Content Menu

● Understanding High Precision SMT PCB Assembly

>> The SMT Process

● Cost Reduction Through High Precision SMT PCB Assembly

>> 1. Increased Production Efficiency

>> 2. Miniaturization and Material Savings

>> 3. Improved Quality and Reduced Rework

>> 4. Automation and Labor Cost Reduction

>> 5. Economies of Scale

● Implementing High Precision SMT PCB Assembly

>> 1. Invest in Advanced SMT Equipment

>> 2. Optimize PCB Design for SMT

>> 3. Implement Rigorous Quality Control

>> 4. Continuous Process Improvement

>> 5. Staff Training and Development

● The Future of High Precision SMT PCB Assembly

● Case Studies: Cost Savings Through High Precision SMT PCB Assembly

>> Case Study 1: Consumer Electronics Manufacturer

>> Case Study 2: Automotive Electronics Supplier

>> Case Study 3: Medical Device Startup

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is the main difference between SMT and THT assembly?

>> 2. How does high precision SMT PCB assembly impact product reliability?

>> 3. What are the initial costs associated with implementing high precision SMT PCB assembly?

>> 4. Can high precision SMT PCB assembly handle all types of electronic components?

>> 5. How does high precision SMT PCB assembly contribute to environmental sustainability?

● Citations:

In today's rapidly evolving electronics industry, manufacturers are constantly seeking ways to optimize their production processes and reduce costs without compromising quality. One of the most effective methods to achieve this balance is through the implementation of high precision Surface Mount Technology (SMT) in Printed Circuit Board (PCB) assembly. This advanced technique not only enhances the quality and reliability of electronic products but also significantly contributes to cost reduction in manufacturing. Let's delve into how high precision SMT PCB assembly can lead to substantial cost savings while maintaining superior product quality.

Understanding High Precision SMT PCB Assembly

High precision electronic SMT PCB assembly is a sophisticated process that involves placing and soldering surface-mount devices (SMDs) directly onto the surface of a PCB. This method has largely replaced the traditional through-hole technology (THT) in many applications due to its numerous advantages[1].

The SMT Process

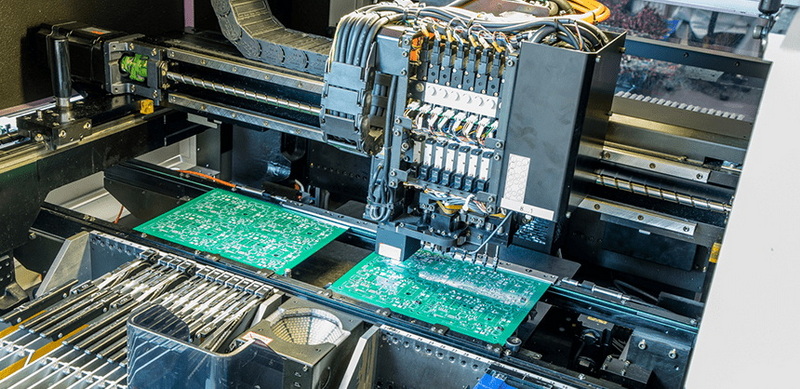

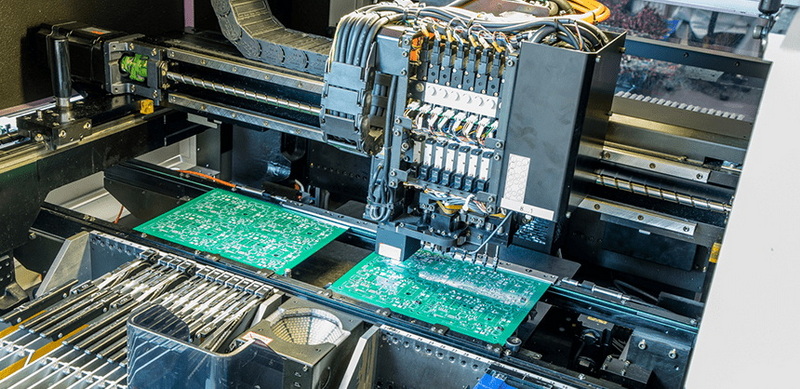

The SMT manufacturing process follows a systematic series of steps designed to efficiently assemble electronic components onto PCBs:

