Content Menu

● Introduction to SMT Flex PCB Manufacturing

>> Advantages of SMT Flex PCBs

● Quality Control Measures in SMT Flex PCB Manufacturing

>> 1. Design Validation

>> 2. Material Control

>> 3. Solder Paste Inspection (SPI)

>> 4. Component Placement

>> 5. Reflow Soldering

>> 6. Inspection and Testing

>> 7. Final Processing

● Technologies Used for Quality Control

● Challenges in SMT Flex PCB Manufacturing

● Solutions to Common Challenges

● Best Practices for Quality Control

● Future Trends in SMT Flex PCB Manufacturing

● Conclusion

● Frequently Asked Questions

>> 1. What is the role of 3D Solder Paste Inspection in SMT Flex PCB manufacturing?

>> 2. How does Automated Optical Inspection (AOI) contribute to quality control?

>> 3. What are the challenges associated with reworking SMT Flex PCBs?

>> 4. How does X-ray inspection enhance quality control in SMT manufacturing?

>> 5. What are the benefits of using Flex PCBs in electronic devices?

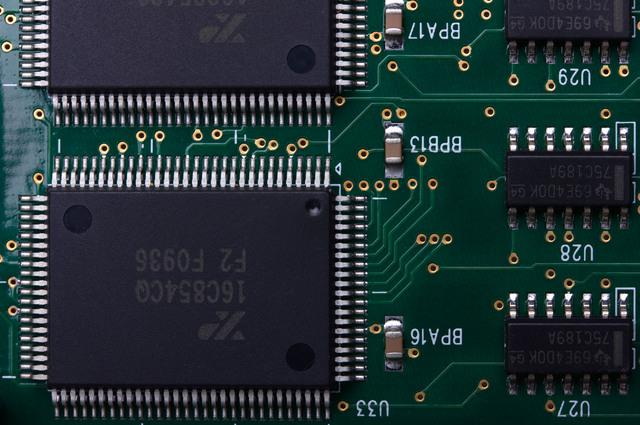

Quality control is a critical aspect of Surface Mount Technology (SMT) flexible printed circuit board (Flex PCB) manufacturing. Ensuring that every step of the process, from design to final assembly, meets stringent standards is essential for producing reliable and efficient electronic products. This article will delve into the methods and technologies used to maintain high-quality standards in SMT Flex PCB manufacturing.

Introduction to SMT Flex PCB Manufacturing

SMT is a method that allows electronic components to be mounted directly onto the surface of a printed circuit board. Flex PCBs, being flexible, offer advantages in terms of space-saving and durability, making them ideal for applications where rigidity is not required, such as in wearable devices or automotive electronics.

Advantages of SMT Flex PCBs

- Space Efficiency: Flex PCBs can be bent and folded, allowing for more complex designs in smaller spaces.

- Durability: They are resistant to vibrations and can withstand harsh environmental conditions.

- Cost-Effective: While the initial cost of setting up an SMT line is high, the long-term benefits include faster production and lower component costs.

Quality Control Measures in SMT Flex PCB Manufacturing

Quality control in SMT Flex PCB manufacturing involves several key steps and technologies to ensure that the final product meets the required standards.

1. Design Validation

Before manufacturing begins, it is crucial to validate the PCB design. This involves checking the design files for any errors or inconsistencies, ensuring that the PCB layout is manufacturable, and verifying that the components selected are compatible with the SMT process. Design for manufacturability (DFM) analysis is also conducted to identify potential issues early on.

2. Material Control

The quality of materials used is paramount. This includes ensuring that the PCBs, components, and solder paste meet the required specifications. For PCBs, this means checking for flatness, cleanliness, and solderability. Components must be sourced from reliable suppliers to ensure consistency. Material traceability is also important to track the origin and quality of components.

3. Solder Paste Inspection (SPI)

After applying solder paste to the PCB, a 3D SPI system is used to inspect the paste for any defects, such as insufficient or excessive paste. This step is critical to prevent soldering issues during the reflow process. Advanced SPI systems can provide detailed measurements of solder paste volume and coverage.

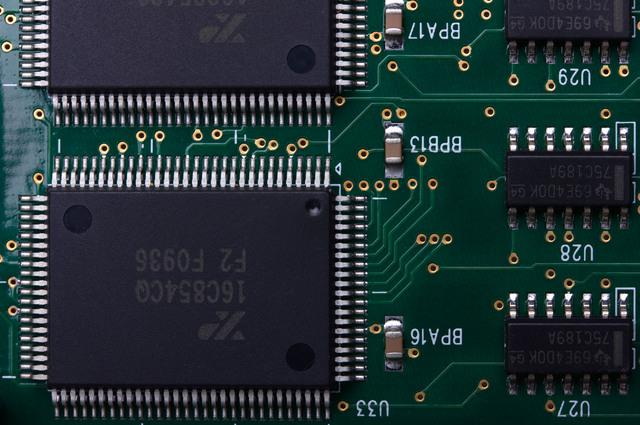

4. Component Placement

Components are placed onto the PCB using pick-and-place machines. The accuracy of placement is crucial to prevent defects like misaligned components or tombstoning. Modern pick-and-place machines offer high precision and speed, allowing for efficient production of complex PCBs.

