Content Menu

● Introduction to SMT Stencils

>> Importance of SMT Stencils in Production

● Benefits of Efficient SMT Stencil Storage

>> Reduced Damage and Maintenance

>> Enhanced Organization and Accessibility

>> Improved Quality Control

● Best Practices for SMT Stencil Storage

>> Storage Environment

>> Storage Solutions

>> Inventory Management

● Innovations in SMT Stencil Storage

>> Advanced Materials and Coatings

>> Automated Storage Systems

● Challenges and Future Directions

>> Cost and Accessibility

>> Sustainability and Environmental Impact

● Integration with Solder Paste Handling

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary benefits of using SMT stencils in PCB assembly?

>> 2. How often should SMT stencils be cleaned and maintained?

>> 3. What are the best practices for storing SMT stencils?

>> 4. Can SMT stencils be reused if they are damaged or worn out?

>> 5. How does efficient SMT stencil storage contribute to environmental sustainability?

● Citations:

Efficient SMT stencil storage is a crucial aspect of optimizing the production workflow in electronics manufacturing, particularly in the context of Surface Mount Technology (SMT). SMT stencils play a vital role in ensuring precise solder paste deposition onto PCBs, which is essential for maintaining product quality and reliability. Proper storage of these stencils not only protects them from damage but also enhances the overall efficiency and productivity of the manufacturing process.

Introduction to SMT Stencils

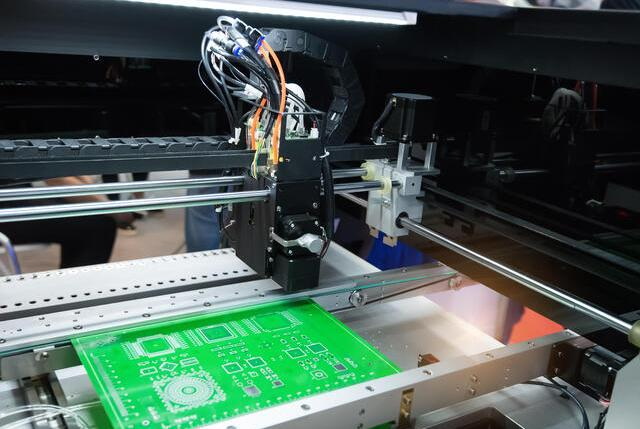

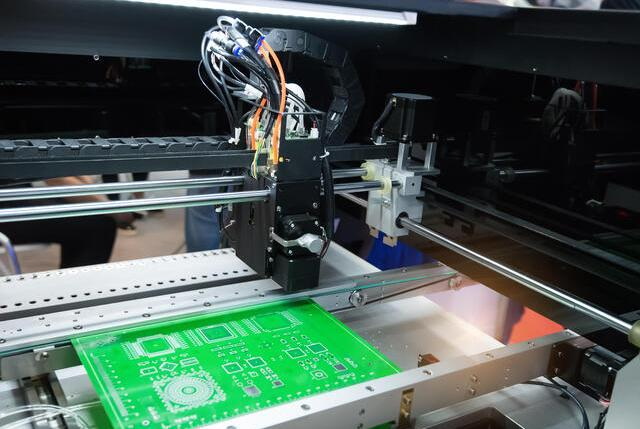

SMT stencils are thin, precision-cut templates used to apply solder paste to specific areas on a printed circuit board (PCB). They are designed to match the layout of components on the PCB, ensuring that the correct amount of solder paste is applied to each pad. This precision is critical for preventing defects such as solder bridging or insufficient solder, which can lead to component failure or electrical malfunctions.

Importance of SMT Stencils in Production

1. Precision and Consistency: SMT stencils ensure that solder paste is applied uniformly across all PCBs, reducing variability and improving product reliability.

2. Efficiency: Stencils enable simultaneous solder paste application to multiple PCBs, significantly speeding up the assembly process.

3. Compatibility with Automation: They are essential for automated assembly lines, allowing for high-volume production with consistent quality.

Benefits of Efficient SMT Stencil Storage

Efficient storage of SMT stencils contributes to several key benefits in the production workflow:

Reduced Damage and Maintenance

- Protection from Physical Damage: Proper storage prevents stencils from being bent, scratched, or damaged by other objects, which can lead to costly replacements.

- Extended Lifespan: By minimizing exposure to contaminants and physical stress, stencils can last longer, reducing the need for frequent replacements.

Enhanced Organization and Accessibility

- Easy Retrieval: Stencils are readily available when needed, reducing downtime and increasing production efficiency.

- Inventory Management: Proper storage systems help track stencil usage and inventory levels, ensuring that the right stencils are available for each production run.

