Content Menu

● Understanding SMT Nozzles

● Common Problems with SMT Nozzles

● Effective Repair Methods for SMT Nozzles

>> 1. Visual Inspection

>> 2. Cleaning Techniques

>> 3. Replacing Worn Components

>> 4. Regular Maintenance Schedule

● Best Practices for Extending Nozzle Lifespan

● Advanced Techniques for Nozzle Maintenance

>> 1. Automated Cleaning Machines

>> 2. Regular Calibration

>> 3. Monitoring Performance Metrics

● Conclusion

● FAQ

>> 1. What are common signs that my SMT nozzle needs repair?

>> 2. How often should I clean my SMT nozzles?

>> 3. Can I use alcohol to clean my SMT nozzles?

>> 4. What should I do if my SMT nozzle is damaged?

>> 5. How can I extend the lifespan of my SMT nozzles?

● Citations:

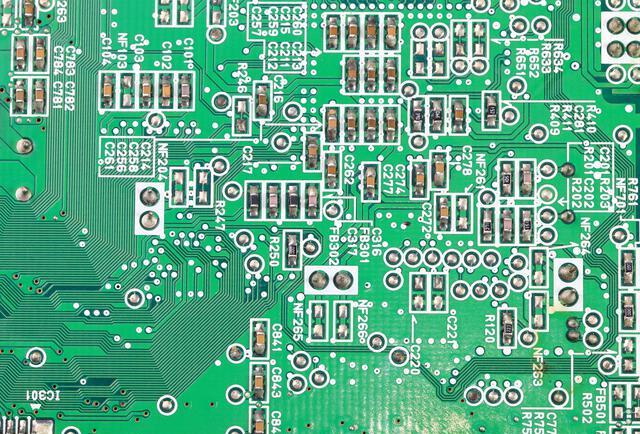

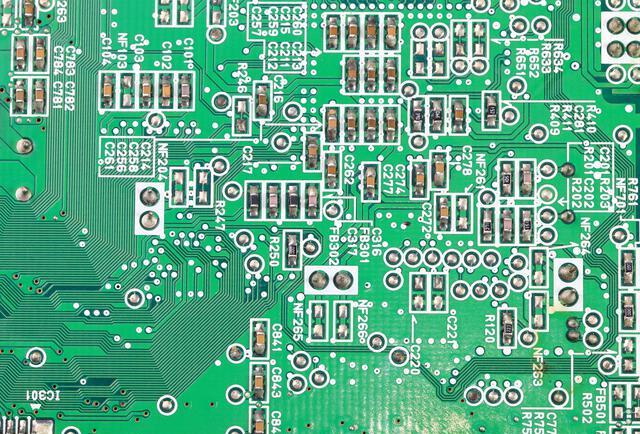

Surface Mount Technology (SMT) nozzles are integral components in the electronics manufacturing process, specifically in pick-and-place machines. These nozzles are responsible for accurately picking up and placing electronic components onto printed circuit boards (PCBs). However, over time, SMT nozzles can experience various issues such as clogging, wear, and damage, which can significantly impact production efficiency and quality. This article provides a comprehensive guide on effectively repairing SMT nozzles, maintaining their functionality, and ensuring optimal performance.

Understanding SMT Nozzles

SMT nozzles are designed to handle a wide range of electronic components during assembly processes. They utilize vacuum pressure to pick components from feeders and accurately place them onto PCBs. The effectiveness of these nozzles directly correlates with the overall quality of the assembly process. Common issues that arise with SMT nozzles include:

- Clogging: Residues from solder paste or flux can accumulate inside the nozzle, obstructing airflow and reducing suction power.

- Wear and Tear: Frequent use leads to physical wear on the nozzle tip, affecting its ability to pick up components accurately.

- Damage: Mishandling or using incompatible cleaning methods can result in cracks or deformation of the nozzle.

- Misalignment: Improper installation or wear can lead to misalignment, causing inaccurate placement of components.

Common Problems with SMT Nozzles

Identifying common problems associated with SMT nozzles is crucial for effective maintenance and repair:

- Loss of Vacuum: This issue may prevent the nozzle from picking up components from the feeder or cause components to shift during transport.

- Short or Worn Nozzles: These can lead to poor pickup and incorrect placement of parts into solder paste, causing them to shift during PCB movement.

- Sticking Nozzles: Material degradation over time can cause nozzles to stick during various stages of operation, leading to inconsistent performance.

- Higher Rejection Rates: Poorly maintained nozzles can result in increased defects during inspection due to inconsistent component placement.

Effective Repair Methods for SMT Nozzles

1. Visual Inspection

Conducting a thorough visual inspection is the first step in repairing an SMT nozzle. Look for signs of wear, deformation, or clogging. Key aspects to check include:

- Inspecting the nozzle tip for visible damage or wear.

- Ensuring there are no foreign objects lodged inside the nozzle.

- Verifying that the nozzle is securely attached to the machine.

