Content Menu

● Understanding SMT Line Inspection

● The Importance of SMT Line Inspection

>> Enhancing Quality Control

● Key Benefits of Implementing SMT Line Inspection Systems

● Implementing Effective SMT Line Inspection Strategies

>> 1. Integrate Inspection at Every Stage

>> 2. Utilize Advanced Technologies

>> 3. Train Personnel

>> 4. Establish Feedback Loops

>> 5. Maintain Documentation

● Challenges in SMT Line Inspection

● Future Trends in SMT Line Inspection

● Conclusion

● FAQ

>> 1. What is Automated Optical Inspection (AOI)?

>> 2. How does Solder Paste Inspection (SPI) work?

>> 3. What are common defects detected during SMT inspections?

>> 4. Why is X-ray Inspection important in SMT?

>> 5. How can manufacturers ensure compliance with industry standards through inspections?

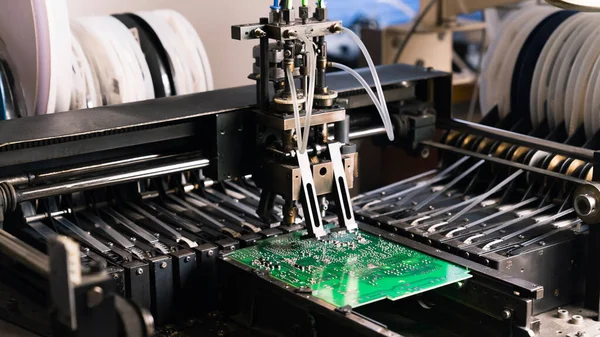

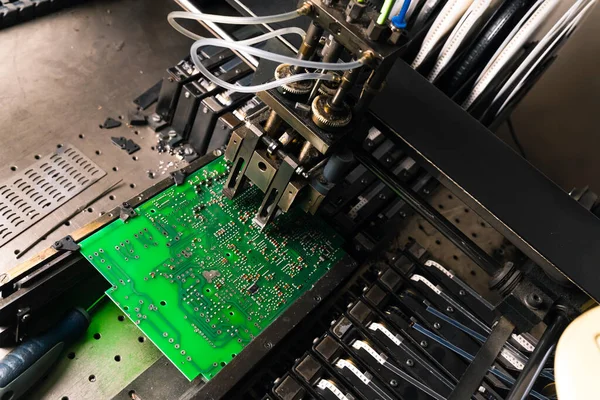

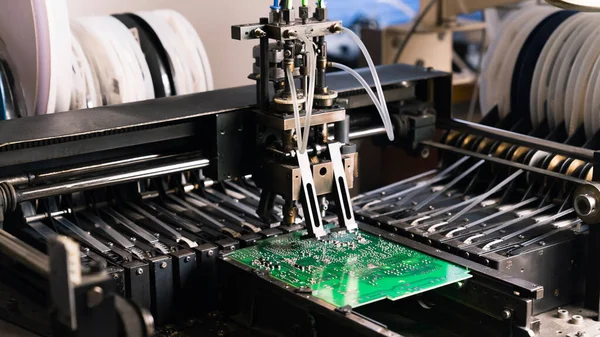

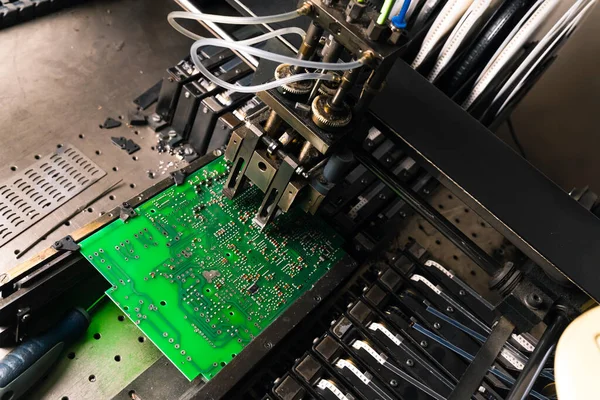

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by allowing for more compact designs and increased production efficiency. However, the complexity of SMT processes introduces significant challenges in maintaining high manufacturing quality. This is where SMT line inspection systems play a crucial role. By integrating advanced inspection techniques throughout the SMT assembly process, manufacturers can significantly enhance product quality, reduce defects, and improve overall operational efficiency.

