Content Menu

● Understanding LED PCB SMT

>> The Role of LEDs

>> PCB: The Foundation

>> SMT: The Assembly Method

● Efficiency Enhancements through LED PCB SMT

>> Energy Efficiency

>>> Reduced Power Consumption

>>> Improved Heat Management

>> Manufacturing Efficiency

>>> Compact Design

>>> Automated Assembly

>>> Reduced Error Rates

>> Performance Efficiency

>>> Improved Signal Integrity

>>> Enhanced Reliability

>>> Versatile Design Options

● Applications Benefiting from LED PCB SMT

>> Lighting Solutions

>>> General Illumination

>>> Automotive Lighting

>>> Specialized Lighting

>> Display Technology

>>> LED Screens and Signage

>>> Consumer Electronics

>> IoT and Wearable Devices

>>> Smart Home Devices

>>> Wearable Technology

● Challenges and Considerations in LED PCB SMT Design

>> Thermal Management

>>> Heat Dissipation Techniques

>> Power Distribution

>>> Voltage Drop Considerations

>> Optical Considerations

>>> Light Output Optimization

● Future Trends in LED PCB SMT

>> Miniaturization

>> Advanced Materials

>> Intelligent Lighting Systems

>> Sustainability Focus

● Conclusion

● FAQ

>> 1. What are the main advantages of using LED PCB SMT in product design?

>> 2. How does LED PCB SMT contribute to better thermal management?

>> 3. What industries benefit most from LED PCB SMT technology?

>> 4. What are the key challenges in designing LED PCB SMT products?

>> 5. What future trends can we expect in LED PCB SMT technology?

● Citations:

In today's rapidly evolving technological landscape, efficiency is paramount for any electronic product. One of the most significant advancements in this realm is the integration of LED (Light Emitting Diode) technology with PCB (Printed Circuit Board) and SMT (Surface Mount Technology). This powerful combination has revolutionized the electronics industry, offering unprecedented levels of efficiency, performance, and reliability. In this article, we will explore how LED PCB SMT can significantly enhance your product's efficiency and why it's becoming an indispensable part of modern electronic design.

Understanding LED PCB SMT

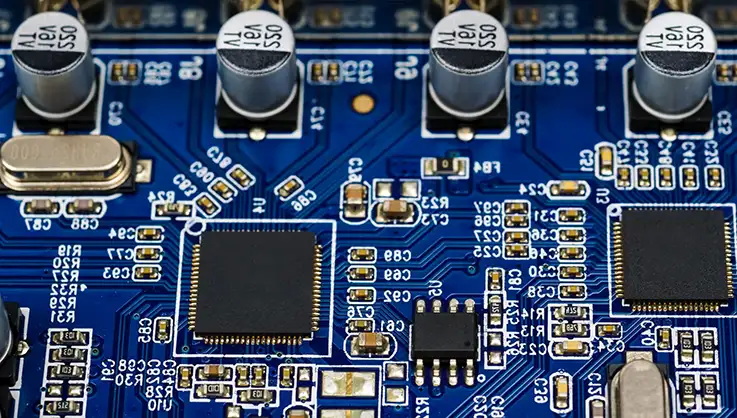

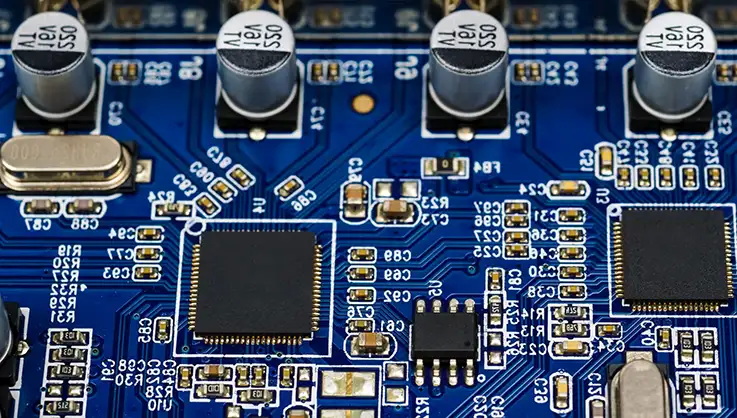

Before delving into the efficiency benefits, it's crucial to understand what LED PCB SMT entails. LED PCB SMT refers to the process of mounting LED components directly onto a printed circuit board using surface mount technology. This method differs from traditional through-hole technology, offering numerous advantages in terms of size, performance, and manufacturing efficiency.