2. Cleaning Techniques

Cleaning is essential for maintaining nozzle performance. Here are several effective cleaning methods:

- Manual Cleaning: Use a soft cloth or brush to clean the exterior of the nozzle. For small diameter nozzles, a fine steel wire can help remove debris without damaging the nozzle. However, manual cleaning may not reach deep into complex structures.

- Ultrasonic Cleaning: This method uses ultrasonic vibrations to dislodge dirt and residues from inside the nozzle. While effective for larger nozzles, it may damage sensitive coatings on some nozzles and is generally not recommended for smaller ones due to potential surface damage.

- High-Pressure Water Mist Cleaning: This modern method employs high-pressure water mist to clean both the exterior and interior of the nozzle without causing damage. It effectively removes stubborn residues and is considered one of the best practices for maintaining SMT nozzles. The cleaning fluid used is typically deionized or distilled water, ensuring that it does not harm the nozzle's surface coating[1][3].

3. Replacing Worn Components

If significant wear or damage is observed during inspection, replacing the nozzle entirely may be necessary. When selecting a replacement:

- Choose high-quality nozzles compatible with your specific pick-and-place machine.

- Consider options featuring advanced materials designed for durability and resistance to wear.

4. Regular Maintenance Schedule

Establishing a regular maintenance schedule can prevent many issues associated with SMT nozzles. Recommended practices include:

- Daily inspections before production runs.

- Cleaning procedures after every shift or production cycle.

- Regularly replacing nozzles based on usage frequency and observed wear patterns[6].

Best Practices for Extending Nozzle Lifespan

To ensure long-lasting performance from your SMT nozzles, consider implementing these best practices:

- Use Appropriate Cleaning Solutions: Avoid corrosive substances like alcohol that can damage nozzle surfaces. Instead, opt for specialized cleaning solutions recommended by manufacturers[5].

- Proper Storage: Store nozzles in protective cases when not in use to prevent physical damage.

- Training Operators: Ensure that all operators are trained on proper handling and maintenance procedures for SMT nozzles[7].

Advanced Techniques for Nozzle Maintenance

In addition to basic cleaning methods, several advanced techniques can further enhance nozzle maintenance:

1. Automated Cleaning Machines

Investing in automated cleaning machines designed specifically for SMT nozzles can greatly improve cleaning efficiency. These machines utilize high-pressure atomization technology to create fine water mists that effectively clean both the interior and exterior surfaces of nozzles without causing damage[8].

2. Regular Calibration

Regular calibration of pick-and-place machines ensures that all components function correctly together. Misalignment due to worn parts can lead to improper component placement; thus, routine calibration checks should be part of your maintenance schedule[9].

3. Monitoring Performance Metrics

Keeping track of performance metrics related to nozzle operation can help identify potential issues before they escalate into significant problems. Metrics such as pickup success rates and component rejection rates should be monitored closely[6].

Conclusion

Effectively repairing and maintaining SMT nozzles is essential for ensuring high-quality electronics manufacturing processes. By conducting regular inspections, employing appropriate cleaning techniques, replacing worn components, and adhering to best practices, manufacturers can significantly enhance the performance and longevity of their SMT nozzles. Investing time in proper maintenance not only reduces downtime but also improves overall production efficiency.

FAQ

1. What are common signs that my SMT nozzle needs repair?

Common signs include decreased suction power, visible wear on the nozzle tip, frequent misplacement of components during assembly, and clogging due to residue buildup.

2. How often should I clean my SMT nozzles?

It is recommended to clean SMT nozzles after every production cycle or shift to prevent residue buildup that could affect performance.

3. Can I use alcohol to clean my SMT nozzles?

Using alcohol is generally discouraged as it can be corrosive to certain materials used in nozzle construction. It's better to use specialized cleaning solutions designed for this purpose.

4. What should I do if my SMT nozzle is damaged?

If you find significant damage during inspection, it's advisable to replace the nozzle with a compatible high-quality replacement rather than attempting repairs that may not restore functionality.

5. How can I extend the lifespan of my SMT nozzles?

To extend their lifespan, implement regular maintenance schedules, use appropriate cleaning methods, store them properly when not in use, and train operators on handling procedures.

Citations:

[1] https://silmantech.com/3-common-methods-for-cleaning-smt-nozzles/

[2] https://www.joysmt.com/technique/393.html

[3] https://silmantech.com/cleaning-and-maintenance-methods-for-pick-and-place-machine-nozzles/

[4] https://www.myemssolutions.com/the-most-common-smt-errors-during-the-manufacturing-process/

[5] https://www.neodensmt.com/news/what-is-used-to-clean-smt-nozzle-48216762.html

[6] https://iconnect007.com/index.php/article/52613/smt-preventive-maintenance-stop-5-major-problems-with-pick-and-place-nozzles/52616

[7] https://www.zjyingxing.com/info/five-common-faults-of-smt-machine-50872373.html

[8] https://www.zjyingxing.com/info/how-to-clean-the-nozzle-of-smt-machine-80130038.html

[9] https://smtnet.com/library/files/upload/preventative-maintenance-smt.pdf

[10] https://silmantech.com/summary-of-juki-smt-nozzle-cleaning-methods/