Improved Quality Control

- Cleanliness and Contamination Prevention: Storing stencils in clean environments prevents contamination, which can affect solder paste quality and lead to defects.

- Regular Inspection: Easy access to stencils facilitates regular inspections for wear and damage, ensuring that only high-quality stencils are used in production.

Best Practices for SMT Stencil Storage

Implementing best practices for SMT stencil storage is crucial for maintaining efficiency and quality in the production workflow:

Storage Environment

- Clean and Dry Conditions: Stencils should be stored in a clean, dry environment to prevent corrosion and contamination. Avoid direct sunlight and extreme temperatures, as these can degrade the stencil material over time[1].

- Temperature Control: Ensure that the storage area maintains a stable temperature, ideally between 15°C and 25°C, to prevent thermal stress on the stencil materials.

Storage Solutions

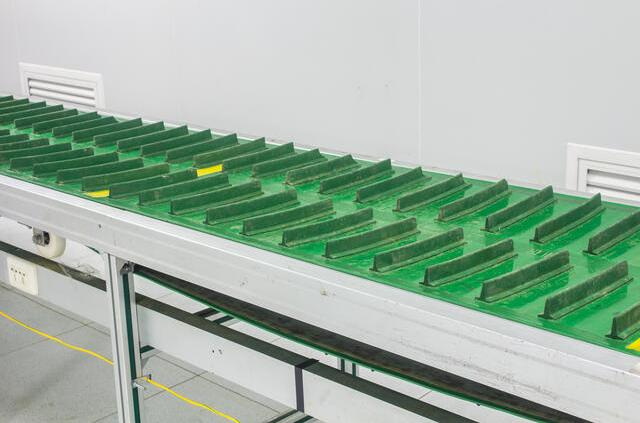

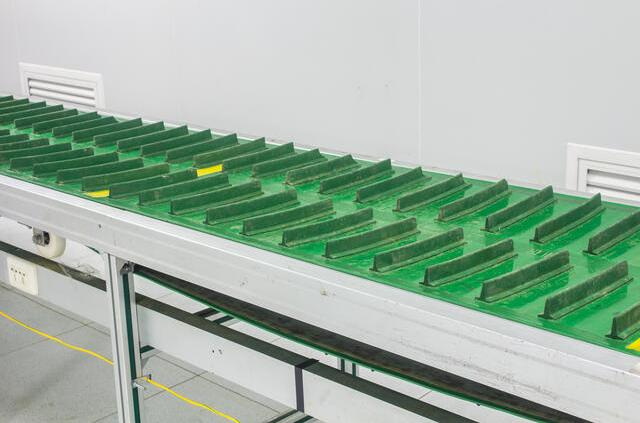

- Vertical Storage Racks: Store stencils vertically to prevent bending and damage. This method also maximizes storage space and makes it easier to retrieve stencils when needed[4].

- ESD Protection: Use ESD-safe storage solutions to protect stencils from electrostatic discharge, which can damage sensitive components. ESD-safe bags and cabinets are effective options for preventing static damage[2].

Inventory Management

- Labeling and Tracking: Clearly label and track stencils to ensure easy identification and retrieval. This can be achieved through barcode scanning or RFID tags, which help automate inventory management.

- Software Tools: Utilize inventory management software to monitor stencil usage and schedule maintenance. This software can also integrate with production planning systems to optimize stencil allocation and reduce waste.

Innovations in SMT Stencil Storage

Recent innovations in SMT stencil storage focus on enhancing efficiency, safety, and environmental sustainability:

Advanced Materials and Coatings

- Nano-Coatings: Some stencils now feature nano-coatings that improve durability and reduce maintenance needs. These coatings can also enhance solder paste release properties, improving print quality.

- Sustainable Materials: The use of environmentally friendly materials in stencil production and storage is becoming more prevalent. This includes recyclable materials and biodegradable packaging options.

Automated Storage Systems

- Barcode Scanning: Implementing barcode scanning for stencil tracking can automate inventory management and reduce errors. This technology ensures that stencils are correctly identified and stored, minimizing mix-ups during production.

- Smart Storage Solutions: Some facilities are adopting smart storage systems that integrate with production planning software to optimize stencil usage and availability. These systems often include features like pick-to-light technology, which guides operators to the correct stencil location, reducing retrieval time and improving workflow efficiency[5][8].

Challenges and Future Directions

Despite the advancements in SMT stencil storage, there are ongoing challenges and areas for improvement:

Cost and Accessibility

- Cost of Advanced Storage Solutions: Implementing high-tech storage systems can be costly for smaller manufacturers. However, the long-term benefits in terms of reduced waste and improved efficiency can justify the investment.

- Accessibility to Best Practices: Smaller operations may lack access to best practices and resources for optimal stencil storage. Collaborations with industry experts or training programs can help bridge this gap.

