Content Menu

● Introduction to SMD Soldering Machines

>> Types of SMD Soldering Machines

● Key Factors to Consider When Choosing an SMD Soldering Machine

● Essential Tools for SMD Soldering

● Best Practices for Using SMD Soldering Machines

● Trends in SMD Soldering Techniques

● Choosing the Right Soldering Tip

● Advanced Features in Modern SMD Soldering Machines

● Conclusion

● FAQs

>> 1. What is the primary difference between contact and hot air soldering stations?

>> 2. How important is temperature control in SMD soldering?

>> 3. What tools are essential for handling SMD components?

>> 4. Can I use a soldering iron for all types of SMD components?

>> 5. How do I maintain my SMD soldering machine?

● Citations:

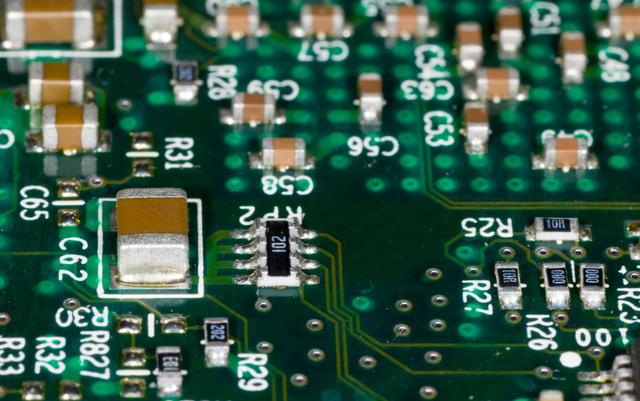

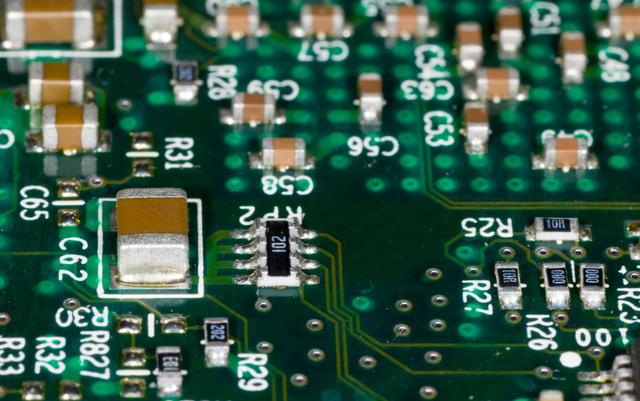

Choosing the right SMD soldering machine is crucial for efficiently and effectively soldering surface mount devices (SMDs) onto circuit boards. SMD components are small and require precise soldering techniques to ensure they are securely attached without damaging the components or the board. In this article, we will explore the key factors to consider when selecting an SMD soldering machine, discuss different types of machines available, and provide guidance on how to make the best choice for your specific needs.

Introduction to SMD Soldering Machines

SMD soldering machines are specialized tools designed to handle the unique challenges of soldering small electronic components directly onto circuit boards. These machines typically include precise temperature-controlled soldering irons and may offer additional features such as hot air rework for desoldering and reflowing components. The primary goal of an SMD soldering machine is to provide accurate temperature control and precise heat application to ensure reliable solder joints without overheating sensitive components.

Types of SMD Soldering Machines

1. Contact Soldering Stations: These are the most common type of soldering stations and are suitable for soldering a wide range of components. They offer thermal stabilization to prevent overheating and are compatible with both lead and lead-free solders.

2. Hot Air Soldering Stations: These machines use heated air to melt solder, making them ideal for surface mount technology (SMT) components and small SMD parts. They are particularly useful for reflowing circuits and desoldering components from boards.

3. Combined Soldering Stations: These machines integrate both contact soldering irons and hot air guns, providing versatility for various soldering tasks. They are popular for their ability to handle different types of components and soldering needs.

4. Desoldering Stations: These are specialized for removing solder from components and are often used in conjunction with other soldering equipment.

Key Factors to Consider When Choosing an SMD Soldering Machine

When selecting an SMD soldering machine, several factors must be considered to ensure you choose the right tool for your needs:

- Temperature Control: Precise temperature control is essential for preventing overheating and ensuring reliable solder joints. Look for machines with adjustable temperature settings and thermal stabilization. For most solder types, the optimal temperature range is between 350°C to 375°C[3].