1. Solder Paste Application: A precise layer of solder paste is applied to the PCB pads using a stencil[2].

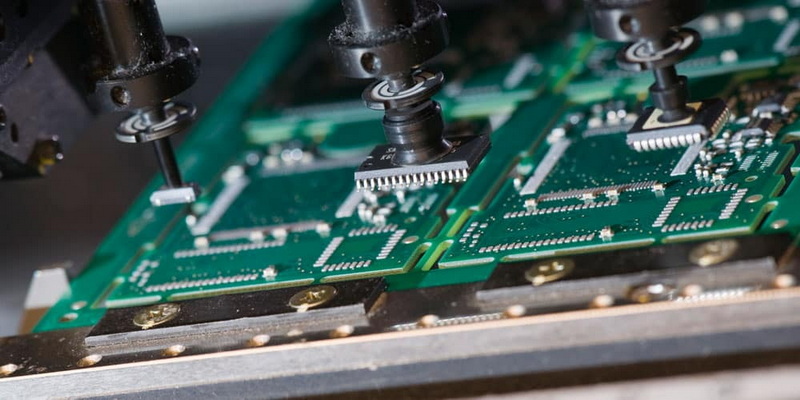

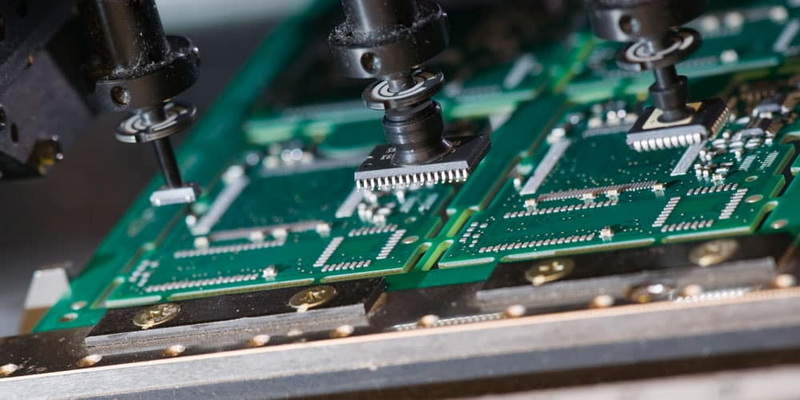

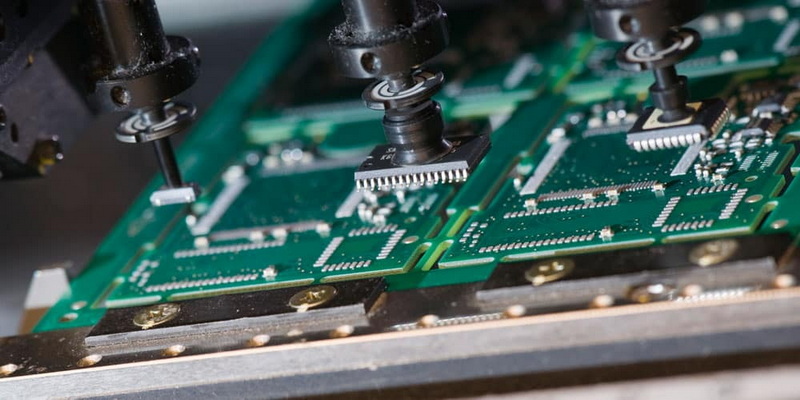

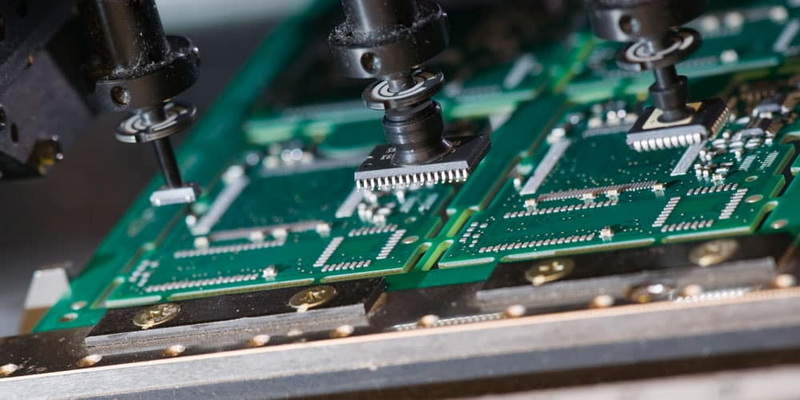

2. Component Placement: Automated pick-and-place machines accurately position SMDs onto the solder paste-covered pads[2].

3. Reflow Soldering: The PCB passes through a reflow oven, where the solder paste melts and forms solid solder joints between the components and the PCB[2].

