Content Menu

● Introduction

● Understanding Mirae SMT Nozzles

>> Types of Mirae SMT Nozzles

>> Key Features and Specifications

● Factors to Consider When Choosing Mirae SMT Nozzles

>> Component Type and Size

>> Production Speed and Accuracy Requirements

>> Compatibility with Existing Equipment

>> Environmental Considerations

>> Cost-Effectiveness

● Step-by-Step Guide to Selecting the Right Nozzle

● Common Mistakes to Avoid

● Advanced Considerations for High-Density Assemblies

>> Micro-Miniature Components

>> Vision Systems Integration

>> Automation Compatibility

● Conclusion

● FAQ

>> 1. What are the different types of Mirae SMT nozzles?

>> 2. How do I determine the right nozzle for my components?

>> 3. Can I use Mirae nozzles with other brands of pick-and-place machines?

>> 4. What maintenance is required for SMT nozzles?

>> 5. How does nozzle choice affect production speed?

● Citations:

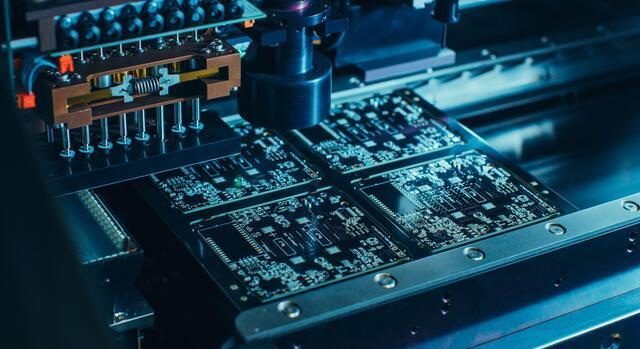

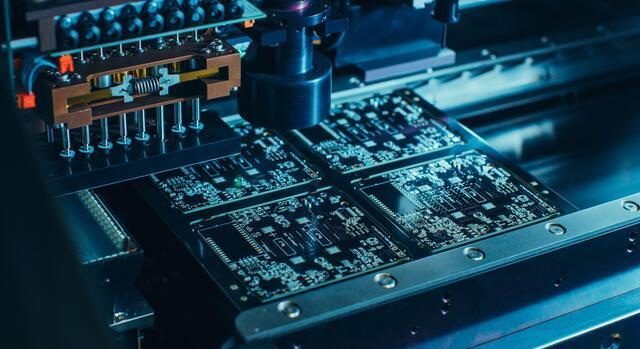

Introduction

Surface Mount Technology (SMT) nozzles are essential components in the PCB assembly process, playing a critical role in the accurate placement of electronic components on printed circuit boards. The choice of the right nozzle can significantly impact the efficiency, speed, and quality of the assembly process. Among various options available in the market, Mirae SMT nozzles are recognized for their reliability and performance. This article will guide you through the process of selecting the right Mirae SMT nozzle for your specific PCB assembly needs.

Understanding Mirae SMT Nozzles

Mirae provides a diverse range of SMT nozzles tailored to accommodate different types and sizes of components. These nozzles are designed to enhance the precision and speed of component placement, making them suitable for various applications in the electronics manufacturing industry.

Types of Mirae SMT Nozzles

Mirae's SMT nozzles can be categorized based on their design and application:

- Standard Nozzles: These are typically used for standard components such as resistors and capacitors.

- Specialty Nozzles: Designed for specific components like BGA (Ball Grid Array) or CSP (Chip Scale Package), these nozzles ensure optimal handling and placement.

- Custom Nozzles: For unique or non-standard components, custom nozzles can be designed to meet specific requirements.

Key Features and Specifications

When evaluating Mirae SMT nozzles, consider the following key features:

- Durability: Made from high-quality materials to withstand wear and tear during operation.

- Compatibility: Designed to work seamlessly with various Mirae pick and place machines.

- Ease of Maintenance: Many models are engineered for easy cleaning and maintenance, ensuring longevity.

Factors to Consider When Choosing Mirae SMT Nozzles

Selecting the right nozzle involves several critical factors:

Component Type and Size

The first step in choosing a Mirae SMT nozzle is to assess the types of components you will be working with. Different components require different nozzle designs. For example:

- Flat Chips: Require a nozzle with a specific opening size to securely hold and place them.

- BGA Components: Often need specialized nozzles that can handle their unique shapes and weights.

Production Speed and Accuracy Requirements

Your production goals will influence your nozzle choice. If speed is a priority, you may need a nozzle that allows for rapid placement without sacrificing accuracy. Conversely, if precision is paramount (for example, in high-density assemblies), select a nozzle designed for tight tolerances.

Compatibility with Existing Equipment

Ensure that the Mirae SMT nozzle you choose is compatible with your existing pick and place machinery. This compatibility is crucial for maintaining operational efficiency and avoiding potential issues during production.