- Precision and Accuracy: For SMD components, precision is crucial. Choose a machine with fine tips for soldering irons and consider the accuracy of hot air guns if needed. A chisel-shaped tip between 1 and 2 mm is often recommended for SMD soldering due to its effective heat transfer[6].

- Compatibility with Components: Ensure the machine is compatible with the types of components you work with, including lead and lead-free solders. The industry has shifted towards lead-free solders due to environmental concerns[4].

- Ease of Use: Consider the ergonomics and user interface of the machine. A comfortable and intuitive design can improve productivity and reduce errors. Advanced stations often include features like LCD screens for real-time monitoring and adjustable parameters to prevent overheating[2].

- Budget: Determine your budget and balance it with the features and quality you need. Professional-grade machines may offer more advanced features but at a higher cost.

Essential Tools for SMD Soldering

In addition to the soldering machine itself, several other tools are essential for successful SMD soldering:

- Solder Paste and Flux: Solder paste is a mixture of solder and flux that is applied to the solder pads before component placement. Flux helps remove oxides and impurities, ensuring strong solder joints. The metal-to-flux ratio in solder paste is critical to prevent slumping, which can lead to solder bridging[8].

- Tweezers and Pick-and-Place Tools: Anti-static tweezers are crucial for handling SMD components without causing electrostatic discharge (ESD) damage. A pick-and-place tool can assist with precise component placement.

- Magnification and Illumination: A magnifying glass or microscope and proper lighting are necessary for working with small components.

- Solder Wick and Desoldering Pump: These tools are used to remove excess solder or correct mistakes during the soldering process.

- Cleaning Tools: Isopropyl alcohol and a lint-free cloth are used to clean solder joints and remove flux residue.

Best Practices for Using SMD Soldering Machines

To get the most out of your SMD soldering machine, follow these best practices:

- Maintain a Clean Workspace: Ensure your workspace is free from dust and debris to prevent contamination of components.

- Use ESD Protection: Work on an anti-static mat and wear an anti-static wrist strap to protect sensitive components from ESD damage.

- Regularly Calibrate the Machine: Check and adjust the temperature settings regularly to ensure accuracy and consistency.

- Choose the Right Solder: Select solder with the appropriate melting point for your components. Lead-free solder typically requires a slightly higher temperature than leaded solder[5].

- Avoid Common Soldering Mistakes: Common mistakes include solder bridges, cold joints, overheated joints, and excess solder. Use a fine-tip iron and precise amounts of solder to avoid bridges. Ensure the iron reaches the correct temperature for cold joints, and avoid leaving the iron on the joint too long to prevent overheating[3].

Trends in SMD Soldering Techniques

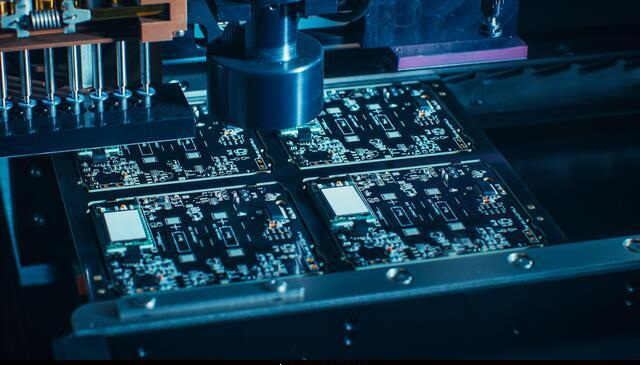

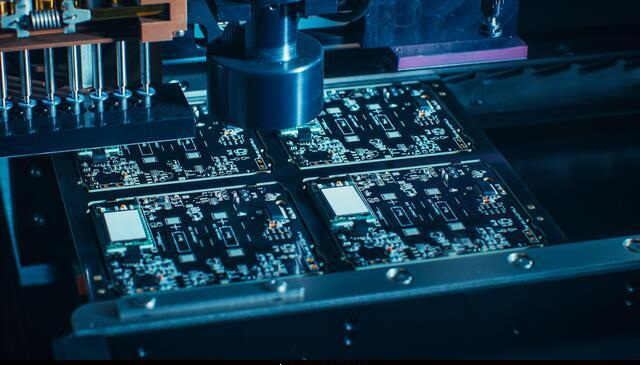

The trend in soldering techniques is evolving with the miniaturization of components. Non-contact methods like infrared and hot gas reflow are becoming more prevalent for SMDs, offering advantages in precision and efficiency[4]. Additionally, the use of specialized equipment such as pick-and-place machines and automated inspection tools is increasing due to the complexity and density of modern PCBs[4].

