Content Menu

● Introduction to LED SMD Machines

>> Benefits of LED SMD Machines

● Factors Affecting the Longevity of LED SMD Machines

>> Environmental Conditions

>> Operating Parameters

>> Maintenance Practices

● Strategies for Extending Lifespan

>> Thermal Management

>> Quality Components

>> Regular Maintenance Checks

>> Training and Documentation

>> Upgrades and Refurbishment

● Advanced Technologies for Enhanced Longevity

>> Smart Monitoring Systems

>> Automated Maintenance Scheduling

>> Energy Harvesting Technologies

● Conclusion

● FAQs

>> 1. What does SMD stand for in LED machines?

>> 2. How does temperature affect LED SMD machines?

>> 3. What are the benefits of using SMD LEDs in machines?

>> 4. How can you protect LED SMD machines from moisture?

>> 5. Why is regular cleaning important for LED SMD machines?

Ensuring the longevity of an LED SMD machine is crucial for maintaining optimal performance and extending its lifespan. LED SMD (Surface Mount Device) machines are widely used in various applications, including lighting and display manufacturing, due to their efficiency and compact design. However, like any electronic device, they require proper care and maintenance to function effectively over time. In this article, we will explore the key factors and strategies for maintaining and extending the lifespan of your LED SMD machine.

Introduction to LED SMD Machines

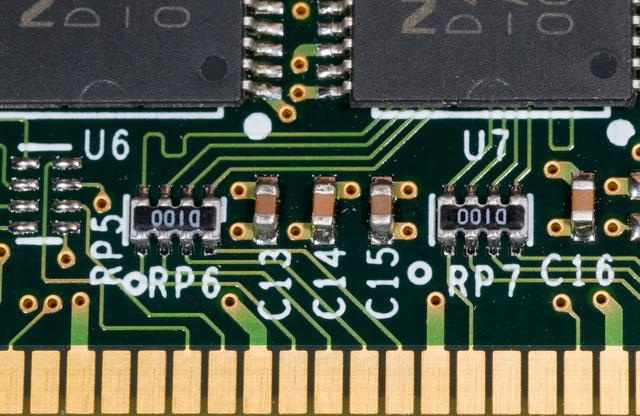

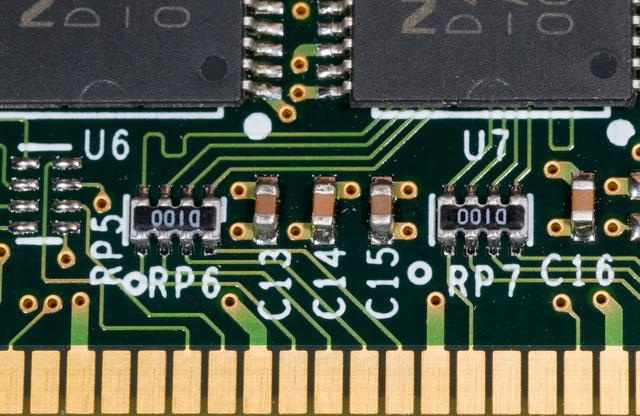

LED SMD machines are built using surface mount technology (SMT), which allows for the direct mounting of LED chips onto a printed circuit board (PCB). This technology enhances the machine's compactness, energy efficiency, and reliability compared to traditional through-hole technology. SMD LEDs are available in various sizes, such as 5050, 3528, and 2835, each offering different brightness levels and applications.

Benefits of LED SMD Machines

1. Energy Efficiency: SMD LEDs operate at lower voltages and currents, reducing energy consumption and heat generation, which contributes to their extended lifespan and improved stability.

2. Compact Design: The surface mount technology allows for more components to be packed into a smaller space, making the machines more compact and versatile.

3. Versatility: SMD LEDs can be used to create multi-color or full-color displays by combining red, green, and blue LED units.

Factors Affecting the Longevity of LED SMD Machines

Several factors can impact the longevity of LED SMD machines, including environmental conditions, operating parameters, and maintenance practices.

Environmental Conditions

1. Temperature: Extreme temperatures can significantly affect the performance and lifespan of LED SMD machines. High temperatures can accelerate aging and reduce the lifespan of components, while low temperatures may affect their operational efficiency.

2. Humidity and Moisture: Moisture can cause corrosion and damage to electronic components. Proper handling and storage in dry environments are essential to prevent moisture-related issues.