4. Inspection: Automated optical inspection (AOI) or X-ray inspection ensures the quality of solder joints and component placement[5].

Cost Reduction Through High Precision SMT PCB Assembly

1. Increased Production Efficiency

High precision SMT assembly significantly increases production efficiency compared to traditional methods. The automated nature of SMT allows for the placement of thousands of components per hour with exceptional accuracy[2]. This high-speed assembly process translates to reduced production time and increased output, ultimately lowering the cost per unit.

2. Miniaturization and Material Savings

One of the key advantages of high precision SMT PCB assembly is the ability to work with smaller components and achieve higher component density. This miniaturization leads to:

- Smaller PCB sizes: Reducing the overall size of PCBs results in material cost savings[3].

- Reduced raw material usage: Smaller components require less material to manufacture, further decreasing costs[3].

- Lower shipping and packaging costs: Compact products are cheaper to package and transport[1].

3. Improved Quality and Reduced Rework

High precision SMT assembly significantly reduces the likelihood of errors and defects in the manufacturing process. This improvement in quality leads to:

- Lower rework costs: Fewer defects mean less time and resources spent on rework and repairs[1].

- Reduced waste: Higher first-pass yields result in less material waste and fewer scrapped boards[2].

- Improved reliability: Better quality assemblies lead to longer-lasting products and fewer warranty claims[5].

4. Automation and Labor Cost Reduction

The high degree of automation in SMT assembly processes significantly reduces labor costs:

- Reduced manual labor: Automated pick-and-place machines and reflow ovens minimize the need for manual intervention[3].

- Higher productivity: Automated systems can work continuously with minimal downtime, increasing overall productivity[2].

- Skilled labor optimization: Human resources can be redirected to more complex tasks, optimizing the use of skilled labor[1].

5. Economies of Scale

As production volumes increase, the cost benefits of high precision SMT PCB assembly become even more pronounced:

- Lower cost per unit: The initial investment in SMT equipment is spread across a larger number of units, reducing the cost per board[1].

- Bulk component purchasing: Larger production runs allow for bulk purchasing of components at lower prices[3].

- Optimized production planning: Higher volumes enable more efficient production scheduling and resource allocation[7].

Implementing High Precision SMT PCB Assembly

To fully leverage the cost-saving potential of high precision SMT PCB assembly, manufacturers should consider the following strategies:

1. Invest in Advanced SMT Equipment

While the initial investment in high-precision SMT equipment can be substantial, the long-term benefits in terms of efficiency, quality, and cost savings make it worthwhile. Modern SMT lines can place up to 130,000 parts per hour with exceptional accuracy[5].

2. Optimize PCB Design for SMT

Designing PCBs specifically for SMT assembly can further enhance cost savings:

- Component selection: Choose SMT components that are compatible with automated assembly[9].

- Layout optimization: Design PCB layouts that facilitate efficient pick-and-place operations and minimize the risk of assembly errors[9].

- Design for manufacturability (DFM): Implement DFM principles to ensure smooth production and reduce potential issues[9].

3. Implement Rigorous Quality Control

Investing in advanced inspection technologies, such as AOI and X-ray systems, can help identify and rectify issues early in the production process, preventing costly rework and ensuring high-quality output[5].

4. Continuous Process Improvement

Regularly analyze production data and implement continuous improvement strategies to optimize the SMT assembly process further. This may include:

- Fine-tuning machine parameters: Optimize pick-and-place machine settings for maximum efficiency[2].

- Refining solder paste application: Improve stencil design and solder paste formulation for better solder joint quality[2].

- Enhancing reflow profiles: Optimize reflow oven temperature profiles for different board types and component mixes[2].

5. Staff Training and Development

Ensure that your workforce is well-trained in the latest SMT technologies and best practices. Skilled operators and technicians can significantly contribute to the efficiency and effectiveness of high precision SMT PCB assembly[1].

The Future of High Precision SMT PCB Assembly

As technology continues to advance, high precision SMT PCB assembly is expected to evolve further, offering even greater cost-saving potential:

- AI and machine learning integration: These technologies will enhance process control and predictive maintenance, further reducing downtime and improving efficiency[5].

- Advanced materials: New solder paste formulations and PCB substrates will enable even finer pitch components and higher density assemblies[2].

- Industry 4.0 integration: Increased connectivity and data exchange between machines will lead to smarter, more efficient production lines[5].