The Role of LEDs

LEDs are semiconductor devices that emit light when an electric current passes through them. They have become increasingly popular due to their energy efficiency, long lifespan, and versatility. LEDs are used in a wide range of applications, from simple indicator lights to complex lighting systems and displays[1].

PCB: The Foundation

PCBs serve as the backbone of electronic devices, providing mechanical support and electrical connections for the components. In LED applications, PCBs play a crucial role in heat dissipation and power distribution, which are critical factors in LED performance and longevity[5].

SMT: The Assembly Method

Surface Mount Technology is a method of producing electronic circuits where components are mounted directly onto the surface of PCBs. SMT has largely replaced the older through-hole technology in many applications due to its numerous advantages, including smaller size, higher component density, and improved performance[1].

Efficiency Enhancements through LED PCB SMT

Now that we've established the basics, let's explore how LED PCB SMT can enhance your product's efficiency across various dimensions.

Energy Efficiency

One of the most significant advantages of LED PCB SMT is its superior energy efficiency. LEDs are inherently more energy-efficient than traditional lighting sources, and when combined with SMT on a well-designed PCB, this efficiency is further enhanced.

Reduced Power Consumption

LED modules can produce more light per watt of electricity consumed compared to incandescent or fluorescent lighting. High-efficiency LED modules can produce more than 120 lumens per watt, while even standard LED modules offer 80 to 120 lumens per watt[9]. This translates to significant energy savings, especially in large-scale applications like industrial lighting or street lighting.

Improved Heat Management

Efficient heat dissipation is crucial for LED performance and longevity. PCBs designed specifically for LEDs often incorporate features like metal-core substrates or additional copper layers to enhance thermal management. This improved heat dissipation allows LEDs to operate at lower temperatures, increasing their efficiency and lifespan[8].

Manufacturing Efficiency

LED PCB SMT also brings substantial improvements to the manufacturing process, leading to increased production efficiency and reduced costs.

Compact Design

SMT allows for a much higher component density on PCBs compared to through-hole technology. This compact design not only reduces the overall size of the product but also minimizes the amount of material used, leading to cost savings in production[1].

