Content Menu

● Introduction to SMT Reel Storage Bins

>> Key Features of SMT Reel Storage Bins

● Strategies for Maximizing Space with SMT Reel Storage Bins

>> 1. Vertical Storage Solutions

>> 2. Customizable Storage Options

>> 3. Automated Storage and Retrieval Systems (AS/RS)

>> 4. Intelligent Material Management

>> 5. Modular Design for Easy Expansion

● Benefits of SMT Reel Storage Bins

>> Improved Efficiency

>> Enhanced Production Quality

>> Cost Savings

>> Sustainability

● Emerging Trends in SMT Reel Storage

>> Integration of AI and IoT

>> Automated Guided Vehicles (AGVs)

>> Sustainable Storage Solutions

● Conclusion

● FAQ

>> 1. What are the primary benefits of using SMT reel storage bins?

>> 2. How do SMT reel storage bins protect electronic components?

>> 3. Can SMT reel storage bins accommodate different reel sizes?

>> 4. How do SMT reel storage bins enhance traceability and quality control?

>> 5. What types of integration do high-quality SMT reel storage bins support?

● Citations:

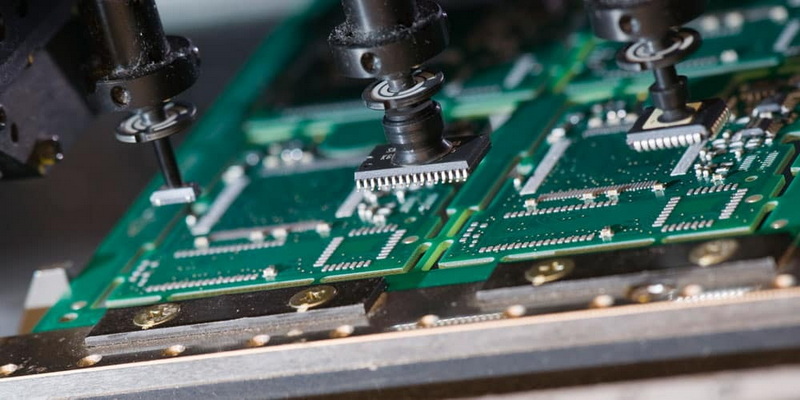

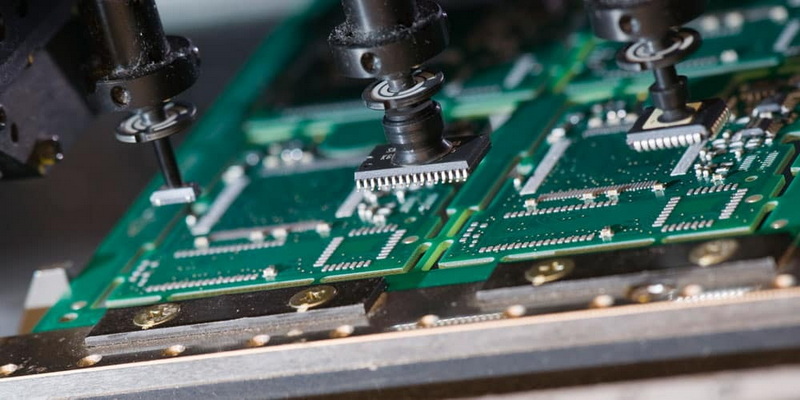

In the electronics manufacturing industry, particularly in surface mount technology (SMT), efficient storage and management of component reels are crucial for maintaining production efficiency and quality. SMT reel storage bins are designed to optimize space, enhance inventory management, and protect sensitive electronic components from environmental damage. This article delves into the strategies and technologies used to maximize space with SMT reel storage bins, highlighting their importance in modern manufacturing environments.

Introduction to SMT Reel Storage Bins

SMT reel storage bins are specialized solutions for storing and managing reels of electronic components used in surface mount technology. These systems are essential for electronics manufacturing facilities, as they help streamline production processes by ensuring quick access to components, reducing errors, and maintaining component integrity. The primary goal of these systems is to make the most efficient use of available space while ensuring that components are easily accessible and protected from damage.

Key Features of SMT Reel Storage Bins

1. Space Optimization: High-quality SMT reel storage bins, such as Vertical Carousel Modules (VCMs) and Vertical Lift Modules (VLMs), maximize vertical space utilization, potentially saving up to 85% of floor space compared to traditional shelving systems[5][6]. This allows manufacturers to use their space more effectively without reducing storage capacity.

2. Efficient Inventory Management: These systems often integrate with inventory management software, providing real-time tracking of component quantities, locations, and usage history. This ensures accurate stock levels, reduces the risk of production delays due to component shortages, and enhances traceability throughout the manufacturing process[5][6].

