Content Menu

● Introduction to SMT PCB Chip Mounters

>> Key Features of SMT PCB Chip Mounters

● Enhancing Circuit Board Quality with SMT PCB Chip Mounters

● Benefits of Using SMT PCB Chip Mounters

>> Advantages Over Traditional Through-Hole Technology

>> Challenges and Limitations

● Effective Measures to Improve SMT Assembly Quality

● Advanced Technologies in SMT PCB Chip Mounters

● Case Studies: Successful Implementation of SMT PCB Chip Mounters

● Future Trends in SMT PCB Chip Mounters

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary advantages of using SMT PCB chip mounters?

>> 2. How do SMT PCB chip mounters improve circuit board reliability?

>> 3. What are some challenges associated with SMT PCB chip mounters?

>> 4. How can manufacturers optimize the use of SMT PCB chip mounters?

>> 5. Can SMT PCB chip mounters be used for both high and low-volume production?

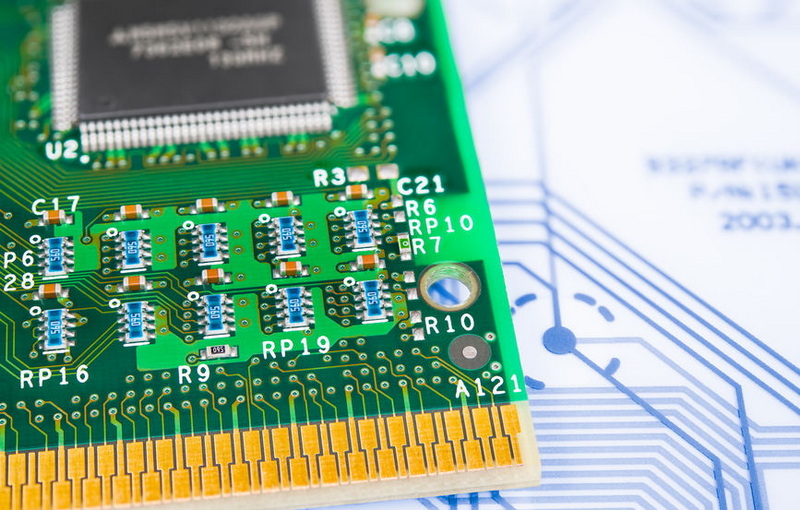

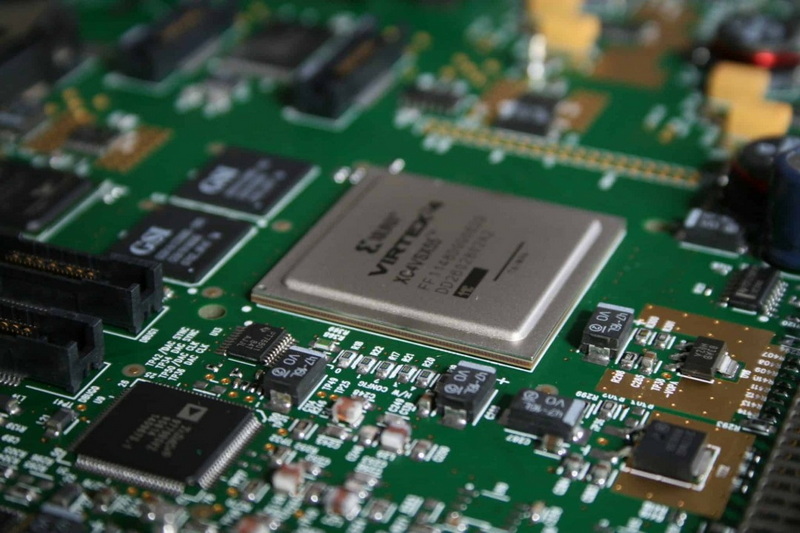

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by enabling the production of smaller, more complex, and reliable electronic devices. At the heart of this technology are SMT PCB chip mounters, which play a crucial role in enhancing the quality of circuit boards. In this article, we will delve into the world of SMT PCB chip mounters, exploring how they contribute to improved circuit board quality and discussing the benefits and challenges associated with their use.

