Content Menu

● Introduction to SMD Resistors

>> Benefits of SMD Resistors

● SMD Resistor Manufacturing Process

>> Role of SMD Resistor Manufacturing Machines

● Strategies for Optimizing SMD Resistor Production Lines

>> 1. Balanced Load Distribution

>> 2. Equipment Optimization

>> 3. Eliminating Bottlenecks

>> 4. Effective Management Practices

>> 5. Adoption of Advanced Technologies

● Advanced Technologies in SMD Resistor Manufacturing

>> Laser Trimming Technology

>> Thin-Film and Thick-Film Technologies

● Thermal Management in SMD Resistor Production

● SMT Line Efficiency and Its Impact on SMD Resistor Production

● Supply Chain Management and Logistics

● Quality Control and Testing

● Conclusion

● FAQs

>> 1. What are the primary benefits of using SMD resistors in electronic devices?

>> 2. How does laser trimming improve SMD resistor manufacturing?

>> 3. What role do SMD resistor manufacturing machines play in optimizing production?

>> 4. How can bottlenecks in an SMD resistor production line be addressed?

>> 5. Why is thermal management important in SMD resistor production?

In the rapidly evolving electronics industry, optimizing the production line for Surface Mount Device (SMD) resistors is crucial for maximizing output and efficiency. SMD resistors are widely used in various applications due to their compact size, high precision, and reliability. This article will delve into the strategies and technologies that can enhance the productivity of an SMD resistor production line, focusing on the role of SMD resistor manufacturing machines.

Introduction to SMD Resistors

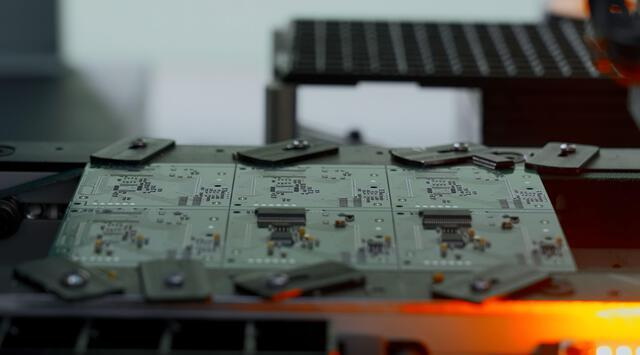

SMD resistors are a cornerstone of modern electronic devices, from smartphones to aerospace equipment. Their small size allows for dense component placement on printed circuit boards (PCBs), which is essential for miniaturization and high-frequency applications. However, their small size also presents challenges in handling and manufacturing, making automation and precision critical in the production process.

Benefits of SMD Resistors

- Space Efficiency: SMD resistors are much smaller than through-hole resistors, allowing for more components to be placed on a PCB, which is vital for compact designs.

- Automated Assembly: They are designed for automated placement and soldering, significantly reducing production time and costs.

- High-Frequency Performance: SMD resistors offer better performance in high-frequency circuits due to lower inductance and capacitance.

- Reliability: They provide enhanced reliability in challenging environments due to their robust construction and reduced vibration sensitivity.

SMD Resistor Manufacturing Process

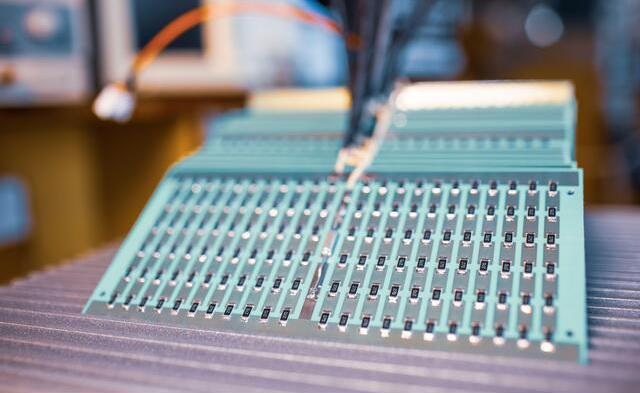

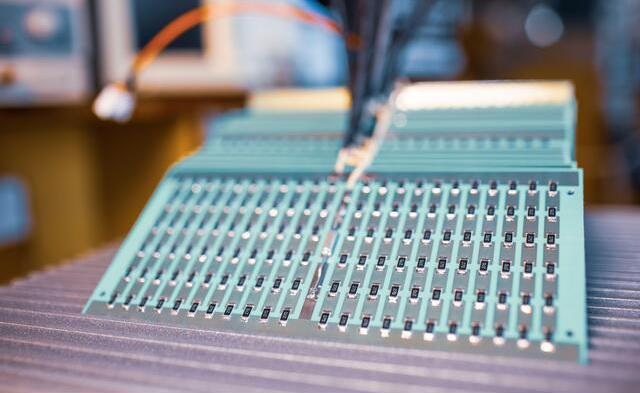

The manufacturing process of SMD resistors involves several key steps:

1. Material Selection and Deposition: The resistor material is deposited onto a substrate, typically alumina, which is chosen for its mechanical strength and thermal properties.

2. Screen Printing: The resistor pattern is created using screen printing techniques, where a paste is applied to the substrate through a screen mask.

3. Laser Trimming: To achieve precise resistance values, laser trimming is used to adjust the resistor element by selectively removing material.

4. Overcoating and Singulation: The resistors are overcoated for protection and then singulated into individual chips.

5. Termination and Packaging: The resistors are terminated with metal contacts and packaged for distribution.

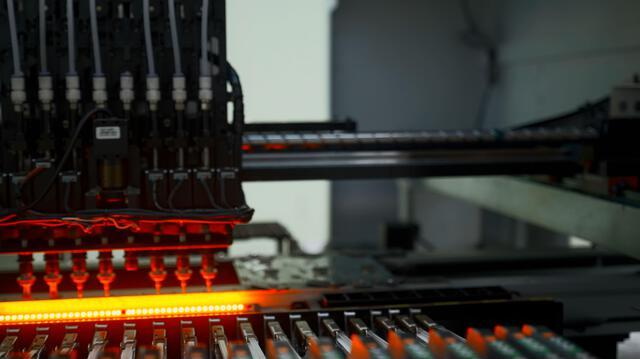

Role of SMD Resistor Manufacturing Machines

SMD resistor manufacturing machines play a pivotal role in optimizing production efficiency. These machines automate various stages of the manufacturing process, ensuring consistency and precision:

- Automatic Resistor Lead Cutting and Forming Machines: These machines handle the precise cutting and forming of resistor leads, ensuring uniformity and reducing manual labor.

- SMD Resistor Capping Machines: These machines automate the capping process, protecting the resistor elements from environmental factors.

- Resistor Coating Machines: These machines apply protective coatings to resistors, enhancing durability and performance.

Strategies for Optimizing SMD Resistor Production Lines

1. Balanced Load Distribution

To maximize output, it's crucial to balance the load across different machines in the production line. This involves allocating components efficiently to ensure that no single machine becomes a bottleneck. By optimizing the placement time of each device, production can be streamlined to achieve higher throughput.

2. Equipment Optimization

Each SMD resistor manufacturing machine has a maximum operational speed. Optimizing the numerical control programs of these machines can help achieve this speed consistently, reducing placement times and increasing overall efficiency.

3. Eliminating Bottlenecks

Identifying and addressing bottlenecks in the production line is essential. Adding more machines or upgrading existing ones can significantly improve production capacity without overly complicating line management.

4. Effective Management Practices

Implementing strict quality control and management practices ensures that the production line operates smoothly. This includes regular maintenance of machines, training personnel, and monitoring production metrics.

5. Adoption of Advanced Technologies

Recent technological advancements in SMD resistors include the use of high-stability metal films and ceramics, which enhance performance and reliability by offering better resistance stability over a wide range of temperatures and operating conditions. Additionally, improvements in manufacturing processes such as laser trimming and thin-film deposition allow for more precise control over resistance values and tighter tolerance levels.

Advanced Technologies in SMD Resistor Manufacturing

Laser Trimming Technology

Laser trimming allows for precise adjustment of resistance values, ensuring tight tolerances and consistent performance. This technology is crucial for producing high-precision SMD resistors.

Thin-Film and Thick-Film Technologies

Both thin-film and thick-film technologies are used in SMD resistor manufacturing. Thin-film resistors offer higher precision and lower temperature coefficients, while thick-film resistors are more cost-effective and suitable for a wide range of applications. Recent innovations have enabled thin-film resistors to deliver a combination of precision and power performance without sacrificing accuracy.