Automated Assembly

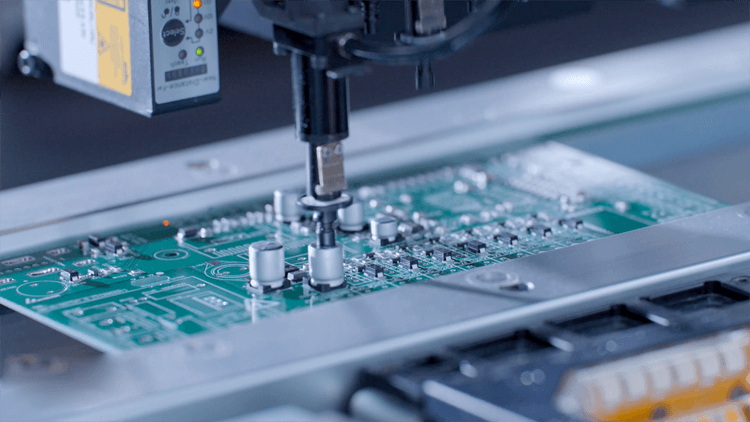

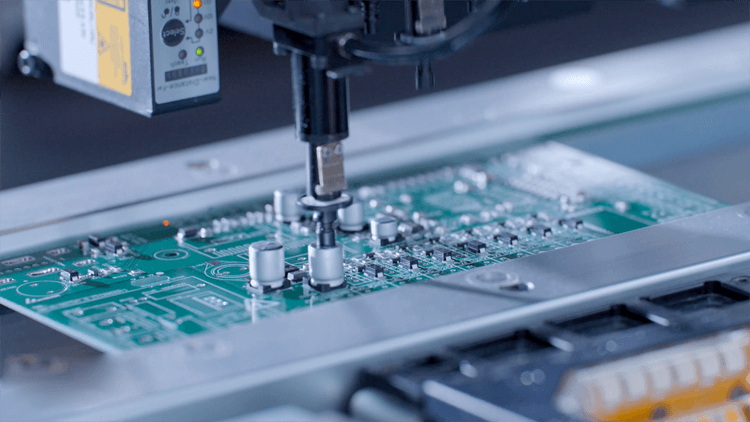

SMT is highly compatible with automated assembly processes. Pick-and-place machines can rapidly and accurately place SMD LEDs and other components onto PCBs, significantly increasing production speed and reducing labor costs[5].

Reduced Error Rates

The precision of SMT assembly reduces the likelihood of errors during the manufacturing process. This leads to fewer defects, less waste, and improved overall product quality[4].

Performance Efficiency

LED PCB SMT doesn't just improve energy and manufacturing efficiency; it also enhances the overall performance of the product.

Improved Signal Integrity

The shorter connection paths in SMT designs result in reduced parasitic capacitance and inductance. This leads to better signal integrity, which is particularly important in high-frequency applications or in devices requiring precise timing[1].

Enhanced Reliability

SMT components typically have stronger mechanical bonds to the PCB compared to through-hole components. This increased durability makes LED PCB SMT products more resistant to shock and vibration, enhancing their reliability in various operating conditions[7].

Versatile Design Options

The compact nature of SMT allows for more flexible and creative PCB designs. This versatility enables designers to optimize the layout for specific applications, further enhancing efficiency and performance[4].

Applications Benefiting from LED PCB SMT

The efficiency enhancements offered by LED PCB SMT make it an excellent choice for a wide range of applications. Let's explore some areas where this technology is making a significant impact.

Lighting Solutions

LED PCB SMT has revolutionized the lighting industry, offering energy-efficient and long-lasting solutions for various lighting needs.

General Illumination

From residential to commercial spaces, LED PCB SMT-based lighting fixtures provide bright, uniform illumination while consuming significantly less power than traditional lighting sources. The compact design of SMT LEDs allows for sleek, modern lighting fixtures that can be easily integrated into various architectural designs[9].

Automotive Lighting

The automotive industry has widely adopted LED PCB SMT for both interior and exterior lighting. LED headlights, taillights, and dashboard displays offer improved visibility, energy efficiency, and design flexibility. The durability of SMT assemblies also makes these components more resistant to the vibrations and temperature fluctuations common in automotive applications[7].

Specialized Lighting

LED PCB SMT is also ideal for specialized lighting applications such as horticultural lighting, UV disinfection systems, and medical lighting. The precise control over light output and spectrum that LEDs offer, combined with the compact and efficient SMT design, allows for highly optimized lighting solutions in these fields[4].

Display Technology

The efficiency and versatility of LED PCB SMT have made it a cornerstone of modern display technology.

LED Screens and Signage

Large-scale LED displays and digital signage benefit greatly from SMT technology. The high density of SMD LEDs allows for high-resolution displays with excellent brightness and color reproduction. The energy efficiency of LEDs also makes these displays more economical to operate, especially for outdoor applications where they may need to compete with sunlight[7].

Consumer Electronics

LED PCB SMT is widely used in the displays of smartphones, tablets, laptops, and televisions. The thin profile and low power consumption of SMD LEDs contribute to the sleek design and long battery life of portable devices[2].

IoT and Wearable Devices

The Internet of Things (IoT) and wearable technology sectors have embraced LED PCB SMT for its compact size and energy efficiency.

Smart Home Devices

IoT devices for smart homes, such as thermostats, security cameras, and smart speakers, often incorporate LED indicators or displays. The small footprint and low power consumption of SMD LEDs are crucial for these devices, which are often battery-powered or need to maintain a sleek aesthetic[4].