3. Dust and Contaminants: Dust accumulation can impair heat dissipation and lead to overheating, which can damage components. Regular cleaning is necessary to maintain optimal performance.

Operating Parameters

1. Power Supply: Fluctuations in voltage can adversely affect the lifespan of LED components. Using voltage stabilizers or surge protectors can help maintain a stable power supply.

2. Current and Voltage: Operating LEDs at lower currents and voltages can extend their lifespan. However, it is crucial to follow the manufacturer's guidelines for optimal performance.

Maintenance Practices

1. Regular Cleaning: Use appropriate cleaning methods to remove dust and contaminants without damaging the components. Ethanol is often recommended for cleaning SMD LEDs.

2. Inspection and Repair: Regularly inspect the machine for signs of wear or damage and address any issues promptly to prevent further deterioration.

3. Proper Storage: When not in use, store the machine in a dry, cool environment, covered to prevent dust accumulation.

Strategies for Extending Lifespan

Thermal Management

Proper thermal management is critical for maintaining the longevity of LED SMD machines. Excessive heat can reduce the lifespan of components, so ensuring adequate cooling and ventilation is essential. This can be achieved through the use of heat sinks, fans, or even liquid cooling systems in more demanding applications.

Quality Components

Investing in high-quality components, including LEDs and PCBs, can significantly enhance the machine's reliability and lifespan. High-quality LEDs are designed with better heat dissipation mechanisms, such as improved thermal interfaces or enhanced materials, which help maintain optimal operating temperatures.

Regular Maintenance Checks

Perform regular maintenance checks to identify and address any issues before they become major problems. This includes checking power connections, inspecting for physical damage, and ensuring proper ventilation. Regular software updates can also be beneficial if the machine is controlled by software, as updates often include bug fixes and performance enhancements.

Training and Documentation

Providing training to operators on proper handling and maintenance techniques can help prevent accidental damage. Maintaining detailed documentation of maintenance activities and any repairs can also aid in tracking the machine's history and identifying recurring issues.

Upgrades and Refurbishment

Consider upgrading or refurbishing components as needed. For example, replacing older LED modules with newer, more efficient ones can improve performance and extend the machine's lifespan. Refurbishing PCBs or replacing worn-out components can also help maintain optimal functionality.

Advanced Technologies for Enhanced Longevity

Smart Monitoring Systems

Implementing smart monitoring systems can help track the machine's performance in real-time, allowing for early detection of potential issues. These systems can monitor parameters such as temperature, voltage, and current, providing alerts when deviations occur.

Automated Maintenance Scheduling

Using automated maintenance scheduling tools can ensure that regular maintenance tasks are performed consistently. These tools can send reminders or automatically schedule maintenance sessions based on usage patterns or calendar dates.

Energy Harvesting Technologies

In some applications, integrating energy harvesting technologies can help reduce the load on the power supply, potentially extending the lifespan of components by reducing wear and tear.

Conclusion

Ensuring the longevity of your LED SMD machine requires careful consideration of environmental conditions, operating parameters, and maintenance practices. By implementing strategies such as proper thermal management, using high-quality components, and performing regular maintenance checks, you can significantly extend the lifespan of your machine. Regular cleaning, inspection, and prompt repair of any issues are also crucial for maintaining optimal performance. Additionally, leveraging advanced technologies like smart monitoring systems and automated maintenance scheduling can further enhance the machine's reliability and lifespan.

FAQs

1. What does SMD stand for in LED machines?

- SMD stands for Surface Mount Device, referring to the technology used to mount LED chips directly onto a printed circuit board without leads.

2. How does temperature affect LED SMD machines?

- Temperature significantly impacts the performance and lifespan of LED SMD machines. High temperatures can accelerate aging, while low temperatures may affect operational efficiency.

3. What are the benefits of using SMD LEDs in machines?

- SMD LEDs offer benefits such as energy efficiency, compact design, and versatility in creating multi-color displays.

4. How can you protect LED SMD machines from moisture?

- Protecting LED SMD machines from moisture involves proper handling and storage in dry environments, using moisture-proof materials, and ensuring good ventilation.

5. Why is regular cleaning important for LED SMD machines?

- Regular cleaning is essential to remove dust and contaminants that can impair heat dissipation and lead to overheating, which can damage components.