3. Protection of Components: SMT reel storage bins include features like temperature control, humidity regulation, and ESD (Electrostatic Discharge) protection to maintain the integrity and longevity of stored components. This is crucial for preventing damage from environmental factors that could compromise component quality[5][10].

4. Modular and Scalable Design: These systems are modular and scalable, allowing for easy expansion as storage needs increase. This scalability is a cost-effective solution in the long run, as it eliminates the need for complete system replacements as the business grows[5].

5. Integration with Manufacturing Systems: High-quality SMT reel storage bins support integration with various manufacturing systems, including Manufacturing Execution Systems (MES), Enterprise Resource Planning (ERP) systems, and automated guided vehicles (AGVs). This integration enhances automation and efficiency by enabling seamless data exchange and workflow automation[5][8].

Strategies for Maximizing Space with SMT Reel Storage Bins

1. Vertical Storage Solutions

Using vertical storage solutions such as VCMs and VLMs is a key strategy for maximizing space. These systems store components vertically, significantly reducing the footprint required for storage while maintaining or increasing storage capacity[6]. This approach is particularly beneficial in facilities with limited floor space.

2. Customizable Storage Options

SMT reel storage bins can be customized to accommodate different sizes and types of reels. This flexibility ensures that every available space is utilized efficiently, reducing waste and improving overall storage density[2][7].

3. Automated Storage and Retrieval Systems (AS/RS)

Implementing AS/RS can further enhance space utilization by automating the storage and retrieval process. These systems minimize human error, optimize space, and provide real-time inventory tracking, ensuring that components are always accessible when needed[6][9].

4. Intelligent Material Management

Integrating RFID or barcode technology into SMT reel storage bins enables precise material tracking and management. This technology helps prevent material loss, misplacement, or expiration by providing real-time feedback on material status[3][8].

5. Modular Design for Easy Expansion

Using modular storage systems allows for easy expansion or reconfiguration as production needs change. This modular approach ensures that storage capacity can be adjusted without significant investment in new infrastructure[5][9].

Benefits of SMT Reel Storage Bins

Improved Efficiency

SMT reel storage bins improve operational efficiency by reducing the time spent searching for components. Automated systems can retrieve reels in seconds, significantly speeding up production setup times[9]. This efficiency also reduces labor costs and minimizes the risk of errors during the production process.

Enhanced Production Quality

By ensuring that components are stored in optimal conditions and are easily accessible, SMT reel storage bins help maintain high production quality. This is achieved through features such as climate control and ESD protection, which safeguard sensitive components from environmental damage[5][10].

Cost Savings

Maximizing space with SMT reel storage bins can lead to significant cost savings. By reducing the need for additional storage facilities and minimizing waste, manufacturers can lower their operational costs while maintaining or increasing production capacity[8].

Sustainability

The emphasis on sustainability in manufacturing is driving the adoption of eco-friendly storage solutions. SMT reel storage bins that optimize space and reduce waste contribute to more sustainable operations, aligning with global environmental goals[5].

Emerging Trends in SMT Reel Storage

Integration of AI and IoT

The integration of Artificial Intelligence (AI) and Internet of Things (IoT) technologies into SMT reel storage systems is transforming inventory management. These technologies provide real-time tracking and predictive analytics, helping optimize production cycles and reduce downtime[5].

Automated Guided Vehicles (AGVs)

The use of AGVs for material transport is becoming more prevalent. These vehicles seamlessly connect with SMT reel storage systems, enhancing factory automation and efficiency[5].

Sustainable Storage Solutions

Manufacturers are increasingly focusing on sustainable storage solutions that optimize space, reduce waste, and use energy-efficient technologies. This shift supports environmental stewardship while enhancing operational efficiency[5].

Conclusion

SMT reel storage bins are indispensable for modern electronics manufacturing, offering benefits such as space optimization, efficient inventory management, and protection of sensitive components. By integrating advanced automation and inventory management features, these systems significantly enhance production efficiency and reduce costs. As the electronics industry continues to evolve, the importance of these systems will only grow.

FAQ

1. What are the primary benefits of using SMT reel storage bins?

The primary benefits include space optimization, efficient inventory management, protection of components, and improved production efficiency. These systems help reduce errors, enhance traceability, and support sustainable manufacturing practices.

2. How do SMT reel storage bins protect electronic components?

SMT reel storage bins protect components through features like temperature control, humidity regulation, and ESD protection. These measures ensure that components remain in optimal condition, reducing the risk of damage from environmental factors.

3. Can SMT reel storage bins accommodate different reel sizes?

Yes, many SMT reel storage systems are designed to accommodate various reel sizes, often ranging from 7" to 15" in diameter and 8-56mm in width. They also offer customizable storage options for other component types.