Wearable Technology

Fitness trackers, smartwatches, and other wearable devices rely on LED PCB SMT for their displays and sensor systems. The compact and energy-efficient nature of this technology allows for longer battery life and more comfortable, lightweight designs[2].

Challenges and Considerations in LED PCB SMT Design

While LED PCB SMT offers numerous benefits, it also presents some unique challenges that need to be addressed to maximize efficiency.

Thermal Management

One of the primary challenges in LED PCB design is managing heat. Although LEDs are more efficient than traditional light sources, they still generate heat that needs to be dissipated effectively to maintain performance and longevity.

Heat Dissipation Techniques

Designers often employ various techniques to enhance heat dissipation in LED PCBs:

- Using metal-core PCBs (MCPCBs) with high thermal conductivity

- Incorporating thermal vias to conduct heat away from the LED

- Designing optimal copper pour patterns to spread heat across the board

- Integrating heat sinks or other cooling solutions into the overall product design[8]

Power Distribution

Efficient power distribution is crucial in LED PCB design, especially for high-power applications.

Voltage Drop Considerations

In large LED arrays or long LED strips, voltage drop along the PCB traces can lead to uneven brightness. Designers must carefully calculate trace widths and consider using power planes or multiple power injection points to ensure uniform power distribution[5].

Optical Considerations

The optical performance of LEDs can be affected by their placement and surrounding components on the PCB.

Light Output Optimization

Factors such as LED spacing, reflector design, and the use of lenses or diffusers need to be considered to achieve the desired light output and distribution. The PCB layout should be optimized to minimize interference between LEDs and maximize overall luminous efficacy[9].

Future Trends in LED PCB SMT

As technology continues to advance, we can expect to see further innovations in LED PCB SMT that will drive even greater efficiencies.

Miniaturization

The trend towards smaller and more powerful LEDs is likely to continue, enabling even more compact and efficient designs. This will open up new possibilities for LED integration in various products and applications[2].

Advanced Materials

Research into new PCB materials with improved thermal properties and electrical characteristics will lead to more efficient LED PCB designs. These materials could enhance heat dissipation, reduce power loss, and improve overall performance[8].

Intelligent Lighting Systems

The integration of LED PCB SMT with smart control systems and sensors will enable more adaptive and efficient lighting solutions. These systems can adjust light output based on ambient conditions, occupancy, and user preferences, further optimizing energy consumption[9].

Sustainability Focus

As environmental concerns grow, there will be an increased emphasis on sustainable manufacturing processes and materials for LED PCB SMT. This could include the use of recyclable materials, lead-free solders, and more energy-efficient production methods[4].

Conclusion

LED PCB SMT technology has proven to be a game-changer in enhancing product efficiency across various industries. From significant energy savings and improved manufacturing processes to enhanced performance and versatility in design, the benefits of this technology are far-reaching. As we've explored, LED PCB SMT is not just about creating brighter lights or more colorful displays; it's about optimizing every aspect of electronic product design for maximum efficiency.

The challenges presented by LED PCB SMT, such as thermal management and power distribution, are being continually addressed through innovative design solutions and advanced materials. As technology progresses, we can expect even greater efficiencies and capabilities from LED PCB SMT in the future.

For product designers and manufacturers looking to stay competitive in today's market, embracing LED PCB SMT is not just an option; it's a necessity. The efficiency gains in energy consumption, manufacturing processes, and overall performance can provide a significant edge in product development and market success.

As we look to the future, the continued evolution of LED PCB SMT technology promises to bring even more exciting possibilities. From smarter, more adaptive lighting systems to increasingly miniaturized and powerful electronic devices, LED PCB SMT will undoubtedly play a crucial role in shaping the efficient, high-performance products of tomorrow.

FAQ

1. What are the main advantages of using LED PCB SMT in product design?

LED PCB SMT offers several key advantages in product design:

- Energy Efficiency: LEDs consume less power and produce more light per watt compared to traditional lighting sources.