Understanding SMT Line Inspection

SMT line inspection involves a series of automated and manual checks performed at various stages of the SMT assembly process to ensure that printed circuit boards (PCBs) are manufactured to the highest quality standards. This includes verifying component placement, solder joint integrity, and overall board functionality. Key inspection methods include:

- Automated Optical Inspection (AOI): Utilizes high-resolution cameras to detect surface defects such as misaligned components, solder bridges, and insufficient solder.

- Solder Paste Inspection (SPI): Conducted after the solder paste application to ensure the correct volume and placement of solder paste on PCB pads.

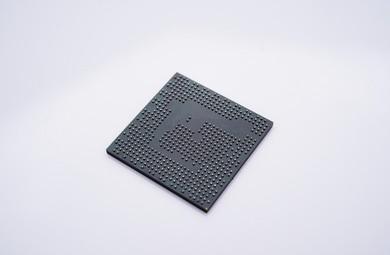

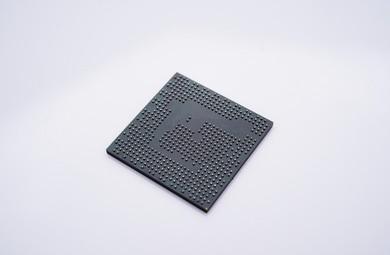

- X-ray Inspection: Essential for examining hidden solder joints, particularly in complex components like Ball Grid Arrays (BGAs).

- In-Circuit Testing (ICT): Electrically tests each component on the PCB to verify functionality and identify faults.

Each of these inspection methods contributes to a comprehensive quality assurance strategy that addresses potential issues before they escalate into more significant problems.

The Importance of SMT Line Inspection

Enhancing Quality Control

The primary goal of SMT line inspection is to enhance quality control throughout the manufacturing process. By implementing rigorous inspection protocols, manufacturers can achieve:

- Early Detection of Defects: Identifying defects at various stages allows for immediate corrective actions, preventing defective products from progressing further down the production line.

- Reduced Rework Costs: Early detection minimizes the need for costly rework or scrapping of defective products, leading to significant cost savings.

- Improved First Pass Yield (FPY): A higher FPY indicates that more products pass quality checks on the first attempt, which is essential for maintaining production efficiency and reducing waste.

- Enhanced Reliability: Consistent inspection practices ensure that only high-quality products reach customers, thereby enhancing brand reputation and customer satisfaction.

Key Benefits of Implementing SMT Line Inspection Systems

1. Increased Efficiency: Automation in inspection processes reduces the time spent on manual inspections while increasing throughput. For instance, AOI systems can inspect thousands of components per hour compared to manual checks.

2. Data-Driven Insights: Modern SMT line inspection systems generate valuable data that can be analyzed to identify trends and root causes of defects. This data-driven approach enables continuous improvement in manufacturing processes.

3. Flexibility and Scalability: Advanced inspection systems can adapt to different product designs and volumes, making it easier for manufacturers to scale operations without compromising quality.

4. Cost Savings: By preventing defects early in the process, companies can save on costs associated with rework, returns, and warranty claims. For example, implementing an automated first article inspection system can significantly reduce setup times and related costs by ensuring accurate machine programming from the outset.

5. Compliance with Industry Standards: Many industries require adherence to strict quality standards. Implementing robust SMT line inspections helps manufacturers meet these requirements consistently.

Implementing Effective SMT Line Inspection Strategies

To maximize the benefits of SMT line inspections, manufacturers should consider several best practices:

1. Integrate Inspection at Every Stage

Implement inspections at critical points in the SMT process:

- Pre-production: Verify component specifications and solderability before assembly begins.

- During Production: Use SPI after solder paste application and AOI after component placement and reflow soldering.

- Post-production: Conduct ICT or functional testing to ensure overall board performance.

2. Utilize Advanced Technologies

Invest in cutting-edge technologies such as 3D AOI systems that provide volumetric data for more accurate defect detection compared to traditional 2D systems. These technologies enhance defect identification capabilities and improve overall inspection accuracy.

In addition to 3D AOI, manufacturers should also consider using Machine Learning (ML) algorithms integrated into their inspection systems. These algorithms can learn from historical defect data to improve detection rates over time by adapting to new defect patterns that may arise with evolving product designs.

3. Train Personnel

Ensure that operators are adequately trained in using inspection equipment and interpreting results. Well-trained personnel can better recognize potential issues during inspections and take appropriate actions promptly.