Sustainability and Environmental Impact

- Reducing Waste: Efforts to minimize waste and reduce environmental impact through sustainable storage practices are ongoing. This includes using recyclable materials for storage containers and optimizing storage space to reduce energy consumption.

- Recyclable Materials: The development of recyclable stencil materials is a future direction for reducing environmental footprint. Manufacturers are exploring new materials that can be recycled at the end of their life cycle, reducing landfill waste.

Integration with Solder Paste Handling

Solder paste handling and storage are closely related to SMT stencil management. Proper storage of solder paste is essential to maintain its quality and shelf life. Refrigerated storage is recommended to prolong the shelf life of solder paste, typically between -20°C and 10°C[7]. Ensuring that solder paste is handled correctly and stored in a controlled environment complements efficient stencil storage by maintaining overall print quality and reducing defects.

Conclusion

Efficient SMT stencil storage is a critical component of optimizing production workflows in electronics manufacturing. By implementing best practices in storage and leveraging innovations in materials and technology, manufacturers can enhance product quality, reduce costs, and improve overall efficiency. As technology continues to evolve, the importance of effective stencil storage will only grow, supporting advancements in miniaturization and high-density interconnections.

Frequently Asked Questions

1. What are the primary benefits of using SMT stencils in PCB assembly?

SMT stencils offer several key benefits, including precise solder paste deposition, increased efficiency through simultaneous application to multiple PCBs, and compatibility with automated assembly lines. These factors contribute to higher product quality and reduced production costs.

2. How often should SMT stencils be cleaned and maintained?

The frequency of cleaning and maintenance depends on usage and environmental conditions. Generally, stencils should be cleaned every 4 to 8 hours of continuous use or when print quality begins to deteriorate. Regular maintenance extends the stencil's lifespan and ensures optimal performance[1].

3. What are the best practices for storing SMT stencils?

Best practices include storing stencils in a clean, dry environment away from direct sunlight and extreme temperatures. Use vertical storage racks to prevent bending, and ensure ESD protection to safeguard against electrostatic discharge. Regularly inspect stencils for damage and maintain a clean storage area[1][4].

4. Can SMT stencils be reused if they are damaged or worn out?

While minor damage might not render a stencil unusable, significant wear or damage can compromise its performance. Reusing a damaged stencil can lead to inconsistent solder paste application, potentially causing defects. It is generally recommended to replace stencils when they show signs of significant wear[1].

5. How does efficient SMT stencil storage contribute to environmental sustainability?

Efficient storage helps reduce waste by extending the lifespan of stencils and minimizing the need for replacements. Additionally, using environmentally friendly storage materials and optimizing production processes can reduce energy consumption and lower carbon emissions, contributing to a more sustainable manufacturing environment[2].

Citations:

[1] https://rigidflexpcb.org/comprehensive-guide-to-smt-stencils/

[2] https://www.photocad.de/en/smt-stencils/accessories/storage-and-archives/

[3] https://jlcpcb.com/blog/guide-to-smt-stencils-in-pcb-assembly

[4] https://www.linkedin.com/pulse/best-worst-practices-stencil-care-maintenance-vslpc

[5] https://global.neotel.tech/products/neo-light-series/smt-stencil-storage-neo-light-stencil/

[6] https://www.indium.com/blog/stencil-printing-for-success-solder-paste-handling-and-storage.php

[7] https://smtindustrial.com/solder-paste-handling-and-storage/

[8] https://www.scienscope.com/smart-rack-for-stencils/

[9] https://fctsolder.com/wp-content/uploads/2017/08/123386-361848.smt-printing-challenges.pdf

[10] https://pcbpit.com/smt-stencil-a-comprehensive-guide/

[11] https://inovaxe.com/stencil-storage-solutions/

[12] https://www.aimsolder.com/wp-content/uploads/legacy-files/smt_ts.pdf

[13] https://www.aimsolder.com/wp-content/uploads/legacy-files/aim_paste_handling_guideline_revnf1.pdf

[14] https://www.youtube.com/watch?v=5HSHyfGPpxY

[15] https://www.reddit.com/r/PCB/comments/113nq4h/stencil_printing_issues_that_you_can_have_if_you/

[16] https://www.indium.com/technical-documents/application-notes/download/2703/

[17] https://smt.asmpt.com/en/products/process-support-products/stencil-storage-systems/

[18] https://www.pcbway.com/blog/PCB_Assembly/The_Main_Factors_Affect_the_Quality_of_SMT_Soldering_and_Its_Solutions.html

[19] https://electronics.stackexchange.com/questions/295050/good-practice-when-designing-a-pcb-and-stencil

[20] https://os.passioniot.com/smt-stencil-storage