Choosing the Right Soldering Tip

Selecting the right soldering tip is crucial for effective soldering. The tip should have enough thermal mass to handle the components and a wide contact area for efficient heat transfer. Avoid using tips that are too large for the solder pads, as this can cause overheating and damage[1]. For SMD components, a chisel-shaped tip is often recommended due to its ability to transfer heat effectively[6].

Advanced Features in Modern SMD Soldering Machines

Modern SMD soldering machines often include advanced features that enhance their functionality and efficiency. These may include:

- Digital Temperature Control: Allows for precise temperature adjustments, which is critical for working with sensitive components.

- Interchangeable Tips: Enables the use of different tips for various soldering tasks, improving versatility.

- Hot Air Rework: Useful for desoldering and reflowing components, especially in complex PCBs.

- LCD Displays: Provides real-time information about temperature, current flow, and other parameters, helping to prevent overheating and ensure optimal soldering conditions[2].

Conclusion

Choosing the right SMD soldering machine is a critical decision that can significantly impact the quality and efficiency of your work. By understanding the different types of machines available, considering key factors such as temperature control and precision, and using essential tools and best practices, you can ensure successful soldering of SMD components. Whether you are a hobbyist or a professional, selecting the appropriate SMD soldering machine will help you achieve reliable and precise solder joints.

FAQs

1. What is the primary difference between contact and hot air soldering stations?

- Contact soldering stations use a direct heat source from the soldering iron tip, while hot air soldering stations use heated air to melt solder, making them more suitable for surface mount components.

2. How important is temperature control in SMD soldering?

- Temperature control is crucial in SMD soldering to prevent overheating and ensure reliable solder joints. Precise temperature control helps protect sensitive components.

3. What tools are essential for handling SMD components?

- Essential tools include anti-static tweezers, a pick-and-place tool, magnification (such as a microscope), and ESD protection equipment like an anti-static wrist strap and mat.

4. Can I use a soldering iron for all types of SMD components?

- While soldering irons are versatile, they may not be suitable for all SMD components, especially those requiring reflow or desoldering, where hot air stations are more effective.

5. How do I maintain my SMD soldering machine?

- Regularly clean the machine, check and adjust temperature settings, and replace worn-out tips to maintain optimal performance.

Citations:

[1] https://www.hakko.com/english/support/maintenance/detail.php?seq=171

[2] https://scanditronictech.com/resources/smd-soldering-rework-stations/

[3] https://electronicsgroup.co.uk/common-soldering-mistakes/

[4] https://www.pcbpower.us/blog/trends_in_surface_mount_technology_and_its_relevance_with_pcb_surface_finish

[5] https://www.bobvila.com/articles/best-soldering-station/

[6] https://eleshop.eu/knowledgebase/tips-smd-soldering/

[7] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[8] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[9] https://blueringstencils.com/top-5-smt-industry-trends-for-2019/

[10] https://www.tomshardware.com/best-picks/best-soldering-irons

[11] https://www.linkedin.com/pulse/smd-soldering-equipment-complete-guide-tools-jayden-tooling-oagfc

[12] https://vicoimaging.com/smd-and-smt-comprehensive-guide/

[13] https://www.mwrf.com/materials/article/21126700/common-pcb-soldering-problems-to-avoid

[14] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[15] https://www.nytimes.com/wirecutter/reviews/best-soldering-irons/

[16] https://www.eevblog.com/forum/beginners/choice-of-soldering-iron-tips-for-smd/

[17] https://www.hayawin.com/news-smt-machine-types-and-features-of-excellent-smt-machines.html

[18] https://www.eptac.com/blog/5-common-solder-mistakes-and-how-to-resolve-them

[19] https://smttoday.com/2024/07/29/smt-component-market-trends-and-win-sources-strategic-responses/

[20] https://www.youtube.com/watch?v=NLaB142d22A