Case Studies: Cost Savings Through High Precision SMT PCB Assembly

To illustrate the real-world impact of high precision SMT PCB assembly on manufacturing costs, let's examine a few hypothetical case studies:

Case Study 1: Consumer Electronics Manufacturer

A medium-sized consumer electronics company transitioned from manual THT assembly to high precision SMT for their flagship product line. The results were significant:

- 40% reduction in assembly time

- 30% decrease in PCB size, leading to material cost savings

- 50% reduction in rework and quality control costs

- Overall cost per unit decreased by 25%

Case Study 2: Automotive Electronics Supplier

An automotive electronics supplier implemented advanced high precision SMT PCB assembly for their engine control units:

- Production capacity increased by 200% without expanding floor space

- Defect rate reduced from 2% to 0.1%

- Labor costs decreased by 60%

- Total manufacturing cost reduced by 35% over three years

Case Study 3: Medical Device Startup

A medical device startup adopted high precision SMT PCB assembly for their wearable health monitoring devices:

- Achieved 70% reduction in PCB size, enabling a more compact product design

- Improved first-pass yield from 85% to 99%

- Reduced time-to-market by 40%

- Overall product cost decreased by 30%, allowing for more competitive pricing

These case studies demonstrate the significant cost-saving potential of high precision SMT PCB assembly across various industries and product types.

Conclusion

High precision electronic SMT PCB assembly has revolutionized the electronics manufacturing industry, offering a powerful means to reduce costs while improving product quality and reliability. By increasing production efficiency, enabling miniaturization, improving quality, reducing labor costs, and leveraging economies of scale, this advanced technology provides manufacturers with a competitive edge in today's challenging market.

As the electronics industry continues to evolve, with demands for smaller, more complex, and higher-performance devices, the role of high precision SMT PCB assembly in cost reduction will only become more critical. Manufacturers who invest in this technology and continuously optimize their processes will be well-positioned to meet these challenges while maintaining profitability.

The key to success lies in a holistic approach that combines investment in advanced equipment, optimized PCB design, rigorous quality control, continuous process improvement, and skilled workforce development. By embracing these principles, manufacturers can fully harness the cost-saving potential of high precision SMT PCB assembly and stay ahead in an increasingly competitive global market.

Frequently Asked Questions (FAQ)

1. What is the main difference between SMT and THT assembly?

Surface Mount Technology (SMT) involves placing components directly onto the surface of a PCB, while Through-Hole Technology (THT) requires components to be inserted into holes drilled through the board. SMT allows for higher component density, faster assembly, and typically lower costs for high-volume production[3].

2. How does high precision SMT PCB assembly impact product reliability?

High precision SMT PCB assembly significantly improves product reliability by ensuring more accurate component placement and better solder joint quality. This results in fewer defects, reduced failure rates, and longer product lifespans[2].

3. What are the initial costs associated with implementing high precision SMT PCB assembly?

Initial costs can be substantial, including investments in pick-and-place machines, reflow ovens, inspection equipment, and staff training. However, these costs are typically offset by increased efficiency and reduced per-unit costs over time, especially for medium to high-volume production[1].

4. Can high precision SMT PCB assembly handle all types of electronic components?

While SMT can handle a wide range of component types, some large or specialized components may still require through-hole mounting. Many modern PCBs use a combination of SMT and THT, known as mixed technology assembly, to accommodate all necessary components[6].

5. How does high precision SMT PCB assembly contribute to environmental sustainability?

High precision SMT PCB assembly contributes to sustainability by reducing material waste, lowering energy consumption through more efficient processes, and enabling the production of smaller, more energy-efficient electronic devices. Additionally, the improved quality and reliability of SMT-assembled products can lead to longer product lifespans, reducing electronic waste[1][3].

Citations:

[1] https://www.pcbasic.com/blog/PCB_Assembly_Cost.html

[2] https://www.x-pcb.com/smt-technology-the-key-to-achieving-high-precision-in-pcb-assembly/

[3] https://www.wevolver.com/article/smt-vs-smd-vs-tht-a-comprehensive-guide-to-electronics-assembly-techniques

[4] https://electronics.stackexchange.com/questions/30671/estimating-assembly-cost

[5] https://www.youtube.com/watch?v=mzhLiR8B39M

[6] https://www.medicaldesignbriefs.com/component/content/article/46458-surface-mount-technology-for-pcb-assembly-use-case-and-smt-in-healthcare-systems

[7] https://www.7pcb.com/blog/pcb-assembly-cost

[8] https://www.circuits-central.com/blog/a-comprehensive-guide-to-surface-mount-technology-in-pcb-assembly/

[9] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/