Content Menu

● Understanding SMT Stencil Printing and Its Role in PCB Production

>> What is SMT Stencil Printing?

>> Components of an SMT Stencil Printing Machine

● How SMT Stencil Printers Reduce PCB Production Time

>> 1. High-Speed and Consistent Solder Paste Application

>> 2. Improved Accuracy and Reduced Defects

>> 3. Reduced Operator Dependence and Labor Costs

>> 4. Optimized Solder Paste Volume Control

>> 5. Quick Changeover and Flexibility

>> 6. Enhanced Process Monitoring and Quality Control

● Advantages of Using SMT Stencil Printing Machines in PCB Production

● Key Features of High-Precision SMT Stencil Printers

● The Impact of SMT Stencil Printers on PCB Assembly Quality

● Integrating SMT Stencil Printing Machines into the Production Line

>> Seamless Integration with Pick-and-Place Machines

>> Compatibility with Automated Optical Inspection (AOI)

>> Role in Lean Manufacturing and Just-In-Time Production

● Future Trends in SMT Stencil Printing Technology

>> Advances in Stencil Materials and Coatings

>> Integration of Artificial Intelligence and Machine Learning

>> Environmental Considerations

● Conclusion

● FAQ

>> 1. What is the main function of an SMT stencil printing machine?

>> 2. How does SMT stencil printing improve PCB production speed?

>> 3. Can SMT stencil printers handle different PCB sizes and designs?

>> 4. What role does the stencil design play in SMT printing?

>> 5. Are SMT stencil printers suitable for fine-pitch and complex PCBs?

In the fast-paced world of electronics manufacturing, reducing production time without compromising quality is crucial. One of the most effective tools for achieving this in Printed Circuit Board (PCB) assembly is the SMT stencil printing machine. This article explores how SMT stencil printers contribute to faster PCB production, enhance quality, and reduce costs, making them indispensable in modern Surface Mount Technology (SMT) assembly lines.

Understanding SMT Stencil Printing and Its Role in PCB Production

What is SMT Stencil Printing?

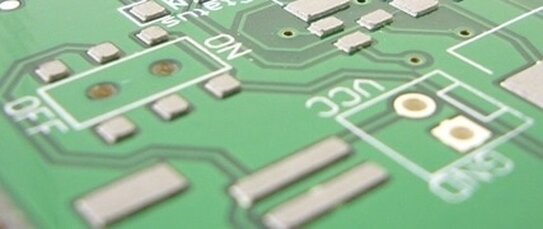

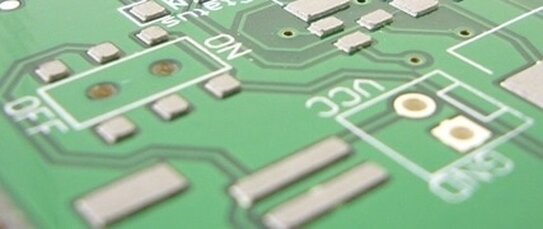

SMT stencil printing is a process used in PCB assembly where solder paste is applied precisely onto the PCB pads through a stencil. The stencil is a thin sheet, typically stainless steel or nickel, with apertures that align exactly with the PCB's solder pads. The solder paste is spread across the stencil, depositing the right amount of paste only where components will be placed.

This process is critical because it directly affects the solder joint quality, component placement accuracy, and ultimately the reliability of the finished PCB.

