Content Menu

● Introduction to SMT Stencil Alignment

>> Importance of Alignment

>> Challenges in Alignment

● Factors Affecting Alignment

● Techniques for Improving Alignment

>> 1. Use of Fiducial Marks

>> 2. High-Precision Alignment Systems

>> 3. Stencil Tensioning

>> 4. Environmental Control

>> 5. Regular Maintenance

● Stencil Design Guidelines

● Advanced Alignment Technologies

>> Vision Systems

>> Laser-Based Alignment

● Best Practices for Alignment

● Conclusion

● FAQ

>> 1. What is the importance of fiducial marks in SMT stencil alignment?

>> 2. How does environmental control impact SMT stencil alignment?

>> 3. What are the differences between laser-cut and electroformed stencils in terms of alignment?

>> 4. How does stencil tensioning affect alignment?

>> 5. What role does stencil thickness play in alignment and solder paste deposition?

● Citations:

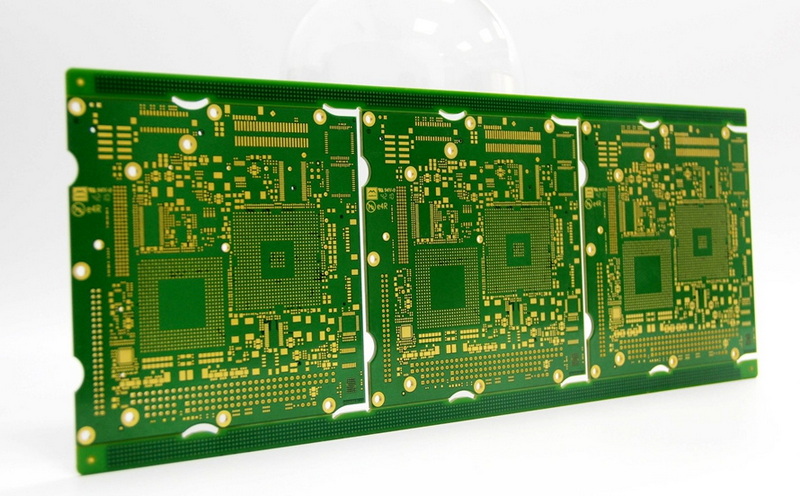

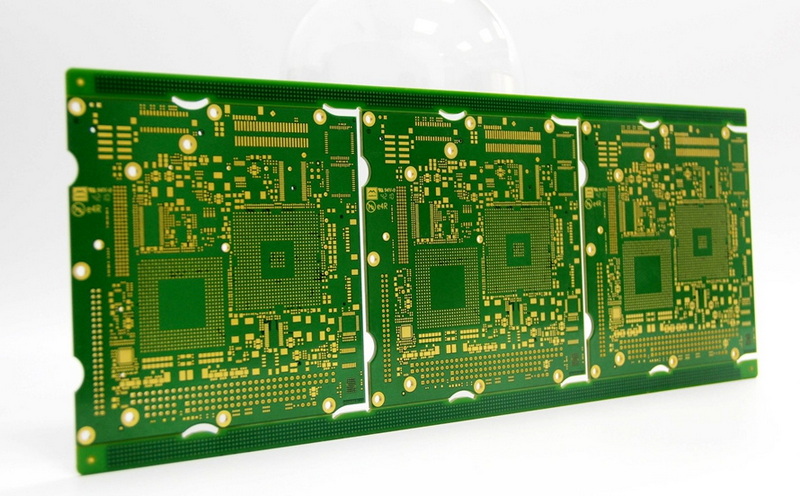

Ensuring accurate alignment is crucial when using SMT (Surface Mount Technology) foil stencils in the assembly of printed circuit boards (PCBs). Misalignment can lead to defects such as insufficient solder paste on pads, solder bridging, or even component failure. This article will delve into the techniques and considerations necessary for achieving precise alignment with SMT foil stencils.

Introduction to SMT Stencil Alignment

SMT stencil printing is a critical step in PCB assembly. It involves transferring solder paste onto the PCB pads through apertures in the stencil. The accuracy of this process depends on several factors, including the design of the stencil, the quality of the PCB, and the alignment system used.

Importance of Alignment

Alignment ensures that the solder paste is deposited accurately onto the PCB pads. Misalignment can result in reduced solder paste coverage, leading to weak solder joints or component failure. As components become smaller and PCBs more complex, precise alignment becomes increasingly important. Modern PCBs often feature components with very small pitches, making accurate alignment even more critical.

Challenges in Alignment

Achieving accurate alignment is challenging due to several factors:

- Component Miniaturization: As components shrink in size, the tolerance for misalignment decreases. This requires more precise alignment systems and techniques.

- PCB Complexity: Complex PCBs with multiple layers and dense component placement demand higher alignment accuracy to prevent defects.

- Material Variability: Variations in PCB and stencil materials can affect their dimensional stability, impacting alignment.

Factors Affecting Alignment

Several factors can affect the alignment between the SMT foil stencil and the PCB:

1. Stencil Design: The design of the stencil apertures must match the PCB pad layout. Apertures should be slightly smaller than the pads to prevent solder bridging and ensure good gasketing.

2. PCB Shrinkage: PCBs can shrink during manufacturing due to thermal stress, affecting pad locations. This shrinkage must be accounted for in the stencil design.

3. Environmental Conditions: Temperature and humidity fluctuations can cause dimensional changes in both the PCB and the stencil, affecting alignment. Maintaining a stable environment is crucial.

4. Stencil Material and Manufacturing: The choice between laser-cut and electroformed stencils impacts alignment. Laser-cut stencils generally offer better aperture registration.