- Compact Size: SMT allows for higher component density, resulting in smaller and lighter products.

- Improved Performance: Better heat dissipation and signal integrity lead to enhanced overall performance.

- Manufacturing Efficiency: SMT is highly compatible with automated assembly processes, reducing production time and costs.

- Durability: SMT components typically have stronger mechanical bonds, increasing product reliability.

2. How does LED PCB SMT contribute to better thermal management?

LED PCB SMT contributes to better thermal management in several ways:

- Efficient Heat Dissipation: PCBs designed for LEDs often use materials with high thermal conductivity, such as metal-core PCBs.

- Optimized Layout: SMT allows for more efficient PCB layouts that can include thermal vias and copper pour patterns to spread heat.

- Compact Design: The smaller size of SMT components can allow for better airflow and heat dissipation within the product.

- Integration with Cooling Solutions: The design flexibility of SMT makes it easier to incorporate heat sinks or other cooling mechanisms.

3. What industries benefit most from LED PCB SMT technology?

LED PCB SMT technology benefits a wide range of industries, including:

- Lighting Industry: For energy-efficient general illumination, architectural lighting, and specialized lighting applications.

- Automotive Sector: In vehicle lighting, dashboards, and infotainment systems.

- Consumer Electronics: For displays in smartphones, tablets, laptops, and TVs.

- IoT and Wearables: In smart home devices, fitness trackers, and other compact, battery-powered devices.

- Signage and Advertising: For large-scale LED displays and digital billboards.

4. What are the key challenges in designing LED PCB SMT products?

The main challenges in designing LED PCB SMT products include:

- Thermal Management: Efficiently dissipating heat to maintain LED performance and longevity.

- Power Distribution: Ensuring uniform power delivery, especially in large LED arrays or strips.

- Optical Performance: Optimizing LED placement and surrounding components for desired light output.

- Miniaturization: Balancing the desire for compact designs with thermal and performance requirements.

- Cost Optimization: Managing the cost of specialized PCB materials and high-quality LEDs.

5. What future trends can we expect in LED PCB SMT technology?

Several exciting trends are emerging in LED PCB SMT technology:

- Further Miniaturization: Development of smaller, more efficient LEDs and SMT components.

- Advanced Materials: New PCB materials with improved thermal and electrical properties.

- Intelligent Lighting Systems: Integration with smart controls and sensors for adaptive lighting solutions.

- Sustainability Focus: Increased use of recyclable materials and energy-efficient manufacturing processes.

- Enhanced Automation: More advanced automated assembly techniques for even greater manufacturing efficiency.

Citations:

[1] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[2] https://tehnoblog.org/smd-led-chips-characteristics-size-power-efficiency/

[3] https://patents.google.com/patent/CN103594603A/zh

[4] https://www.u-cpcb.com/news/top-benefits-of-smd-led-pcb-board-technology-for/

[5] https://rushpcb.com/line-efficiency-of-a-pcb-manufacturer/

[6] https://baike.baidu.com/item/%E5%85%88%E8%BF%9B%E7%94%B5%E5%AD%90%E5%B0%81%E8%A3%85%E6%8A%80%E6%9C%AF%E4%B8%8E%E5%85%B3%E9%94%AE%E6%9D%90%E6%96%99%E4%B8%9B%E4%B9%A6--%E4%BB%8ELED%E5%88%B0%E5%9B%BA%E6%80%81%E7%85%A7%E6%98%8E%EF%BC%9A%E5%8E%9F%E7%90%86%E3%80%81%E6%9D%90%E6%96%99%E3%80%81%E5%B0%81%E8%A3%85%E3%80%81%E8%A1%A8%E5%BE%81%E5%8F%8A%E5%BA%94%E7%94%A8%EF%BC%88%E8%8B%B1%E6%96%87%E7%89%88%EF%BC%89/63038846

[7] https://www.ptcled.com/academy/smd-led-display.html

[8] https://resources.pcb.cadence.com/blog/2022-challenges-and-considerations-in-led-pcb-design

[9] https://jhdpcb.com/blog/led-module-feature/