Introduction to SMT PCB Chip Mounters

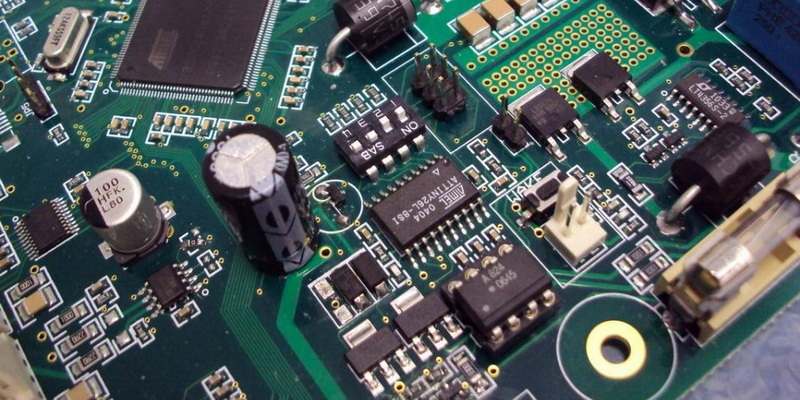

SMT PCB chip mounters are sophisticated machines designed to automate the placement of electronic components onto printed circuit boards (PCBs). These machines are equipped with advanced vision systems and precision mechanics, allowing them to accurately place components such as resistors, capacitors, and integrated circuits (ICs) onto the PCB. The use of SMT PCB chip mounters has become indispensable in modern electronics manufacturing due to their ability to enhance production efficiency, reduce costs, and improve product reliability.

Key Features of SMT PCB Chip Mounters

1. High-Speed Placement: SMT PCB chip mounters can place thousands of components per hour, significantly increasing production speed compared to manual assembly methods.

2. Precision Placement: These machines use advanced vision systems to ensure accurate placement of components, minimizing errors and improving overall product quality.

3. Flexibility: SMT PCB chip mounters can handle a wide range of component types and sizes, making them versatile for various applications.

4. Automation: The automated nature of these machines reduces labor costs and human errors, leading to more consistent and reliable production.

Enhancing Circuit Board Quality with SMT PCB Chip Mounters

The quality of circuit boards is significantly enhanced by the use of SMT PCB chip mounters in several ways:

1. Improved Reliability: The precise placement of components ensures robust connections, reducing the likelihood of electrical failures and improving the overall reliability of the circuit board.

2. Increased Component Density: SMT PCB chip mounters allow for higher component densities, enabling more complex designs within smaller form factors. This miniaturization is crucial for modern electronic devices.

3. Better High-Frequency Performance: By reducing lead lengths and inductance, SMT components improve signal integrity and high-frequency performance, which is essential for applications requiring fast data transmission.

4. Reduced Production Costs: The automation provided by SMT PCB chip mounters reduces labor costs and minimizes material waste, making production more cost-effective.