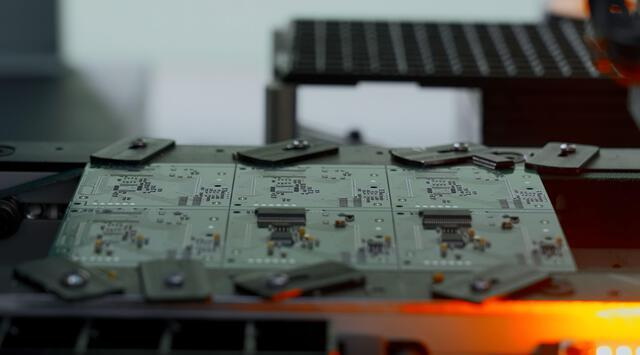

Thermal Management in SMD Resistor Production

Thermal management is critical in high-power applications to prevent overheating and ensure component longevity. Strategies include:

- Thermal Vias and Copper Pours: These enhance heat dissipation by providing a path for heat to escape from the PCB.

- Thermal Simulations: Conducting thermal simulations during the design phase helps identify potential hotspots and optimize thermal management strategies.

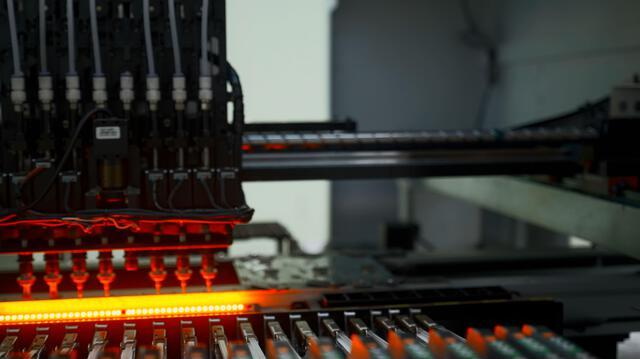

SMT Line Efficiency and Its Impact on SMD Resistor Production

Surface Mount Technology (SMT) plays a crucial role in the assembly and production of PCBs, which are integral to SMD resistor applications. Optimizing SMT line efficiency involves:

- Automated Processes: Utilizing full-auto SMT lines automates key processes like solder paste application, component placement, and reflow soldering, enhancing productivity and reducing errors.

- Layout Optimization: Minimizing material handling and optimizing the layout of the SMT production line reduces turnaround times and production costs.

- Advanced Equipment: Investing in state-of-the-art SMT line machines with enhanced precision and defect detection capabilities further boosts operational efficiency.

Supply Chain Management and Logistics

Effective supply chain management is vital for maintaining a smooth production flow. This includes ensuring timely delivery of raw materials, managing inventory levels, and maintaining strong relationships with suppliers. Implementing just-in-time (JIT) inventory systems can help reduce storage costs and minimize the risk of material obsolescence.

Quality Control and Testing

Implementing rigorous quality control measures is essential to ensure that SMD resistors meet the required specifications and standards. This involves conducting thorough inspections and tests at various stages of production, including resistance value checks, visual inspections for defects, and environmental stress testing to validate reliability.

Conclusion

Optimizing an SMD resistor production line requires a combination of advanced technologies, efficient machine utilization, and effective management practices. By leveraging SMD resistor manufacturing machines and implementing strategies to balance production loads and eliminate bottlenecks, manufacturers can significantly increase output while maintaining high-quality standards. As the demand for compact and reliable electronic components continues to grow, the importance of optimizing SMD resistor production will only increase.

FAQs

1. What are the primary benefits of using SMD resistors in electronic devices?

SMD resistors offer several benefits, including space efficiency, automated assembly, improved high-frequency performance, and enhanced reliability in challenging environments.

2. How does laser trimming improve SMD resistor manufacturing?

Laser trimming allows for precise adjustment of resistance values by selectively removing material from the resistor element, ensuring tight tolerances and consistent performance.

3. What role do SMD resistor manufacturing machines play in optimizing production?

These machines automate various stages of the manufacturing process, ensuring consistency and precision. They handle tasks such as lead cutting, capping, and coating, reducing manual labor and increasing efficiency.

4. How can bottlenecks in an SMD resistor production line be addressed?

Bottlenecks can be addressed by adding more machines or upgrading existing ones to increase production capacity without overly complicating line management.

5. Why is thermal management important in SMD resistor production?

Thermal management is crucial to prevent overheating and ensure component longevity, especially in high-power applications. Strategies like thermal vias and copper pours help enhance heat dissipation.