4. How do SMT reel storage bins enhance traceability and quality control?

SMT reel storage bins enhance traceability and quality control by providing real-time tracking of component locations, usage history, and remaining quantities. This level of detail ensures that components can be traced throughout the production process, meeting quality control standards and facilitating easier audits.

5. What types of integration do high-quality SMT reel storage bins support?

High-quality SMT reel storage bins support integration with various manufacturing systems, including MES, ERP, and AGVs. This integration enhances automation and efficiency by enabling seamless data exchange and workflow automation.

Citations:

[1] https://www.southwestsolutions.com/ssg/material-handling/smt-reel-storage-solutions/

[2] https://global.neotel.tech/2023/01/13/boost-productivity-with-our-smt-reel-storage-system/

[3] https://www.futureatt.com/blog/what-are-the-advantages-of-future-att-smt-intelligent-electronic-material-rack_b14

[4] https://global.neotel.tech/2023/01/05/what-is-smt-reel-storage-solution/

[5] https://www.gssmt-parts.com/what-are-the-key-features-of-high-quality-smt-reel-storage-systems.html

[6] https://www.allsmt.com/automated-warehouse-systems-smt-production

[7] https://www.smtfactory.com/Smd-Reel-Storage-Systemd.html

[8] https://www.infismash.com/smt-reel-storage/

[9] https://inovaxe.com/smt-reel-storage/

[10] https://www.neotel-technology.de/what-is-smt-reel-storage-solution/

[11] https://www.allegromicro.com/en/insights-and-innovations/technical-documents/general-semiconductor-information/semiconductor-handling-storage-shelf-life

[12] https://www.circuitinsight.com/programs/53166.html

[13] https://en.neotel.tech/2023/01/02/how-to-implement-intelligent-storage-system-in-smt-industry/

[14] https://industrial4less.com/blogs/warehouse-storage-solutions/optimizing-electronic-component-storage-in-the-ai-era

[15] https://inovaxe.com/solutions/

[16] https://global.neotel.tech/2022/12/27/10-benefits-of-using-smart-storage-system/

[17] https://cornerstone.lib.mnsu.edu/cgi/viewcontent.cgi?article=2230&context=etds

[18] https://www.gotopac.com/products/packaging-labeling/esd-packaging/esd-packing-boxes/reel-storage-boxes.html

[19] https://www.ams-electronics.co.uk/shop/inovaxe-storage/smt-reel-storage/inovaxe-inoauto-smart-cart-ia-series-smt-reel-storage/

[20] https://flexcontainer.com/product-category/reel-storage/

[21] https://blog.inovaxe.com/en/how-rack-and-bin-storage-hurts-your-bottom-line-0

[22] https://www.youtube.com/watch?v=FqXA2UmkJRY

[23] https://www.correctproducts.com/bins-totes-storage/esd-storage-bins/conductive-corrugated-reel-bins

[24] https://www.nicomatic.com/company/newsroom/optimize-your-smt-assembly-process-nicomatic-connectors-tape-reel-packaging

[25] https://www.adoptsmt.com/en/efficiency-enhancement-in-smt-manufacturing/

[26] https://en.neotel.tech/2023/01/04/smt-reel-rack-from-the-past-to-the-future/

[27] https://resources.sw.siemens.com/en-US/white-paper-smart-solutions-for-smt-reel-storage/

[28] https://www.youtube.com/watch?v=Rbf_oQBenhU

[29] https://www.mdpi.com/2306-5729/10/2/16

[30] https://inovaxe.com/optimize-storage-efficiency-with-inovaxe-at-smtai-2024/

[31] https://groupdiy.com/threads/diy-storage-of-smt-reels.34948/

[32] https://smt.asmpt.com/en/news-center/news/bridging-the-gap-ipc-2591-cfx-clears-the-way-to-the-integrated-smart-factory-2/

[33] https://www.gotopac.com/cci-fifo-reel-storage-boxes.html

[34] https://global.yamaha-motor.com/business/smt/faq/

[35] https://www.youtube.com/watch?v=5XBx6koW1Os

[36] https://global.neotel.tech/2022/02/24/5-things-you-must-know-about-smt-reel/

[37] https://versae.com/smt-assembly-faq/

[38] https://www.yufapolymer.com/black-plastic-smt-esd-smd-reel-storage-holder-box_p173.html

[39] https://www.reddit.com/r/AskElectronics/comments/11mspyt/storing_smt_reels/

[40] https://www.seamarkzm.com/maintaining-and-calibrating-an-smd-reel-counter.html

[41] https://www.asys-group.com/en/products/smart-factory/material-logistics/central-storage-systems

[42] https://www.linkedin.com/pulse/smd-reel-storage-production-environment-justin-thomas