Training programs should include both theoretical knowledge about defect types and practical experience with equipment operation. Regular refresher courses can help keep staff updated on new technologies and methods in SMT line inspection.

4. Establish Feedback Loops

Create feedback mechanisms between inspection results and manufacturing processes. This allows for real-time adjustments based on defect data collected during inspections, leading to continuous improvement efforts. For example, if a specific defect type is frequently detected during AOI, engineers can investigate potential causes in the assembly process or design changes that may mitigate this issue.

5. Maintain Documentation

Thoroughly document all inspection activities and results. This documentation serves as a valuable resource for analyzing trends over time and identifying recurring issues that may require attention.

Moreover, maintaining detailed records aids in compliance audits and provides transparency for stakeholders regarding quality assurance practices within the organization.

Challenges in SMT Line Inspection

Despite its numerous benefits, implementing an effective SMT line inspection system comes with challenges:

- Complexity of Modern Designs: As PCB designs become more intricate with smaller components and tighter spacing, detecting defects becomes increasingly challenging.

- Integration with Existing Systems: Ensuring that new inspection technologies seamlessly integrate with existing manufacturing processes can require significant investment in time and resources.

- Cost Considerations: While automation can lead to long-term savings, the initial investment in advanced inspection systems may be substantial for some manufacturers.

- Resistance to Change: Employees accustomed to traditional methods may resist adopting new technologies or processes due to fear of job loss or uncertainty about their effectiveness. Effective change management strategies must be employed to address these concerns through clear communication about benefits and training opportunities available during transitions.

Future Trends in SMT Line Inspection

The future of SMT line inspection is poised for significant advancements driven by technological innovations:

1. Artificial Intelligence (AI) Integration: AI will play a pivotal role in enhancing defect detection capabilities by analyzing vast amounts of data collected from inspections to identify patterns that human inspectors might miss.

2. Real-time Monitoring Systems: The development of IoT-enabled devices will allow for real-time monitoring of production lines, providing instant feedback on quality metrics without interrupting workflows.

3. Cloud-Based Solutions: Cloud technology will facilitate centralized data storage accessible across multiple sites or facilities within an organization, enabling better collaboration among teams working on quality assurance initiatives globally.

4. Augmented Reality (AR) Training Tools: AR applications will enhance training programs by providing immersive experiences where operators can practice using equipment under simulated conditions before working on actual production lines.

5. Sustainability Initiatives: As environmental concerns grow within manufacturing sectors worldwide, incorporating sustainability practices into SMT line inspections—such as minimizing waste generated during testing—will become increasingly important for meeting regulatory standards while improving overall efficiency gains through reduced resource consumption over time.

Conclusion

In conclusion, integrating an effective SMT line inspection system is essential for improving manufacturing quality in electronics production. By implementing comprehensive inspection strategies throughout the SMT assembly process—ranging from solder paste application through final testing—manufacturers can significantly reduce defects, enhance product reliability, and achieve substantial cost savings. The evolution of technology continues to enhance these capabilities, making it imperative for companies to stay ahead by adopting advanced inspection methods that ensure their products meet increasingly stringent quality standards.

FAQ

1. What is Automated Optical Inspection (AOI)?

Automated Optical Inspection (AOI) is a technique used in electronics manufacturing that employs high-resolution cameras to automatically inspect printed circuit boards (PCBs) for defects such as misaligned components or soldering issues after assembly or reflow processes.

2. How does Solder Paste Inspection (SPI) work?

Solder Paste Inspection (SPI) evaluates the application of solder paste on PCB pads before components are placed. It measures paste volume and positioning using advanced imaging technology to ensure optimal soldering conditions during reflow.

3. What are common defects detected during SMT inspections?

Common defects include missing components, incorrect placements, insufficient or excessive solder volume, solder bridges, cold joints, and other anomalies that could affect circuit functionality or reliability.

4. Why is X-ray Inspection important in SMT?

X-ray Inspection is crucial for detecting hidden defects within components like BGAs where joints are not visible externally. It helps identify issues such as voids or cracks that could lead to failures later in product life cycles.

5. How can manufacturers ensure compliance with industry standards through inspections?

Manufacturers can implement rigorous inspection protocols at each stage of production while documenting results meticulously to demonstrate adherence to industry standards required for specific markets like automotive or medical devices.