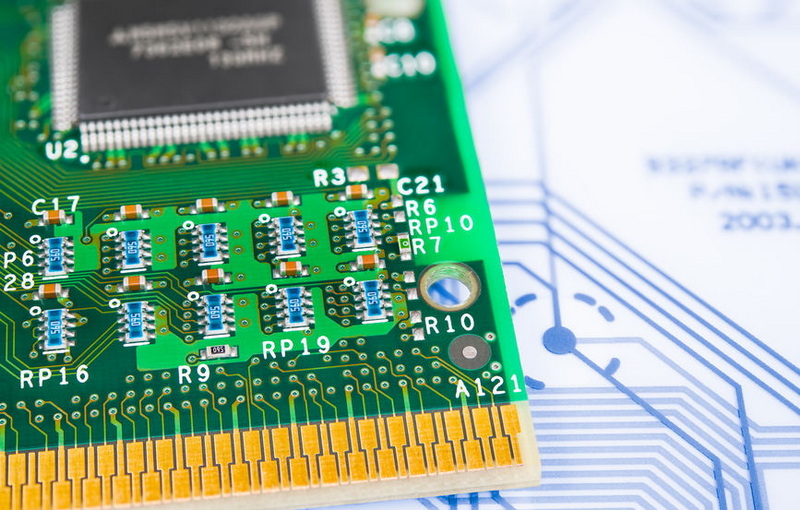

Benefits of Using SMT PCB Chip Mounters

Advantages Over Traditional Through-Hole Technology

1. Smaller and Lighter Assemblies: SMT components are smaller and lighter, allowing for the creation of compact electronic devices.

2. Higher Automation Potential: The process is highly amenable to automation, reducing manual labor and associated errors.

3. Improved Electrical Performance: SMT components offer better high-frequency performance due to shorter lead lengths and lower inductance.

4. Lower Production Costs: Reduced material and labor costs make SMT more economical for large-scale production.

Challenges and Limitations

Despite the advantages, SMT PCB chip mounters also present some challenges:

1. High Initial Investment: The cost of purchasing and maintaining SMT equipment can be substantial.

2. Technical Complexity: The operation and maintenance of these machines require specialized training and expertise.

3. Component Fragility: SMT components are more susceptible to damage during handling and assembly.

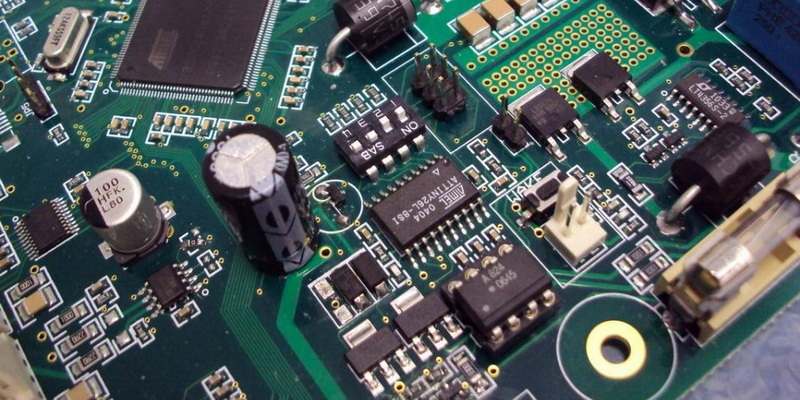

Effective Measures to Improve SMT Assembly Quality

To maximize the benefits of SMT PCB chip mounters, manufacturers must focus on several key factors:

1. Component Quality: Ensuring that components meet specifications and are handled properly is crucial for maintaining assembly quality.