5. Equipment Calibration: Regular calibration of SMT printing equipment is essential to ensure that the alignment system remains accurate over time.

Techniques for Improving Alignment

To ensure accurate alignment, several techniques can be employed:

1. Use of Fiducial Marks

Fiducial marks on both the PCB and the stencil help in aligning them accurately. These marks are used by automated alignment systems to adjust the position of the stencil relative to the PCB. Fiducials should be placed in a manner that allows for easy detection by the alignment system.

2. High-Precision Alignment Systems

Modern SMT printers often include advanced alignment systems that can adjust in multiple axes (X, Y, and theta) to ensure precise positioning of the stencil over the PCB. These systems use vision systems or laser-based technologies to detect fiducial marks and make necessary adjustments.

3. Stencil Tensioning

Proper tensioning of the stencil in its frame is essential to prevent distortion and ensure consistent alignment across the PCB. Tension helps maintain the stencil's dimensional stability, which is critical for accurate solder paste deposition.

4. Environmental Control

Maintaining a stable temperature and humidity environment helps minimize dimensional changes in both the PCB and the stencil, ensuring consistent alignment. This is particularly important in high-volume production environments where consistency is key.

5. Regular Maintenance

Regular inspection and maintenance of the stencil and printing equipment are crucial to prevent wear and tear that could affect alignment accuracy. This includes cleaning the stencil regularly and checking for any signs of damage or distortion.

Stencil Design Guidelines

Proper stencil design is key to achieving accurate alignment and successful solder paste deposition:

- Aperture Size vs. Pad Size: Apertures should be slightly smaller than pads to prevent bridging and ensure good gasketing.

- Aperture Shape: Apertures should match the shape of the PCB pads (e.g., circular for circular pads).

- Stencil Thickness: The thickness of the stencil affects the aspect ratio, which influences solder paste release. Thicker stencils are used for larger components, while thinner stencils are better for smaller components.

- Corner Rounding: Rounding the corners of apertures can improve solder paste release and reduce bridging.

Advanced Alignment Technologies

Recent advancements in alignment technology include the use of machine learning algorithms to improve the accuracy of alignment systems. These systems can learn from past alignments and adjust their strategies to optimize alignment precision.

Vision Systems

Vision systems are widely used in modern SMT printers to detect fiducial marks and align the stencil with the PCB. These systems use high-resolution cameras to capture images of the fiducials and then adjust the stencil position accordingly.

Laser-Based Alignment

Some advanced systems use laser technology to detect fiducial marks. This method offers high precision and is less susceptible to environmental factors compared to vision systems.

Best Practices for Alignment

Implementing best practices in alignment can significantly improve the quality of PCB assemblies:

- Standardize Fiducial Mark Placement: Ensure that fiducial marks are consistently placed across different PCB designs to simplify alignment.

- Use High-Quality Stencil Materials: Choose materials that offer dimensional stability and durability.

- Regularly Calibrate Equipment: Ensure that all equipment is calibrated regularly to maintain alignment accuracy.

Conclusion

Ensuring accurate alignment when using SMT foil stencils is critical for achieving high-quality PCB assemblies. By understanding the factors that affect alignment and implementing techniques such as precise stencil design, fiducial marks, high-precision alignment systems, and environmental control, manufacturers can significantly reduce defects and improve assembly yields.

FAQ

1. What is the importance of fiducial marks in SMT stencil alignment?

Fiducial marks are crucial for aligning the SMT stencil with the PCB. They provide reference points for automated alignment systems to adjust the stencil's position accurately, ensuring that solder paste is deposited correctly onto the PCB pads.

2. How does environmental control impact SMT stencil alignment?

Environmental control, particularly maintaining a stable temperature and humidity, is essential to prevent dimensional changes in both the PCB and the stencil. This stability ensures consistent alignment and reduces the risk of defects during the solder paste printing process.

3. What are the differences between laser-cut and electroformed stencils in terms of alignment?

Laser-cut stencils generally offer better aperture registration and alignment accuracy compared to electroformed stencils. This is because laser-cutting allows for more precise control over aperture size and shape, reducing errors in stencil-to-PCB alignment.

4. How does stencil tensioning affect alignment?

Proper tensioning of the stencil in its frame is vital to prevent distortion and ensure consistent alignment across the PCB. Tension helps maintain the stencil's dimensional stability, which is critical for accurate solder paste deposition.

5. What role does stencil thickness play in alignment and solder paste deposition?

Stencil thickness affects the aspect ratio, which influences the release of solder paste from the stencil apertures. Thicker stencils are used for larger components to ensure sufficient solder volume, while thinner stencils are better suited for smaller components to facilitate paste release.

Citations:

[1] https://app.lpkfusa.com/articles/stencil/Conquering%20SMT%20Stencil%20Challenges%202009-03.pdf

[2] https://www.dianyuan.com/upload/community/2014/12/31/1420004934-48952.pdf

[3] https://tecan.co.uk/printing-parameters-and-smt-stencils/

[4] https://iconnect007.com/article/118546/smt-stencils-101-what-are-industrystandard-stencil-designs/118549/pcb

[5] http://www.qualiecocircuits.co.nz/stencil-technology-other-aspects.htm

[6] https://patents.google.com/patent/US20100170621A1

[7] https://fctsolder.com/wp-content/uploads/2017/08/S06_01-Improve-SMT-Assembly-Yields-Using-Root-Cause-Analysis-in-Stencil-Design-Final.pdf

[8] https://www.epectec.com/smt-stencils/