Content Menu

● Understanding SMT Manufacturing

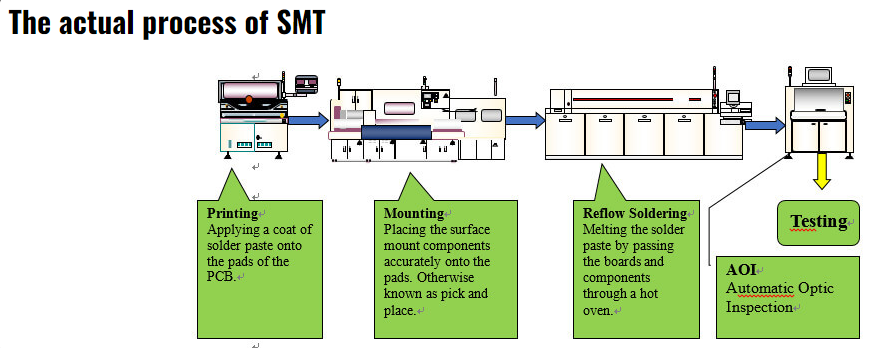

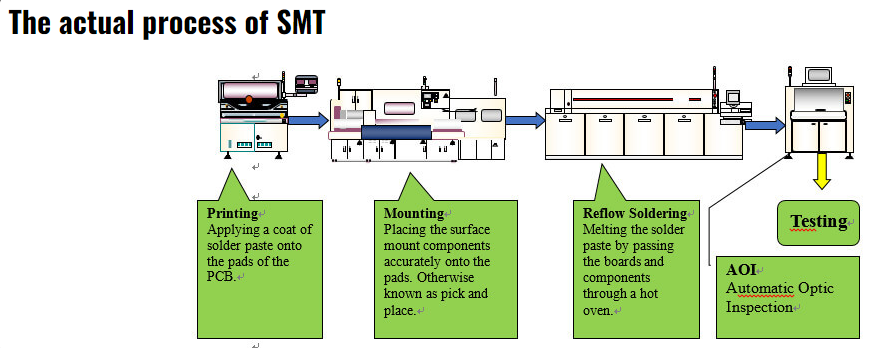

>> The SMT Manufacturing Process

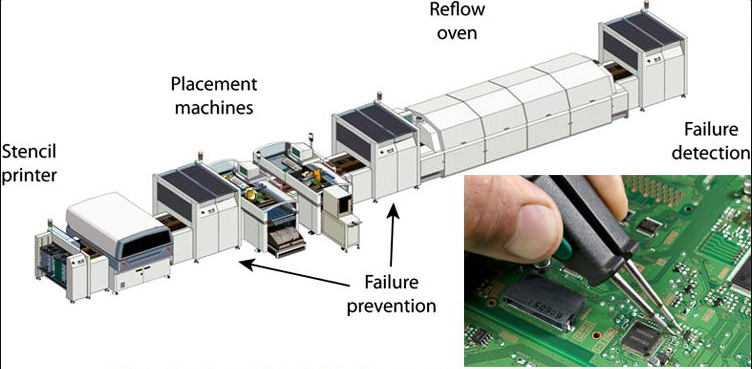

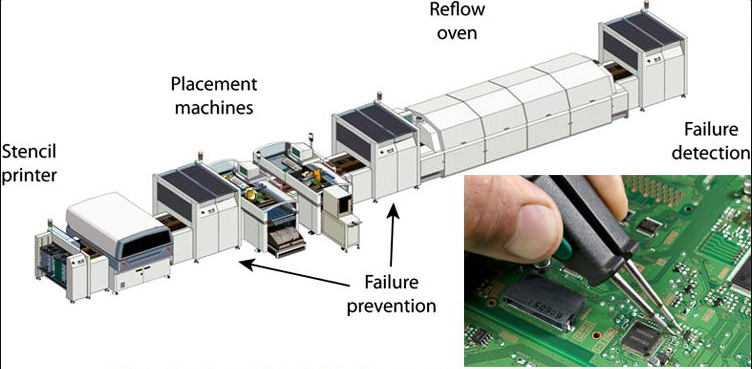

>> Visualizing SMT Manufacturing

● Benefits of SMT Manufacturing

>> The Role of SMT Manufacturing Suppliers

● Future Trends in SMT Manufacturing

● Conclusion

>> Frequently Asked Questions

Understanding SMT Manufacturing

What is SMT?