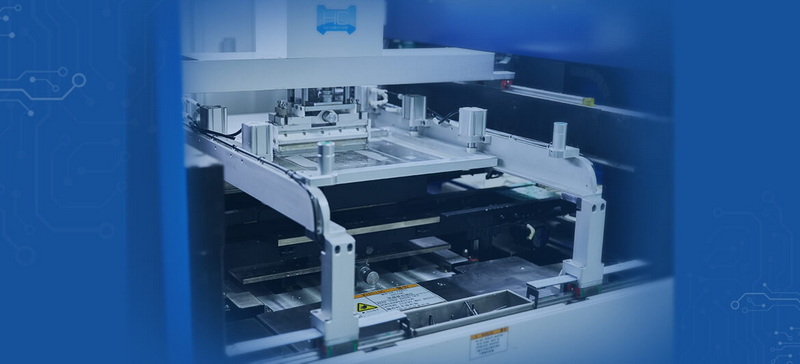

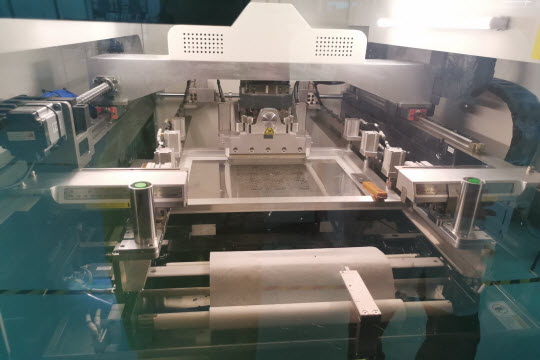

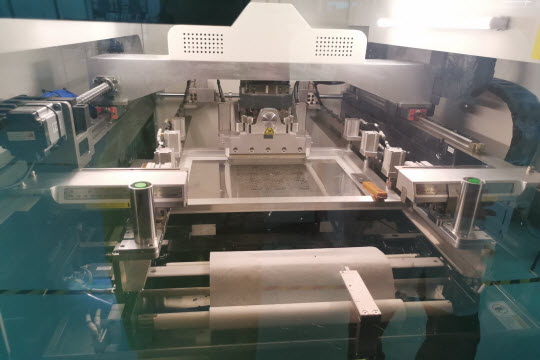

Components of an SMT Stencil Printing Machine

An SMT stencil printing machine typically includes:

- A stencil frame holding the metal stencil.

- A squeegee that spreads solder paste across the stencil apertures.

- A PCB holder or conveyor system to position the PCB accurately.

- A vision system for alignment and inspection.

- Automated controls for pressure, speed, and print stroke.

These components work together to ensure consistent, high-precision solder paste application.

How SMT Stencil Printers Reduce PCB Production Time

1. High-Speed and Consistent Solder Paste Application

Manual solder paste application is slow and prone to inconsistency, leading to defects and rework. SMT stencil printers automate this process, enabling rapid and repeatable solder paste deposition across multiple PCBs. High-precision machines can complete printing cycles in under 7 seconds per board, significantly speeding up production.

The automation of the solder paste printing process removes bottlenecks commonly seen in manual or semi-automated methods. With a consistent and rapid printing cycle, manufacturers can increase throughput without sacrificing quality. This speed is especially beneficial in high-volume production environments where every second counts.

2. Improved Accuracy and Reduced Defects

SMT stencil printers use advanced optical positioning and vision systems to align the stencil with the PCB precisely. This accuracy minimizes solder paste misplacement, reducing defects such as solder bridging, insufficient solder, or tombstoning. Fewer defects mean less time spent on inspection and rework, accelerating overall throughput.

The precision alignment is critical for modern PCBs, which often feature fine-pitch components and complex layouts. Even slight misalignments can cause significant issues in solder joint formation. The vision systems in SMT stencil printing machines provide real-time feedback, allowing for immediate corrections and ensuring the highest quality prints.

3. Reduced Operator Dependence and Labor Costs

Automated SMT stencil printing machines reduce the need for skilled manual labor. Operators no longer need to manually dispense solder paste, which is labor-intensive and variable. This automation not only speeds up production but also lowers labor costs and human error.

By minimizing operator intervention, SMT stencil printers provide a more stable and repeatable process. This consistency reduces the learning curve for new operators and allows production to continue smoothly even with staffing changes. Labor cost savings and improved process stability contribute significantly to overall production efficiency.

4. Optimized Solder Paste Volume Control

The stencil design and thickness determine the volume of solder paste deposited. SMT stencil printers ensure consistent paste volume by controlling printing pressure, speed, and squeegee angle. This precision prevents excess solder paste waste and ensures optimal solder joints, reducing the risk of rework and production delays.

Optimizing solder paste volume is essential for preventing common defects such as solder balls, bridging, or insufficient solder joints. SMT stencil printers allow fine-tuning of printing parameters to match the specific solder paste characteristics and PCB design, ensuring the perfect amount of paste is deposited every time.

5. Quick Changeover and Flexibility

Modern SMT stencil printers support fast product changeovers, often under five minutes. This flexibility allows manufacturers to switch between different PCB designs or production batches quickly, maximizing machine uptime and reducing downtime between runs.

Fast changeover is particularly valuable in contract manufacturing and small to medium batch production where multiple product variants are produced. The ability to rapidly swap stencils and adjust printing parameters without lengthy setup times helps manufacturers respond quickly to customer demands and market changes.

6. Enhanced Process Monitoring and Quality Control

Many SMT stencil printing machines come equipped with software for real-time monitoring of printing parameters and quality control. This capability allows early detection of printing defects, enabling immediate corrective actions and preventing large-scale production issues.

Process monitoring tools track metrics such as print pressure, speed, and paste volume, providing valuable data for Statistical Process Control (SPC) and Continuous Process Improvement (CPI). By maintaining tight control over the printing process, manufacturers can reduce variability and improve overall product quality.

Advantages of Using SMT Stencil Printing Machines in PCB Production

- Speed: Automated printing cycles are much faster than manual methods.

- Precision: Optical alignment and controlled printing parameters ensure high accuracy.

- Consistency: Repeatable solder paste application reduces variability.

- Cost Efficiency: Less solder paste waste and reduced labor costs.