5. Reflow Soldering

The PCB is then passed through a reflow oven, where the solder paste is melted and solidified to form connections. The temperature profile must be carefully controlled to ensure proper soldering without damaging components. The reflow process is monitored using thermal profiling to ensure that the soldering process meets the required specifications.

6. Inspection and Testing

After reflow soldering, the PCB undergoes inspection using Automated Optical Inspection (AOI) systems to detect defects such as solder bridges, insufficient solder, or misaligned components. Functional testing is also conducted to ensure the circuit functions as intended. AOI systems can be programmed to inspect specific areas of the PCB, enhancing their effectiveness.

7. Final Processing

The final steps include cleaning the PCB to remove any residual flux and applying protective coatings if necessary. The PCB is then packaged for shipment or further assembly. Proper packaging is important to prevent damage during transportation.

Technologies Used for Quality Control

Several technologies play a vital role in maintaining quality control during SMT Flex PCB manufacturing:

- 3D Solder Paste Inspection (SPI): Ensures accurate solder paste application.

- Automated Optical Inspection (AOI): Detects defects after soldering.

- X-ray Inspection: Used for inspecting BGA (Ball Grid Array) components.

- High-Definition Microscopes: For detailed inspection of solder joints.

- Thermal Profiling: Monitors the reflow soldering process to ensure optimal temperature conditions.

Challenges in SMT Flex PCB Manufacturing

Despite the advantages, SMT Flex PCB manufacturing faces several challenges:

- High Initial Investment: Setting up an SMT line requires significant investment in specialized equipment.

- Fine Pitch Components: Handling components with very small lead spacings requires advanced equipment and skills.

- Rework Challenges: Due to the compact nature of SMT components, reworking or modifying assembled PCBs can be difficult.

- Material Variability: Variations in material properties can affect the reliability of the PCB.

Solutions to Common Challenges

To address these challenges, manufacturers can implement several strategies:

- Invest in Advanced Equipment: Regularly update machinery to handle fine-pitch components and improve inspection capabilities.

- Training and Skill Development: Ensure operators are well-trained to handle complex components and processes.

- Process Optimization: Implement strict process controls and continuous monitoring to minimize defects.

- Supply Chain Management: Work closely with suppliers to ensure consistent material quality.

Best Practices for Quality Control

Implementing best practices is crucial for maintaining high-quality standards:

- Regular Maintenance: Regularly maintain equipment to prevent breakdowns and ensure optimal performance.

- Continuous Monitoring: Continuously monitor production processes to identify and address issues promptly.

- Employee Training: Provide ongoing training to employees to enhance their skills and knowledge.

- Quality Audits: Conduct regular quality audits to ensure compliance with industry standards.

Future Trends in SMT Flex PCB Manufacturing

The future of SMT Flex PCB manufacturing is expected to involve more advanced technologies and processes:

- Artificial Intelligence (AI) Integration: AI can be used to improve inspection accuracy and predict potential defects.

- Internet of Things (IoT) Integration: IoT technologies can enhance real-time monitoring and control of manufacturing processes.

- Sustainable Practices: There will be a greater emphasis on sustainable manufacturing practices, including reducing waste and energy consumption.

Conclusion

Ensuring quality control in SMT Flex PCB manufacturing is a multifaceted process that involves rigorous design validation, material control, precise component placement, and thorough inspection and testing. By leveraging advanced technologies like 3D SPI and AOI, manufacturers can produce high-quality Flex PCBs that meet the demands of modern electronics. Continuous investment in equipment and personnel training is essential to overcome the challenges associated with SMT manufacturing.

Frequently Asked Questions

1. What is the role of 3D Solder Paste Inspection in SMT Flex PCB manufacturing?

3D Solder Paste Inspection (SPI) plays a crucial role in ensuring that the solder paste is applied accurately and in the correct amount. This step helps prevent soldering defects during the reflow process, such as insufficient or excessive solder, which can lead to electrical failures.

2. How does Automated Optical Inspection (AOI) contribute to quality control?

AOI systems are used to inspect the PCB after soldering to detect defects such as misaligned components, solder bridges, or insufficient solder. This automated process ensures that defects are identified early, reducing the risk of faulty products reaching the market.

3. What are the challenges associated with reworking SMT Flex PCBs?

Reworking SMT Flex PCBs can be challenging due to the compact and leadless nature of many components. This often requires specialized tools and techniques, and in some cases, complete disassembly and reassembly may be necessary.

4. How does X-ray inspection enhance quality control in SMT manufacturing?

X-ray inspection is particularly useful for inspecting components like BGAs, where visual inspection is not possible. It helps ensure that solder joints are properly formed and that there are no defects within the component.

5. What are the benefits of using Flex PCBs in electronic devices?

Flex PCBs offer several benefits, including space efficiency, durability, and flexibility. They can be bent or folded to fit into complex designs, making them ideal for applications where traditional rigid PCBs are not suitable.