Environmental Considerations

Another important factor is the operating environment of your production line. If your assembly process involves exposure to extreme temperatures or humidity levels, selecting a nozzle that can withstand these conditions is critical. Mirae offers nozzles made from materials that can endure such environments, ensuring consistent performance.

Cost-Effectiveness

While it might be tempting to opt for cheaper alternatives, investing in high-quality Mirae SMT nozzles can lead to long-term savings. Quality nozzles reduce downtime due to failures or misplacements, ultimately improving overall productivity.

Step-by-Step Guide to Selecting the Right Nozzle

Choosing the right Mirae SMT nozzle can be streamlined into a few key steps:

1. Assess Your PCB Assembly Needs: Evaluate the types of components you will be using, their sizes, and your production volume.

2. Match Nozzle Types to Component Specifications: Use technical specifications such as dimensions and weights of components to determine which nozzle type is appropriate. For instance, if you are working with 0402 flat chips, you would select a nozzle specifically designed for that size.

3. Testing and Validation: After selecting a nozzle, conduct tests in your production environment to validate its performance. This step is essential to ensure that it meets your speed and accuracy requirements.

4. Consult Manufacturer Guidelines: Always refer to manufacturer guidelines provided by Mirae for additional insights into which nozzles work best with specific components or applications.

5. Seek Expert Advice: If you are uncertain about which nozzle to choose, consulting with experts or reaching out directly to Mirae representatives can provide valuable guidance tailored to your specific needs.

Common Mistakes to Avoid

When selecting Mirae SMT nozzles, avoid these common pitfalls:

- Using Incorrect Nozzle Types: Selecting a nozzle that does not match your component specifications can lead to misplacement or damage during assembly.

- Ignoring Maintenance and Cleaning: Regular maintenance is vital for keeping nozzles in optimal condition. Neglecting this can result in reduced performance over time.

- Overlooking Testing Procedures: Failing to test new nozzles before full-scale production can lead to unexpected issues that could have been avoided with proper validation.

Advanced Considerations for High-Density Assemblies

In high-density PCB assemblies where space is limited, advanced considerations become crucial:

Micro-Miniature Components

For assemblies featuring micro-miniature components, specialized nozzles are necessary. These nozzles must have precise openings capable of handling very small parts without causing damage.

Vision Systems Integration

Integrating vision systems with your pick-and-place machinery can enhance placement accuracy significantly. Ensure that your chosen Mirae nozzles are compatible with any vision systems you plan to implement.

Automation Compatibility

As automation becomes more prevalent in manufacturing processes, selecting nozzles that work seamlessly with automated systems is essential. Consider how well your chosen Mirae SMT nozzles integrate into an automated workflow.

Conclusion

Choosing the right Mirae SMT nozzle is crucial for achieving efficiency and quality in PCB assembly processes. By carefully considering component specifications, production requirements, equipment compatibility, environmental factors, and cost-effectiveness, you can select a nozzle that enhances your production capabilities. Proper selection not only improves operational efficiency but also ensures high-quality outcomes in electronic manufacturing.

FAQ

1. What are the different types of Mirae SMT nozzles?

Mirae offers various types of nozzles tailored for specific component types such as flat chips, BGA (Ball Grid Array), MELF (Metal Electrode Leadless Face), and more. Each type is designed to ensure optimal pickup and placement based on component size and shape.

2. How do I determine the right nozzle for my components?

To determine the appropriate nozzle, match its specifications (such as opening size) with your component dimensions. Consider factors like weight and shape as well; heavier or uniquely shaped components may require specialized nozzles.

3. Can I use Mirae nozzles with other brands of pick-and-place machines?

While Mirae nozzles are primarily designed for use with Mirae machines, some may be compatible with other brands. However, compatibility should always be verified to avoid operational issues during assembly.

4. What maintenance is required for SMT nozzles?

Regular cleaning is essential to maintain nozzle performance. Inspecting for wear or damage should also be part of routine maintenance practices. Replacing worn or damaged nozzles promptly helps ensure consistent quality in production.

5. How does nozzle choice affect production speed?

The choice of nozzle can significantly impact production speed by facilitating accurate component placement without delays caused by misalignment or improper handling. Efficient nozzles help reduce downtime associated with errors during assembly.

Citations:

[1] https://smtnet.com/parts/index.cfm?fuseaction=view_item&company_id=53598&item_id=165049

[2] https://otovon.in/pages/smt-nozzles-for-mirae

[3] https://www.itechsmt.com/blogs/news/how-to-choose-smt-nozzle-for-your-pick-and-place-machine

[4] https://szwenzhan.en.made-in-china.com/product/ZEqYvoQUXaVw/China-SMT-PCB-Assembly-Line-Spare-Parts-Mirae-Type-a-B-C-D-21003-64000-005-Nozzle-Mirae-Nozzle.html

[5] https://smtnet.com/index.cfm?fuseaction=search_submit&searchstring=mirae+and+smt+and+pick+and+place+and+nozzle&collection=site_forum