- Yield Improvement: Fewer defects lead to higher production yields.

- Scalability: Suitable for both small-scale and high-volume production.

- Support for Fine Pitch Components: Essential for ultra-fine pitch and miniaturized PCBs where manual methods fail.

Key Features of High-Precision SMT Stencil Printers

| Feature | Description |

| Maximum PCB Size | Up to 450mm x 350mm or larger, accommodating various board sizes |

| Printing Speed | Up to 200 mm/s for rapid solder paste application |

| Printing Pressure | Adjustable from 0.5kg to 10kg to optimize paste deposition |

| Vision System | Independent cameras for upward/downward imaging and geometric matching |

| Repeatability | ±10 microns for image calibration, ±20 microns for printing precision |

| Cycle Time | Less than 7 seconds per PCB |

| Changeover Time | Less than 5 minutes for product switching |

| Software | SPC and CPK analysis for quality control |

| Optional Features | Automatic solder paste filling, temperature/humidity control, and alarm systems |

These features ensure that SMT stencil printers meet the rigorous demands of modern PCB assembly lines.

The Impact of SMT Stencil Printers on PCB Assembly Quality

The quality of solder paste printing directly influences the final assembly quality. SMT stencil printers help achieve:

- Uniform solder paste deposits that ensure reliable solder joints.

- Reduced solder bridging and insufficient solder issues by controlling paste volume precisely.

- Improved component placement accuracy due to consistent solder paste application.

- Lower defect rates leading to fewer reworks and higher throughput.

By elevating the printing quality, SMT stencil printers contribute to producing PCBs that meet stringent industry standards and customer requirements.

Integrating SMT Stencil Printing Machines into the Production Line

Seamless Integration with Pick-and-Place Machines

SMT stencil printing machines are typically the first step in the SMT assembly line, followed by pick-and-place machines that mount components onto the solder-pasted PCB. The precision and speed of the stencil printer directly impact the efficiency of subsequent processes. Consistent solder paste deposits enable pick-and-place machines to operate at maximum speed with minimal errors.

Compatibility with Automated Optical Inspection (AOI)

After solder paste printing and component placement, AOI systems inspect the PCB for defects. High-quality prints from SMT stencil printers reduce the number of false positives and defects detected by AOI, streamlining inspection and reducing downtime.

Role in Lean Manufacturing and Just-In-Time Production

The rapid printing cycles and quick changeovers of SMT stencil printers align well with lean manufacturing principles and just-in-time (JIT) production strategies. Manufacturers can produce smaller batches with minimal setup time, reducing inventory and improving responsiveness to market demands.

Future Trends in SMT Stencil Printing Technology

Advances in Stencil Materials and Coatings

New stencil materials and anti-wetting coatings are being developed to improve paste release and reduce cleaning frequency. These innovations help maintain print quality over longer production runs, further reducing downtime.

Integration of Artificial Intelligence and Machine Learning

Emerging SMT stencil printing machines are incorporating AI and machine learning algorithms to optimize printing parameters dynamically. These systems can predict defects before they occur and adjust settings in real-time for maximum efficiency.

Environmental Considerations

Modern SMT stencil printers are designed to minimize solder paste waste and reduce energy consumption. This focus on sustainability supports manufacturers' environmental goals and regulatory compliance.

Conclusion

An SMT stencil printing machine is a vital asset in modern PCB production, offering significant time savings, improved accuracy, and enhanced quality control. By automating the solder paste application process, these machines reduce manual labor, minimize defects, and enable rapid production cycles. Their precision and consistency are essential for meeting the demands of high-volume and fine-pitch PCB assembly. Investing in advanced SMT stencil printers ultimately leads to faster production turnaround, higher yields, and cost-effective manufacturing.

FAQ

1. What is the main function of an SMT stencil printing machine?

An SMT stencil printing machine applies solder paste precisely onto PCB pads through a metal stencil, ensuring accurate and consistent solder paste deposition essential for reliable component soldering.

2. How does SMT stencil printing improve PCB production speed?

By automating solder paste application with rapid printing cycles and precise alignment, SMT stencil printers significantly reduce the time required compared to manual methods, enabling faster PCB throughput.

3. Can SMT stencil printers handle different PCB sizes and designs?

Yes, modern SMT stencil printers support a wide range of PCB sizes and designs, with adjustable printing areas and fast changeover capabilities to accommodate various production needs.

4. What role does the stencil design play in SMT printing?

Stencil design, including thickness and aperture size, determines the volume and accuracy of solder paste deposited, directly affecting print quality and assembly reliability.

5. Are SMT stencil printers suitable for fine-pitch and complex PCBs?

Absolutely. SMT stencil printers provide the precision needed for ultra-fine pitch components and complex PCB layouts, which are difficult or impossible to achieve with manual solder paste application.