SMT, or Surface Mount Technology, is a method used to mount electronic components directly onto the surface of PCBs. Unlike traditional through-hole technology, where components are inserted into holes in the board, SMT allows for a more compact design and facilitates automated assembly processes. This technology is pivotal in creating modern electronic devices that require high-density circuit boards.

The SMT Manufacturing Process

The SMT manufacturing process can be broken down into several key stages:

1. Material Preparation

- Selection of Components: The first step involves selecting surface mount components (SMCs) and preparing the PCB. Each PCB features flat pads that are designed to hold the component leads.

- Quality Control: Ensuring that all materials are free from defects is critical to maintaining high-quality standards.

2. Stencil Preparation

- A stencil is created based on the PCB design, which will guide the application of solder paste to specific locations on the board.

3. Solder Paste Printing

- Solder paste, a mixture of flux and metal solder, is applied to the PCB using a stencil and squeegee. This paste serves as a temporary adhesive for the components.

4. Component Placement

- Using automated pick-and-place machines, components are accurately placed onto the soldered pads on the PCB.

5. Reflow Soldering

- The assembled PCBs are passed through a reflow oven where they undergo controlled heating to melt the solder paste, forming permanent connections between the components and the board.

6. Cleaning and Inspection

- After soldering, PCBs are cleaned to remove any residual flux or contaminants. Automated Optical Inspection (AOI) systems are employed to detect any defects in the assembly.

Visualizing SMT Manufacturing

To provide a clearer understanding of these processes, consider including images and videos that illustrate each stage of SMT manufacturing:

- Material Preparation: Images showing raw materials and quality control checks.

- Solder Paste Printing: Diagrams or videos demonstrating stencil application.

- Component Placement: Footage of pick-and-place machines in action.

- Reflow Soldering: Visuals of reflow ovens and temperature profiles.

- Inspection: Examples of AOI systems identifying defects.

Benefits of SMT Manufacturing

SMT manufacturing offers numerous advantages over traditional methods:

- Space Efficiency: Components can be mounted on both sides of a PCB, significantly reducing size.

- Increased Performance: Shorter electrical paths lead to improved signal integrity.

- Cost-Effectiveness: Automated processes reduce labor costs and increase production speed.

- Flexibility: SMT allows for easy modifications in design without significant changes to manufacturing processes.

The Role of SMT Manufacturing Suppliers

Companies like Global Soul Limited play a crucial role as SMT manufacturing suppliers by providing essential components and services:

- SMT Equipment: GS-SMT LTD offers a range of equipment including nozzles, feeders, and pick-and-place machines that are vital for efficient production.

- Consumables: They supply solder paste and other materials necessary for assembly.

- Technical Support: With expertise in SMT processes, suppliers can offer guidance on best practices and troubleshooting.

Future Trends in SMT Manufacturing

As technology advances, several trends are shaping the future of SMT manufacturing:

- Miniaturization: Continued demand for smaller electronic devices drives innovation in component design and PCB layout.

- Smart Manufacturing: The integration of IoT technologies allows for real-time monitoring and optimization of production lines.

- Sustainability: Efforts to reduce waste and improve energy efficiency are becoming increasingly important in manufacturing practices.

Conclusion

SMT manufacturing is at the forefront of modern electronics production, enabling manufacturers to create smaller, more efficient devices. As suppliers like Global Soul Limited continue to innovate and provide essential resources, the industry will likely see further advancements that enhance performance and sustainability.

Frequently Asked Questions

1. What is Surface Mount Technology?

- Surface Mount Technology (SMT) is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs).

2. What are the main steps in SMT manufacturing?

- The main steps include material preparation, stencil preparation, solder paste printing, component placement, reflow soldering, cleaning, and inspection.

3. Why is SMT preferred over traditional methods?

- SMT is preferred due to its space efficiency, increased performance, cost-effectiveness, and flexibility in design modifications.

4. What role do suppliers like GS-SMT play in SMT manufacturing?

- Suppliers provide essential equipment, consumables, and technical support necessary for efficient SMT production.

5. What future trends are expected in SMT manufacturing?

- Trends include miniaturization of components, smart manufacturing through IoT integration, and sustainability efforts to reduce waste.