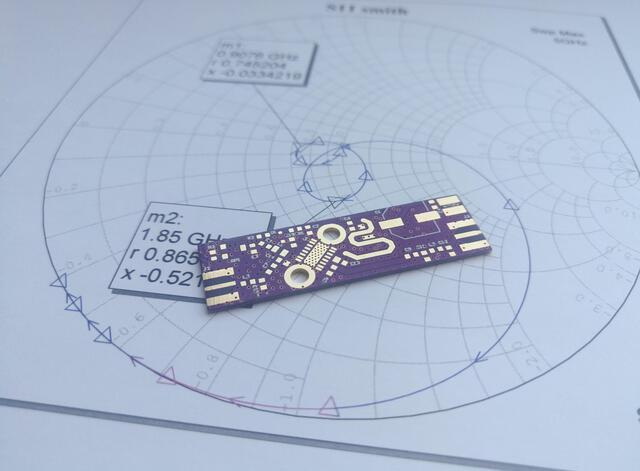

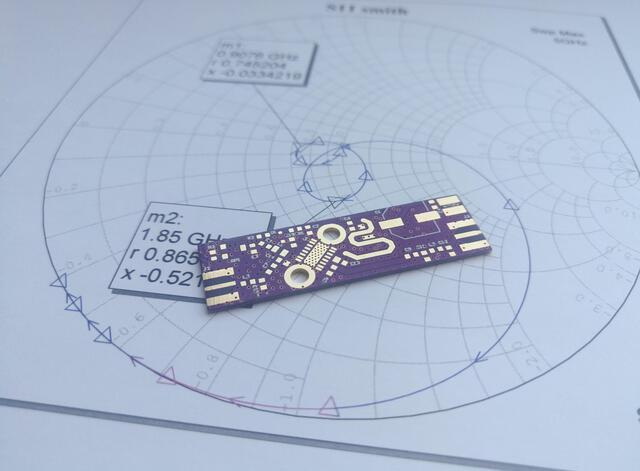

Key Considerations for Choosing Tape and Reel

When selecting tape and reel for your SMT components, several factors must be considered:

1. Component Size and Type: Different components require specific tape widths and reel sizes. For example, larger components may need wider tapes and larger reels to ensure proper handling and protection.

2. Assembly Speed: The speed of your assembly process influences the type of tape and reel needed. High-speed processes often require narrower tapes to ensure smooth feeding through the machinery.

3. Environmental Conditions: The performance of tape and reel can be affected by environmental factors such as temperature and humidity. It is essential to choose materials that maintain their integrity under the specific conditions of your assembly environment.

4. Industry Standards: Compliance with industry standards like EIA-481 and IEC 60286-3 is important for ensuring compatibility across different manufacturing platforms[8].

DIY Tape and Reel Solutions

For those interested in DIY solutions, creating a motorized SMT tape-and-reel feeder can be a cost-effective approach. This involves designing a system with components like stepper motors, feed sprockets, and guide slots to handle tapes of varying widths. However, such systems require careful consideration of mechanical design and material selection to ensure smooth operation and compatibility with automated assembly equipment.

Advantages of DIY Solutions

- Customization: DIY solutions allow for customization based on specific needs, such as handling unique component sizes or orientations.

- Cost Savings: Building your own feeder can reduce costs compared to purchasing commercial systems.

- Flexibility: DIY designs can be adapted to fit different assembly environments and machinery setups.

Challenges of DIY Solutions

- Technical Complexity: Designing a reliable and efficient DIY feeder requires significant technical expertise and resources.

- Material Selection: Choosing the right materials for the feeder components is crucial for ensuring durability and performance.

- Integration with Existing Systems: Ensuring compatibility with existing pick-and-place machinery and software can be challenging.

Best Practices for Using Tape and Reel

To maximize the efficiency and reliability of your tape and reel system, follow these best practices:

- Proper Component Orientation: Ensure that components are correctly oriented in the tape and reel to facilitate smooth assembly and reduce errors.

- Regular Maintenance: Regularly inspect and maintain your tape and reel feeders to prevent mechanical issues and ensure consistent performance.

- Adherence to Standards: Always comply with industry standards for tape and reel packaging to ensure compatibility and reliability across different manufacturing platforms.

Tape and Reel Services for Enhanced Efficiency

Several companies offer specialized tape and reel services designed to optimize component handling and assembly processes. For example, Vestal Electronics provides high-quality tape and reel services for a wide range of SMD components, including standard devices, chip resistors, and odd-form components[3]. These services ensure secure transport and rapid placement during PCB assembly, streamlining production processes.