2. PCB Design and Quality: The design and material of the PCB can significantly impact the success of SMT assembly.

3. Solder Paste Application: Proper solder paste application is essential for creating reliable solder joints.

4. Component Placement Accuracy: Accurate placement is critical for high-quality assemblies.

5. Reflow Soldering Process: Optimizing the reflow soldering process ensures strong and reliable connections.

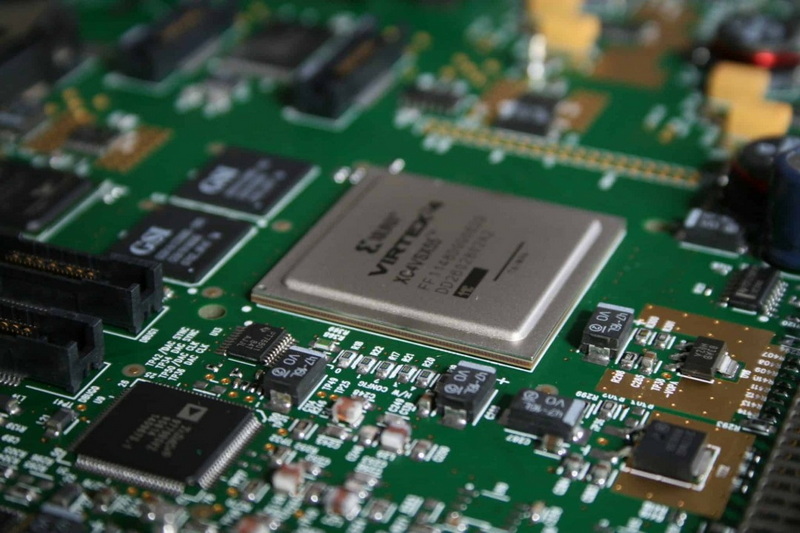

Advanced Technologies in SMT PCB Chip Mounters

Recent advancements in SMT technology have led to the development of more sophisticated chip mounters with enhanced capabilities:

1. Artificial Intelligence (AI) Integration: Some modern SMT PCB chip mounters incorporate AI to improve component recognition, placement accuracy, and predictive maintenance.

2. High-Speed Vision Systems: Advanced vision systems enable faster and more accurate component inspection and placement.

3. Flexible Production Lines: Modular designs allow for easier integration of different machines and processes, enhancing production flexibility.

Case Studies: Successful Implementation of SMT PCB Chip Mounters

Several companies have successfully integrated SMT PCB chip mounters into their production lines, achieving significant improvements in efficiency and product quality:

1. Increased Production Speed: A leading electronics manufacturer increased its production speed by 30% after implementing SMT PCB chip mounters.

2. Reduced Defect Rates: Another company reported a 25% reduction in defect rates due to the precise placement capabilities of SMT machines.

3. Cost Savings: By automating the assembly process, a major electronics firm reduced its labor costs by 40%.

Future Trends in SMT PCB Chip Mounters

As technology continues to evolve, we can expect SMT PCB chip mounters to become even more sophisticated:

1. Increased Use of Robotics: Robotics will play a larger role in SMT assembly, enhancing flexibility and precision.

2. Integration with IoT: The integration of Internet of Things (IoT) technology will enable real-time monitoring and optimization of production processes.

3. Sustainability Initiatives: Manufacturers will focus on reducing environmental impact through more efficient energy use and waste reduction.

Conclusion

In conclusion, SMT PCB chip mounters are indispensable tools in modern electronics manufacturing, offering numerous benefits that enhance the quality and reliability of circuit boards. By understanding the advantages and challenges associated with these machines, manufacturers can optimize their production processes to achieve higher efficiency, reliability, and cost-effectiveness. As technology continues to evolve, the role of SMT PCB chip mounters will remain central to the development of smaller, more complex, and reliable electronic devices.

Frequently Asked Questions

1. What are the primary advantages of using SMT PCB chip mounters?

SMT PCB chip mounters offer several key advantages, including high-speed automated assembly, improved component density, enhanced reliability, and reduced production costs. These machines enable the production of smaller, more complex electronic devices with better high-frequency performance.

2. How do SMT PCB chip mounters improve circuit board reliability?

SMT PCB chip mounters improve circuit board reliability by ensuring precise placement of components, which leads to robust electrical connections. This precision minimizes errors and enhances the overall durability of the circuit board, especially under thermal and vibration stresses.

3. What are some challenges associated with SMT PCB chip mounters?

Challenges include the high initial investment in equipment, technical complexity requiring specialized training, and the fragility of SMT components, which can be easily damaged during handling.

4. How can manufacturers optimize the use of SMT PCB chip mounters?

Manufacturers can optimize the use of SMT PCB chip mounters by focusing on component quality, PCB design, solder paste application, component placement accuracy, and optimizing the reflow soldering process. Regular maintenance and calibration of the equipment are also crucial.

5. Can SMT PCB chip mounters be used for both high and low-volume production?

Yes, SMT PCB chip mounters are versatile and can be used for both high and low-volume production. However, they are particularly cost-effective for mid to high-volume production runs due to their automation capabilities and reduced labor costs.