Benefits of Professional Services

- Customization Options: Professional services often provide customization options for tape widths, pocket sizes, and component orientations to accommodate various specifications.

- ESD Protection: Many vendors offer ESD-protected environments to safeguard sensitive components during handling and packaging.

- Quick-Turn Services: Some vendors provide expedited services for urgent needs, ensuring timely delivery without compromising quality.

Future Trends in Tape and Reel Technology

The future of tape and reel technology involves advancements in materials, automation, and machine learning. These innovations are expected to enhance precision, efficiency, and customization in component handling and assembly processes. Companies are investing in research and development to create more sophisticated and adaptable tape and reel systems that can handle a wide range of component types and sizes.

Selecting a Tape and Reel Packaging Vendor

When choosing a tape and reel packaging vendor, several factors should be considered:

- Experience and Expertise: Ensure the vendor has extensive experience in handling your specific component types.

- Quality Standards: Verify that the vendor adheres to industry standards and maintains a controlled process environment[4].

- Lead Time and Flexibility: Consider vendors offering flexible lead times and expedited services to meet urgent needs.

Conclusion

Choosing the right tape and reel for your SMT components is a critical decision that impacts the efficiency, accuracy, and cost-effectiveness of your assembly process. By considering factors such as component size, assembly speed, environmental conditions, and industry standards, you can optimize your tape and reel selection. Additionally, exploring DIY solutions can offer customization and cost savings, though it requires careful planning and technical expertise. As technology continues to evolve, staying informed about the latest trends and innovations in tape and reel packaging will be essential for maintaining a competitive edge in the electronics manufacturing industry.

FAQs

1. What are the common reel sizes used in SMT assembly?

- Common reel sizes include 7 inches and 13 inches, with larger reels used for bigger components or higher quantities[2][8].

2. How does component orientation affect the assembly process?

- Proper component orientation is crucial for reducing errors and increasing throughput in automated assembly processes. It ensures that components are correctly positioned for pick-and-place machines.

3. What materials are typically used for carrier tapes in tape and reel packaging?

- Carrier tapes are commonly made from polycarbonate or polystyrene materials, which provide durability and flexibility[8].

4. What are the advantages of using SMT splicing tape?

- SMT splicing tape offers increased efficiency, accuracy, and consistency in the assembly process by automating the joining of component reels, reducing labor time and potential errors[3].

5. Can DIY tape and reel feeders be integrated with commercial pick-and-place machines?

- Yes, DIY feeders can be integrated with commercial pick-and-place machines, but this requires careful design to ensure compatibility with existing machinery and software.

Citations:

[1] https://electronics.stackexchange.com/questions/699703/what-should-be-the-minimum-number-of-smd-components-on-a-reel-minimum-tape-leng

[2] https://www.onsemi.com/pub/collateral/brd8011-d.pdf

[3] https://vestalelectronics.com/services/smd-tape-and-reel-services/

[4] https://www.criterialabs.com/resource/blog-our-best-tips-for-selecting-a-tape-and-reel-packaging-vendor/

[5] https://www.proex1.com/blog/posts/2024/january/tape-and-reel-for-smd-components-enhancing-efficiency-and-precision-in-packaging/

[6] https://forum.digikey.com/t/importance-of-tape-and-reel-specs/4790

[7] https://www.npimaterials.com

[8] https://www.proex1.com/blog/posts/2023/january/the-complete-guide-to-tape-and-reel-packaging-standards/

[9] https://www.proex1.com/blog/posts/2022/june/tape-and-reel-faqs/

[10] https://www.iec.ch/blog/iec-standard-specifies-tape-and-reel-requirements

[11] https://www.digikey.com/htmldatasheets/production/778632/0/0/1/tape-reel-packaging-spec.pdf

[12] https://www.advantek.com

[13] https://www.ti.com/lit/ug/snoa403i/snoa403i.pdf

[14] https://www.molex.com/en-us/blog/advanced-packaging-methods-overcoming-connector-packaging-challenges-with-leading-edge-design-options

[15] https://smt.asmpt.com/en/products/advanced-packaging/

[16] https://multimedia.3m.com/mws/media/611487O/choosing-carrier-and-cover-tape.pdf

[17] https://www.matr.com

[18] https://www.analog.com/media/en/package-pcb-resources/tape-and-reel-packaging.pdf

[19] http://www.advanced-monolithic.com/pdf/trspecification.PDF

[20] https://www.forceone-am.com/en/a-SMT_what%20is%20SMT%20and%20SMD.html